Automatic nailing system for anti-fake rivet of baijiu gift box and working method for automatic nailing system

A gift box, automatic technology, applied in the directions of external support, transportation packaging, packaging, etc., can solve the problems of poor centering effect and inconvenient operation, and achieve the effect of improving packaging efficiency, ensuring packaging quality and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

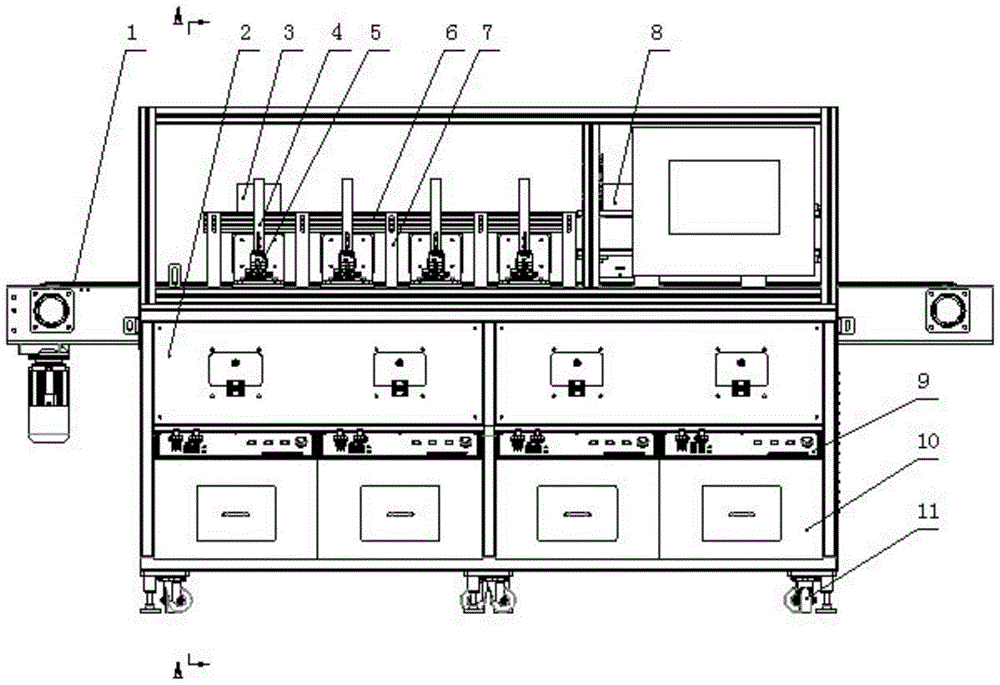

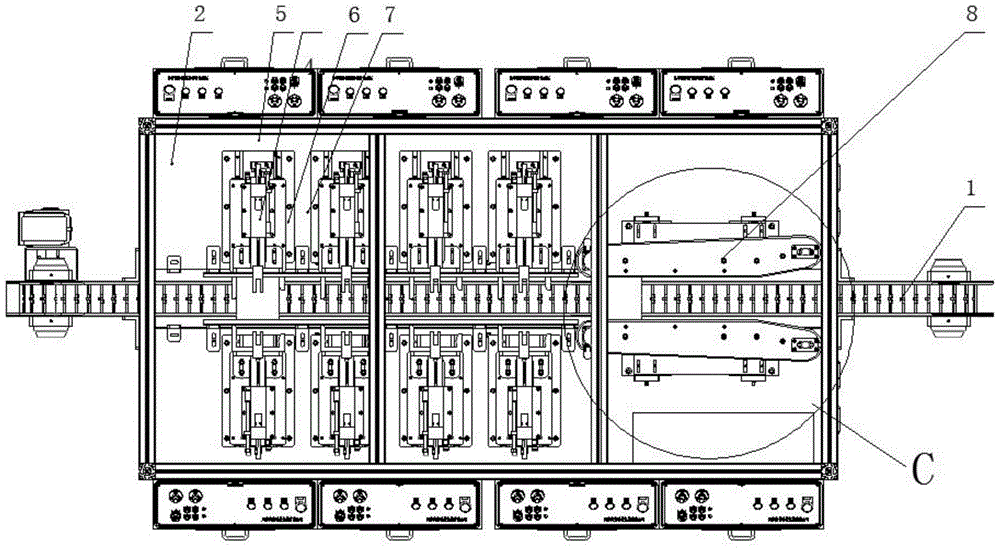

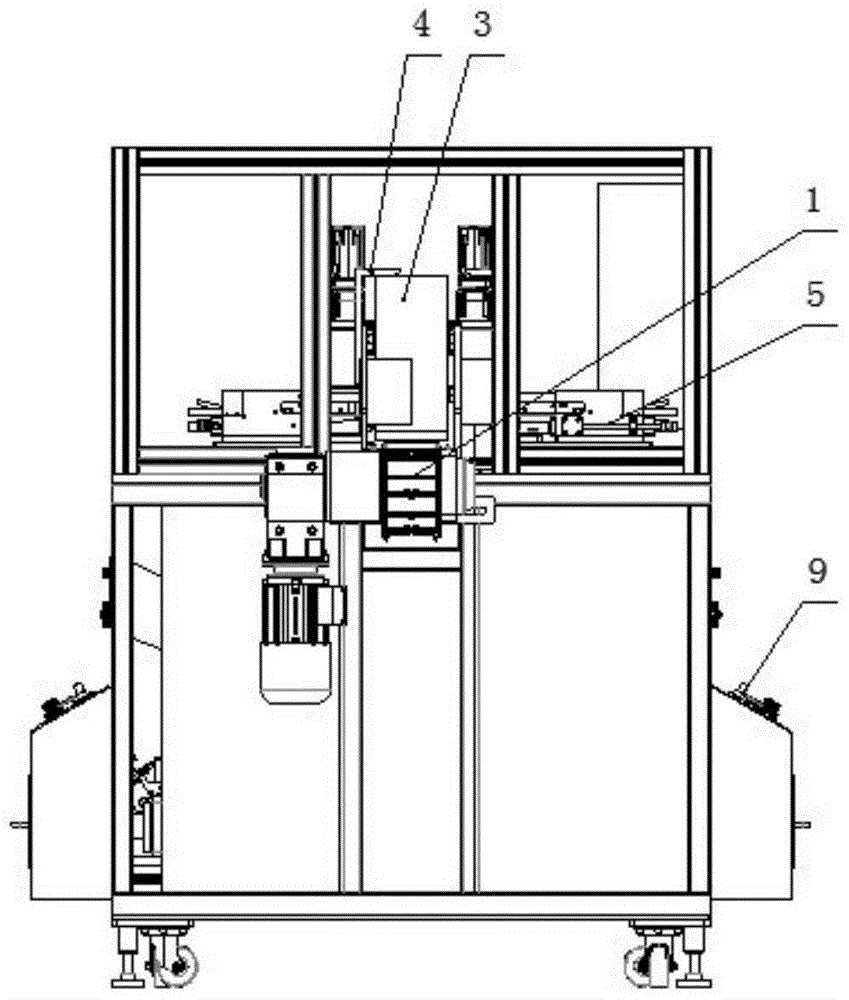

[0035] An automatic nailing system for anti-counterfeit rivets of liquor gift boxes, comprising a frame 2, a conveyor belt 1, a limit conveying device 8, a positioning fixture 4, an automatic riveting gun 5, and an automatic nailing device 10, which are horizontally and laterally installed in the middle of the upper end of the frame On the conveyor belt for conveying the gift box 3, a drive motor is installed at the output end of the conveyor belt, and a limit conveying device is installed on the frame at the input end of the conveyor belt. The limit conveying device controls the conveying speed of the gift box on the conveyor belt or positions the gift box;

[0036] Four sets of positioning jigs are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com