Patents

Literature

122results about How to "Large expansion ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Embolic basket

Owner:ENDOVASCULAR TECH

Embolic filter

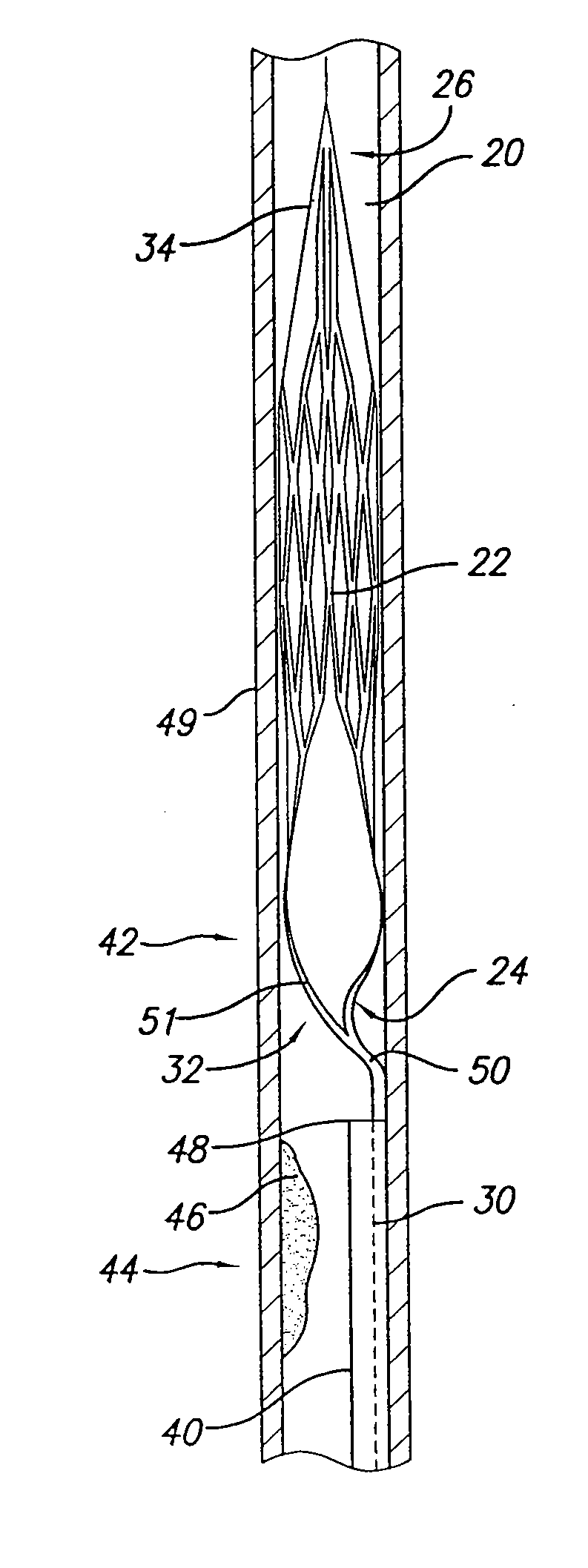

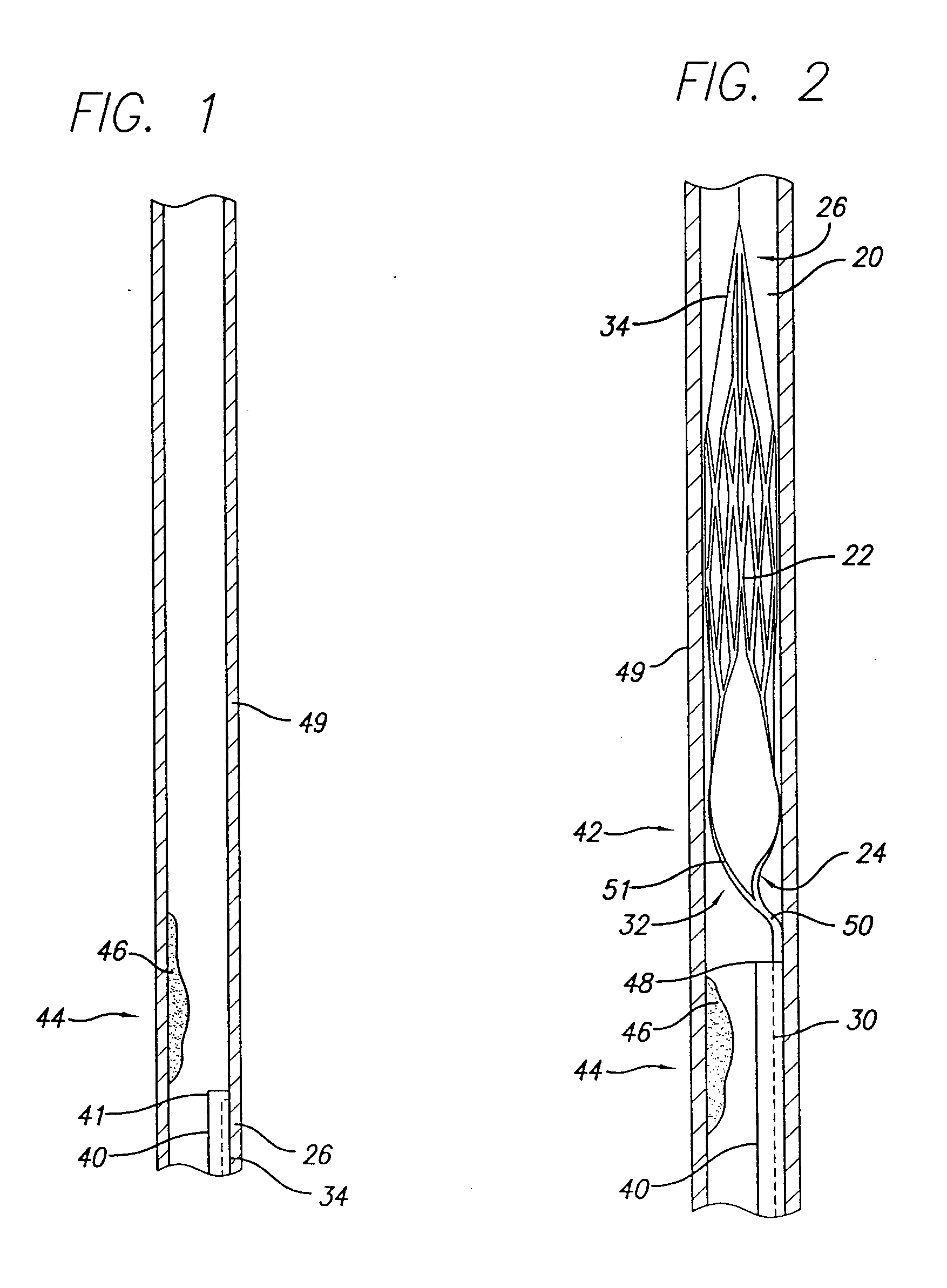

InactiveUS7004955B2Maintaining and restoring patencyImprove the immunitySurgeryDilatorsEndovascular surgeryBiomedical engineering

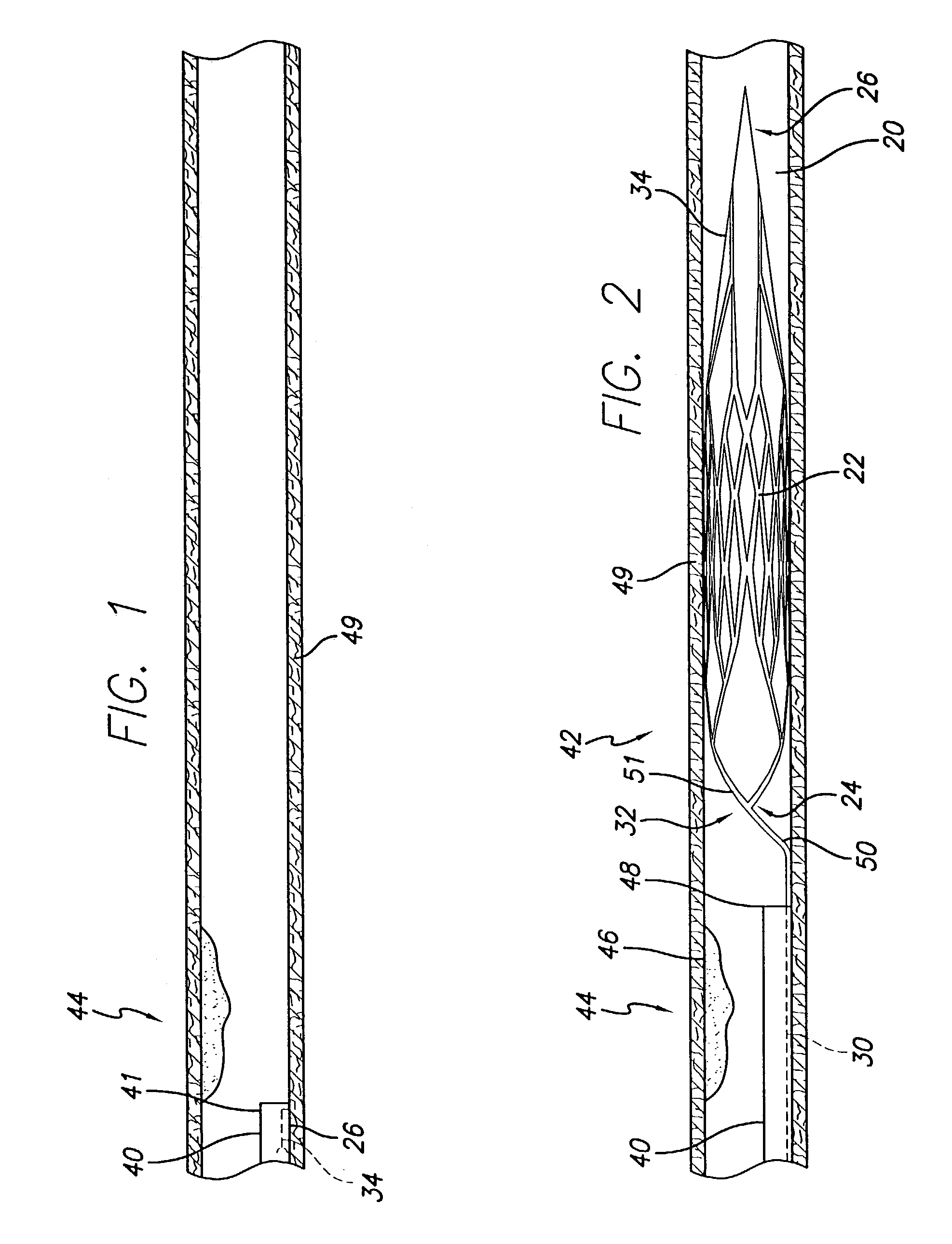

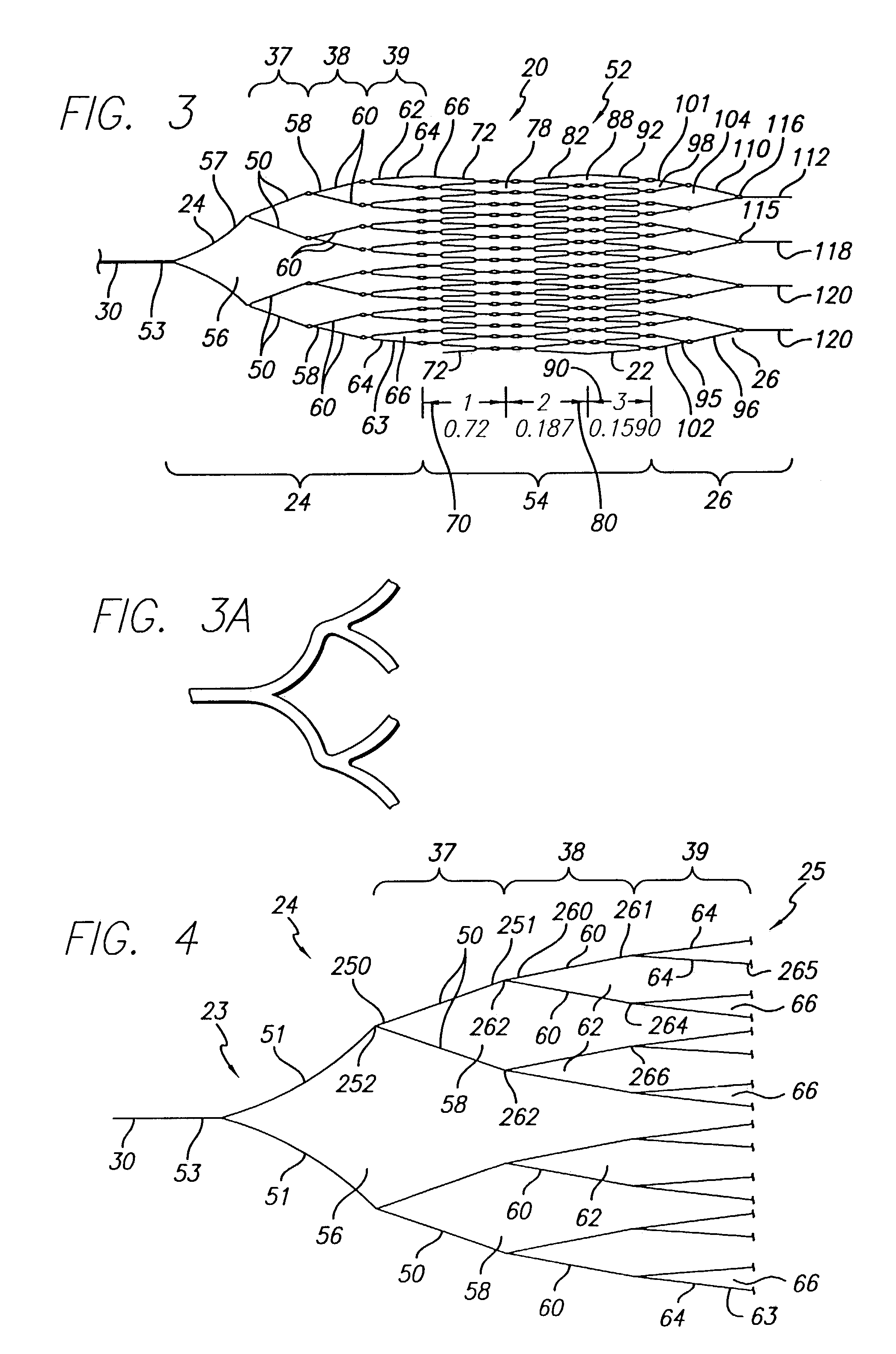

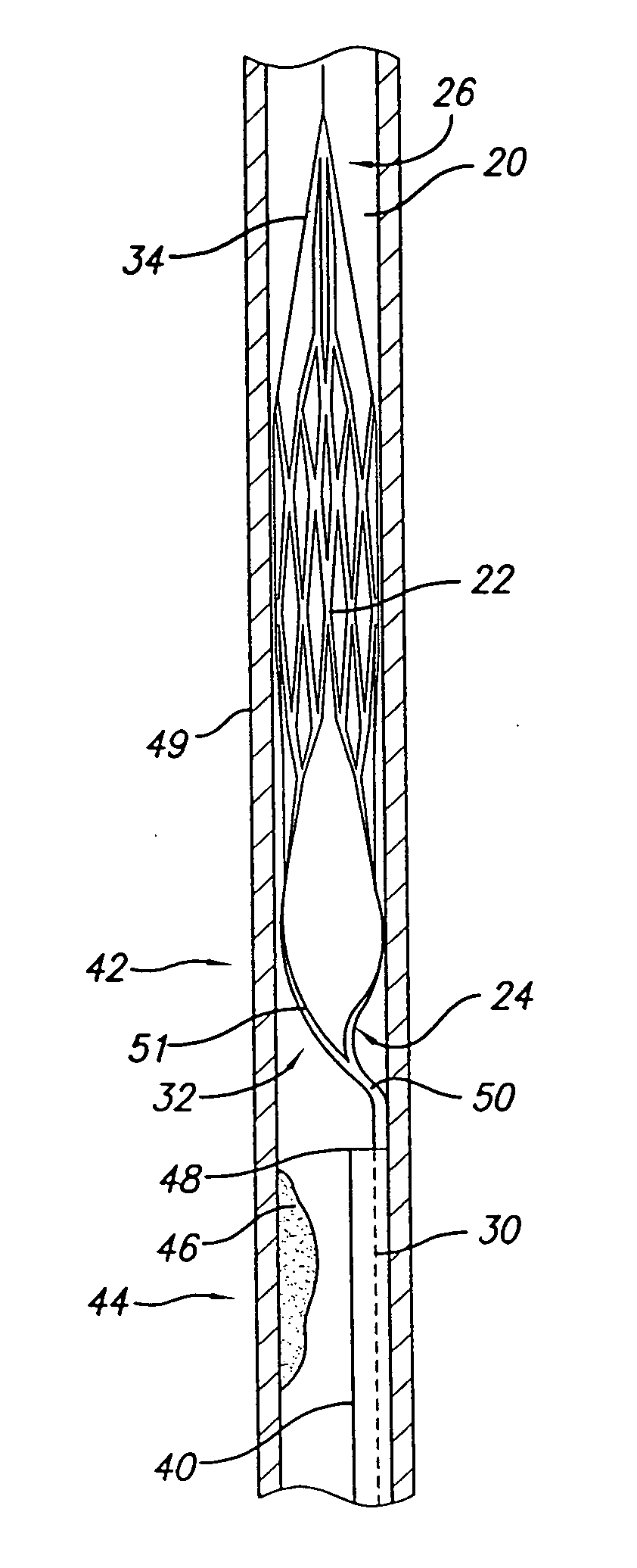

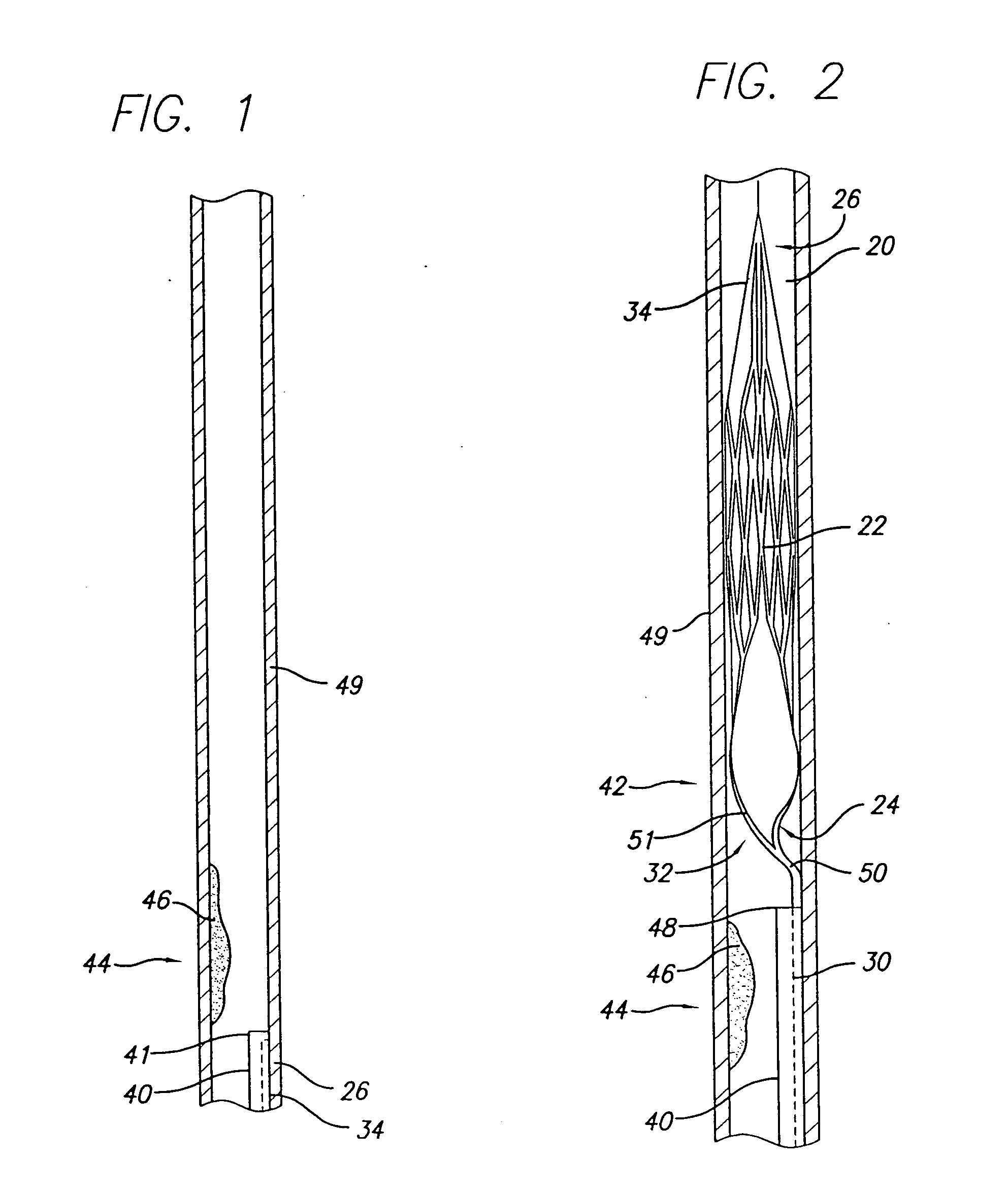

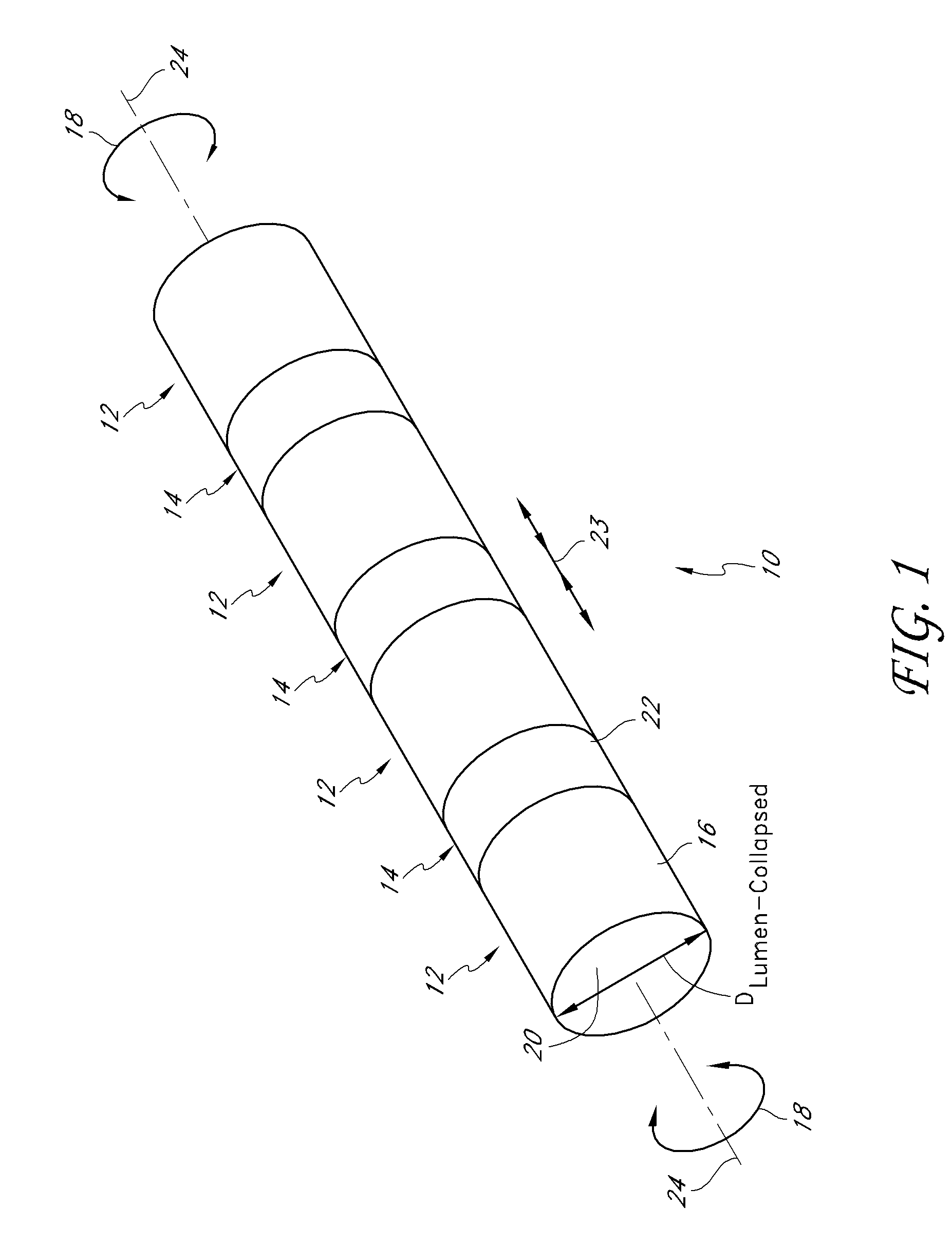

An intravascular filter device for use in capturing debris which may occur as a result of an intravascular procedure. The filter device includes a proximal section, a distal section and a mid-section. The mid-section includes three rings configured in a sixteen apices alternating V-pattern. The filter device specifically embodies structure that provides enhanced radial opening and angular resistance to collapse in its expanded state. While, in its compressed state the filter device provides an extremely small compressed profile giving it the desired ability to be delivered into very small vessels of the human vasculature.

Owner:ENDOVASCULAR TECH

Embolic basket

InactiveUS20060100663A1Improve the immunityRestoring patency of blood vesselsSurgeryDilatorsThree vesselsEmbolus

Owner:PALMER OLIN +1

Embolic basket

InactiveUS20080275498A1Improve the immunityRestoring patency of blood vesselsSurgeryDilatorsThree vesselsEmbolus

