Rivet joint, auxiliary rivet joint and method for stress wave mounting of interference fit fastener

A riveting head and fastener technology, applied in the field of riveting devices, can solve problems such as easy deformation, and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

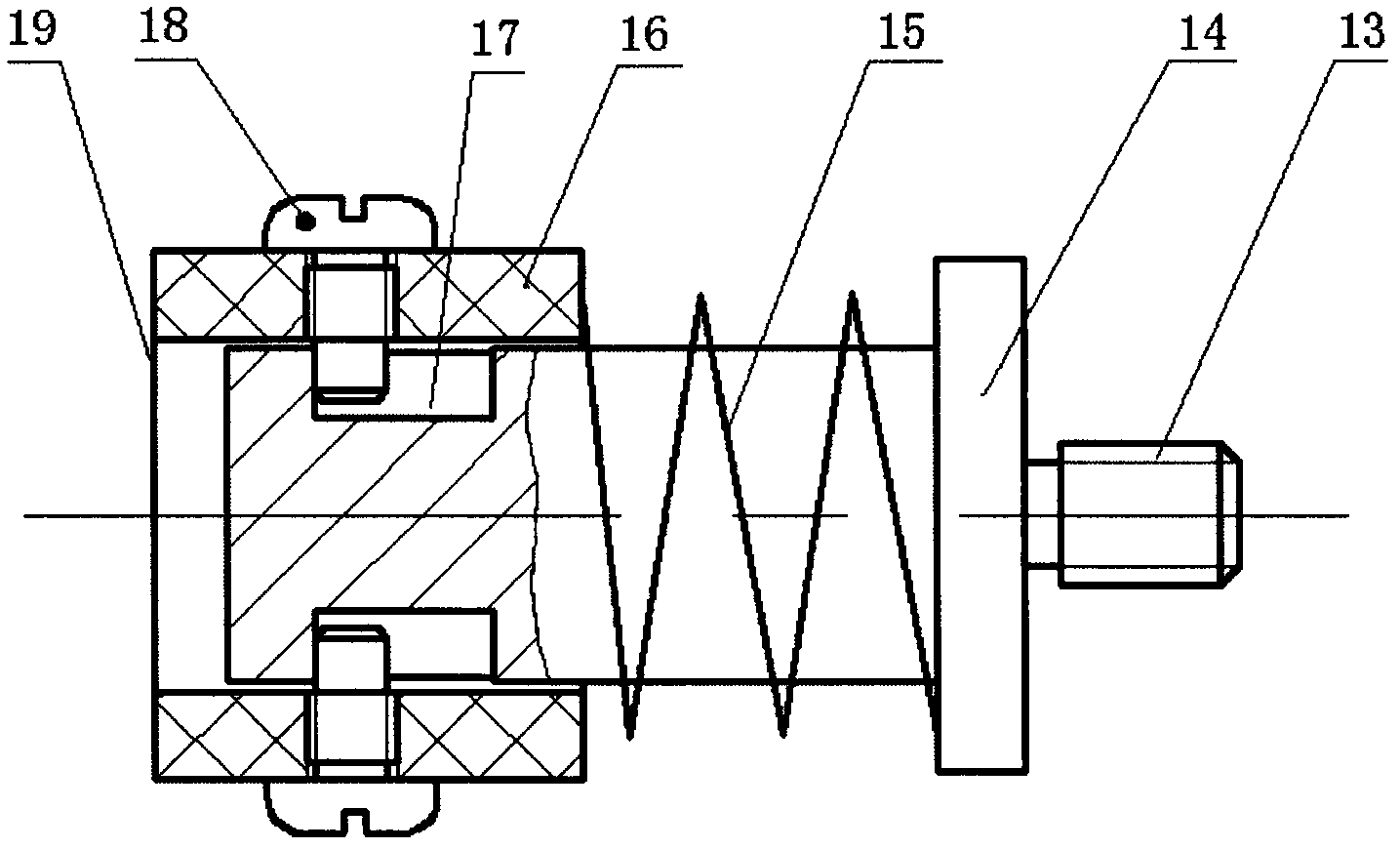

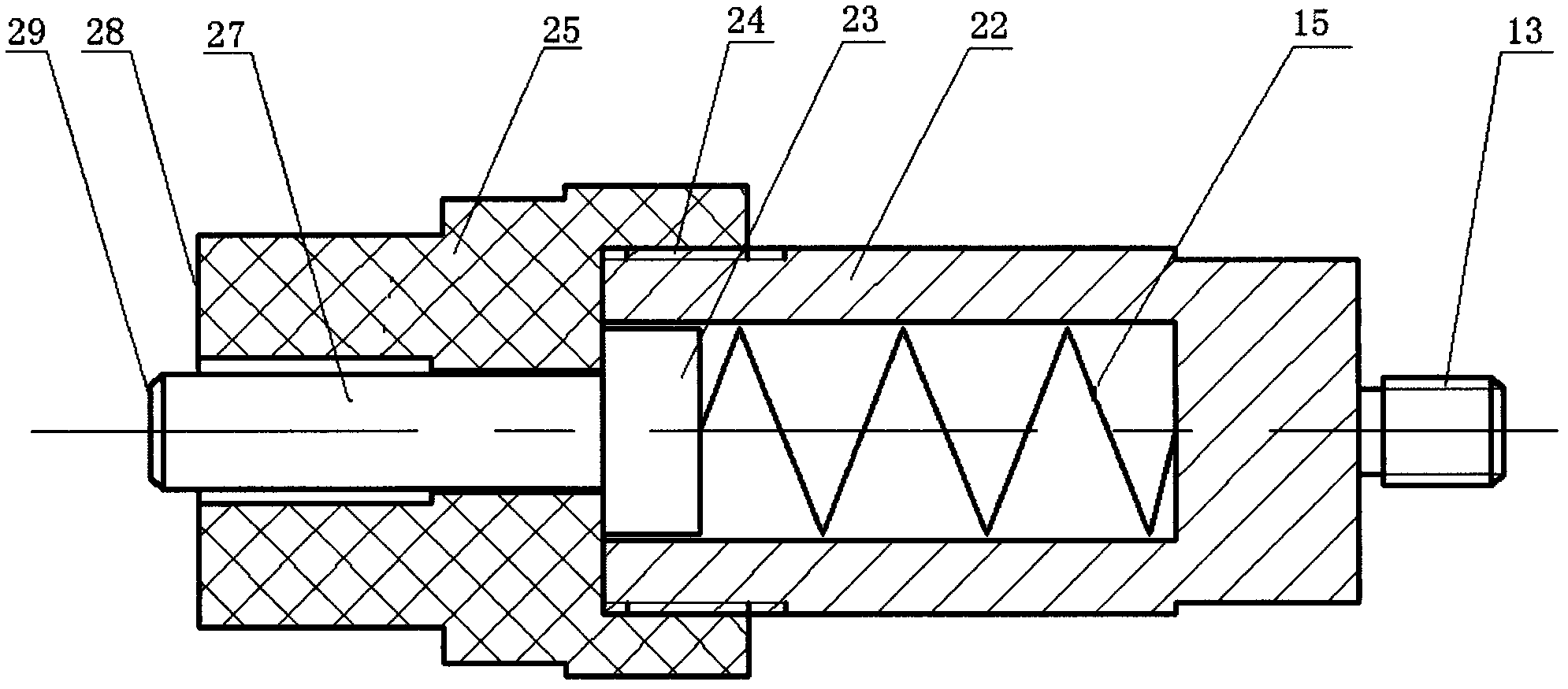

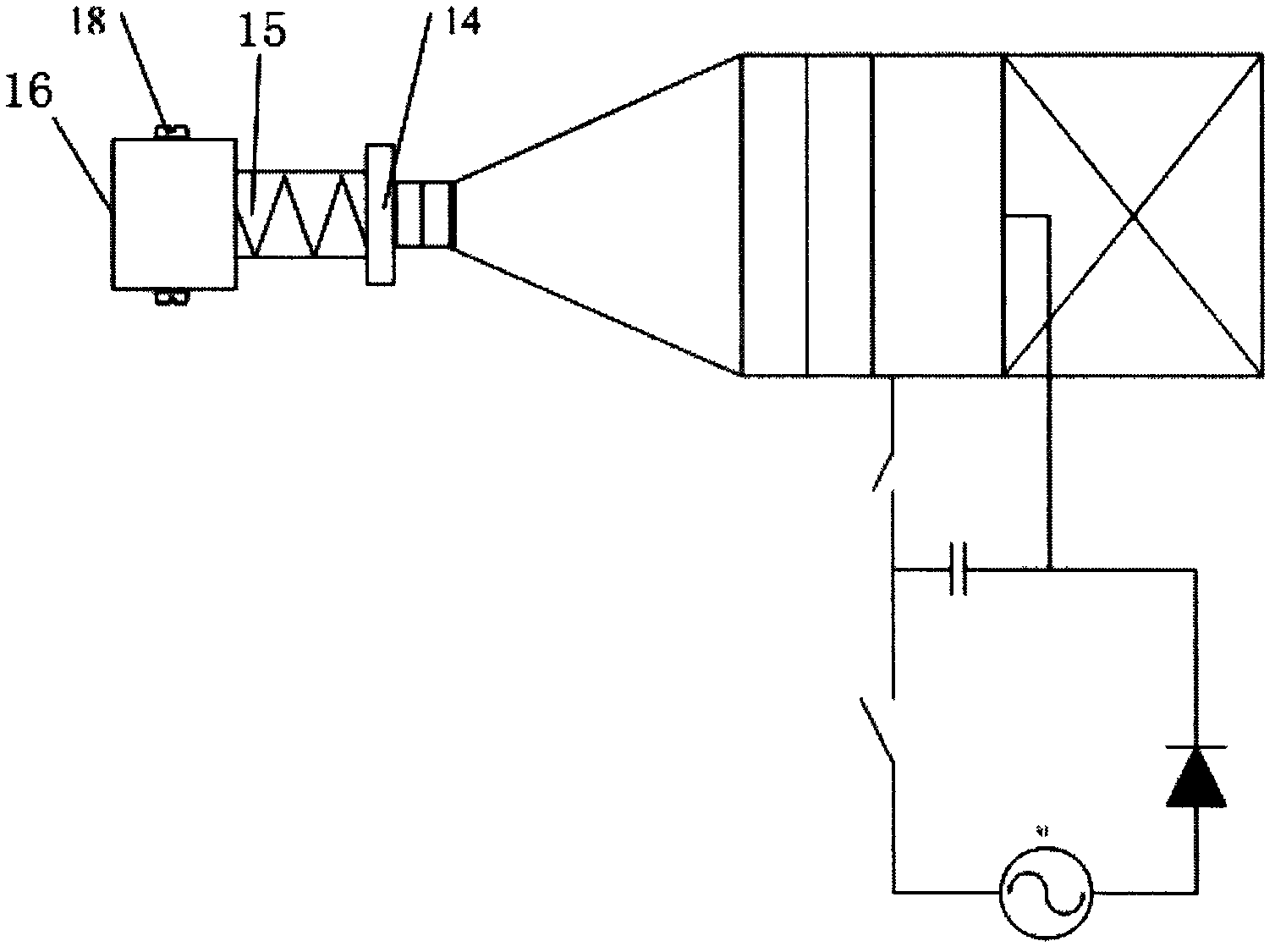

[0019] Reference Figure 1~5 . The riveting joint of the present invention includes a mandrel 14, a spring 15, a limiting cylinder 16 and a screw 18. The mandrel 14 is a piston-like structure. One end of the mandrel 14 is close to the radial position of the head and two key grooves 17 are symmetrically designed. The other end of 14 is a boss structure. The boss of the mandrel 14 is fixedly connected with a connector 13 and the connector 13 has threads; the mandrel 14 and the connector 13 are concentric. The limiting cylinder 16 is a cylindrical structure, which is sleeved on the end of the mandrel 14 close to the head. The mandrel 14 can move in the limiting cylinder 16, and the corresponding positions of the limiting cylinder 16 and the keyway 17 on the mandrel 14 have screw holes. , The screw 18 passes through the screw hole and extends into the keyway 17. The spring 15 is a compression spring, wound on the spindle 14, and located between the limiting cylinder 16 and the bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com