Owner:ABBOTT LAB INC

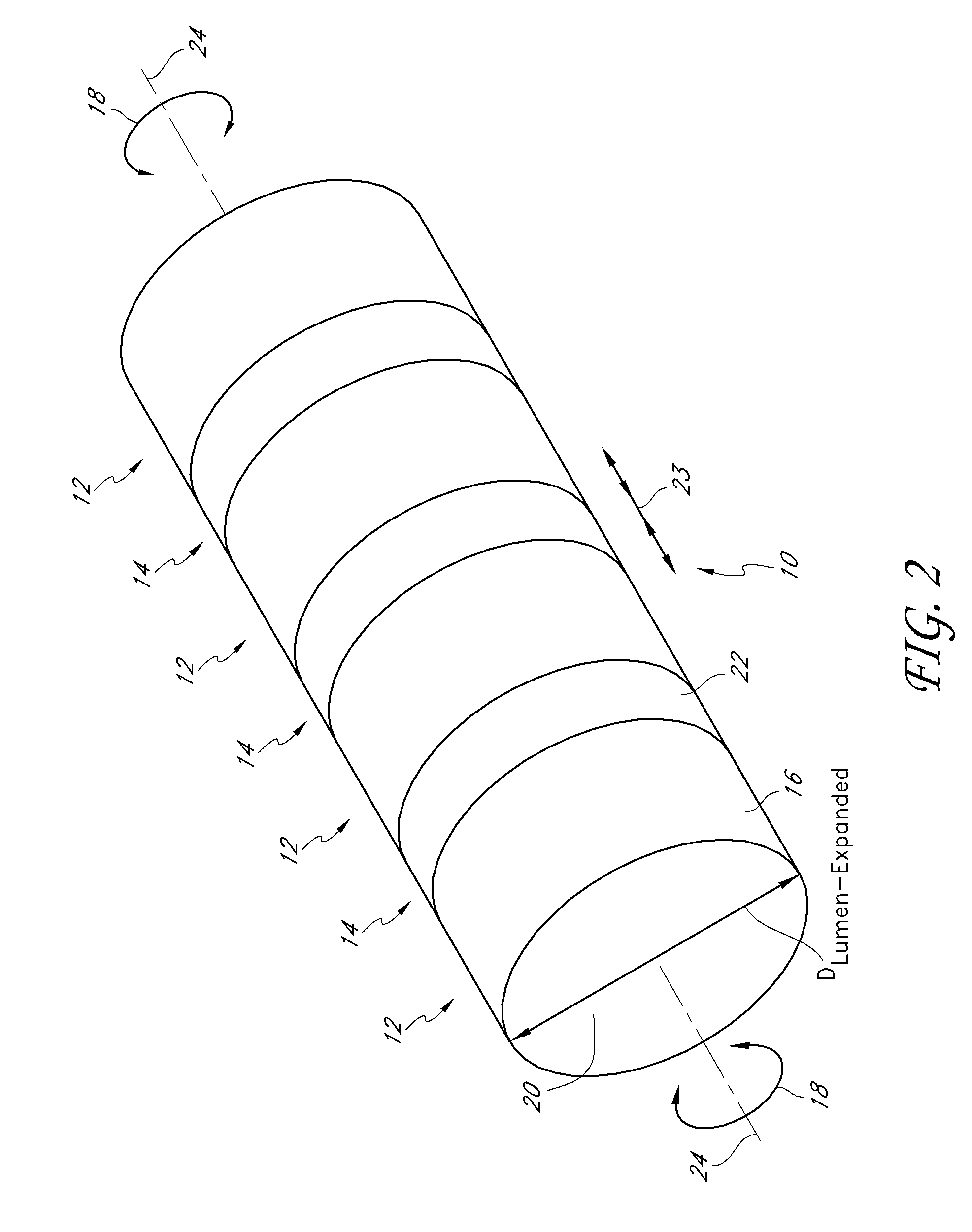

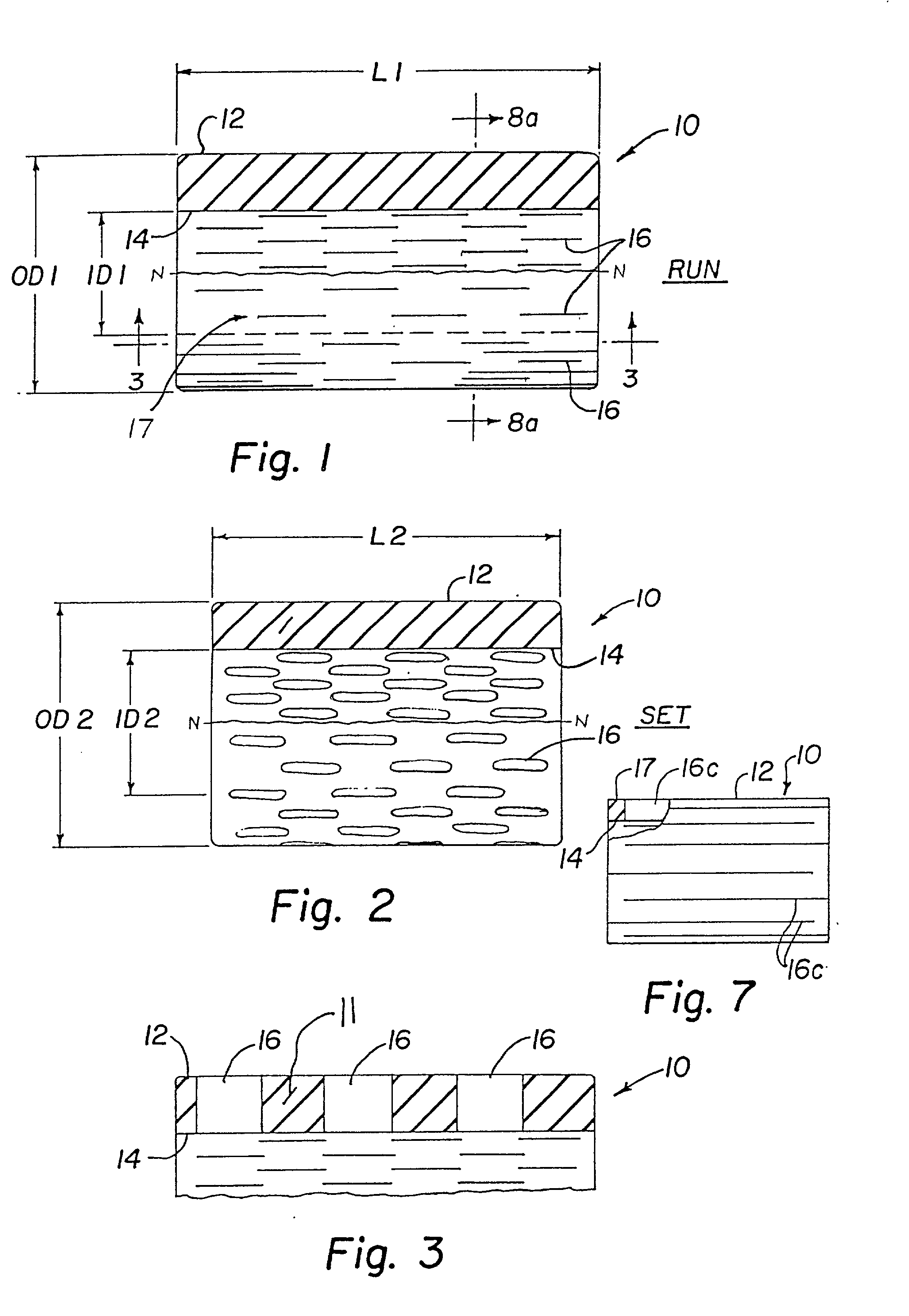

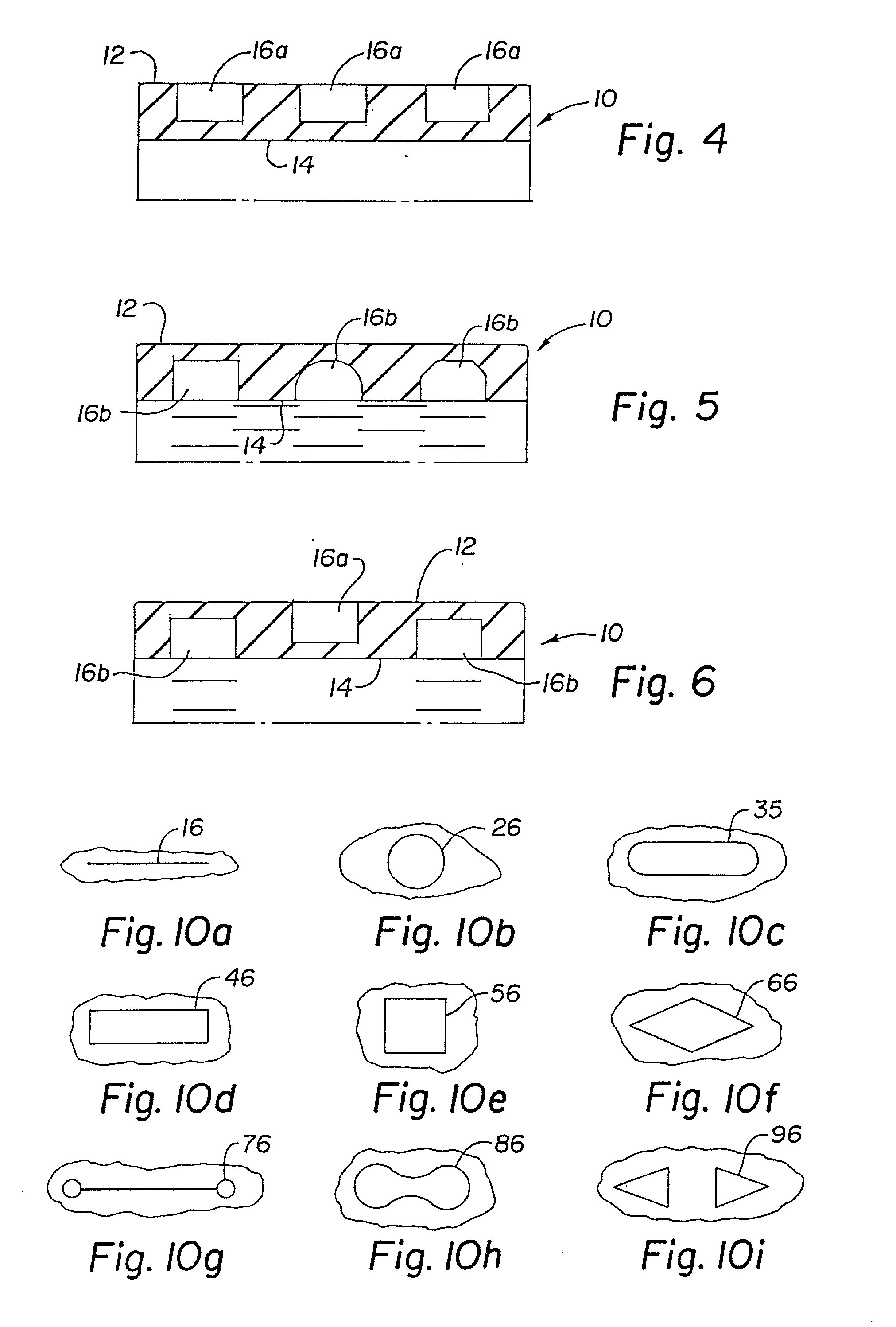

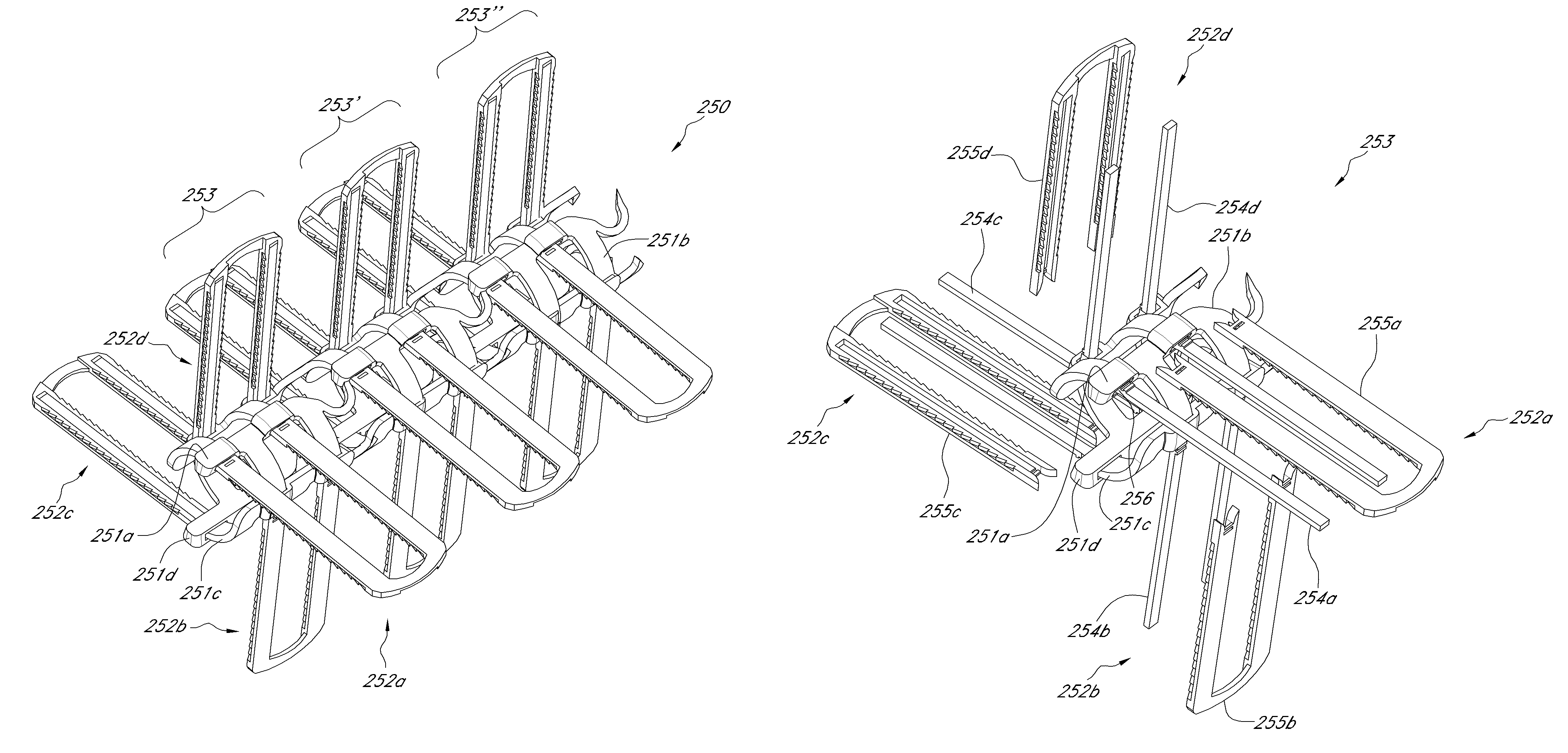

Self-expanding, pseudo-braided intravascular device

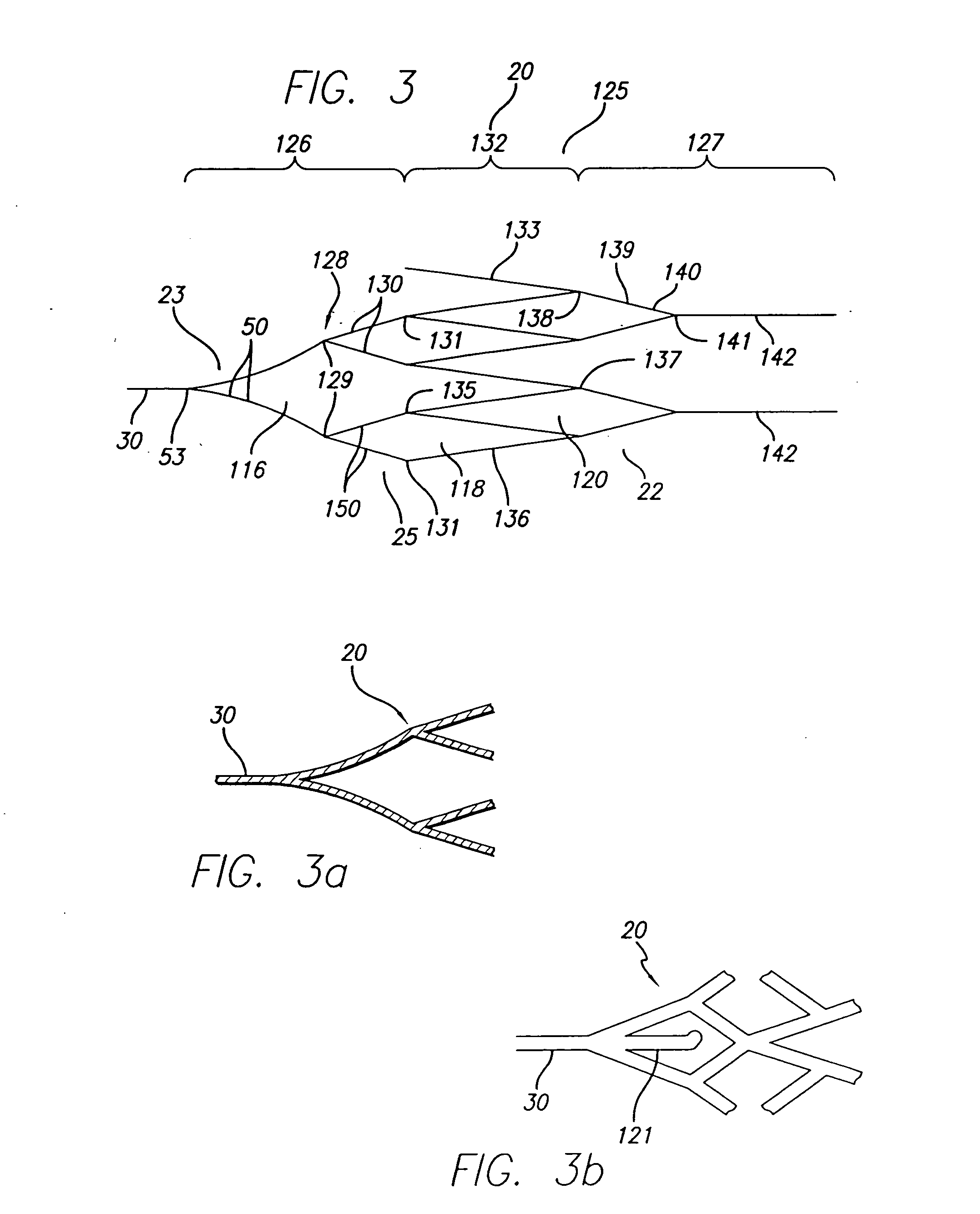

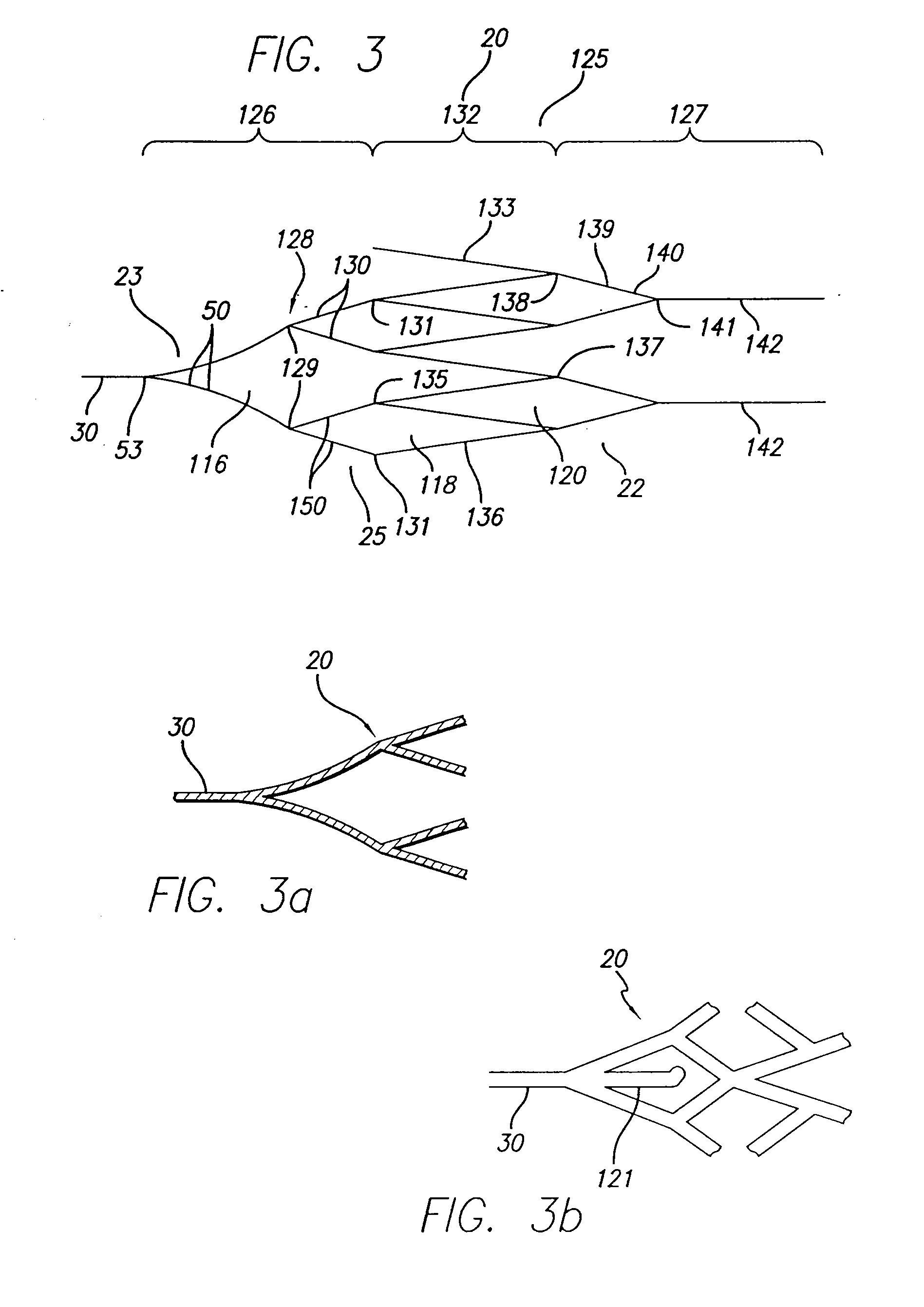

InactiveUS20080109063A1Large expansion ratioIncrease flexibilityStentsHand lacing/braidingThrombusTubular stenosis

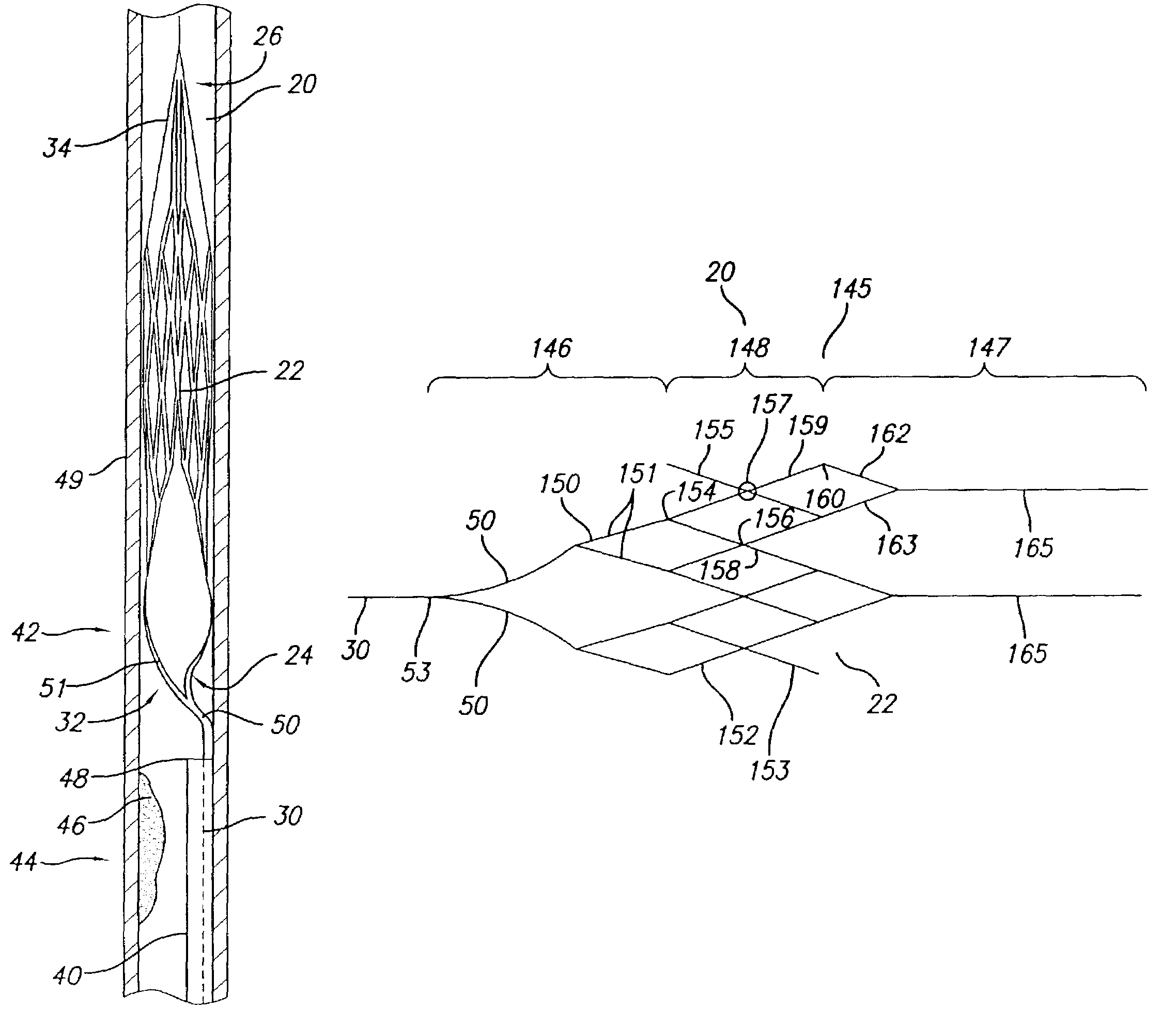

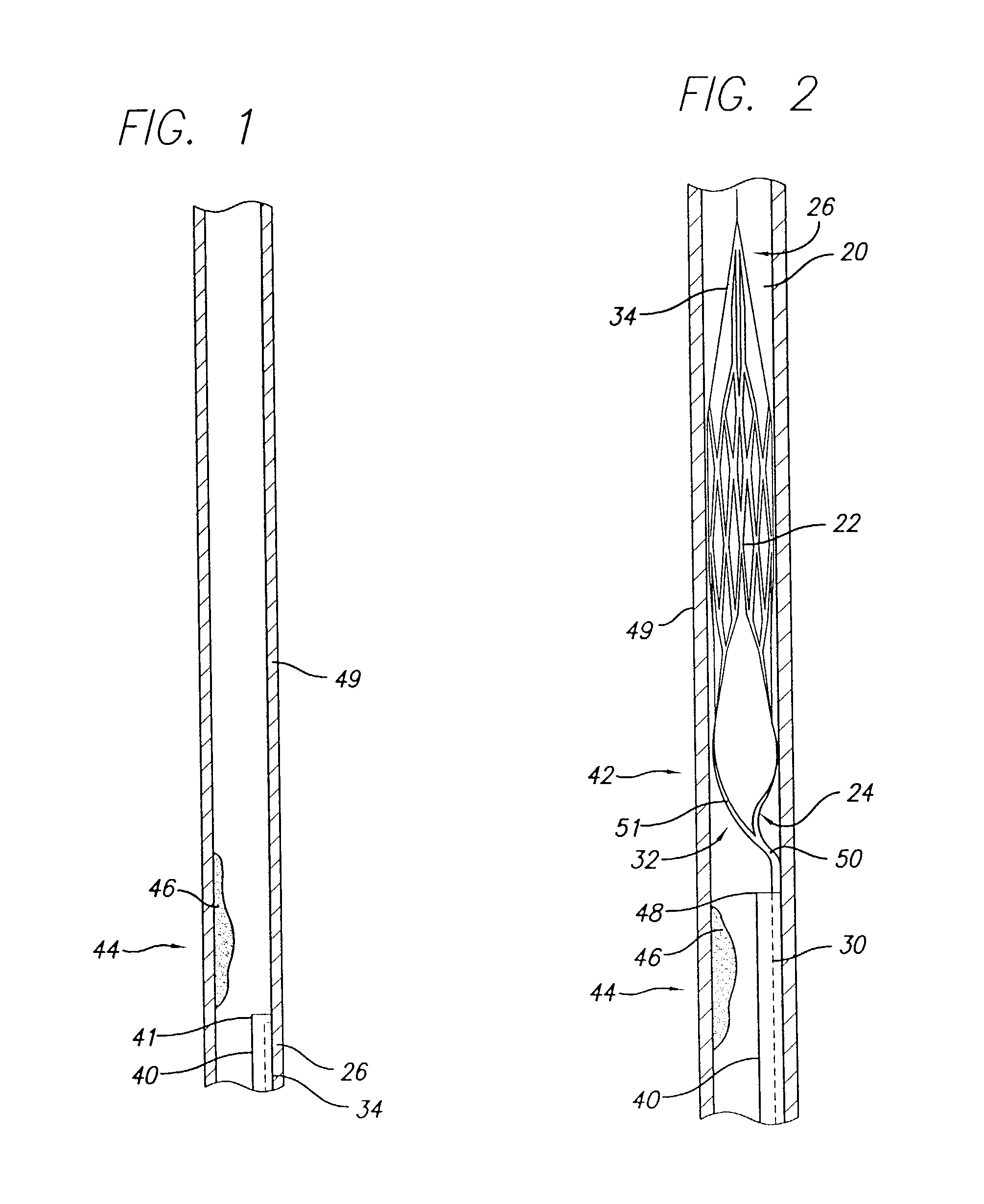

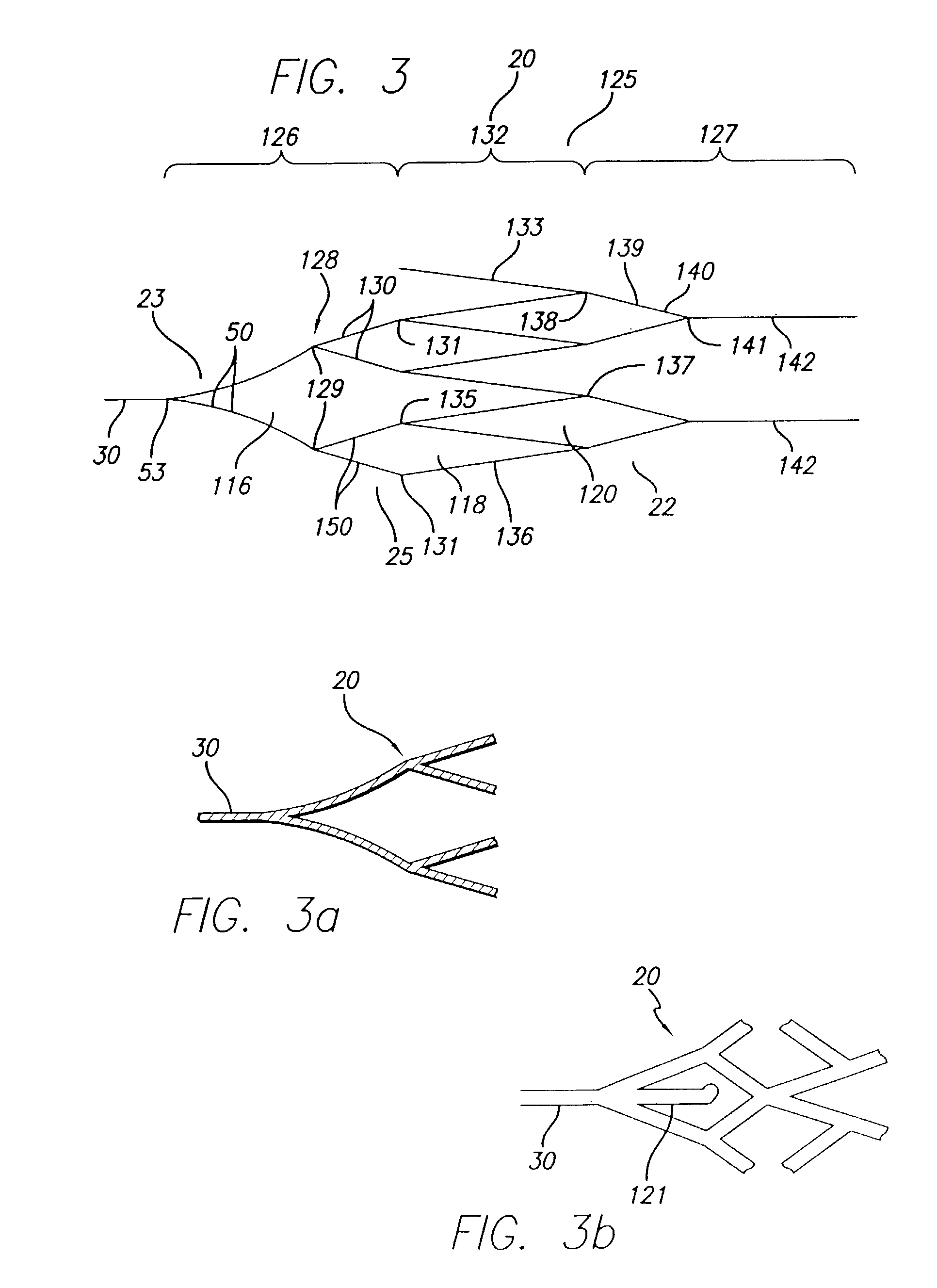

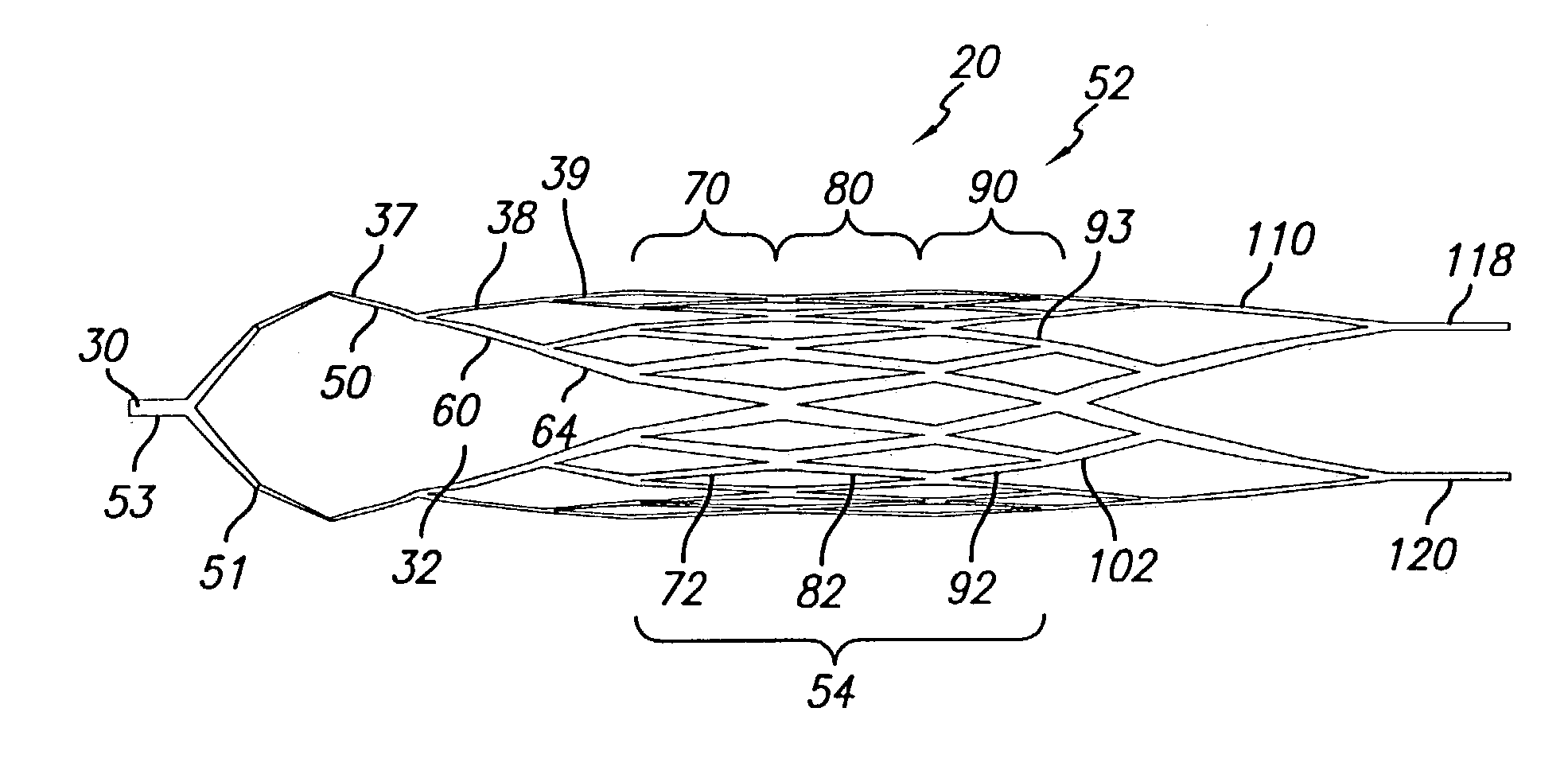

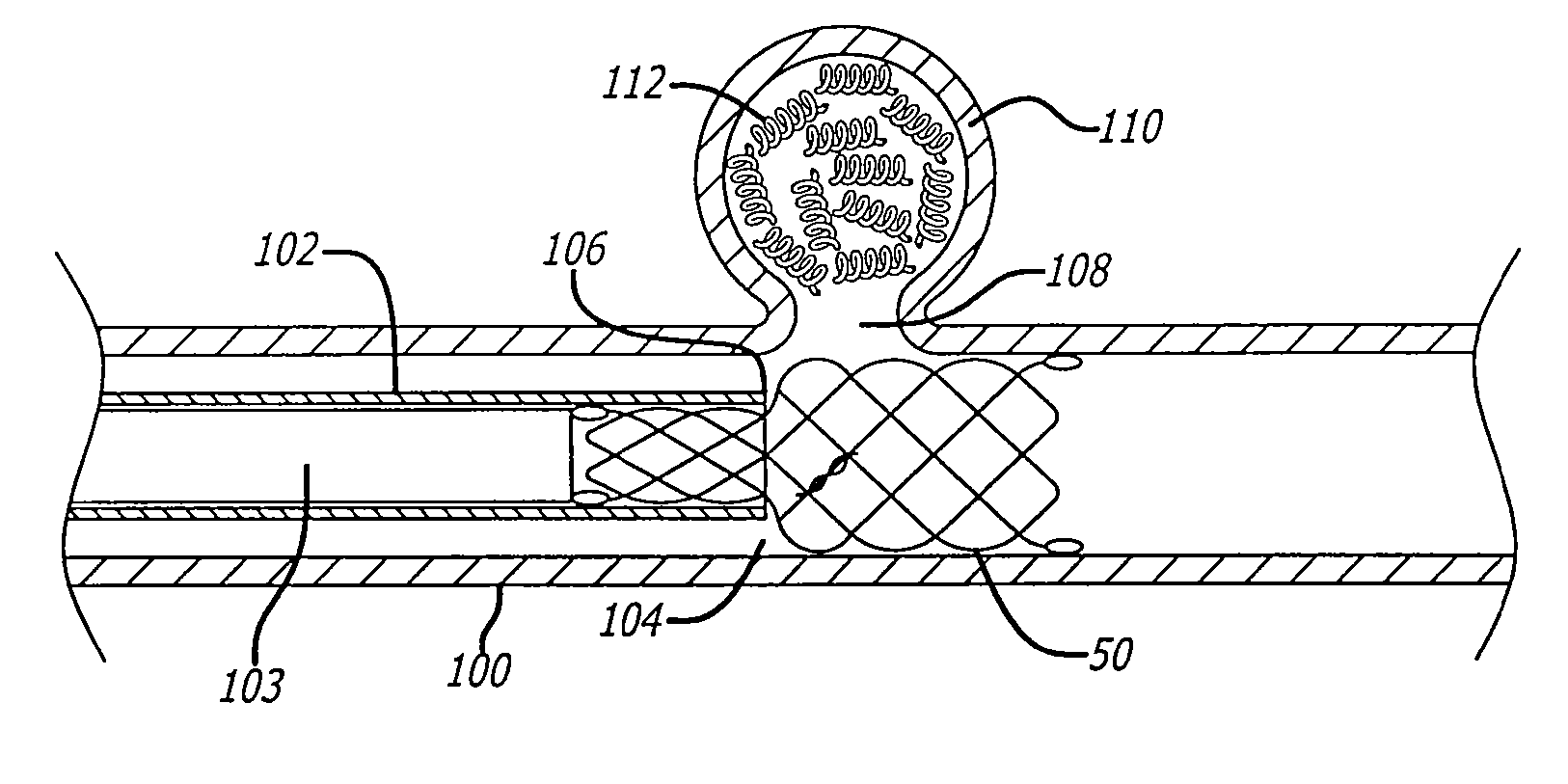

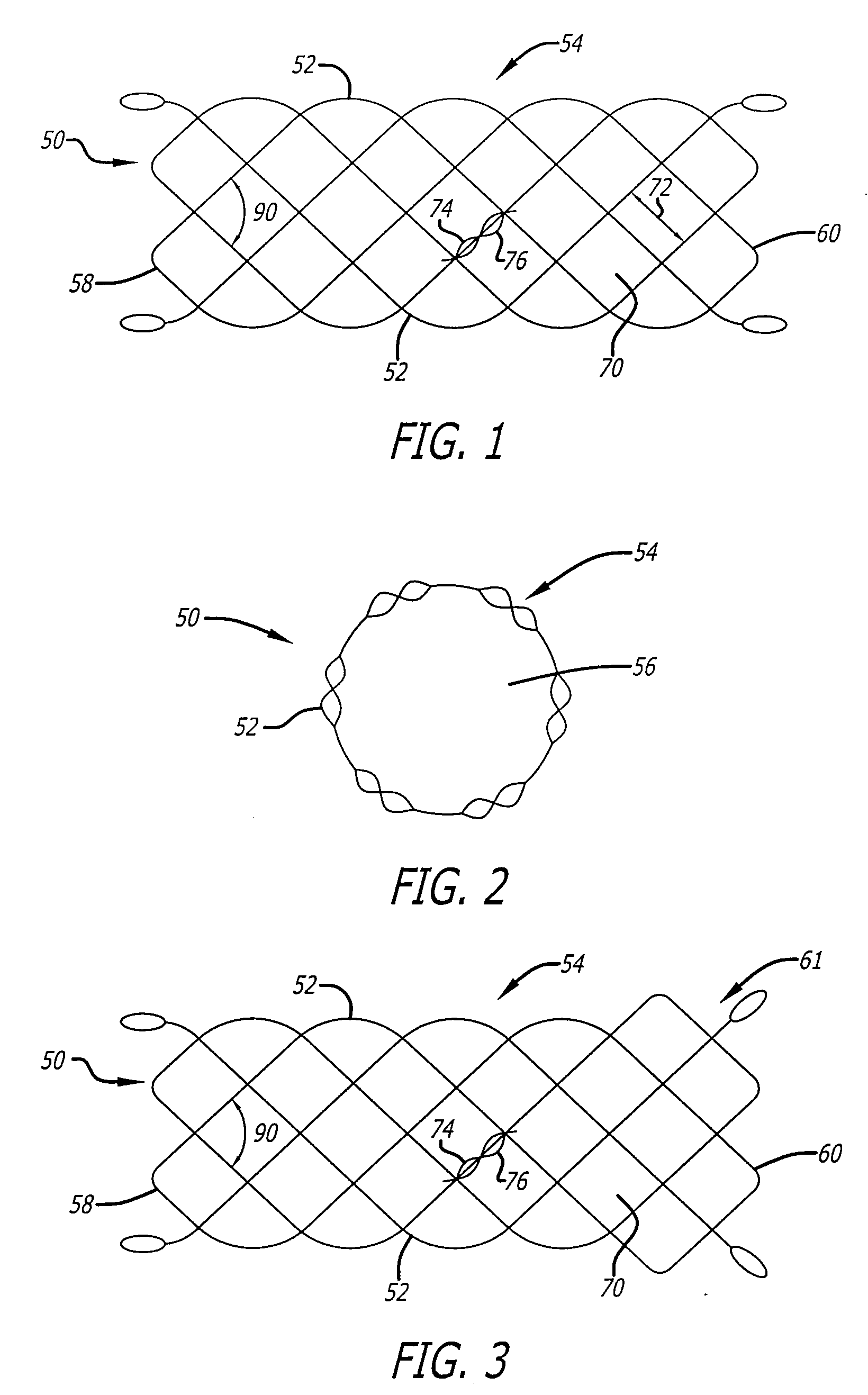

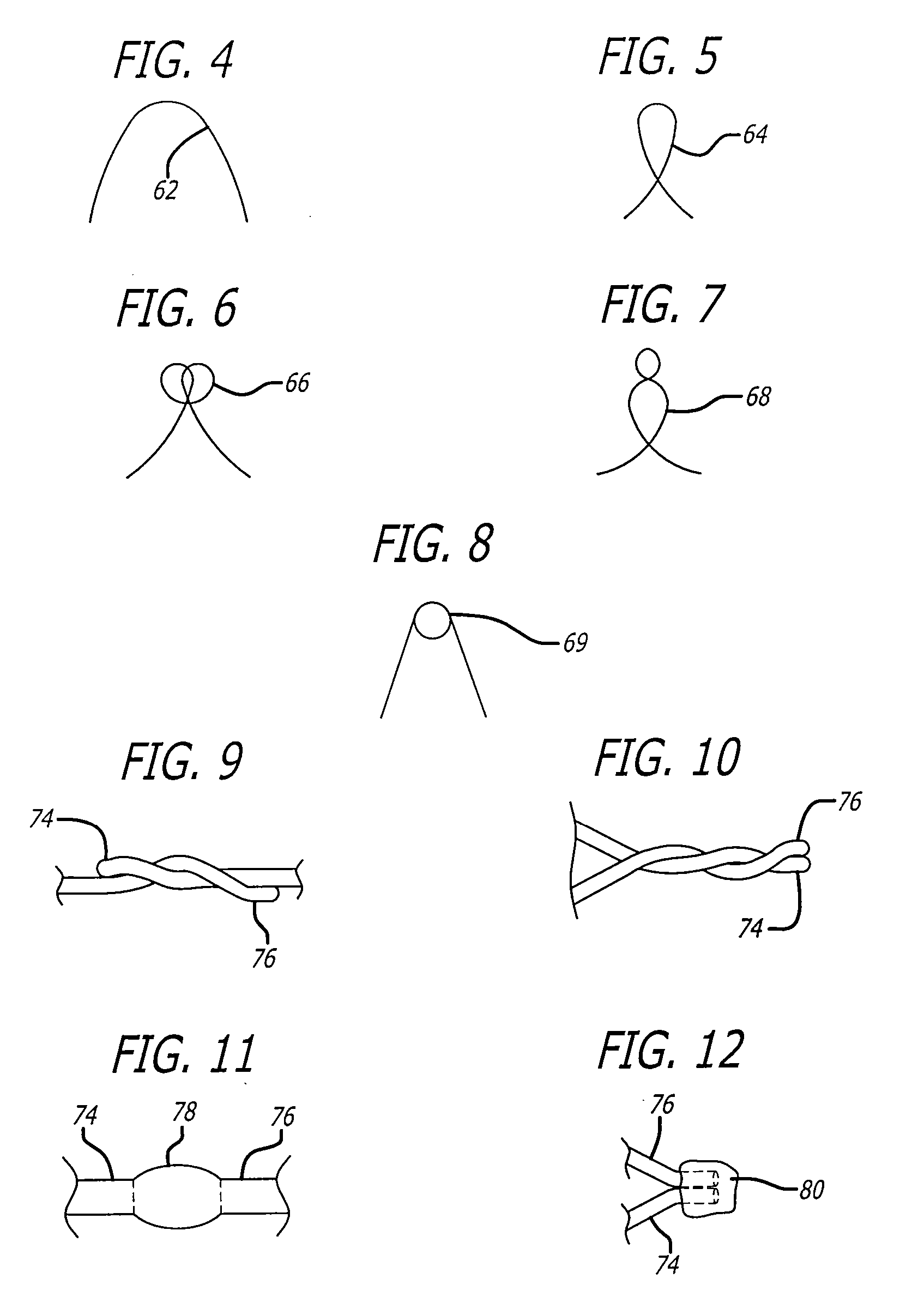

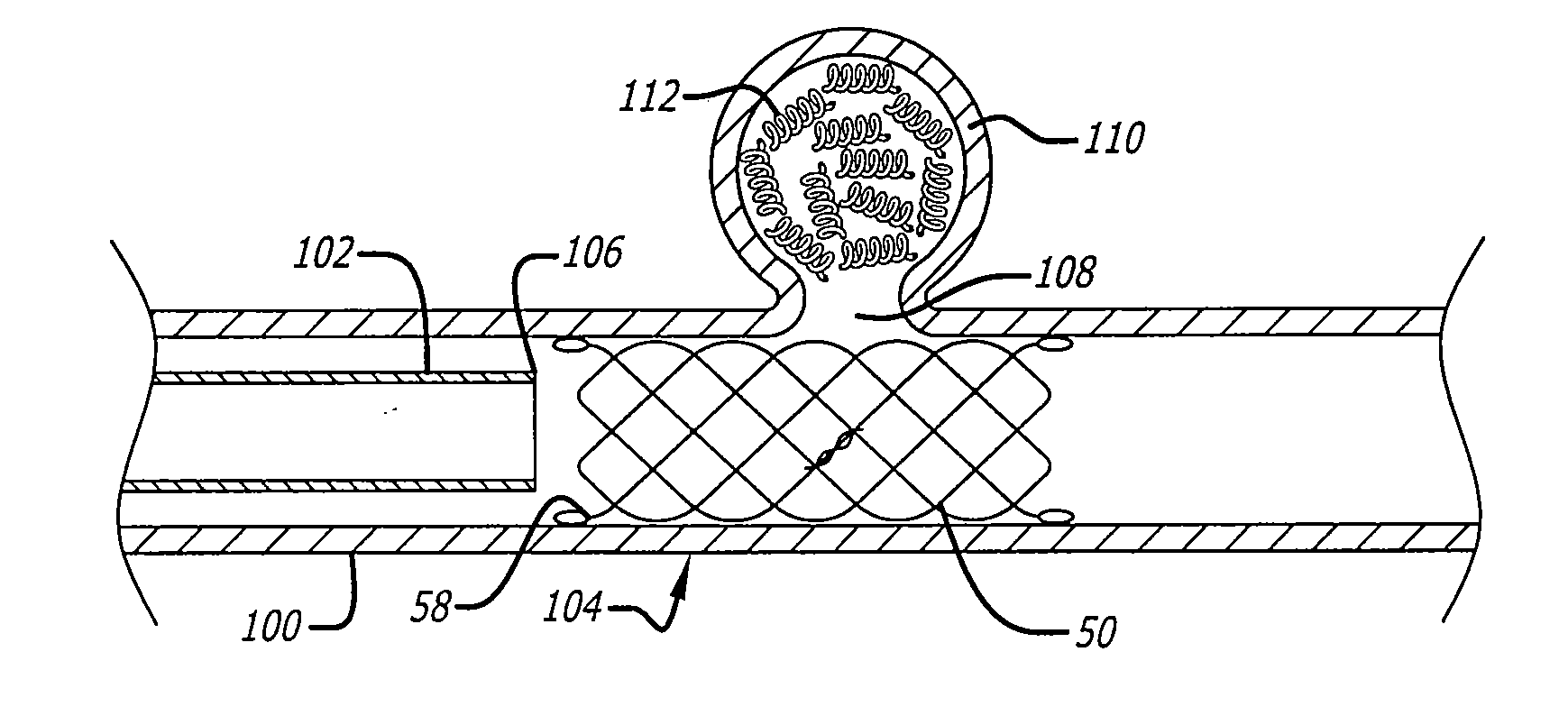

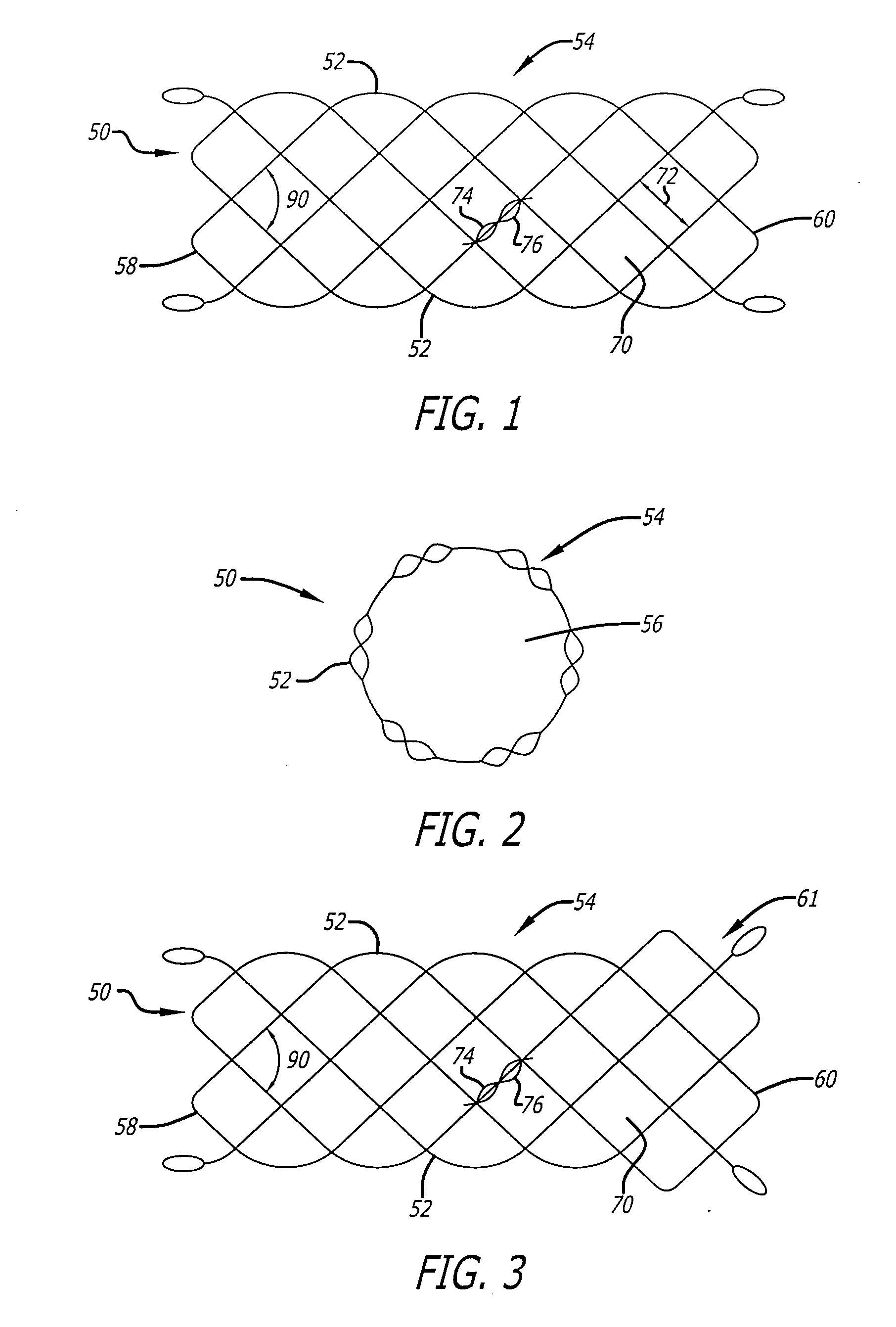

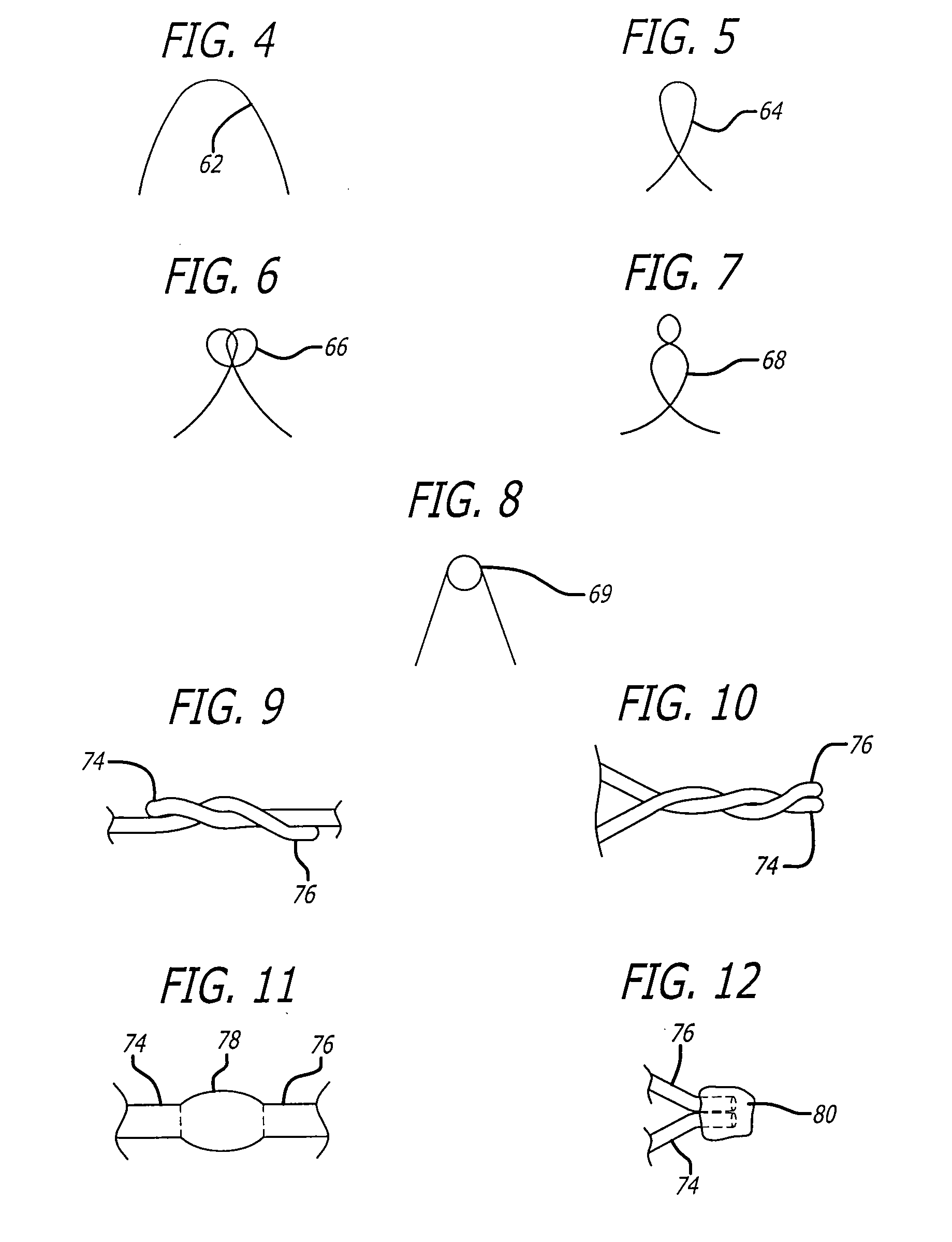

A self-expanding, pseudo-braided device embodying a high expansion ratio and flexibility as well as comformability and improved radial force. The pseudo-braided device is particularly suited for advancement through and deployment within highly tortuous and very distal vasculature. Various forms of the pseudo-braided device are adapted for the repair of aneurysms and stenoses as well as for use in thrombectomies and embolic protection therapy.

Owner:ENDOVASCULAR TECH

Self-expanding pseudo-braided intravascular device

InactiveUS20100004726A1Large expansion ratioIncrease flexibilityStentsHand lacing/braidingThrombusRepair aneurysm

A self-expanding, pseudo-braided device embodying a high expansion ratio and flexibility as well as comformability and improved radial force. The pseudo-braided device is particularly suited for advancement through and deployment within highly tortuous and very distal vasculature. Various forms of the pseudo-braided device are adapted for the repair of aneurysms and stenoses as well as for use in thrombectomies and embolic protection therapy.

Owner:ABBOTT CARDIOVASCULAR

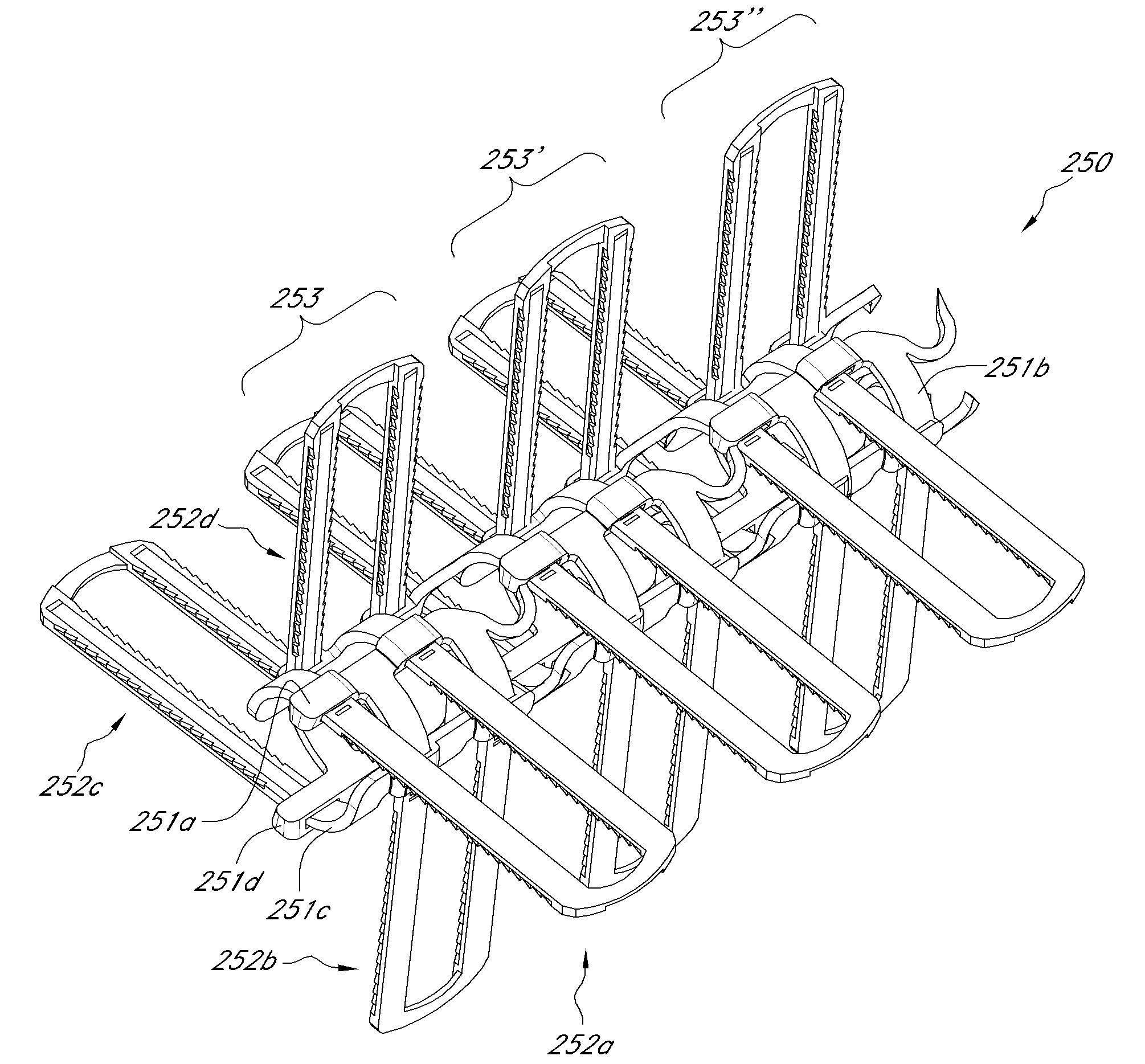

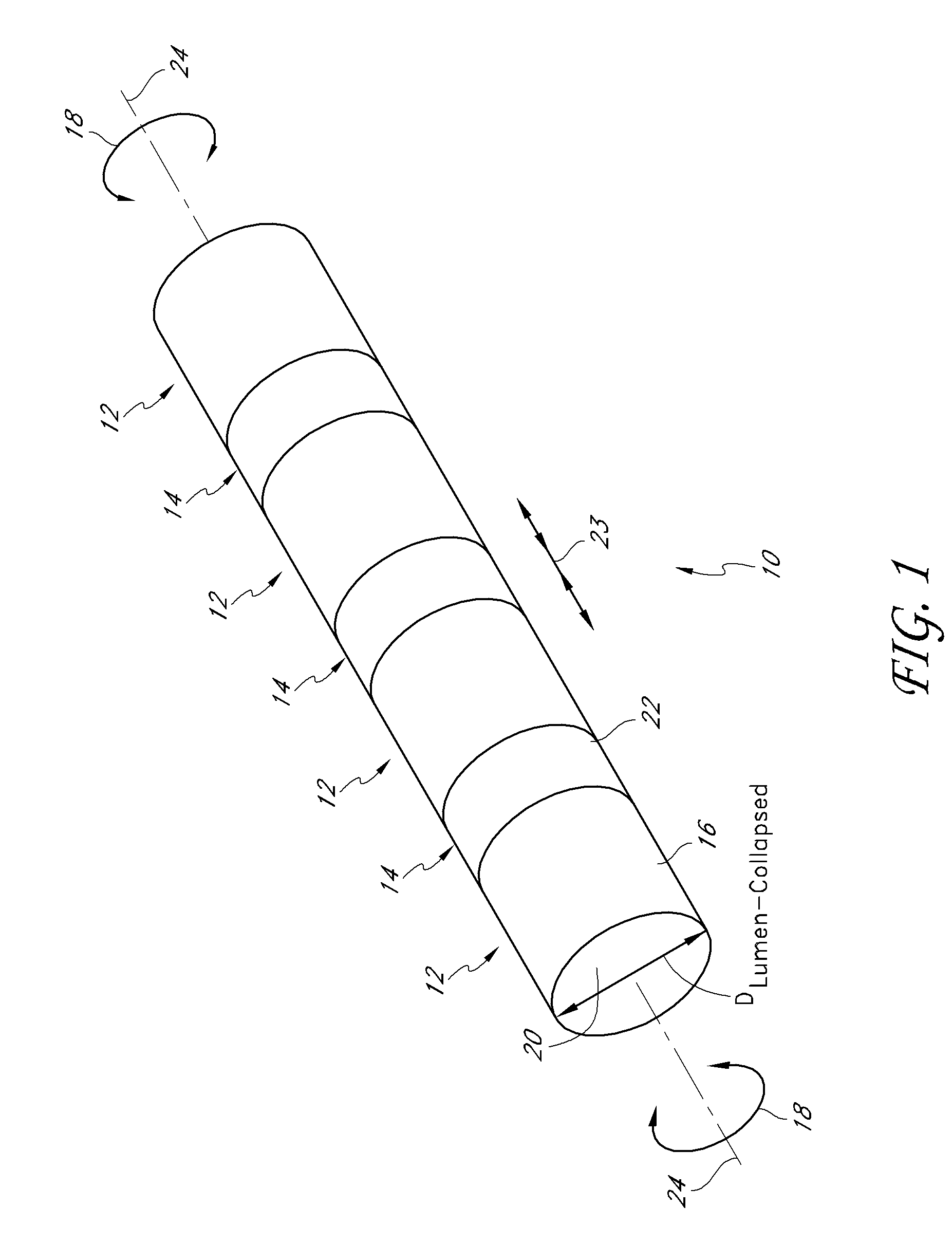

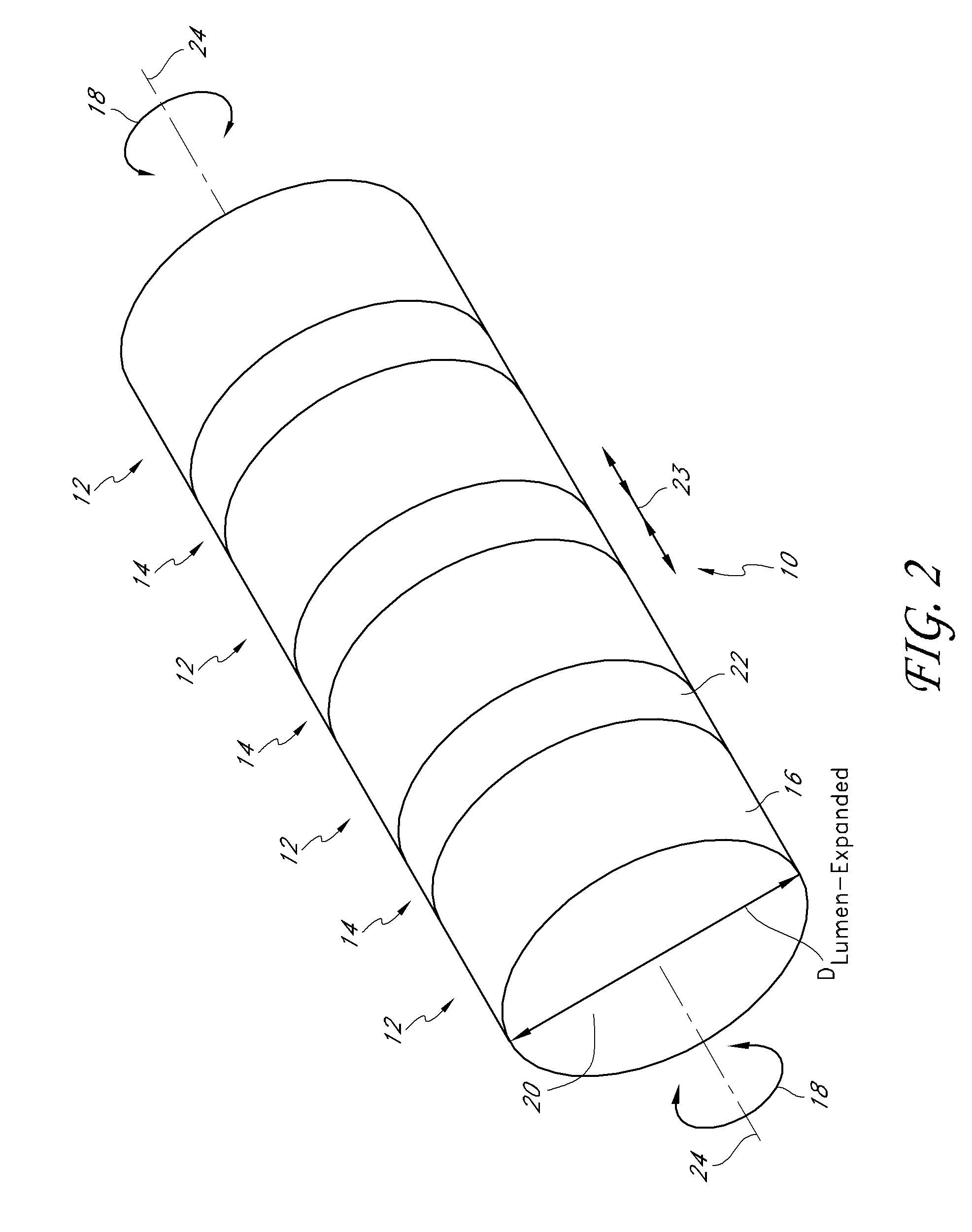

Axially-radially nested expandable device

InactiveUS20090143853A1Small non-deployed profileLow profileStentsAdditive manufacturing apparatusVascular deviceBlood vessel

Expandable medical implants for maintaining support of a body lumen are disclosed. These implants comprise an axially-radially nested, diametrically expandable, moveable vascular device for enlarging an occluded portion of a vessel. The device can be configured to allow for motion such as translating and / or slide and lock. One advantage of the axially-radially nested stent is that it maintains the expanded size, without significant recoil.

Owner:REVA MEDICAL

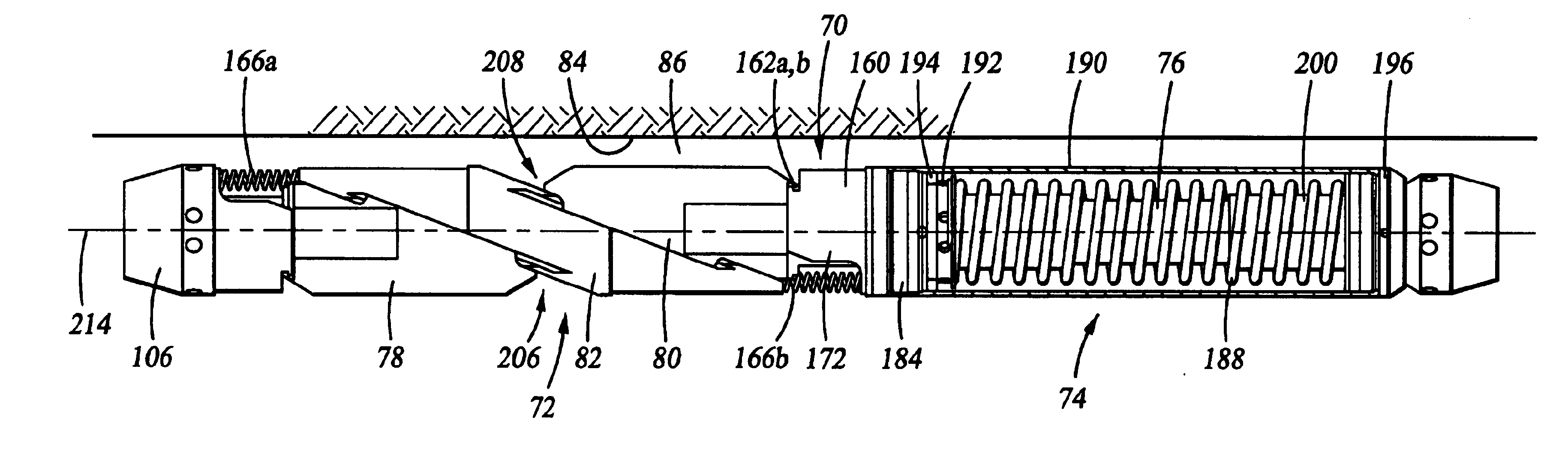

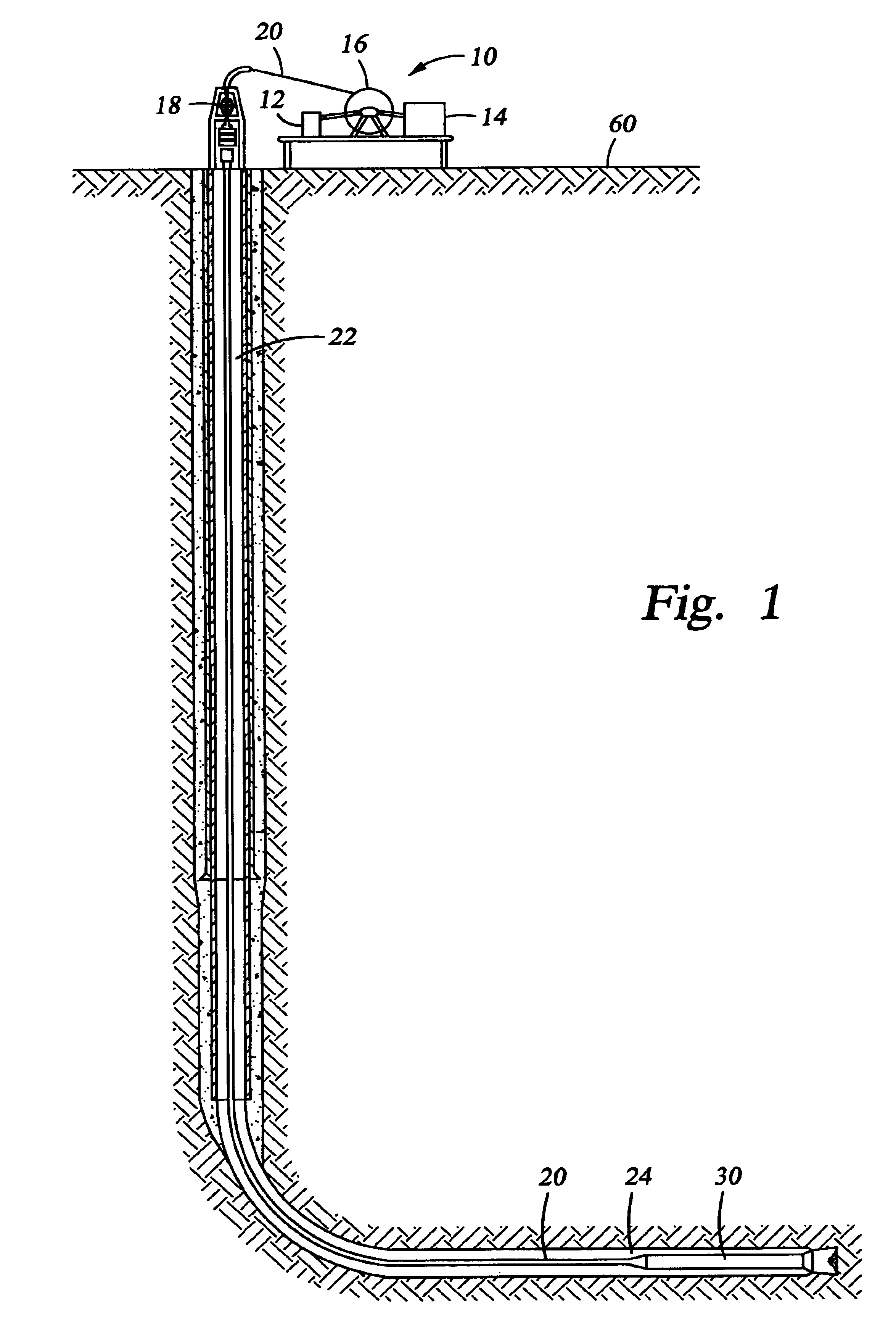

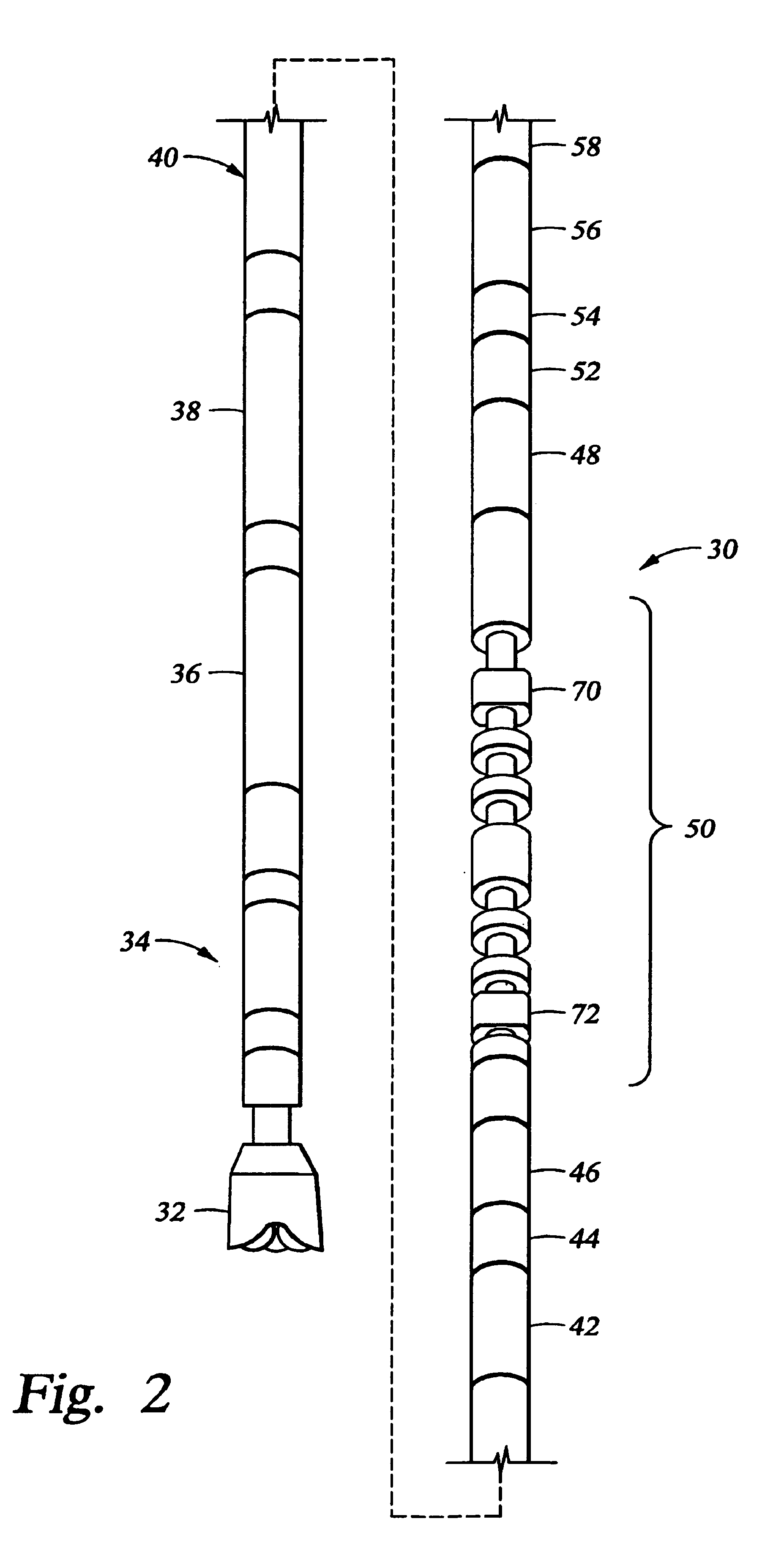

Borehole retention device

InactiveUS6935423B2Large expansion ratioEfficient and reliable and less-expensiveDrilling rodsConstructionsAxial forceMechanical engineering

A borehole retention assembly for anchoring a well tool within a wellbore including a gripping assembly and an actuation assembly. The gripping assembly includes expandable members such that upon expanding the expandable members, the gripping assembly engages the wall of the borehole. The gripping assembly includes a pair of expandable members and a medial member, the members having cooperating tapered surfaces therebetween such that upon the actuation assembly contracting the gripping assembly, the expandable members are cammed outwardly against the borehole wall. The gripping assembly is mounted on a mandrel enabling them to resist rotational and axial forces on the well tool. When engaged, space is provided on each side of the borehole retention assembly such that annular flow is permitted therearound.

Owner:HALLIBURTON ENERGY SERVICES INC

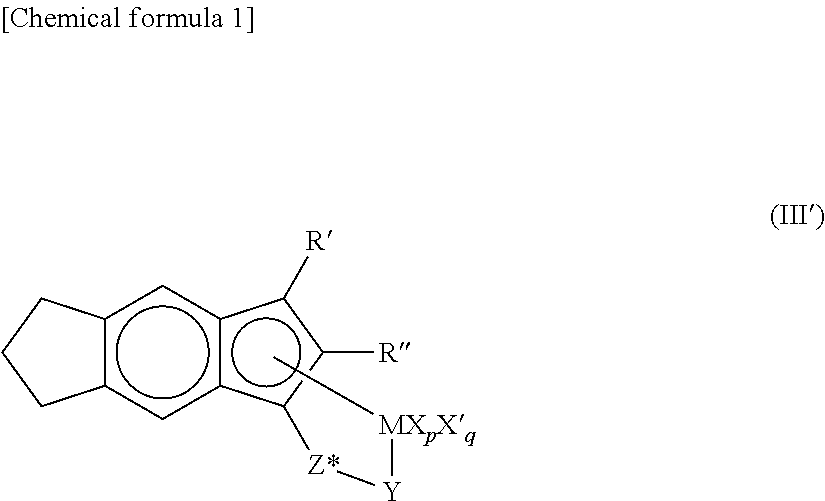

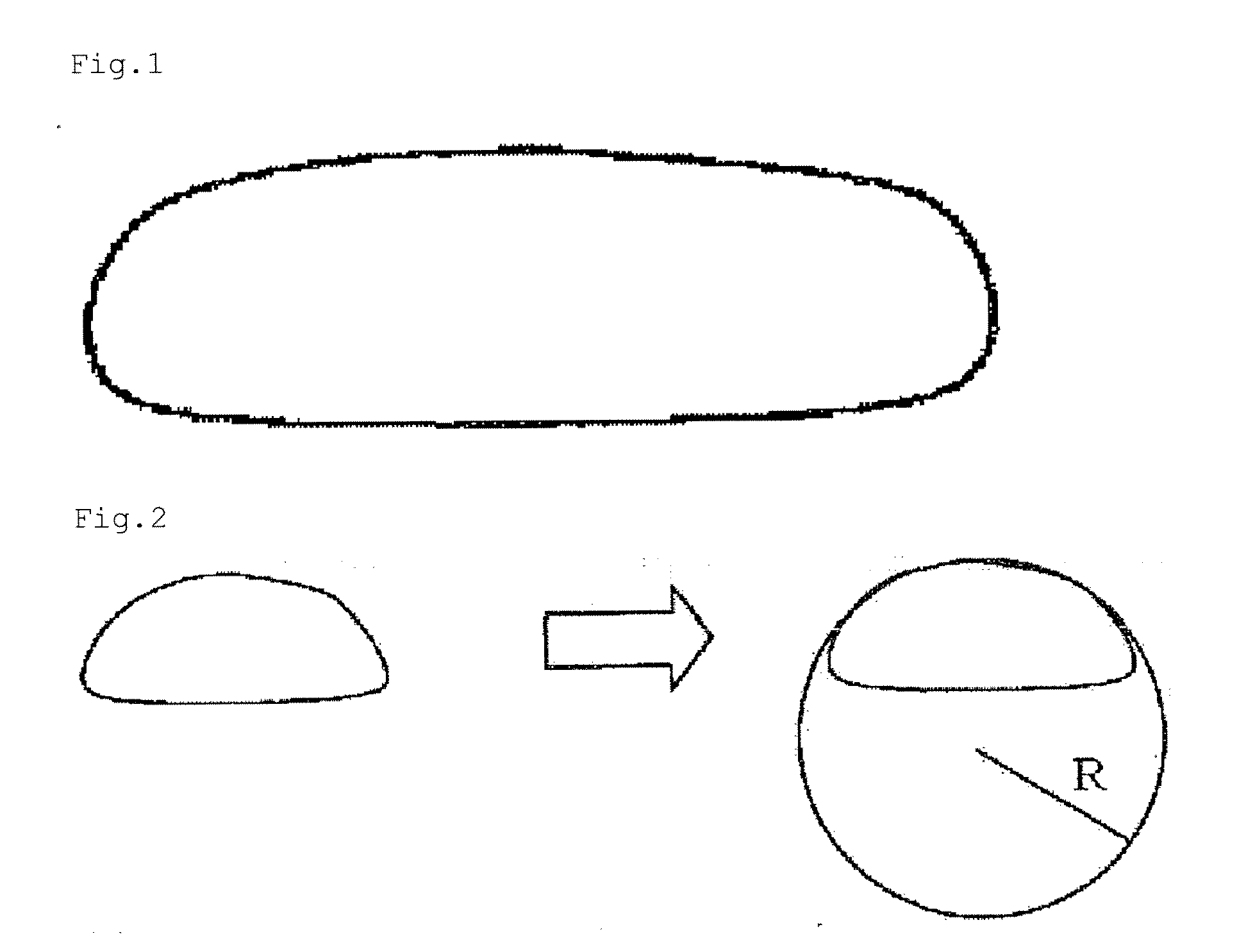

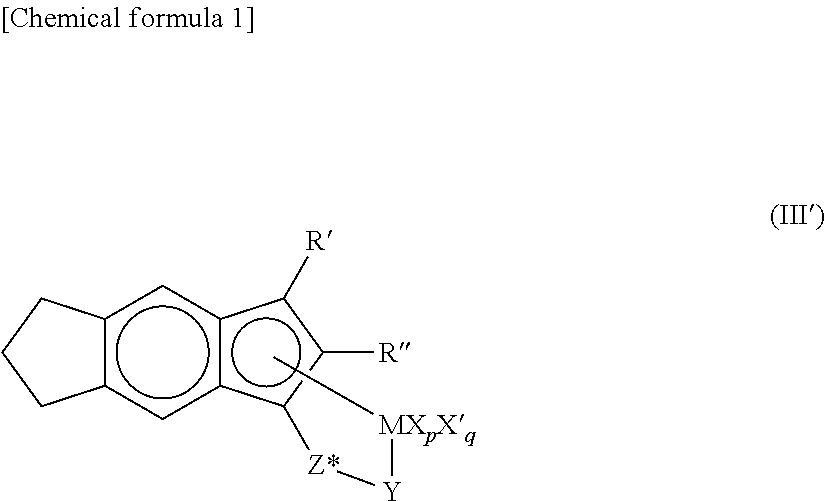

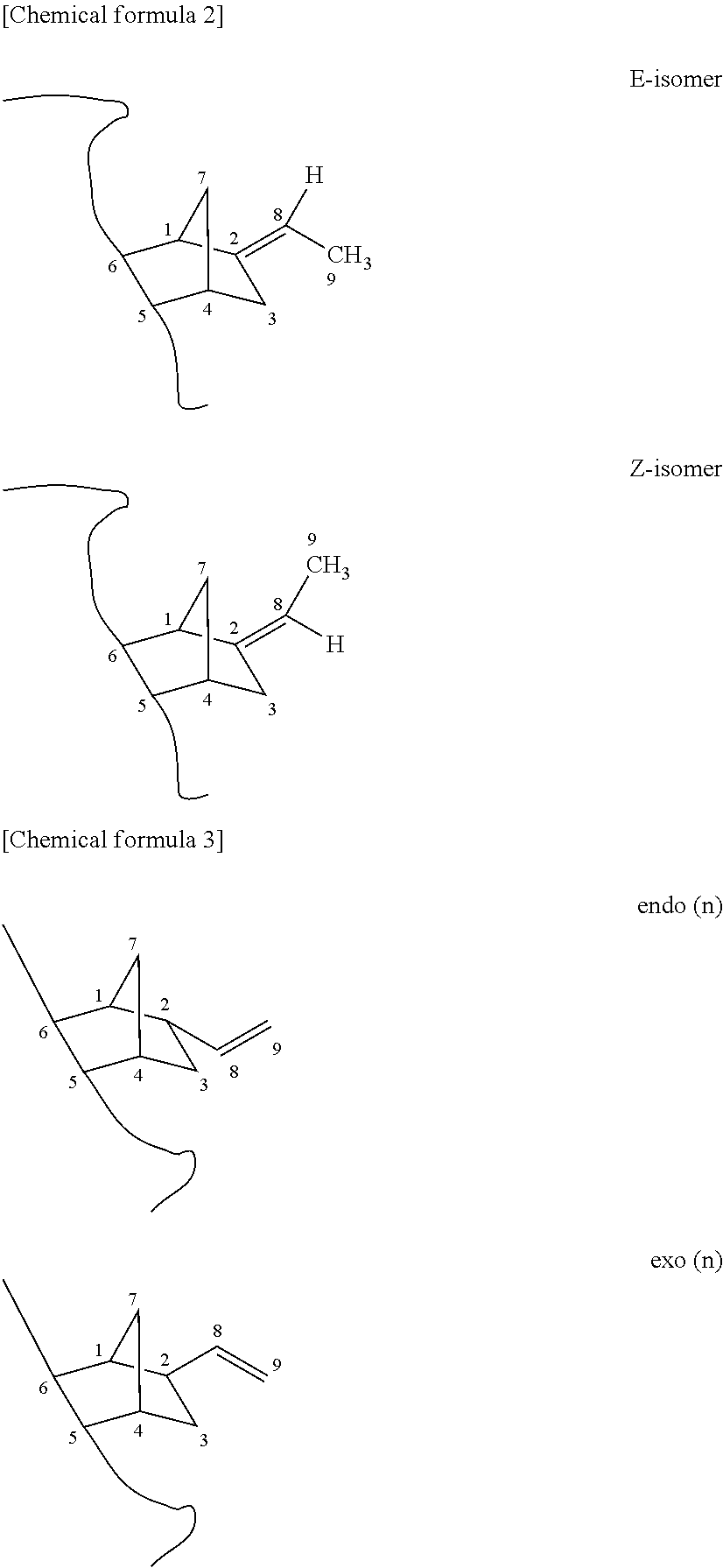

Copolymer, rubber composition, cross-linked rubber, cross-linked foam, and uses thereof

ActiveUS9193856B2Adequate foamabilityLarge expansion ratioBuilding constructionsCross-linkActivation energy

The present invention provides a rubber composition having adequate foamability, uses thereof, a copolymer contained in the rubber composition, a rubber composition capable of providing a cross-linked foam, which has a low specific gravity and an excellent shape-retaining property even when the usage of a nonconjugated polyene is reduced, and a cross-linked rubber and a cross-linked foam, which are produced from the rubber composition. A copolymer (A) according to the present invention is a copolymer including structural units derived from ethylene [A], an α-olefin [B], a nonconjugated polyene [C-1], in which one carbon-carbon double bond (C═C) polymerizable with a metallocene catalyst is present in one molecule, and a nonconjugated polyene [C-2], in which two bonds of C═C polymerizable with the metallocene catalyst are present in one molecule, and being synthesized with the metallocene catalyst, wherein (1) the units derived from the component [B] constitute 10 to 50 percent by mole, (2) the total of the units derived from the component [C-1] and the units derived from the component [C-2] is 1.0 to 6.0 percent by mole, (3) the molar ratio of the units derived from the component [C-1] to the units derived from the component [C-2] is 75 / 25 to 99.5 / 0.5, (4) [ML (1+4) 100° C.] is 10 to 200, and (5) 50>activation energy of fluidization (kJ / mol)>35 is satisfied.

Owner:MITSUI CHEM INC

Seal and method

InactiveUS20030047880A1Improve sealingReduce failureFluid pressure sealed jointsFluid removalEngineeringMechanical engineering

Owner:HALLIBURTON ENERGY SERVICES INC

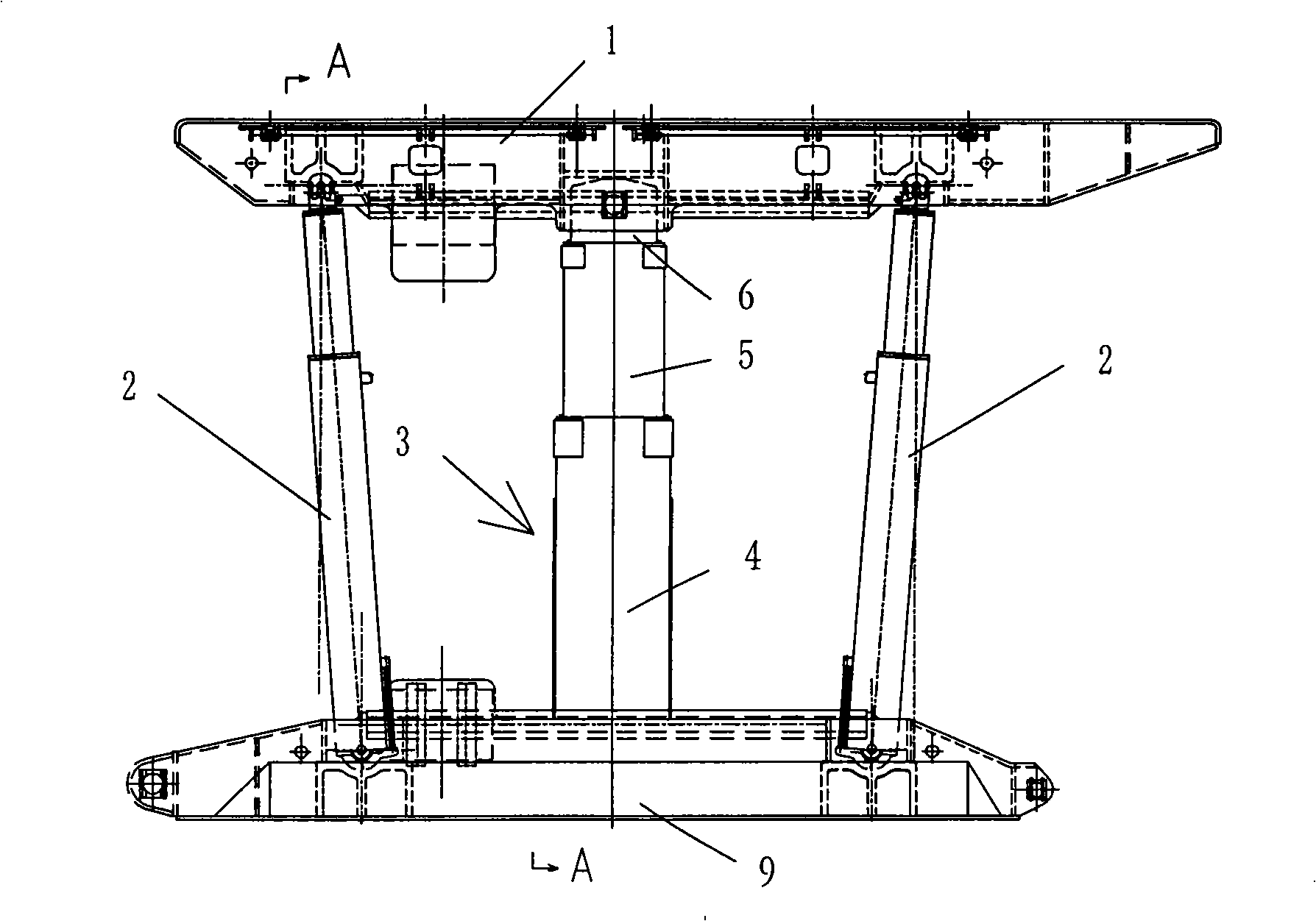

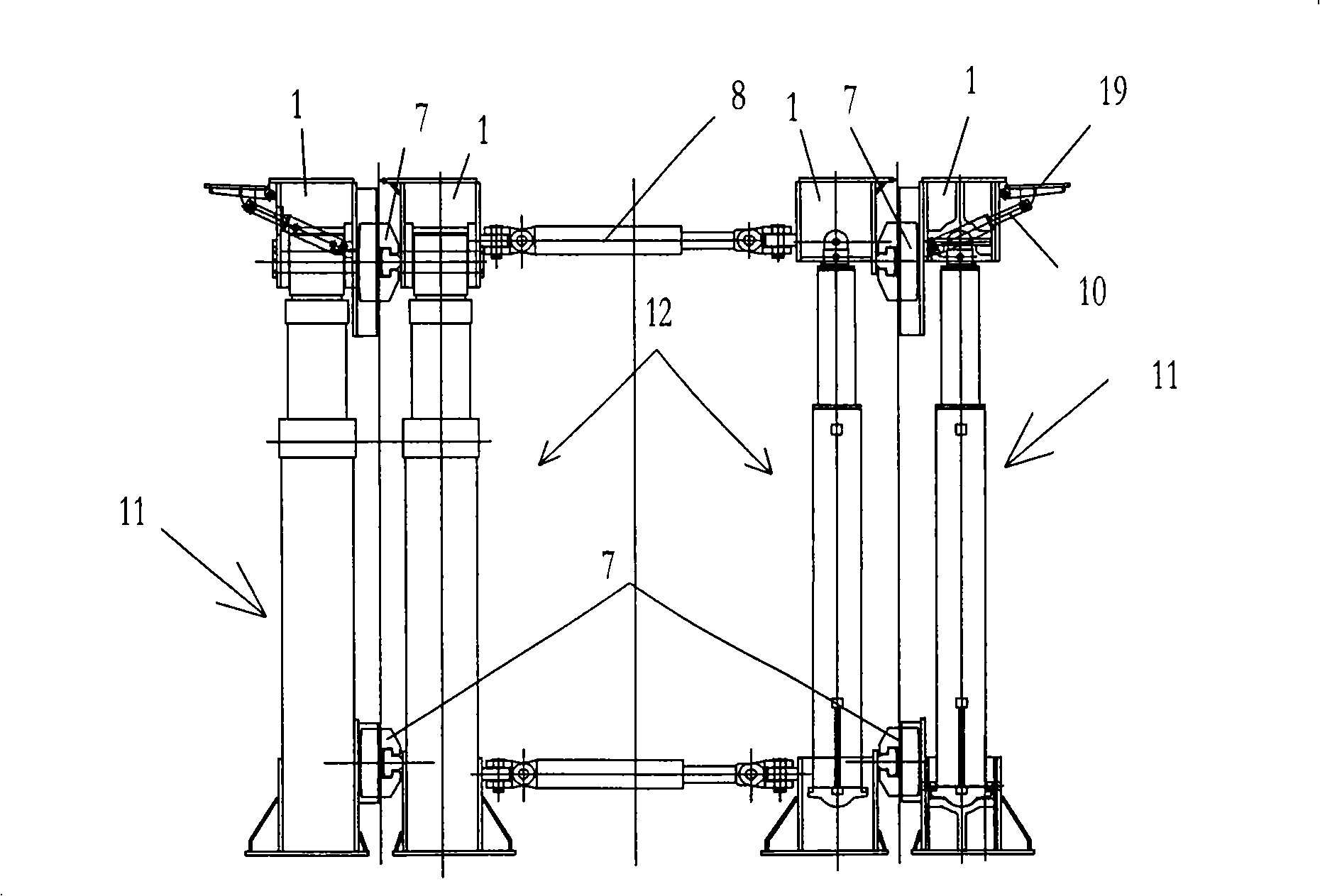

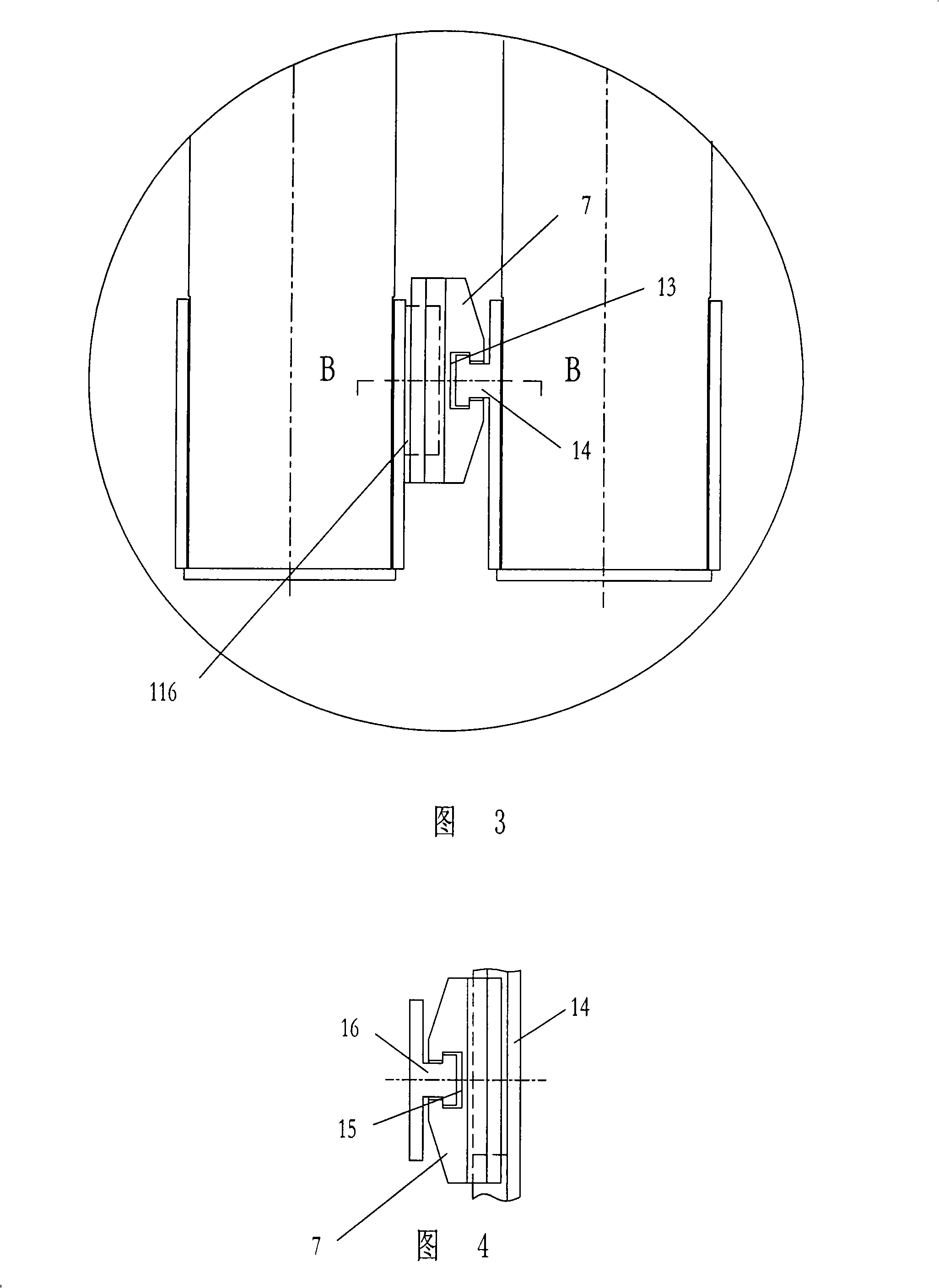

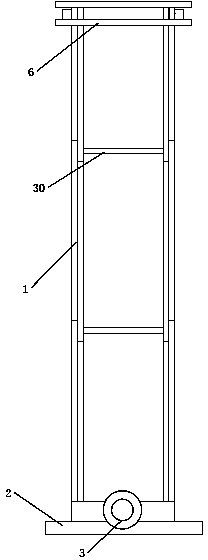

Combined guided slipping type forepoling hydraulic support

ActiveCN101338684AReduce the number of supportsNot easy to fallMine roof supportsHeadframeEngineering

The present invention provides a combined guide slippage type forepoling hydraulic bracket which comprises an internal support unit and an external support unit (12 and 11) which are symmetrical to each other at left and right. Each support unit comprises a top beam (1), a pedestal, a guide stabilizing mechanism and a hydraulic support component upright post. An upright post is articulated between the top beam and the pedestal. A telescopic link type guide stabilizing mechanism is arranged at the middle parts of the top beam and the pedestal. The outer side of the internal support unit is provided with the external support unit. Connecting slide rods (7) are respectively connected between the top beams and the pedestal beams at the same side of the adjacent internal and external support units. An inter-frame jack (8) is articulated between the top beam and the pedestal of the symmetrical internal support unit to form a section of bracket. The bracket forms an independent motor unit. The hydraulic bracket consists of a plurality of independent motor units. An advancing jack (17) is connected between the pedestals (9) of the independent motor units. The front end of the pedestal (9) of a section of bracket at the front end of the hydraulic bracket is connected with a head frame pulling and moving mechanism. The hydraulic bracket can effectively support a big section laneway and realizes the forepoling and the forepoling automatization of the big section laneway.

Owner:TIANDI SCI & TECH CO LTD

Axially-radially nested expandable device

InactiveUS7988721B2Small non-deployed profileLow profileStentsAdditive manufacturing apparatusVascular deviceBlood vessel

Expandable medical implants for maintaining support of a body lumen are disclosed. These implants comprise an axially-radially nested, diametrically expandable, moveable vascular device for enlarging an occluded portion of a vessel. The device can be configured to allow for motion such as translating and / or slide and lock. One advantage of the axially-radially nested stent is that it maintains the expanded size, without significant recoil.

Owner:REVA MEDICAL

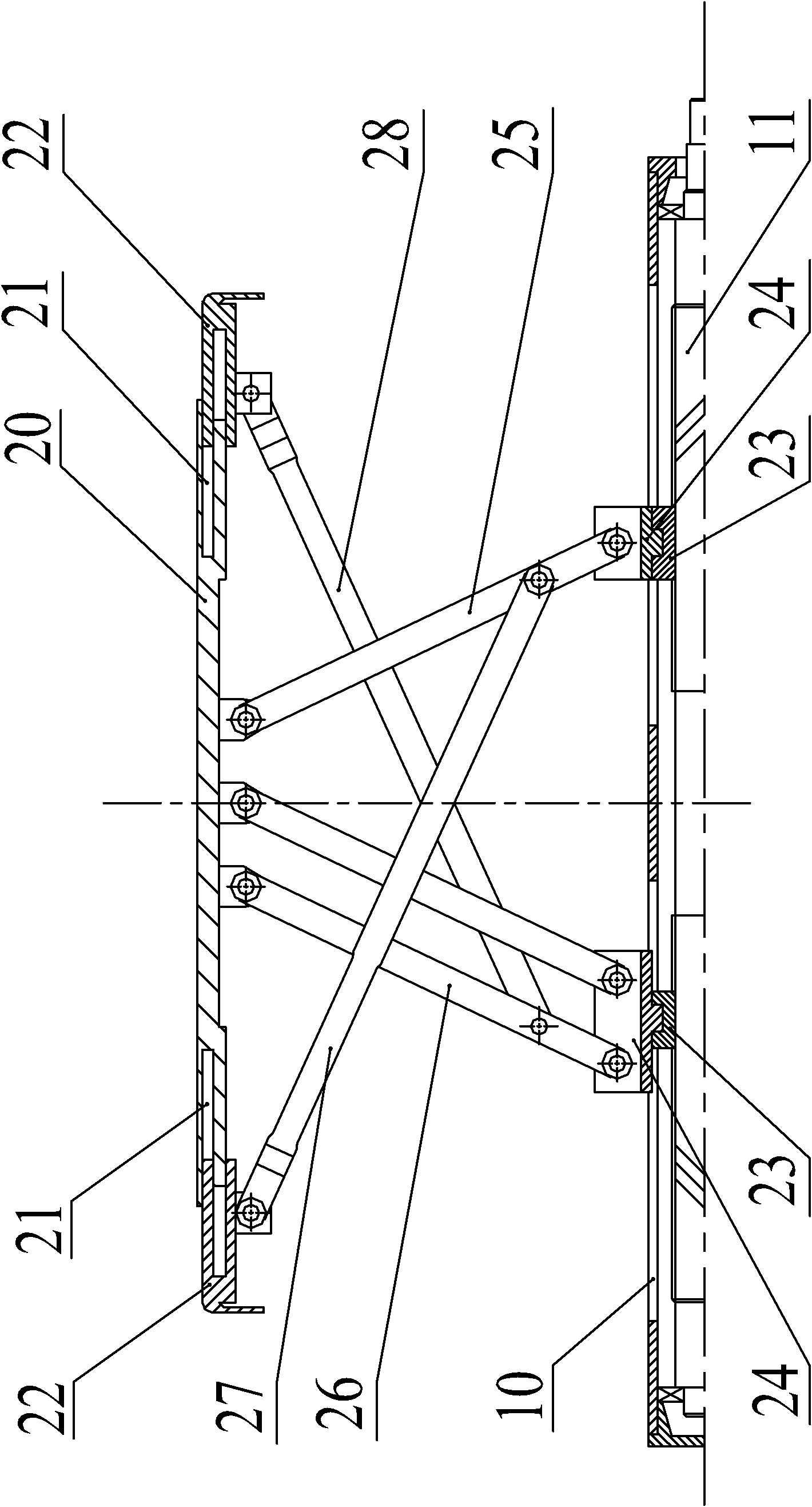

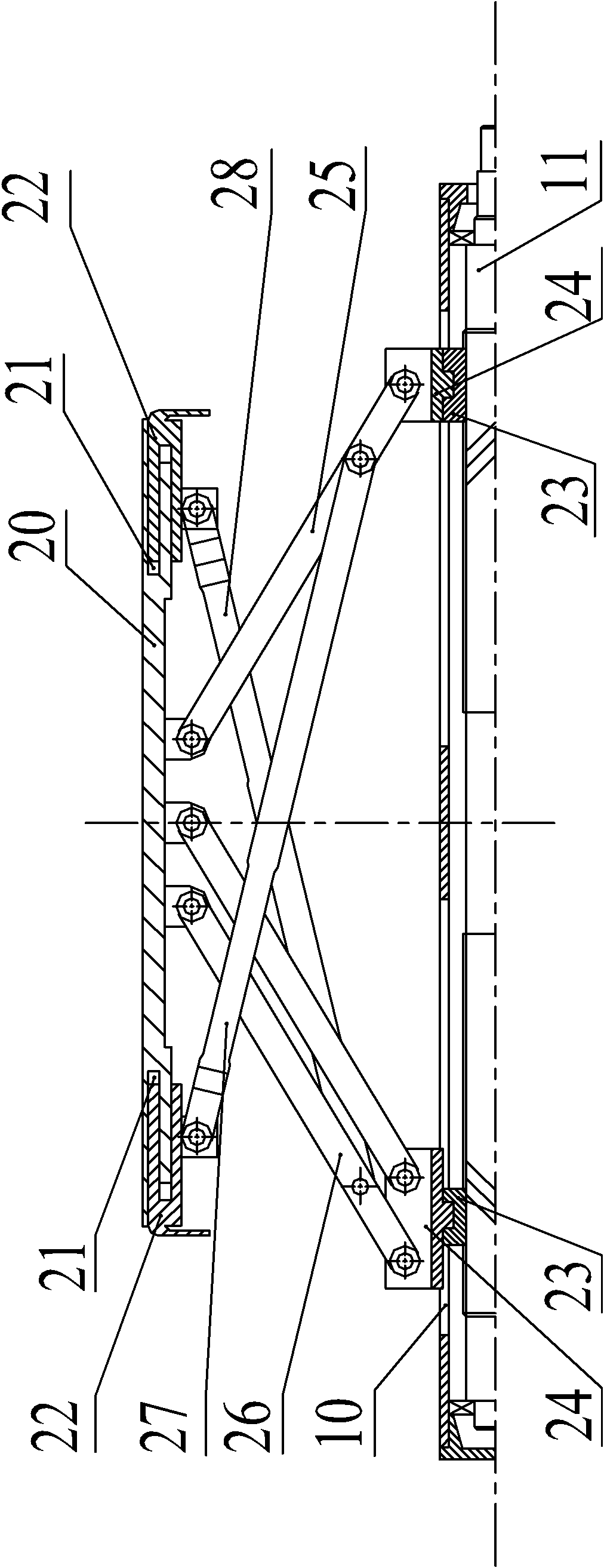

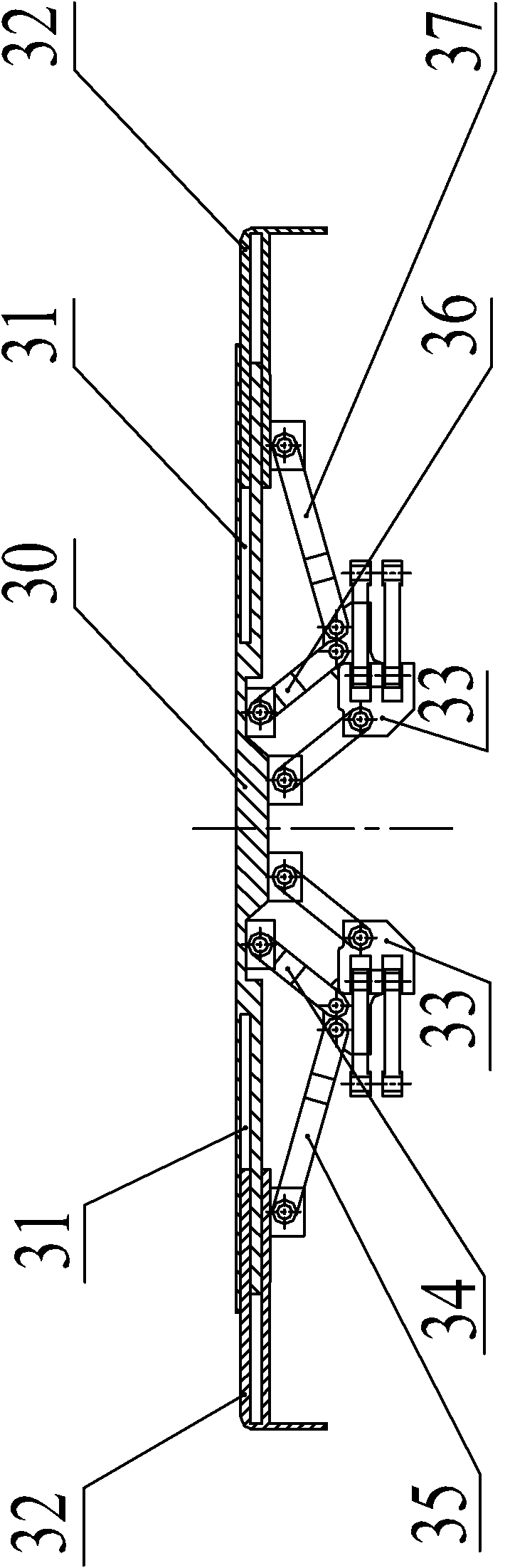

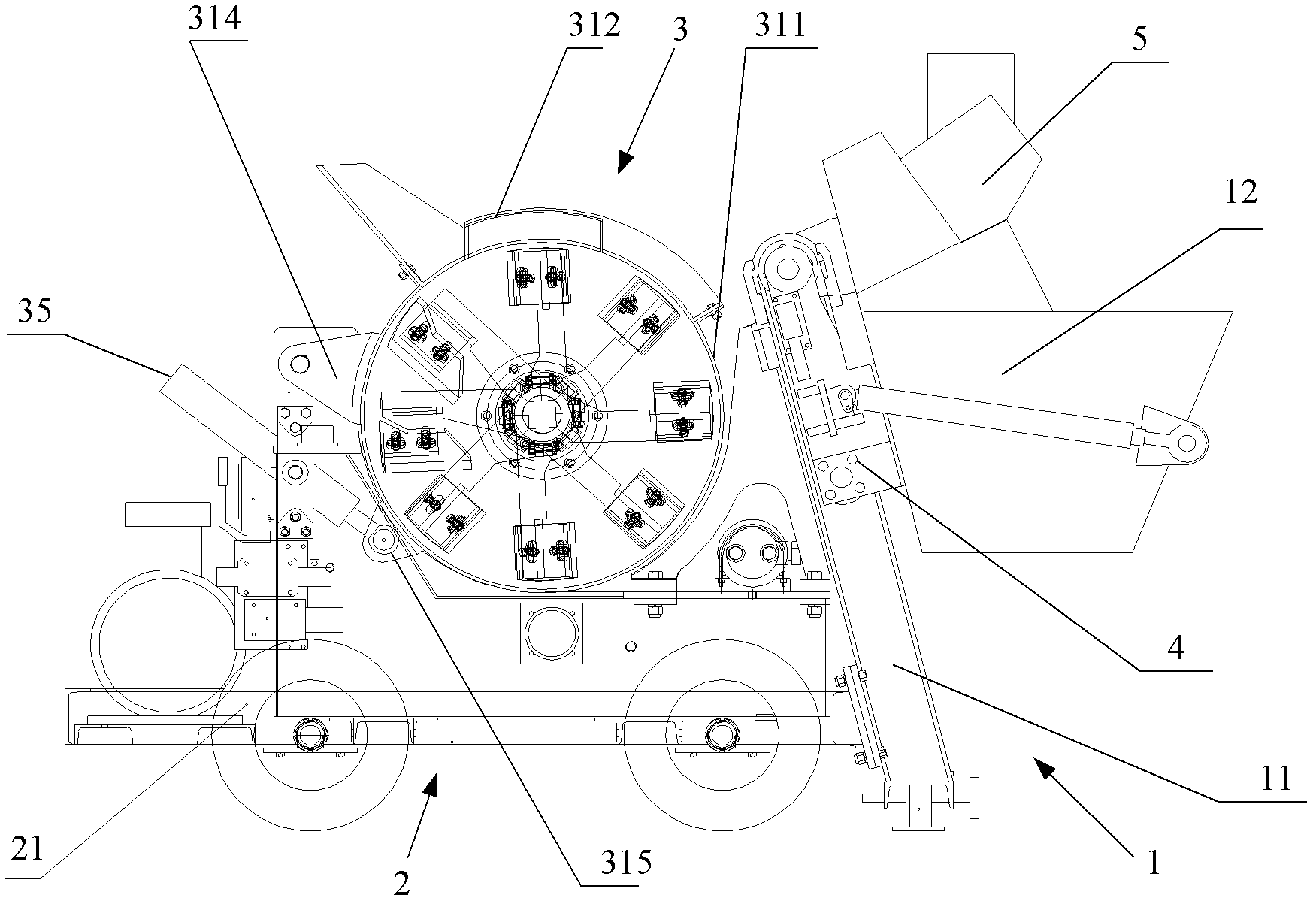

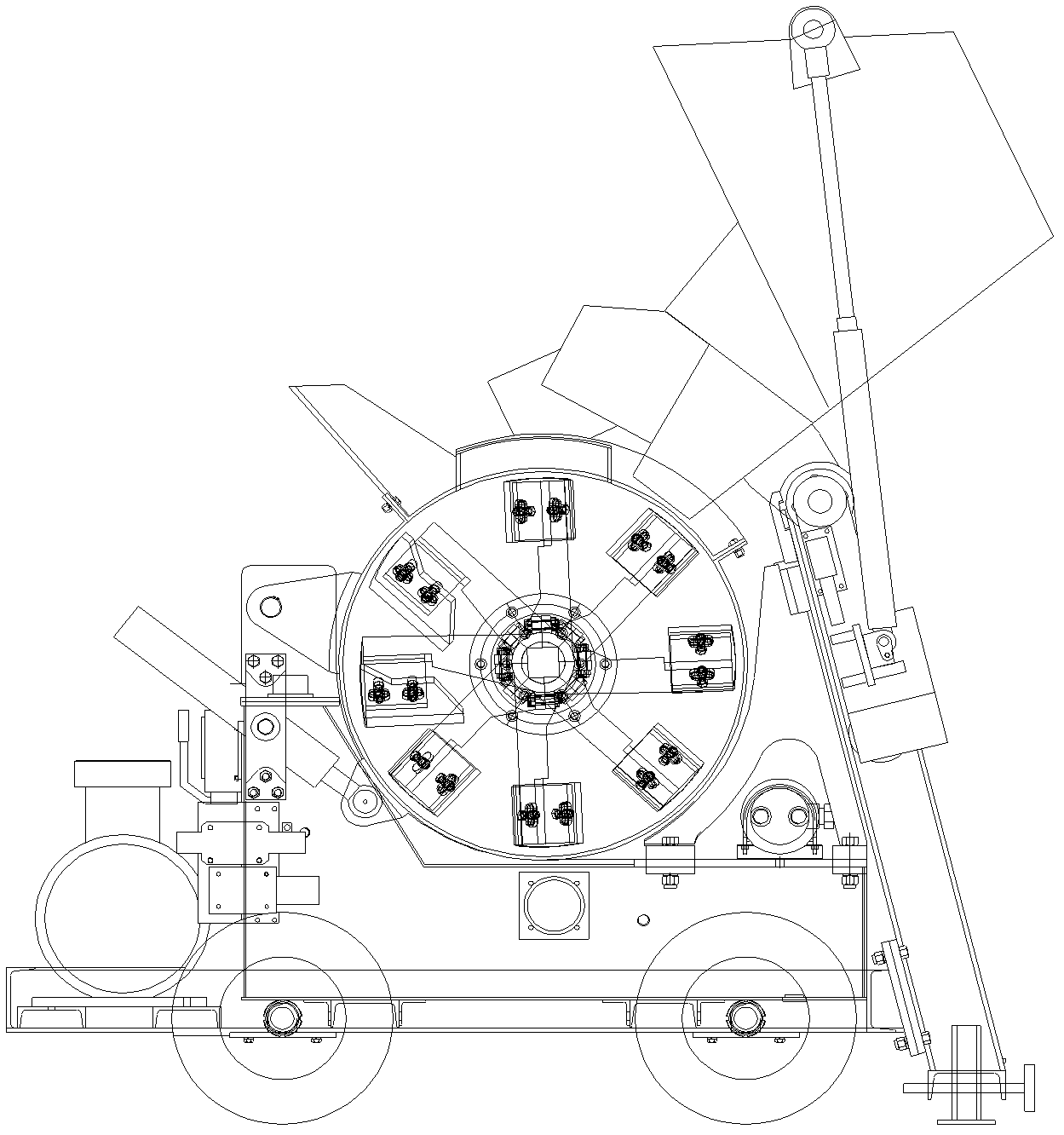

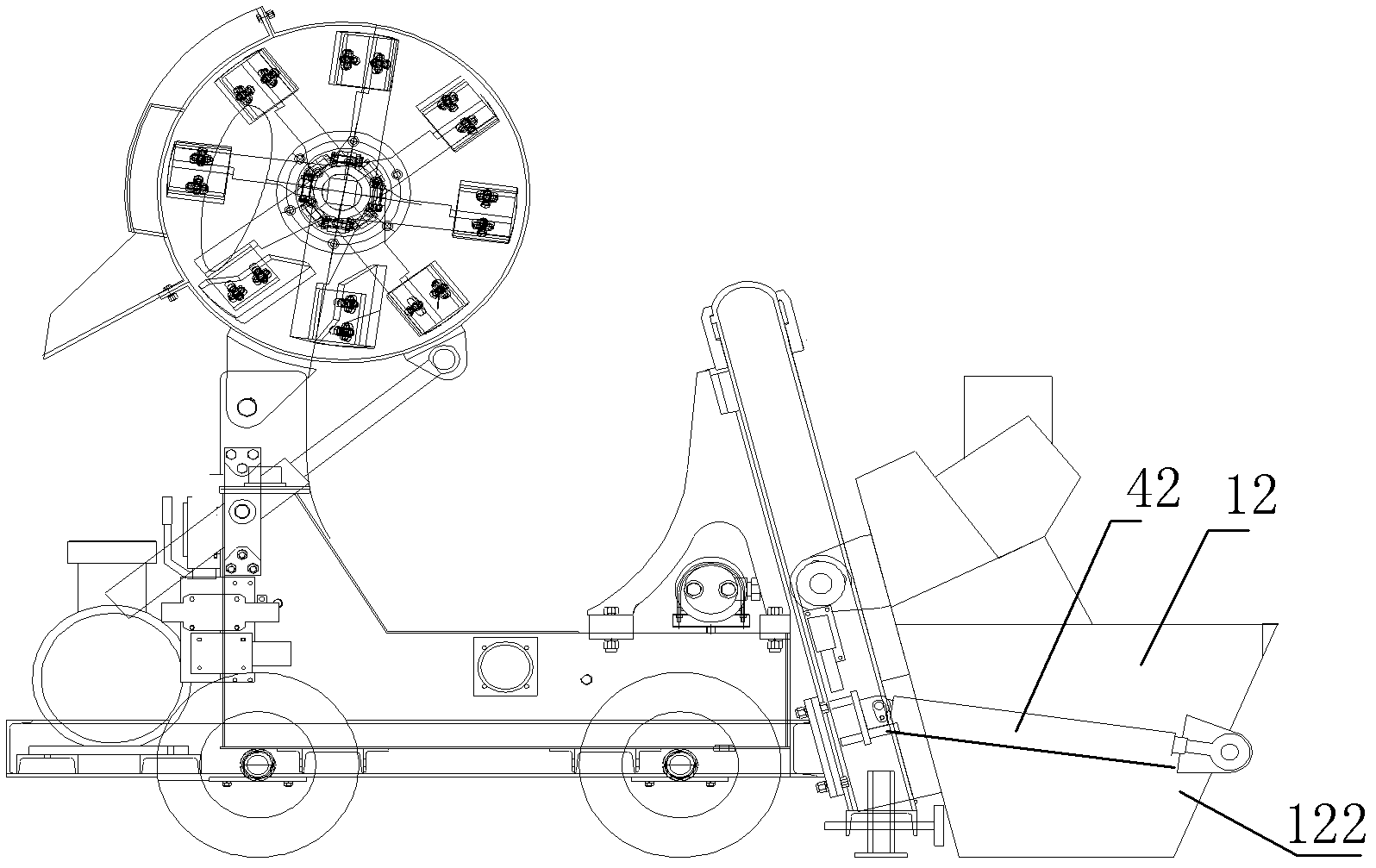

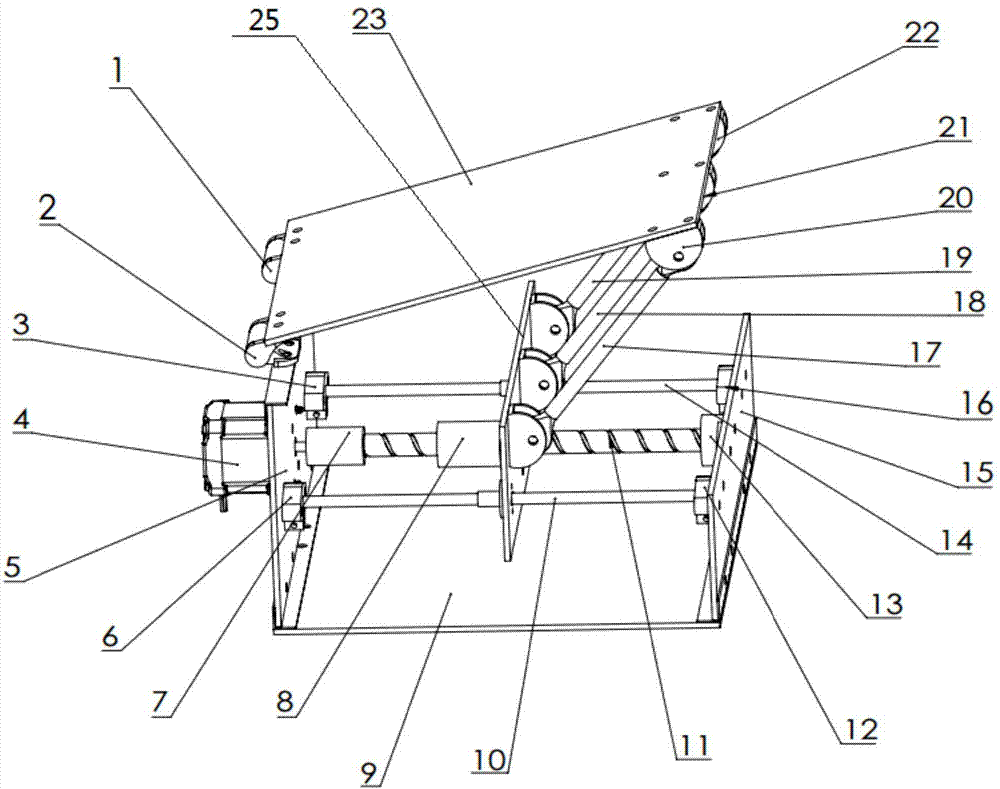

Axial and radial stretching type tire molding drum

The invention discloses an axial and radial stretching type tire molding drum which comprises an inner tile, an inner tile driving mechanism, an outer tile and an outer tile driving mechanism, wherein two axial ends of the inner tile and the outer tile are respectively provided with a drum shoulder capable of doing stretching motions along the axial direction thereof; the inner tile driving mechanism comprises a hollow spindle, a screw rod, a sliding seat and a connecting rod mechanism, and the connecting rod mechanism is used for realizing the stretching motions of the inner tile along the radial direction and the inner tile shoulder drum along the axial direction; the outer tile driving mechanism consists of two groups of space connecting rod mechanisms which are axially symmetrical relative to the outer tile and is used for realizing the stretching motions of the outer tile along the radial direction and the outer tile shoulder drum along the axial direction; the space connecting rod mechanism is formed by hinging a first group of rod pieces and a second group of rod pieces; the motion planes of the second group of rod pieces are all superposed with the radial symmetrical planeof the outer tile; and the motion planes of the first group of rod pieces are all vertical to the motion planes of the second group of rod pieces. The molding drum can be used for realizing axial andradial stretching, is suitable for molding aviation radial tires and has the characteristics of light weight, compact structure and convenience for tire disassembly.

Owner:TIANJIN UNIV

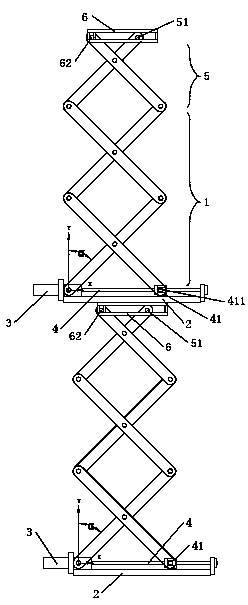

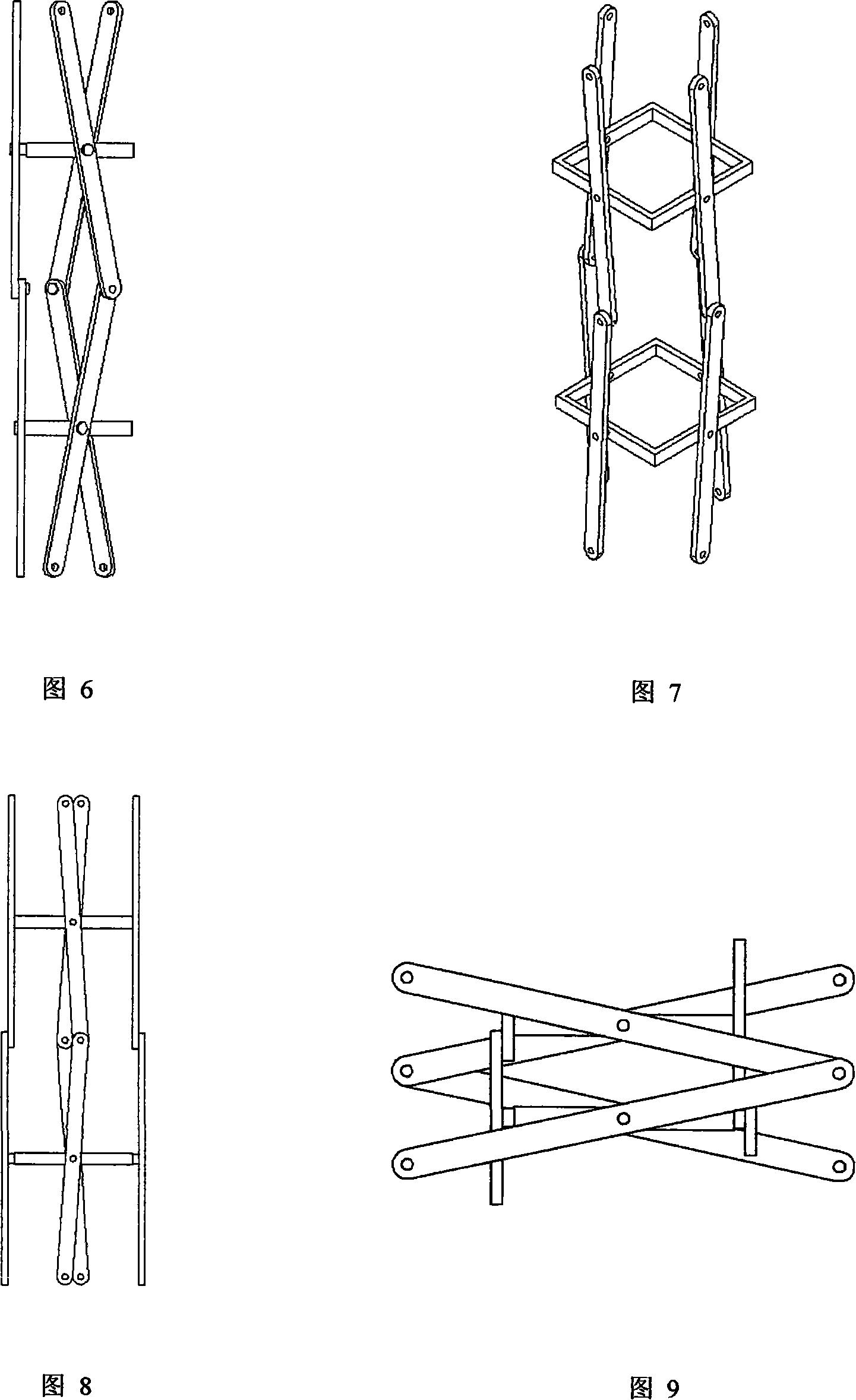

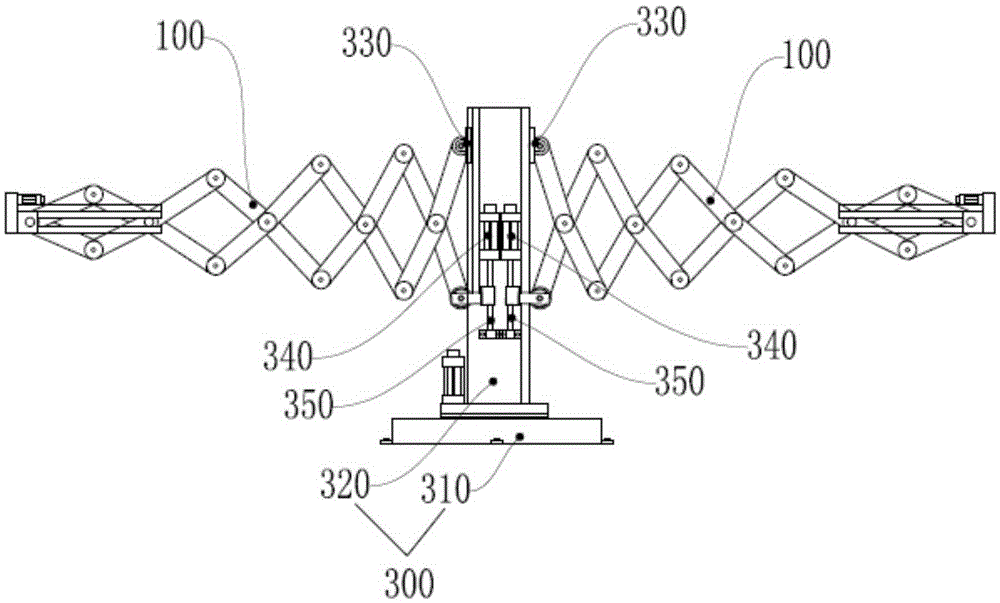

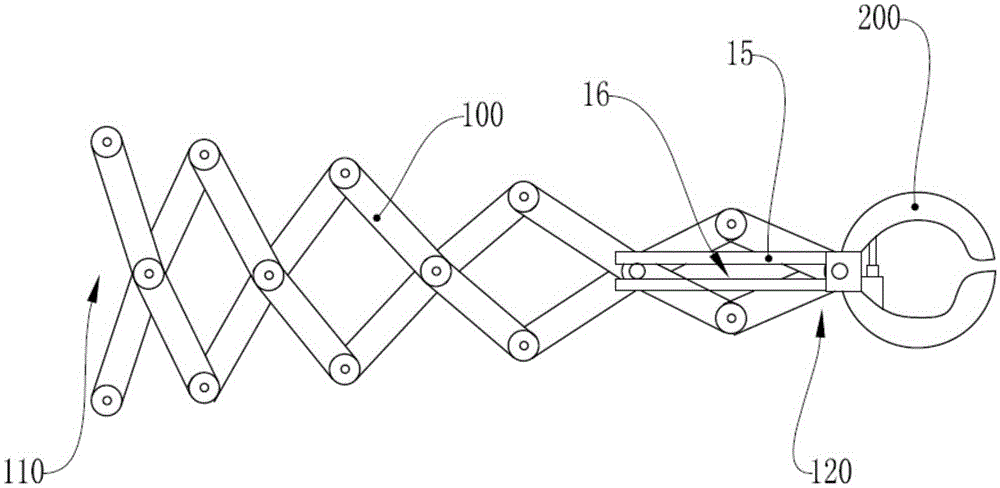

Shear mode mechanism capable of being controlled in numerical mode and shear mode mechanism drive system formed by shear mode mechanisms in combined mode

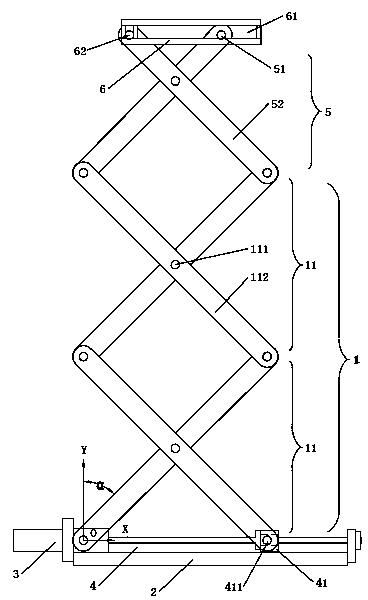

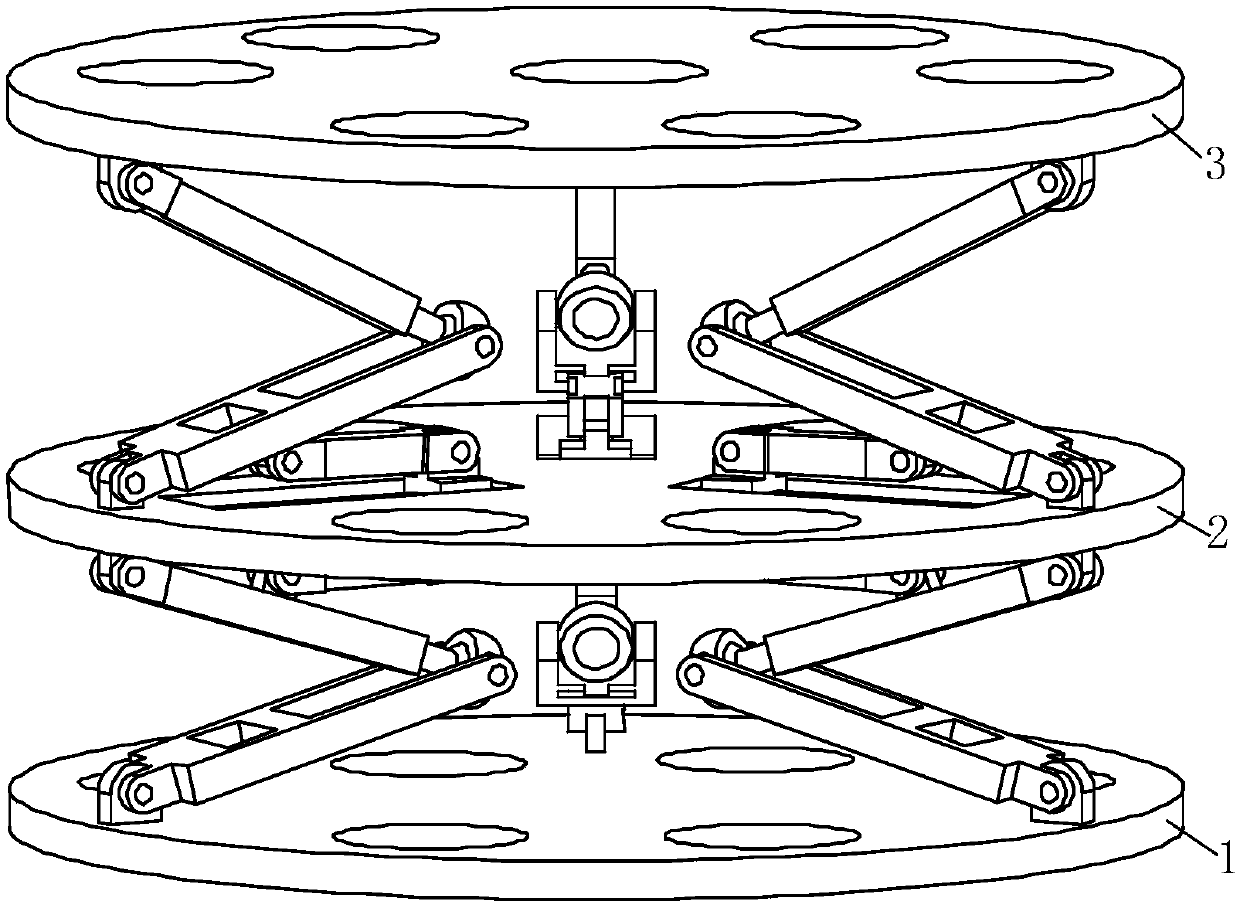

InactiveCN103523707AAccurate telescopic positioningLarge expansion ratioLifting framesNumerical controlBall screw drive

A shear mode mechanism capable of being controlled in a numerical mode comprises a support unit and further comprises a machine base, a numerical control motor arranged on the machine base, and a ball screw driven by the numerical control motor. End portions of multiple pairs of crossed shear mode supports are sequentially hinged to one another to form the support unit, one of the two ends of the bottoms of the nethermost pair of shear mode supports of the support unit is used as the original point and hinged to the machine base, the other of the two ends of the bottoms of the nethermost pair of shear mode supports of the support unit is hinged to a nut of the ball screw, and therefore the displacement of the shear mode mechanism in the vertical direction can be accurately calculated according to the travel of the numerical control motor, and the aim of controlling the displacement of the shear mode mechanism in the numerical mode is achieved. The shear mode mechanism is accurate in stretching positioning and large in stretching ratio in comparison with a shear mode mechanism, driven by a servo motor, of a joint type mechanical arm. In addition, when the shear mode mechanisms are combined in series or in parallel or in series and in parallel to form a shear mode mechanism drive system, the loading capacity and the stability of the shear mode mechanisms can be greatly improved.

Owner:唐易平

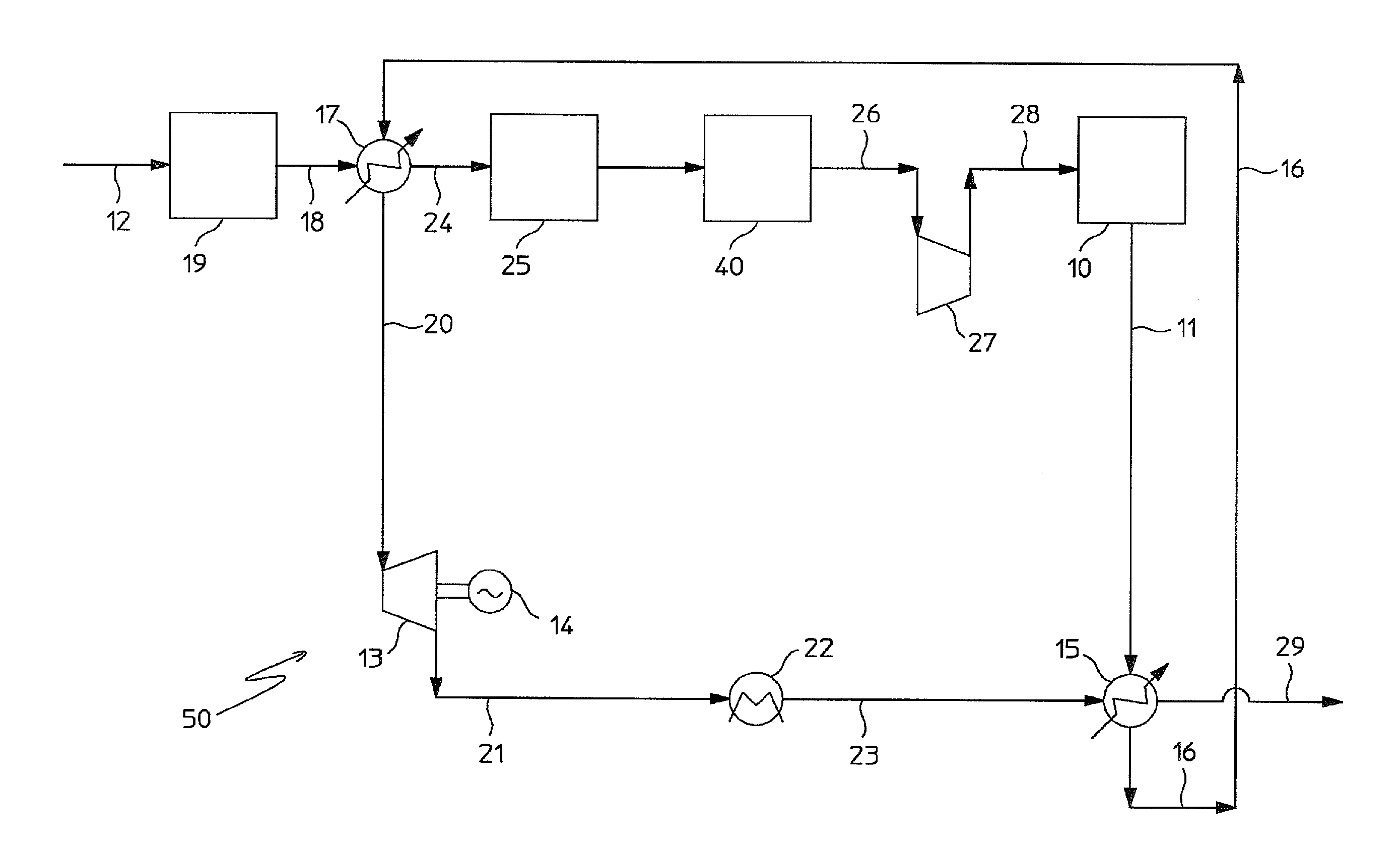

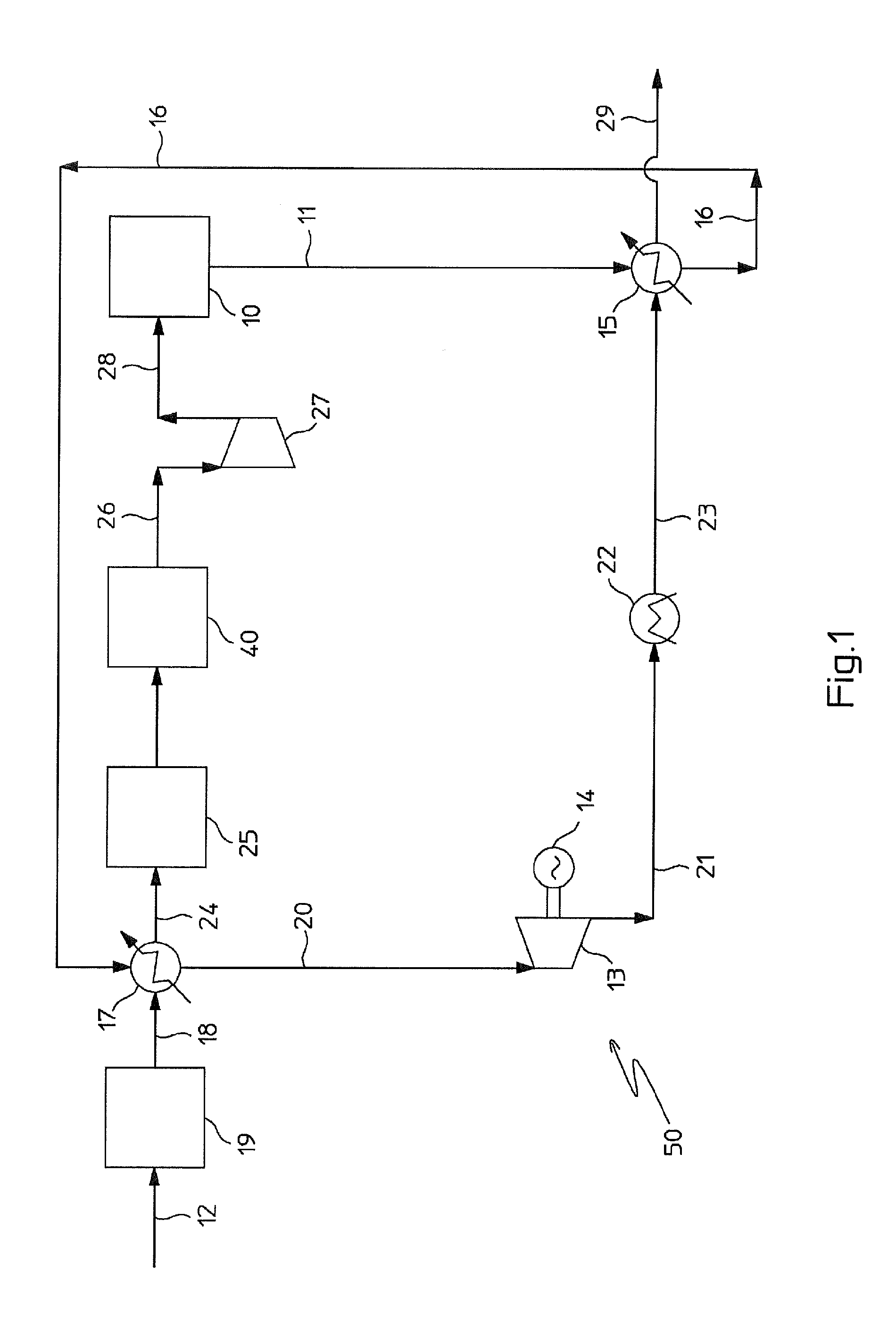

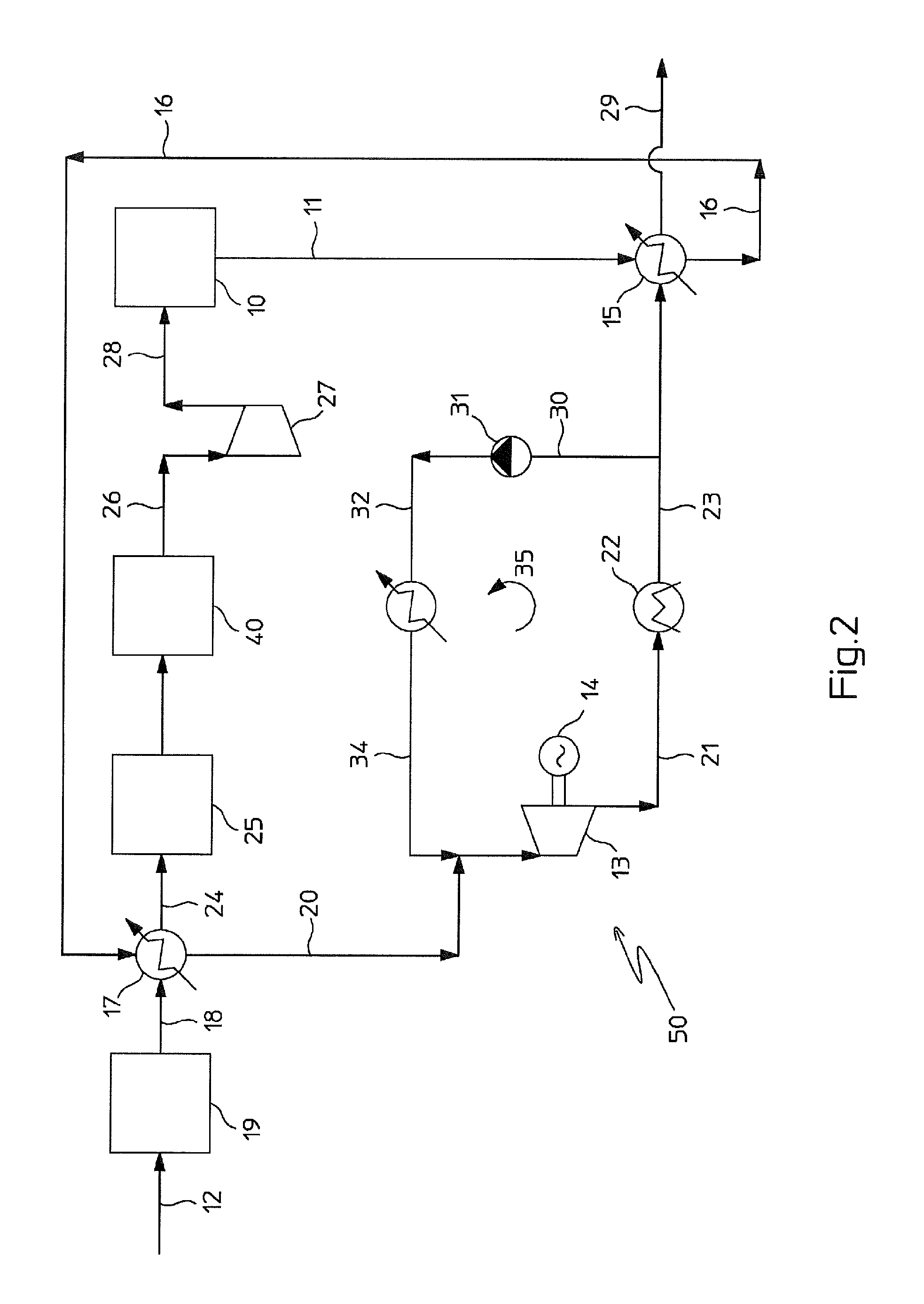

Waste heat recovery in a chemical process and plant, particularly for the synthesis of ammonia

ActiveUS20140331672A1Valuable energy outputImprove processing efficiencyHydrogenEnergy inputSyngasWaste heat recovery unit

A method for recovering waste heat in a process for the synthesis of a chemical product, particularly ammonia, where the product is used as the working fluid of a thermodynamic cycle; the waste heat is used to increase the enthalpy content of a high-pressure liquid stream of said product (11), delivered by a synthesis section (10), thus obtaining a vapour or supercritical product stream (20), and energy is recovered by expanding said vapour or supercritical stream across at least one suitable ex-pander (13); the method is particularly suited to recover the heat content of the syngas effluent after low-temperature shift.

Owner:CASALE SA

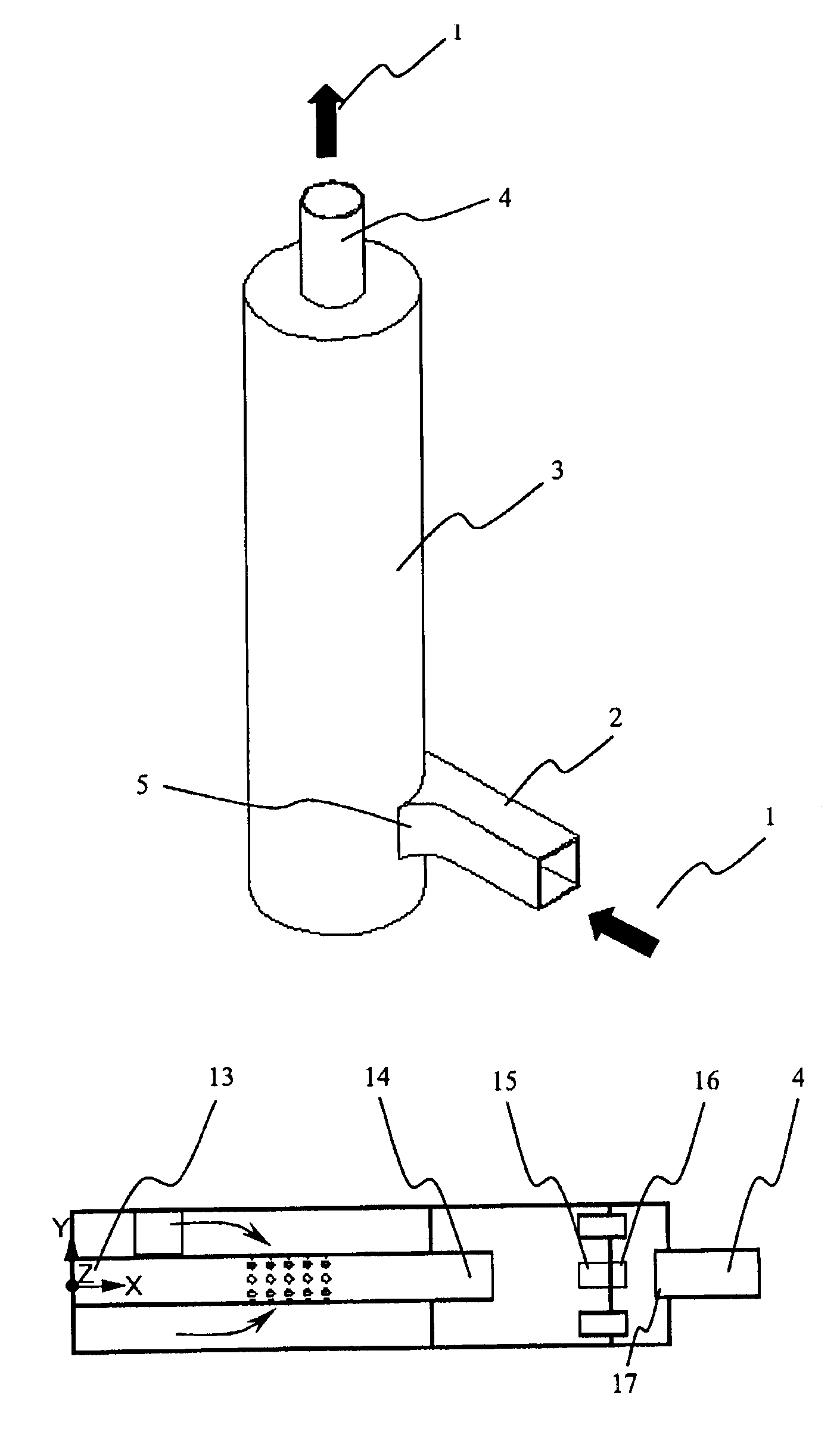

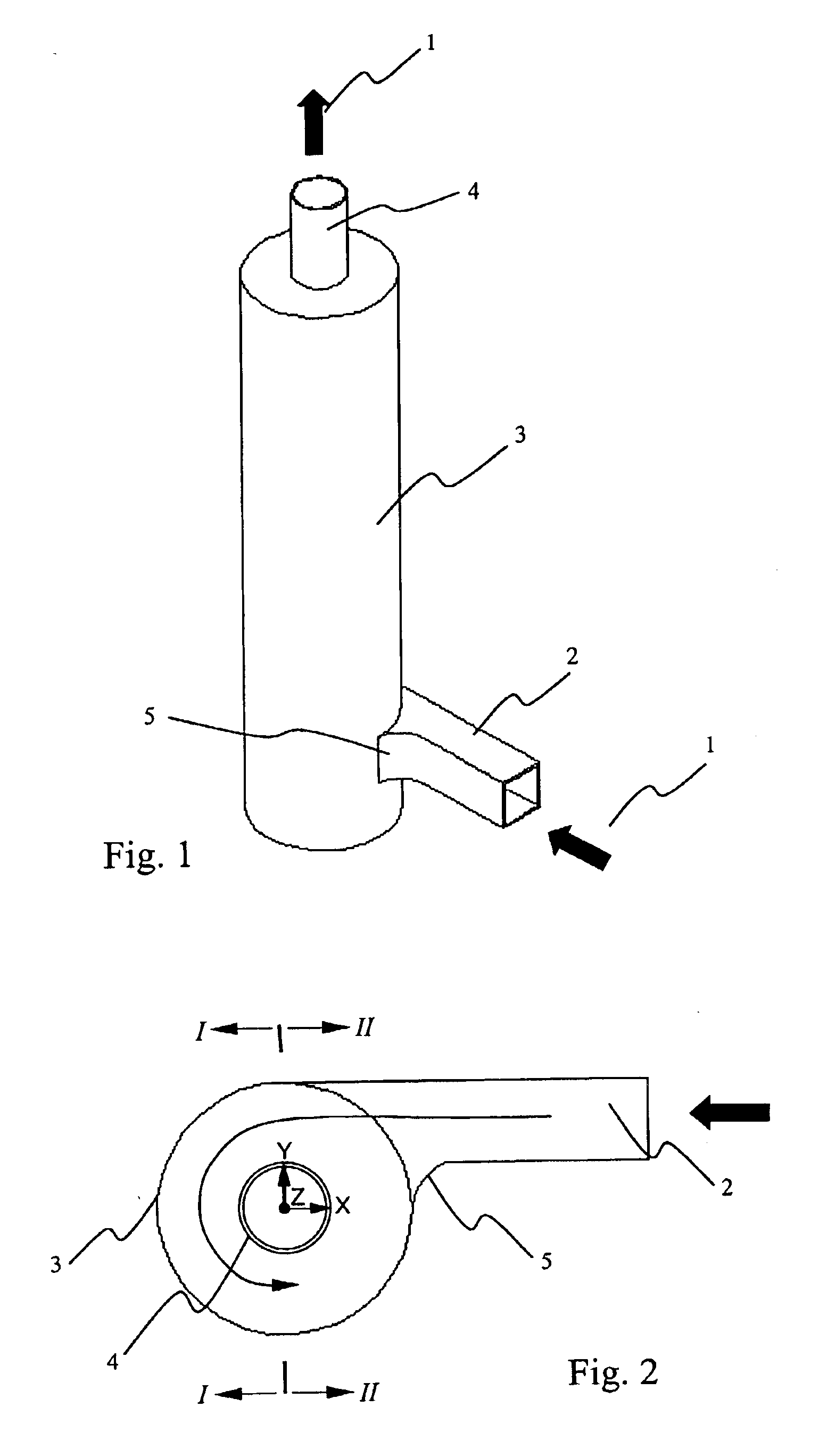

High performance muffler

InactiveUS6892853B2Increase back pressureImprove performanceSilencing apparatusMachines/enginesNuclear engineeringInternal combustion engine

A high performance muffler, e.g., for an internal combustion engine, reduces exhaust or other gas noise while maintaining a low backpressure to prevent engine power loss. A side inlet pipe connects gas to a muffler body. The inlet pipe is flared at its connection to the muffler body to direct flow of the gas through an inlet chamber of the muffler in a spiral path. In an example embodiment, the muffler body includes three chambers separated by panels. An inlet expansion chamber is adjacent to the inlet and includes a first pipe with a perforated portion. An intermediate expansion chamber adjacent to the inlet chamber receives the gas from the first pipe. Four small pipes at the exit end of the intermediate chamber extend into an outlet expansion chamber. The gas in the outlet expansion chamber exits the muffler body by an outlet pipe at the other end of the outlet expansion chamber. The muffler achieves a high sound reduction without increasing backpressure.

Owner:AGENCY FOR SCI TECH & RES

Underground concrete mixer for coal mine

InactiveCN102581954ALarge expansion ratioOvercome the shortcoming that direct drive is not easy to realize overload protectionMixing operation control apparatusCement mixing apparatusHydraulic cylinderHydraulic motor

The invention provides a concrete mixer which is compact in structure and applicable to an underground tunnel of a coal mine. The concrete mixer mainly comprises a rack, a feed mechanism and a mixing mechanism, wherein the feed mechanism is arranged at the front end of the rack, and the mixing mechanism is arranged on the rack. The mixing mechanism can utilize a concrete raw material feeding funnel with fixed proportion to ensure the proportion of concrete and utilizes an adjustable quantitative water supply part to ensure the water-cement ratio of the concrete, a hydraulic cylinder drives a chain wheel to be lifted to feed, and after a hydraulic motor drives the mixer to mix, the hydraulic cylinder pushes the funnel to turn to pour the mixed concrete into a hopper of an underground concrete wet-spray machine. On the premise of not reducing the mixing capacity of the concrete mixer, movement pieces of the concrete mixer occupy the smallest space, so that the concrete mixer is suitable for tunnel work.

Owner:SHANDONG UNIV OF SCI & TECH

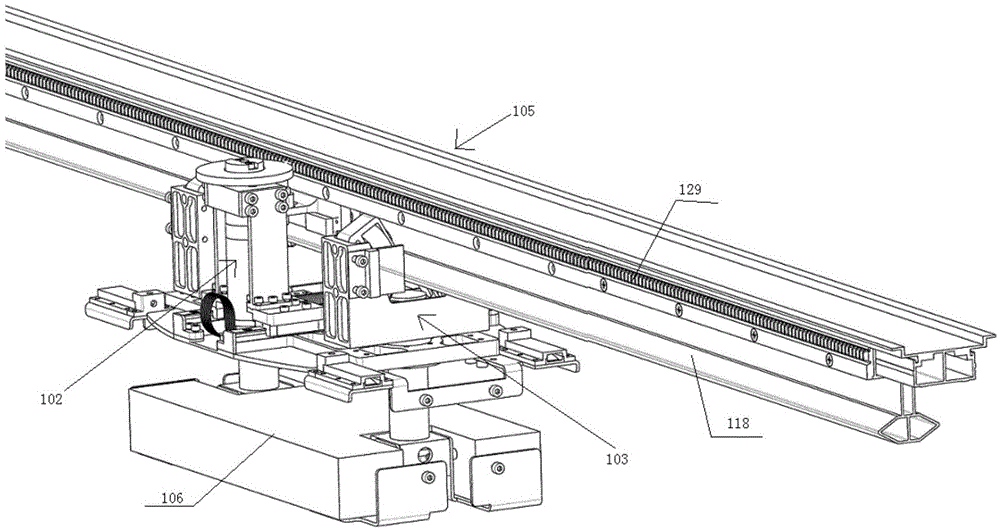

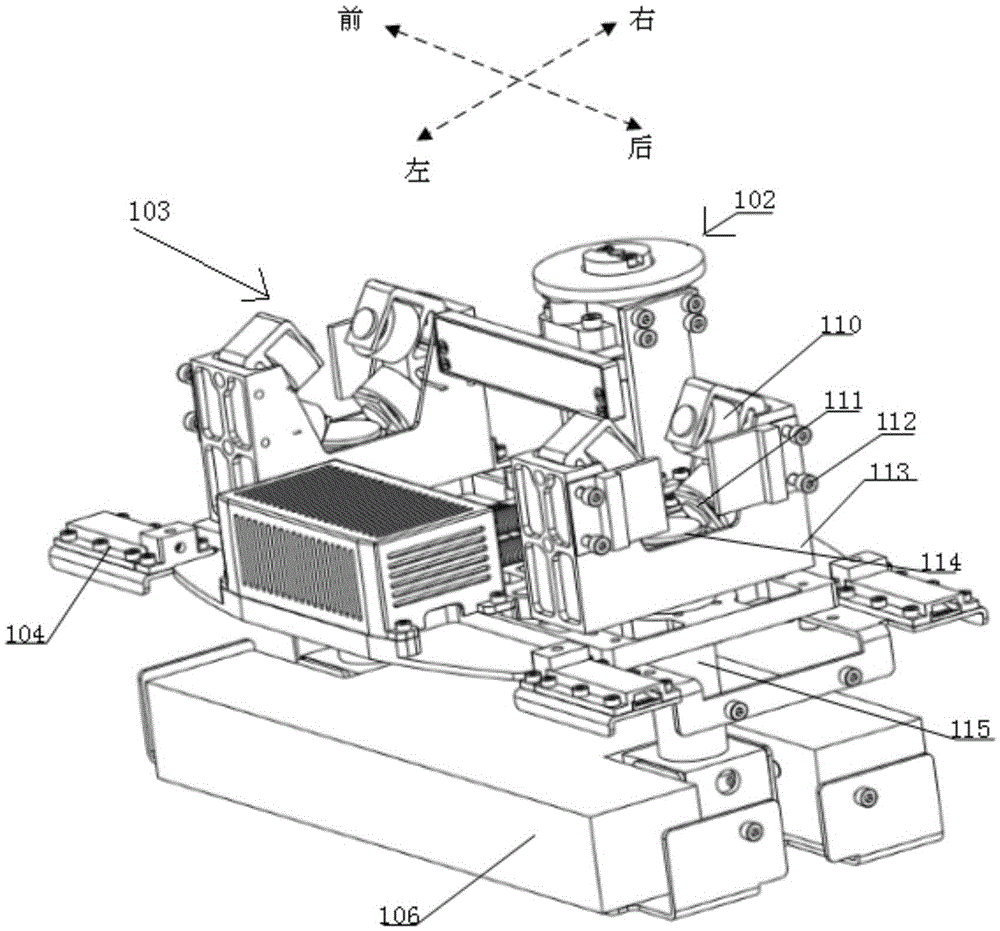

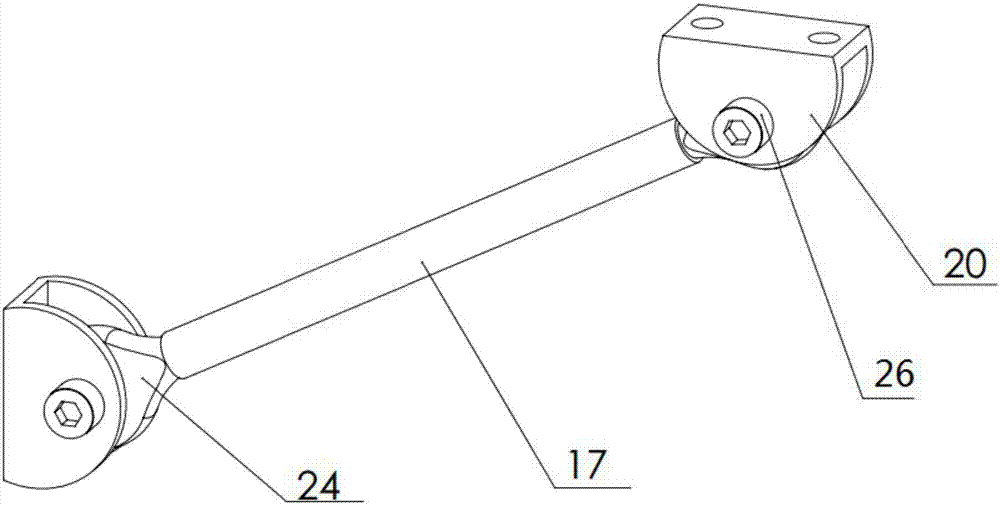

Robot walking mechanism

The invention provides a robot walking mechanism which comprises a mounting part, a driving mechanism and a guide mechanism, wherein the guide mechanism comprises a front guide module and a rear guide module; the front guide module and the rear guide module are same in structure and comprise support rods, guide blocks and guide wheel groups; the guide blocks can be rotatably arranged on the support rods; two ends of the guide bocks are arranged on the guide wheel groups; the bottom ends of the support rods of the front and rear guide modules are respectively arranged at two ends of the mounting parts; and the driving mechanism is arranged on the mounting part in a manner of moving left and right. The guide mechanism and the driving mechanism can adapt to a curve, so that the robot walking mechanism can turn a corner without assistance of an auxiliary device and is simple in structure.

Owner:YIJIAHE TECH CO LTD

Copolymer, rubber composition, cross-linked rubber, cross-linked foam, and uses thereof

ActiveUS20110233448A1Adequate foamabilityExcellent kneading performanceBuilding constructionsPolymer sciencePtru catalyst

The present invention provides a rubber composition having adequate foamability, uses thereof, a copolymer contained in the rubber composition, a rubber composition capable of providing a cross-linked foam, which has a low specific gravity and an excellent shape-retaining property even when the usage of a nonconjugated polyene is reduced, and a cross-linked rubber and a cross-linked foam, which are produced from the rubber composition. A copolymer (A) according to the present invention is a copolymer including structural units derived from ethylene [A], an α-olefin [B], a nonconjugated polyene [C-1], in which one carbon-carbon double bond (C═C) polymerizable with a metallocene catalyst is present in one molecule, and a nonconjugated polyene [C-2], in which two bonds of C═C polymerizable with the metallocene catalyst are present in one molecule, and being synthesized with the metallocene catalyst, wherein (1) the units derived from the component [B] constitute 10 to 50 percent by mole, (2) the total of the units derived from the component [C-1] and the units derived from the component [C-2] is 1.0 to 6.0 percent by mole, (3) the molar ratio of the units derived from the component [C-1] to the units derived from the component [C-2] is 75 / 25 to 99.5 / 0.5, (4) [ML (1+4) 100° C.] is 10 to 200, and (5) 50>activation energy of fluidization (kJ / mol)>35 is satisfied.

Owner:MITSUI CHEM INC

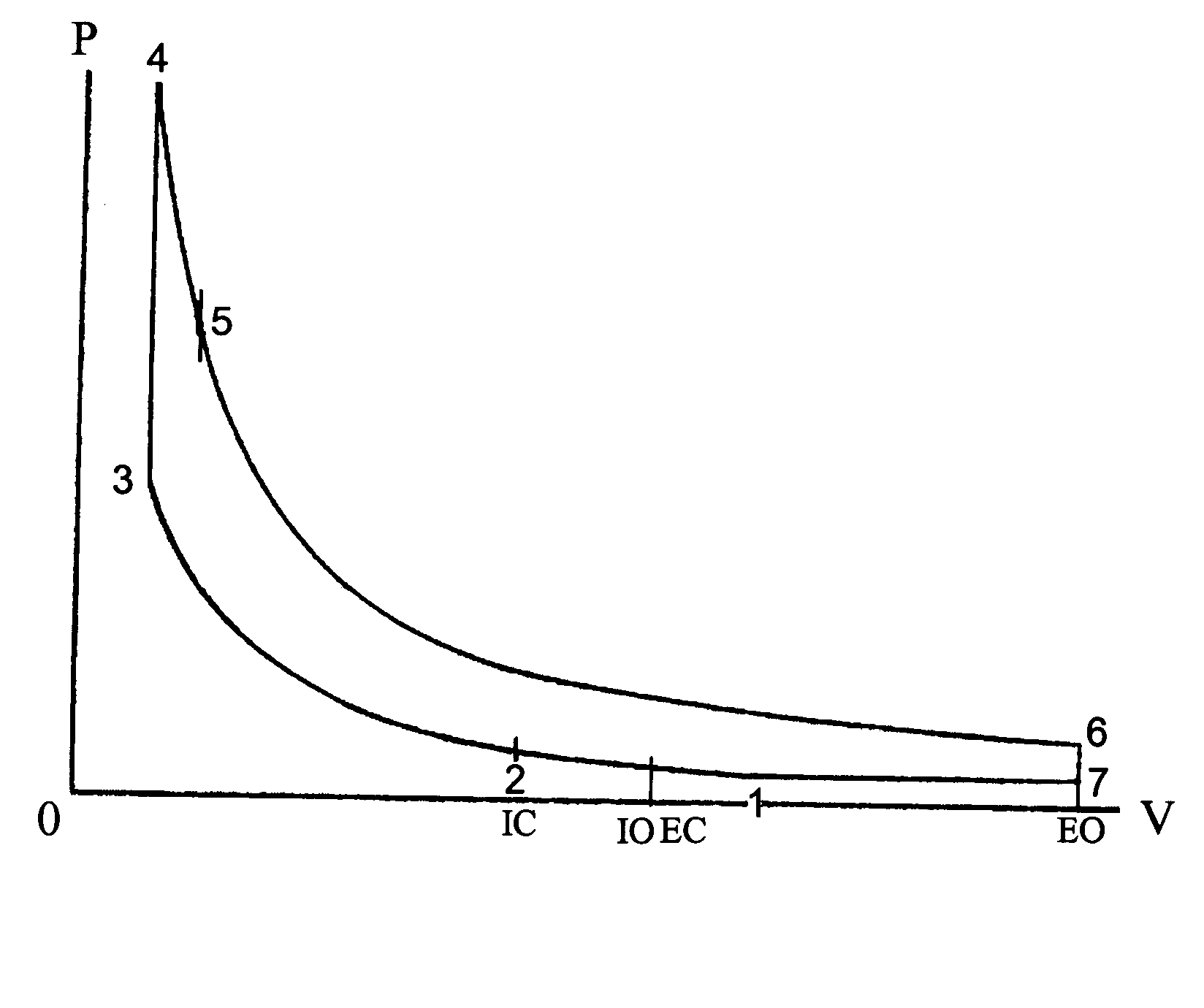

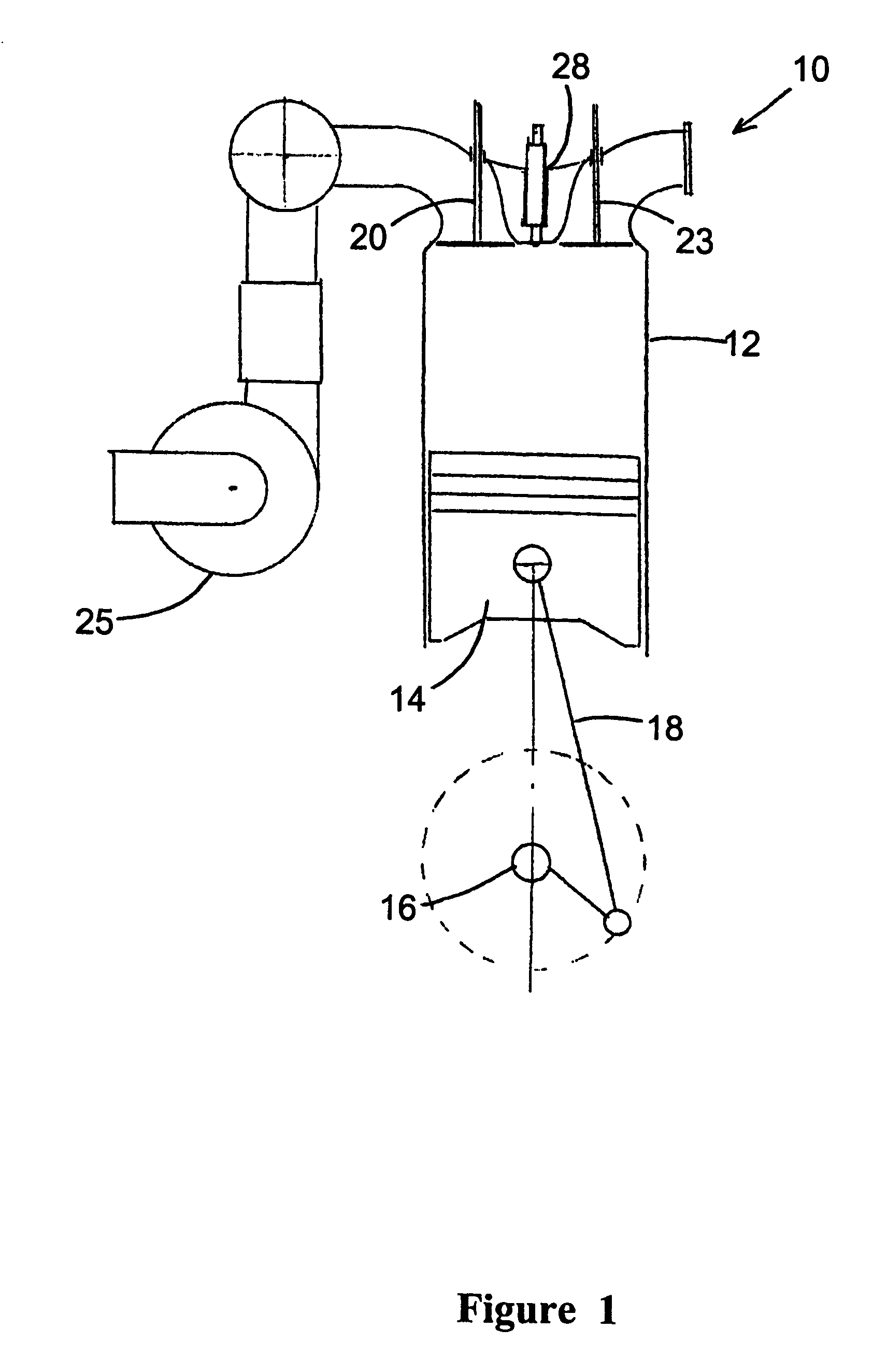

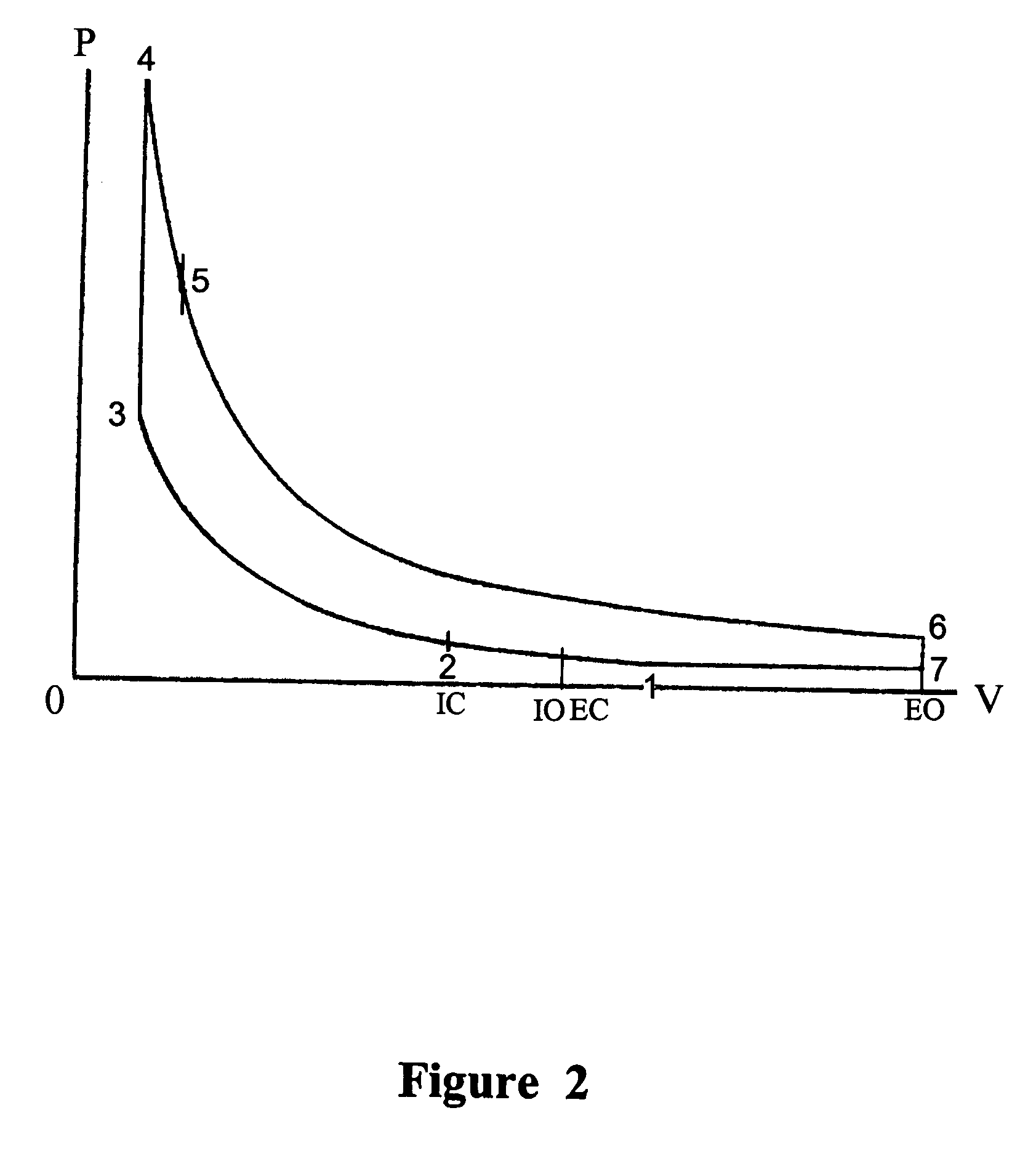

Over expanded two-stroke engines

InactiveUS7114485B2Large expansion processEasy to operateElectrical controlCombustion enginesFour-stroke engineEngineering

A method for combusting fuel in an engine involving decreasing a first volume of a homogeneous lean fuel / air charge to a second volume, in two stages, while increasing the pressure and temperature of that charge (a compression process having a chosen compression ratio), then increasing the pressure at constant volume while adding heat until a predetermined temperature is obtained, increasing the third volume of gas to a fourth volume, in two stages while decreasing the pressure at the predetermined temperature (an expansion process having a chosen expansion ratio much greater than the compression ratio), decreasing the pressure to atmospheric pressure while removing heat under constant volume, and finally decreasing the volume of gas to the first volume while removing heat under constant pressure to complete an over expanded, cycle. Also disclosed is an engine employing said over expanded, two-stroke HCCI cycle.

Owner:PIEN PAO C

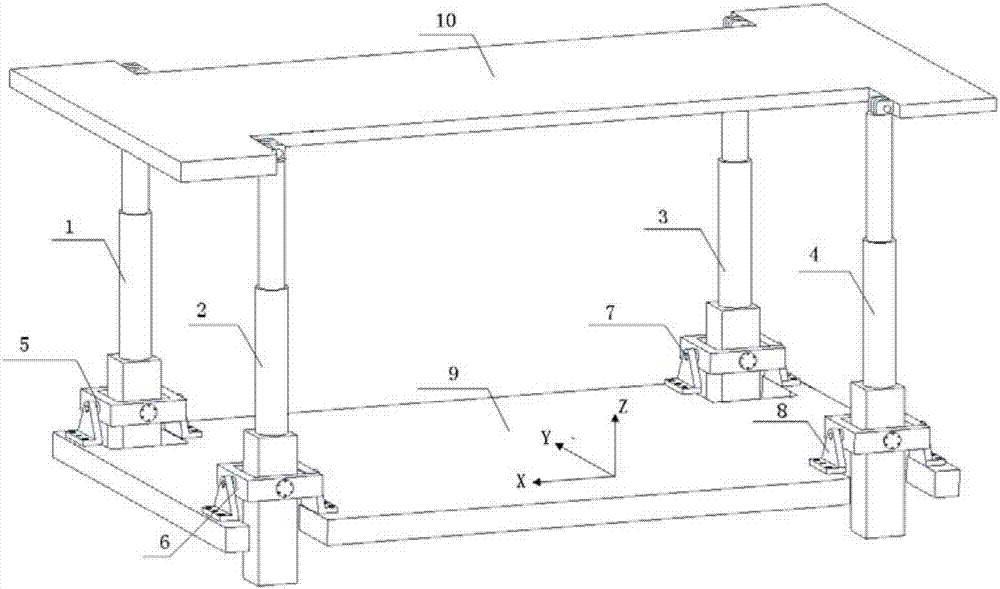

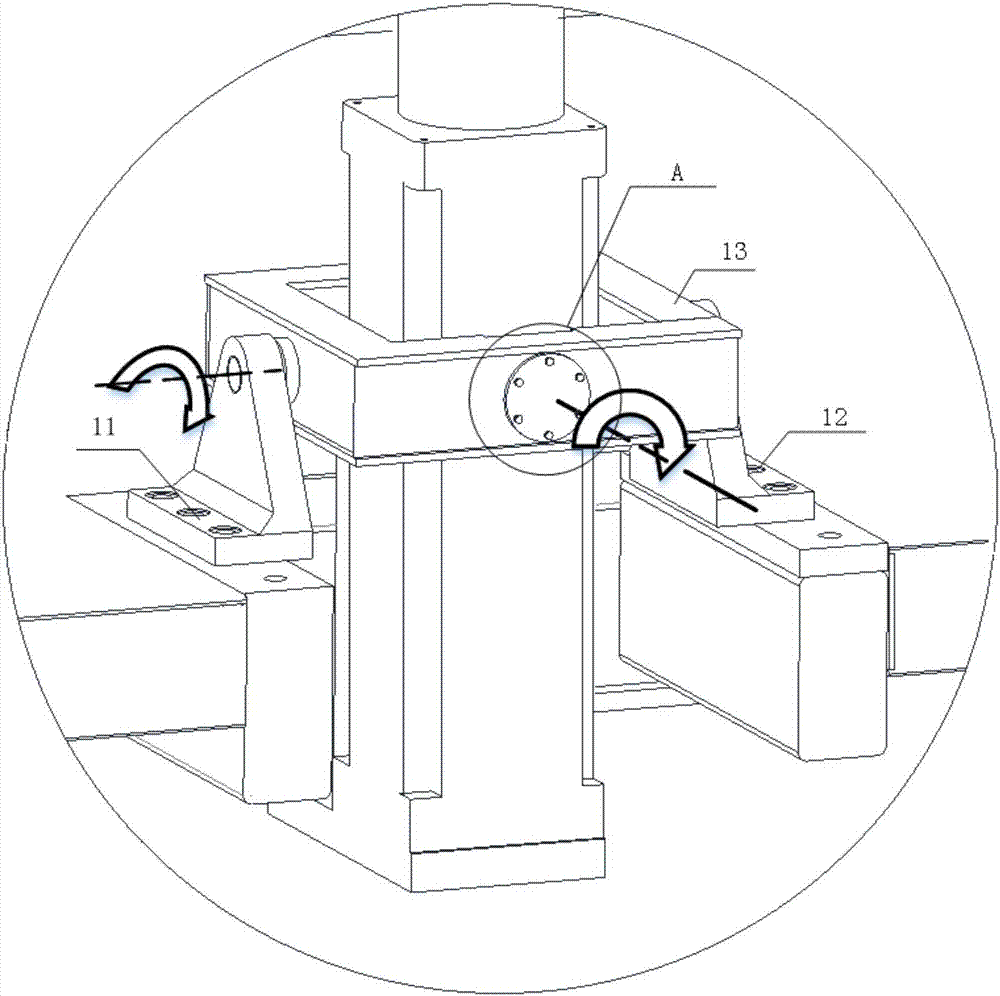

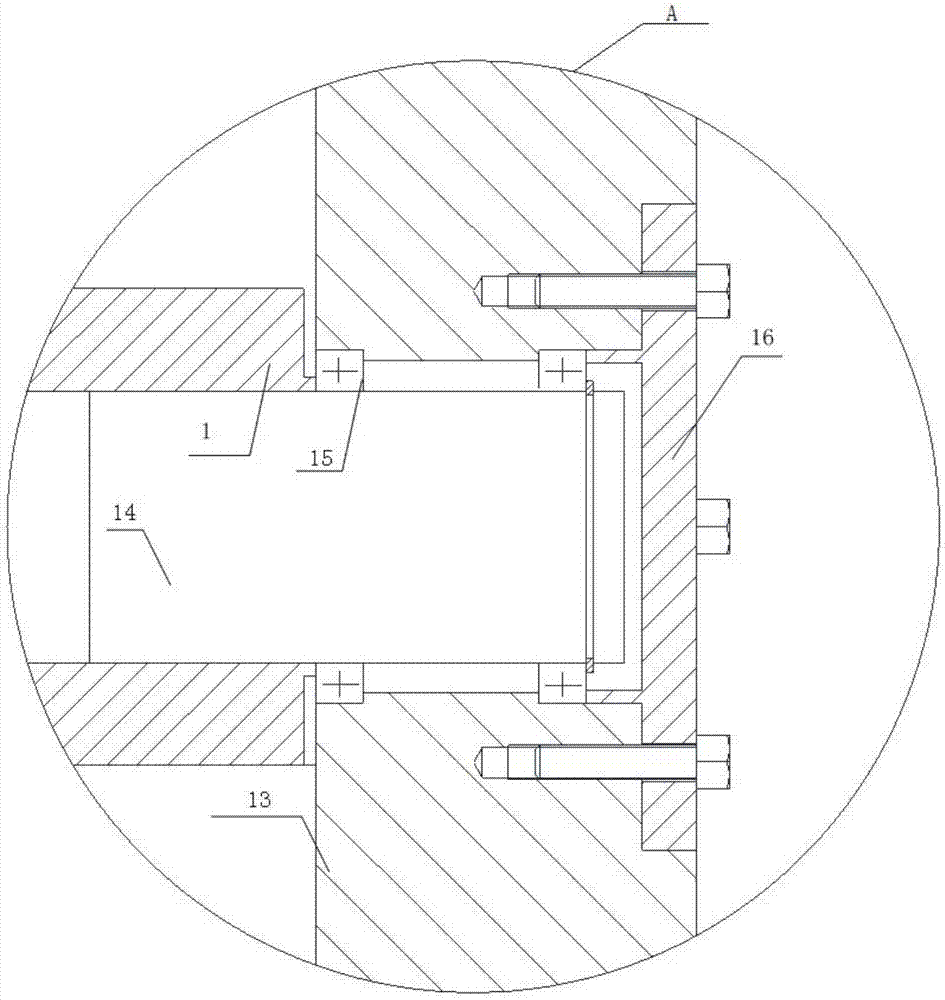

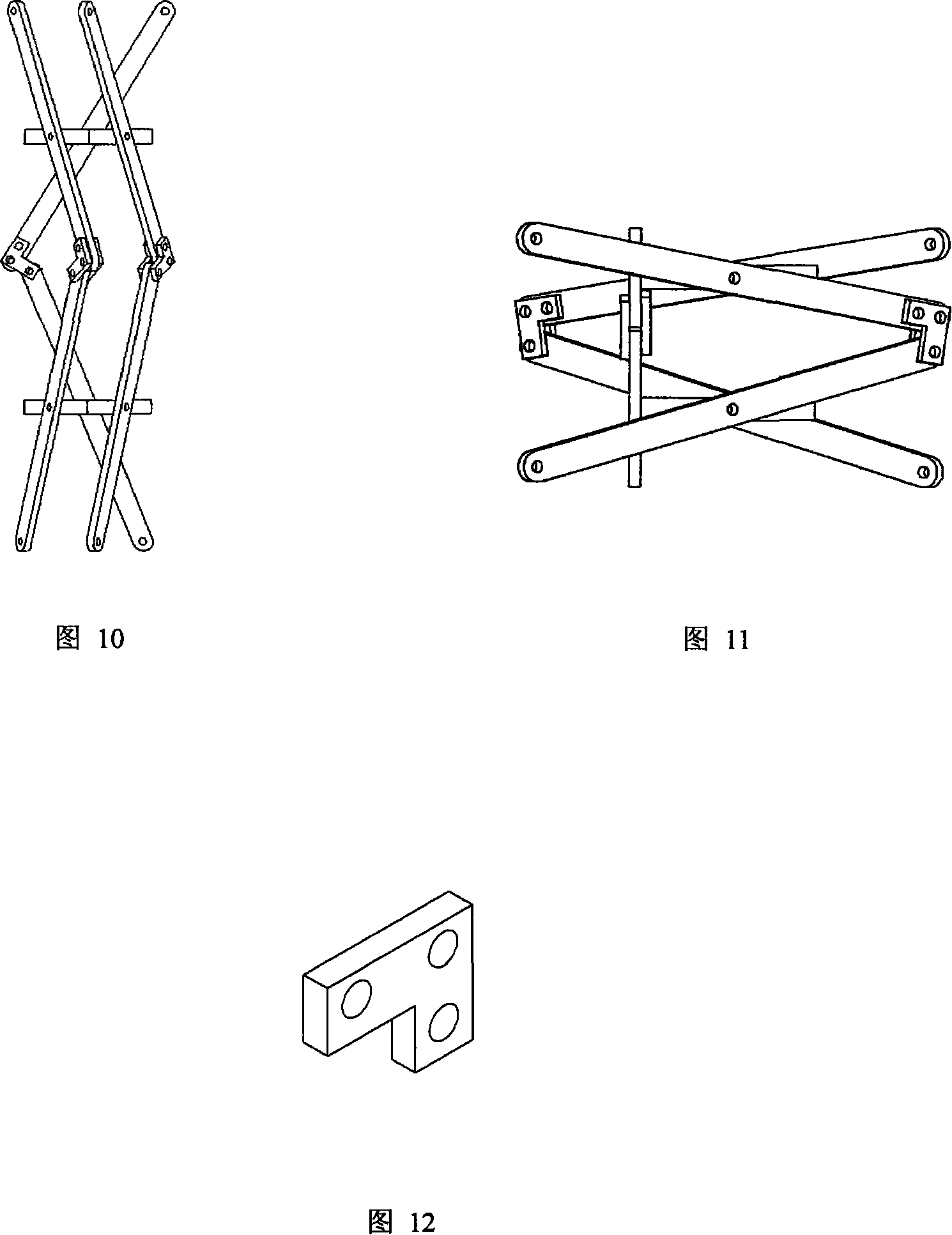

Large-stroke leveling lifting mechanism

ActiveCN107337148ABig work scheduleWith automatic levelingLifting framesBraced frameCarrying capacity

The invention relates to a large-stroke leveling lifting mechanism, which is characterized by comprising a loading upper platform, a loading lower platform, lifting driving mechanisms and lifting driving mechanism mounting bases, wherein four lifting driving mechanism mounting bases which are in rectangular distribution are arranged, each of the lifting driving mechanism mounting bases is provided with one lifting driving mechanism, each mounting base comprises at least two mounting base support legs and a middle support frame, the mounting base support legs are fixedly connected to the loading lower platform, the support frames are connected to lifting driving mechanism shells, and the top ends of the lifting driving mechanisms are connected to the upper loading platform by ball hinges. The lifting mechanism is small in size, high in carrying capacity, simple in control manner and suitable for large-stroke lifting of large-mass workpieces.

Owner:HARBIN INST OF TECH

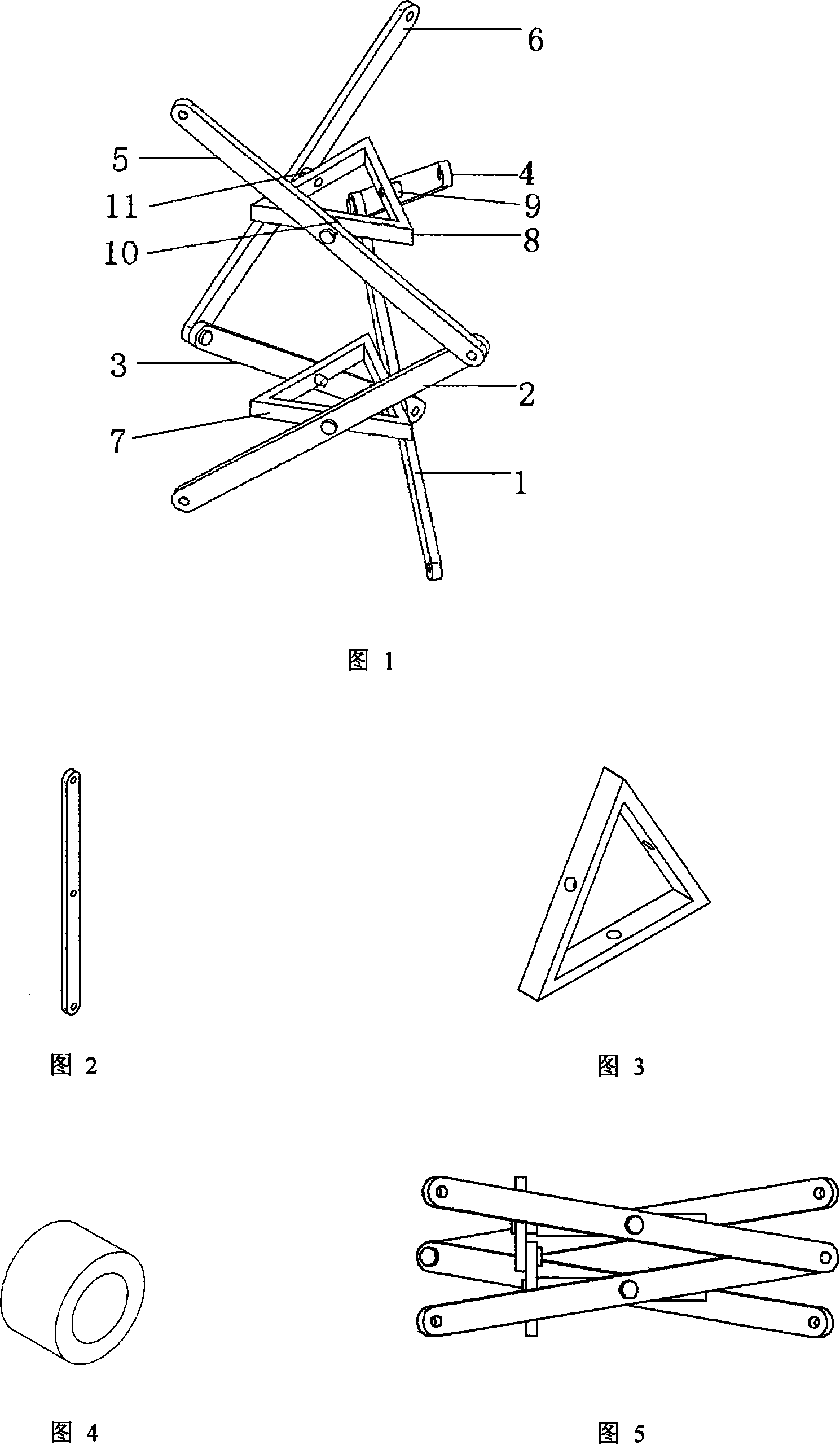

Zigzag rod space telescopic mechanism

InactiveCN101140005AGuaranteed tightLess materialGripping headsRod connectionsMaterial consumptionInterference problem

The invention relates to a zigzag member space telescoping mechanism which comprises a member and a middle bracket and is formed by the series connection of a plurality of layers of same component units. When the mechanism extends or contracts, the members are mutually staggered, which can overcome the interference problem. The arrangement mode of the member and the middle bracket of the mechanism can greatly reduce the occupancy space, which can make the mechanism compact while keeping a large telescopic ratio. When the member length is less than the side length of the middle bracket, the cross section of the mechanism can always remain unchanged. Due to the space symmetry of the mechanism itself, the mechanism has the comparatively uniform distribution of the bearing capacity of the different directions in the space. The mechanism has the advantages of the less material consumption, the large telescopic amplitude, the good stress performance, the strong stability, the wide application range and the simple manufacturing process.

Owner:BEIJING JIAOTONG UNIV

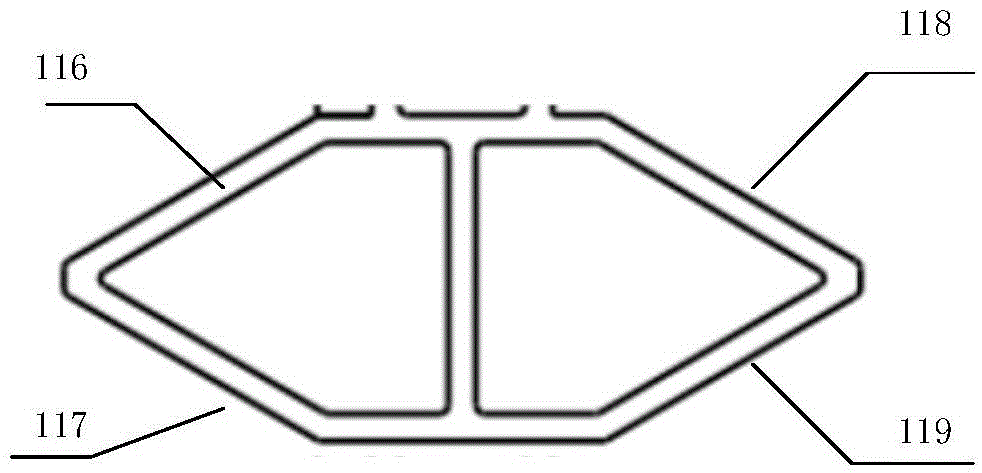

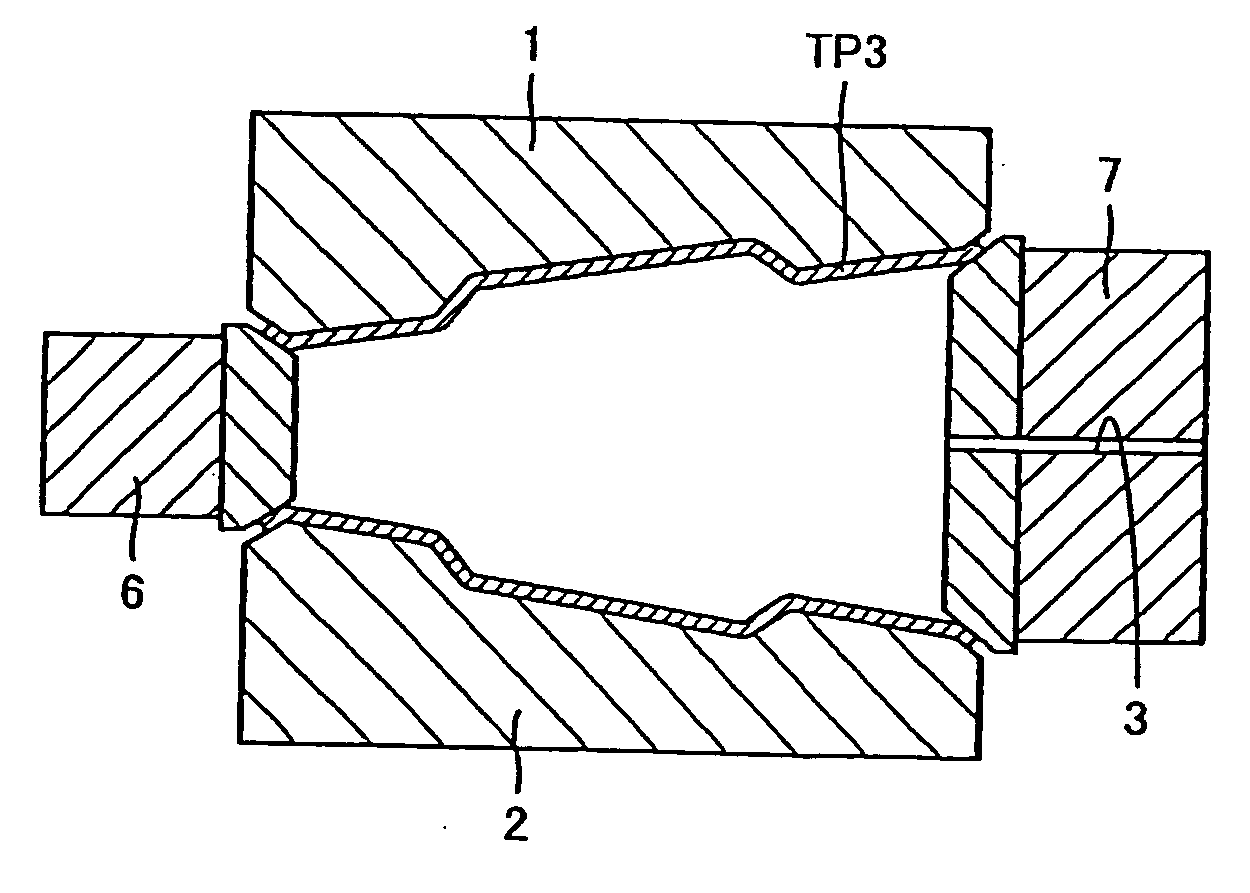

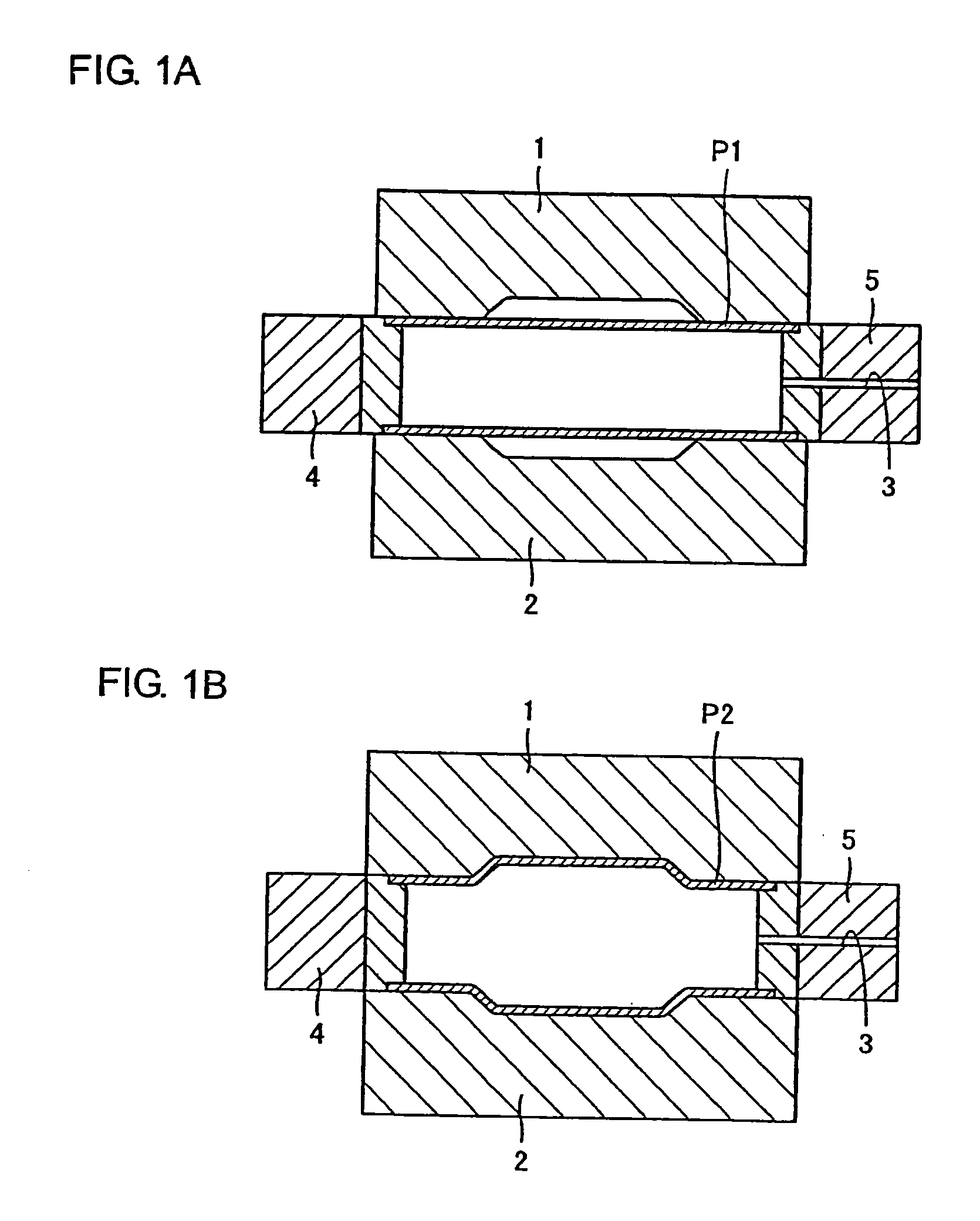

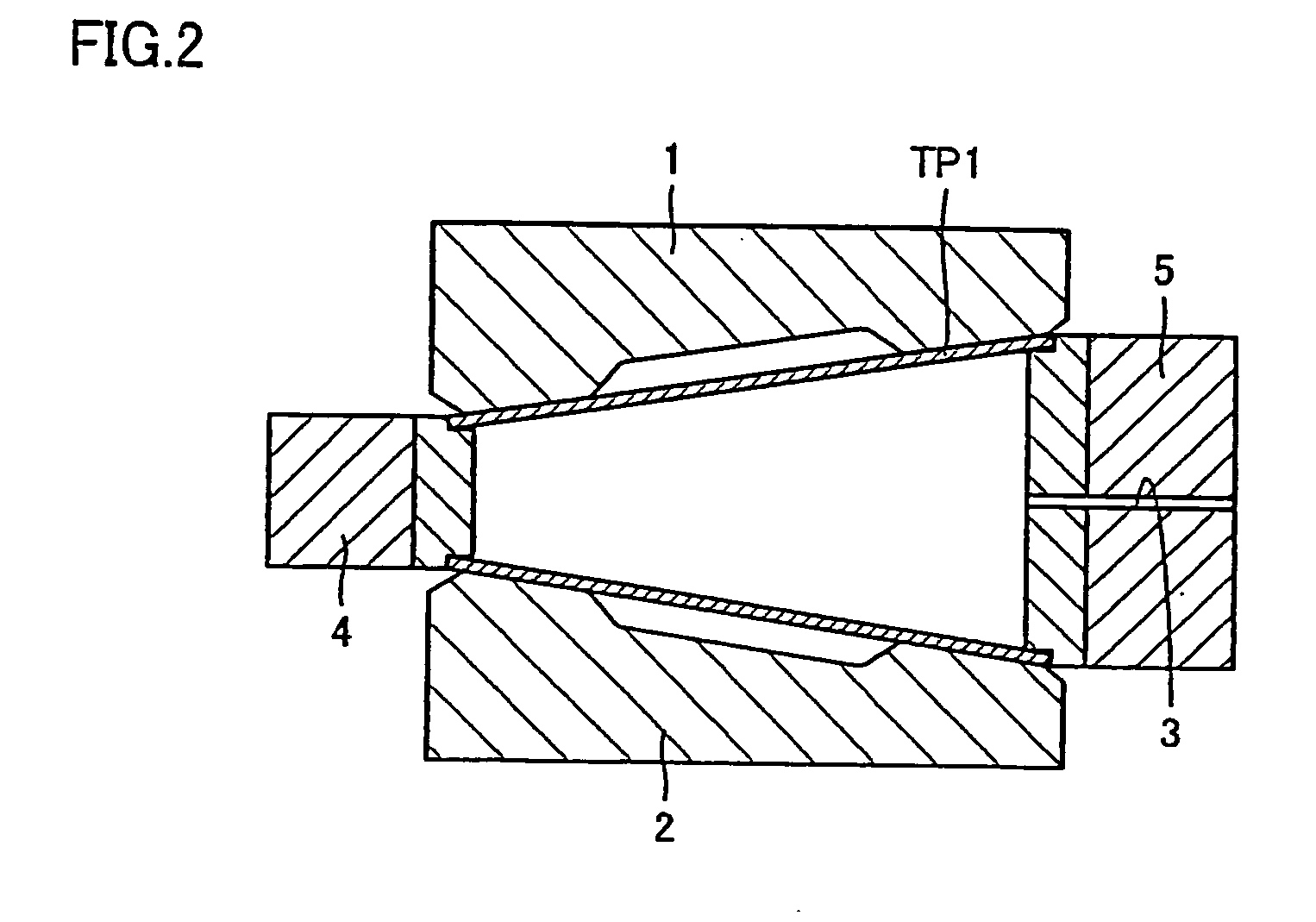

Profile element pipe for hydraulic bulging, hydraulic bulging device using the element pipe, hydraulic bulging method using the element pipe, and hydraulically bulged product

According to a bulging device and a bulging method using a profile element pipe, for example, even when a profile steel pipe having a cross sectional shape varying in the axial direction as in a tapered pipe is hydraulically bulged, a bulging in which an internal pressure loading and an axial pressing are combined with each other can be performed to provide a larger expansion ratio than a conventional case and a joining and socket connection thereof to the other part can also be easily performed.

Owner:SUMITOMO PIPE & TUBE CO LTD +2

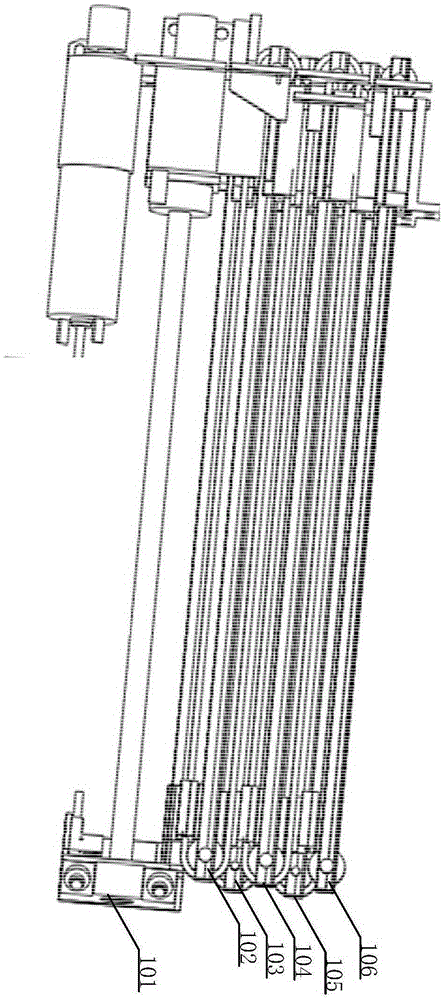

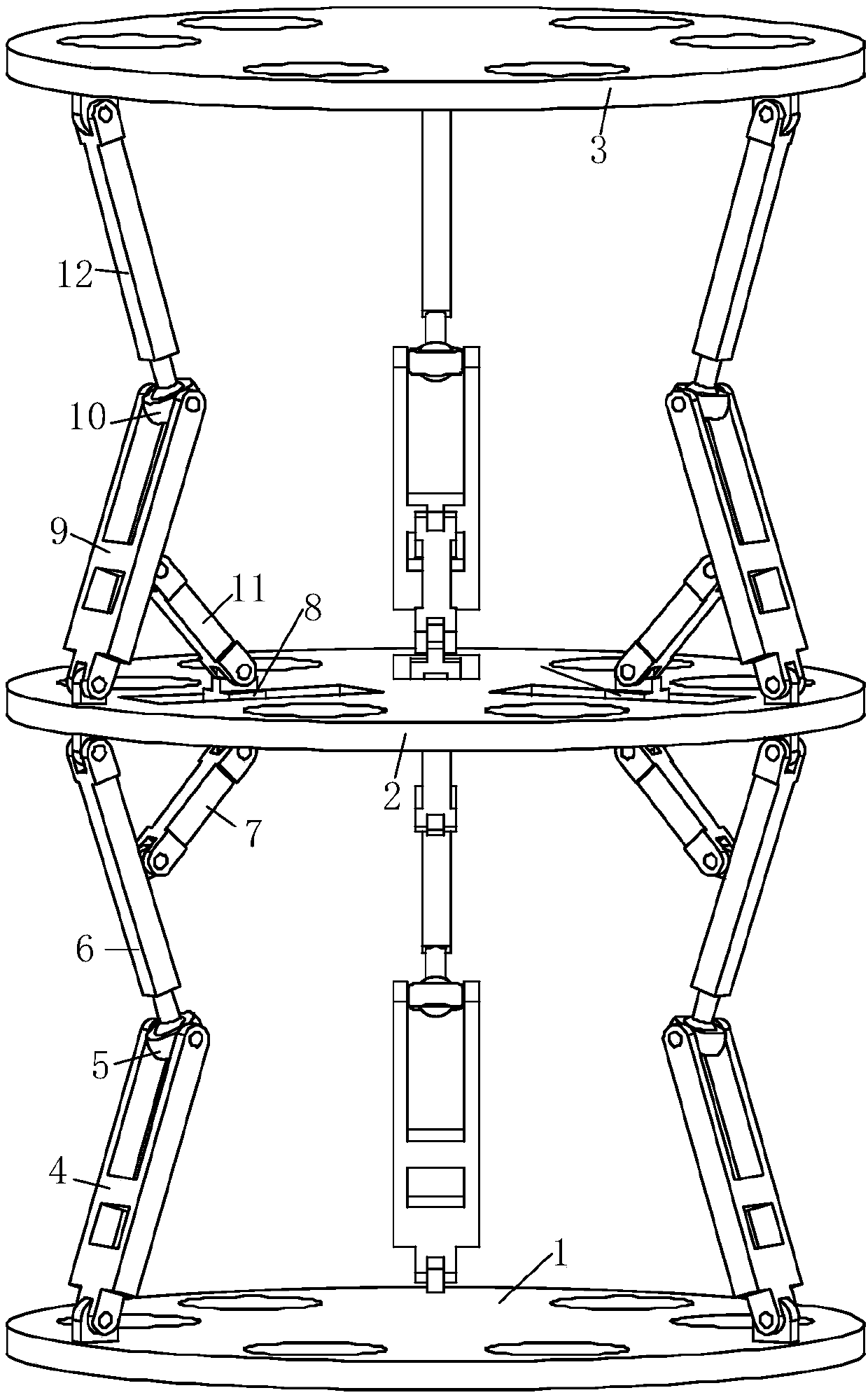

Multistage robot lifting device and lifting method

The invention provides a multistage robot lifting device which comprises a driving module and a plurality of stages of lifting modules. The lifting modules comprise transmitting mechanisms and bayonet locks; the transmitting mechanisms comprise guide rails and conveying belts, top pulleys and bottom pulleys are respectively arranged at the upper ends and the lower ends of the guide rails, and the conveying belts bypass the top pulleys and the bottom pulleys; the conveying belts are clamped by the bayonet locks; and the transmitting mechanism of the first stage lifting module of the lifting modules is connected with the driving module, and the transmitting mechanism of the next stage lifting module is connected with the conveying belt of the last stage lifting module. The multiple stages of lifting modules are sequentially driven by the conveyer belts to operate, the lifting modules can move in the same distance at the same time, and the lifting and descending speed can be quickened.

Owner:YIJIAHE TECH CO LTD

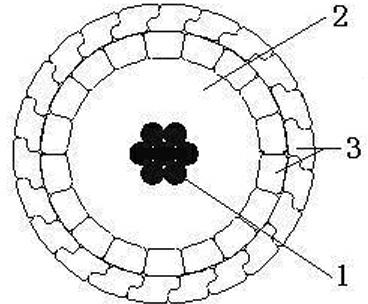

Unbraced expanded steel-cored aluminum stranded wire

InactiveCN102610300AGood self-damping performanceHigh tensile strengthNon-insulated conductorsPower cables with screens/conductive layersHigh voltageMaterials science

The present invention relates to an unbraced expanded steel-cored aluminum stranded wire, belonging to the technical field of overhead transmission lines. The unbraced expanded steel-cored aluminum stranded wire is suitable for severe using environments such as high voltage, high altitude and bold wind and has the characteristics of saved material, reduced corona, reduced energy consumption, reduced vibration and prolonged service life. The unbraced expanded steel-cored aluminum stranded wire comprises an outer aluminum stranded wire layer, a hollow structure layer and a center reinforced steel stranded wire, wherein the hollow structure layer is arranged between the outer aluminum stranded wire layer and the center reinforced steel stranded wire. The hollow structure layer is annular. The outer aluminum stranded wire layer is composed of an inner aluminum conduction wire layer and an outer aluminum conduction wire layer. The inner aluminum conduction wire layer uses a T-shaped wire; and the outer aluminum conduction wire layer uses a T shaped wire, a Z-shaped wire, an S-shaped wire or a round wire. The inner aluminum conduction wire layer of the outer aluminum stranded wire is stranded leftwards, and the outer aluminum conduction wire layer of the outer aluminum stranded wire is stranded rightwards. The unbraced expanded steel-cored aluminum stranded wire is an expanded conduction wire with the characteristics of large expanding rate, stable structure, simple manufacturing process, high tensile strength of the conduction wire, and excellent self-damping performance.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

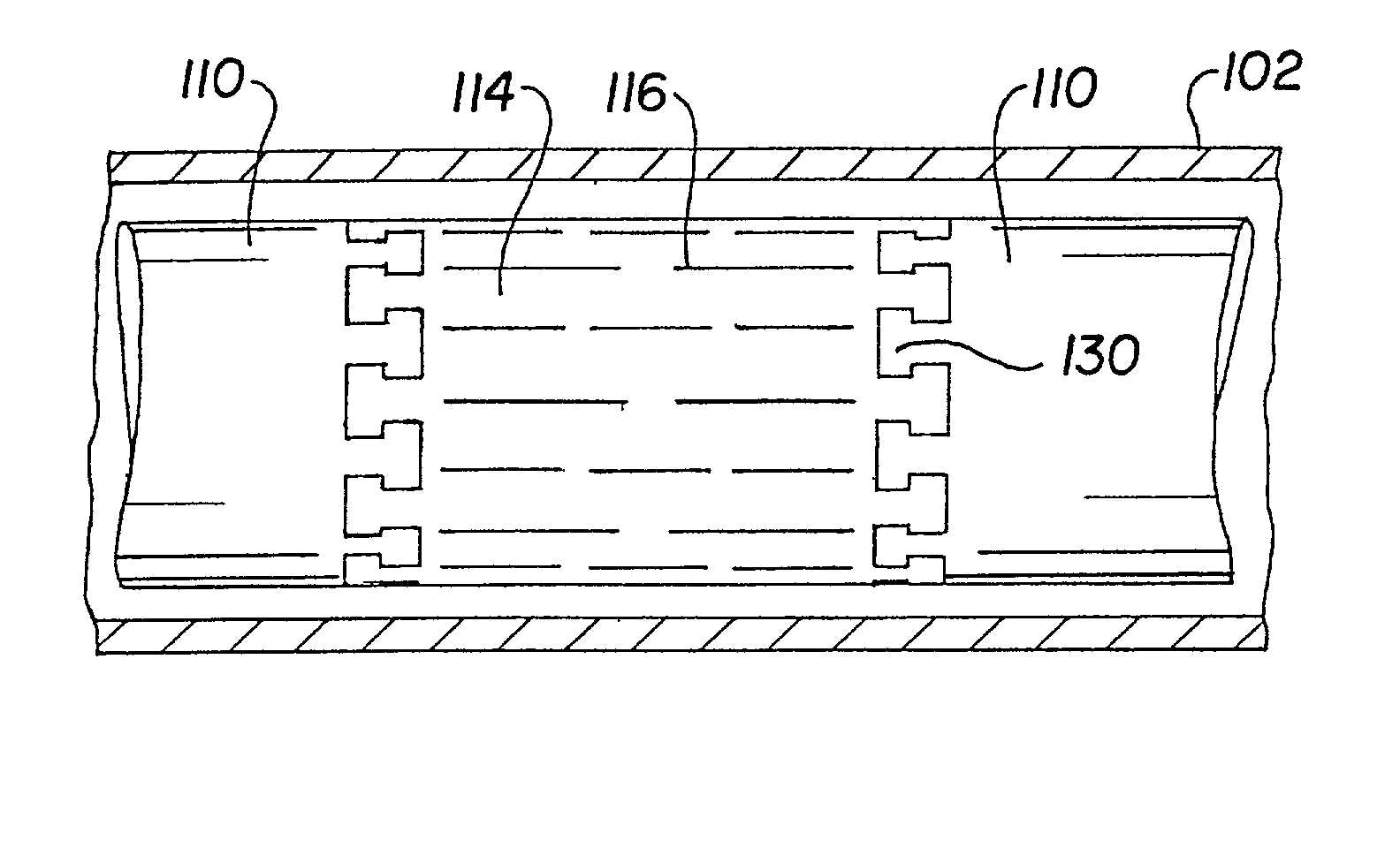

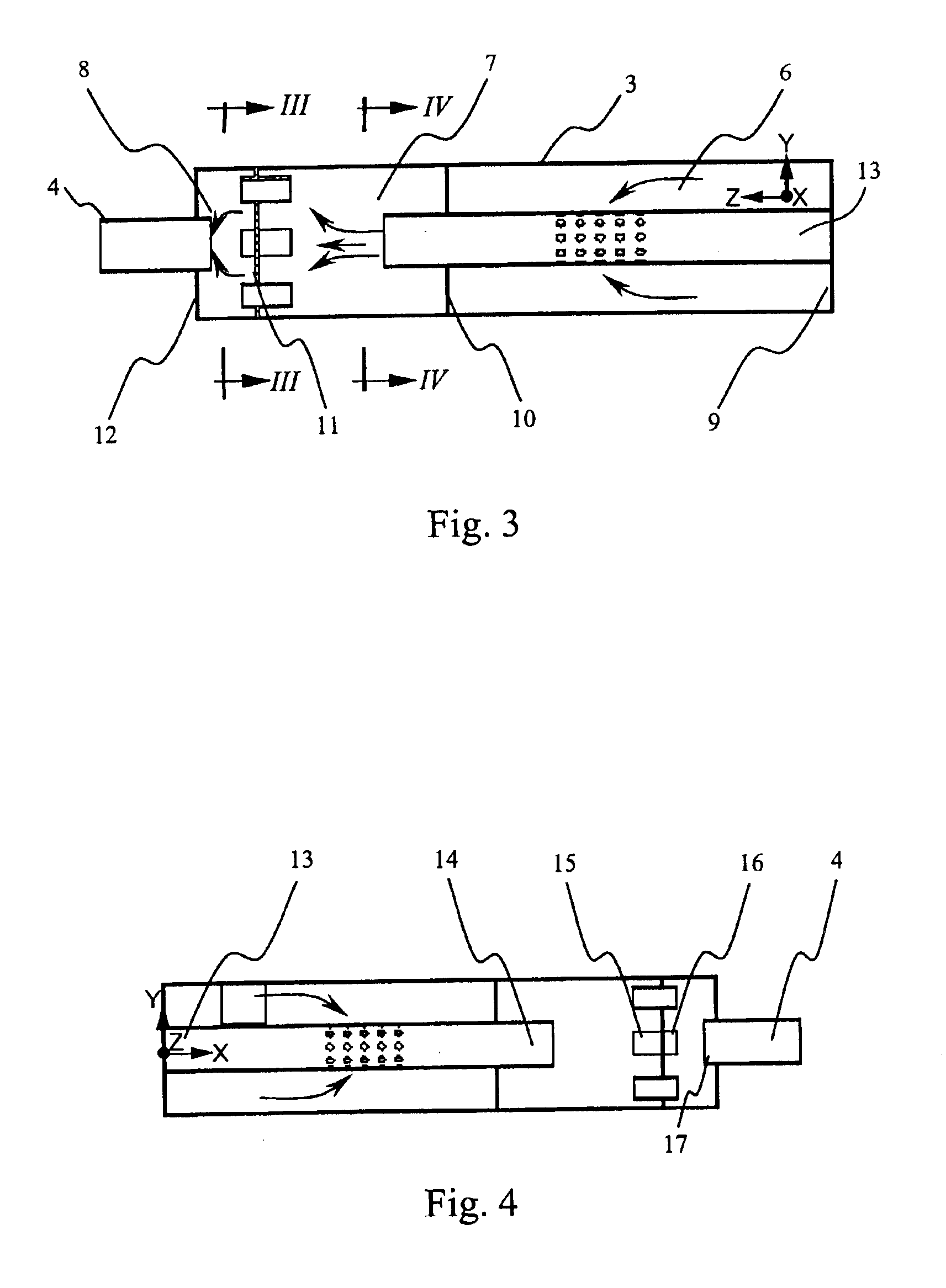

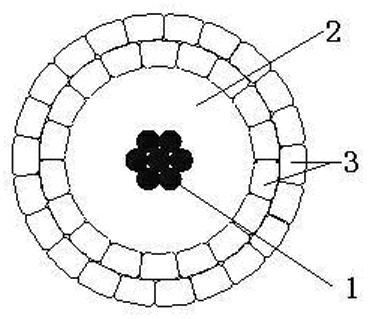

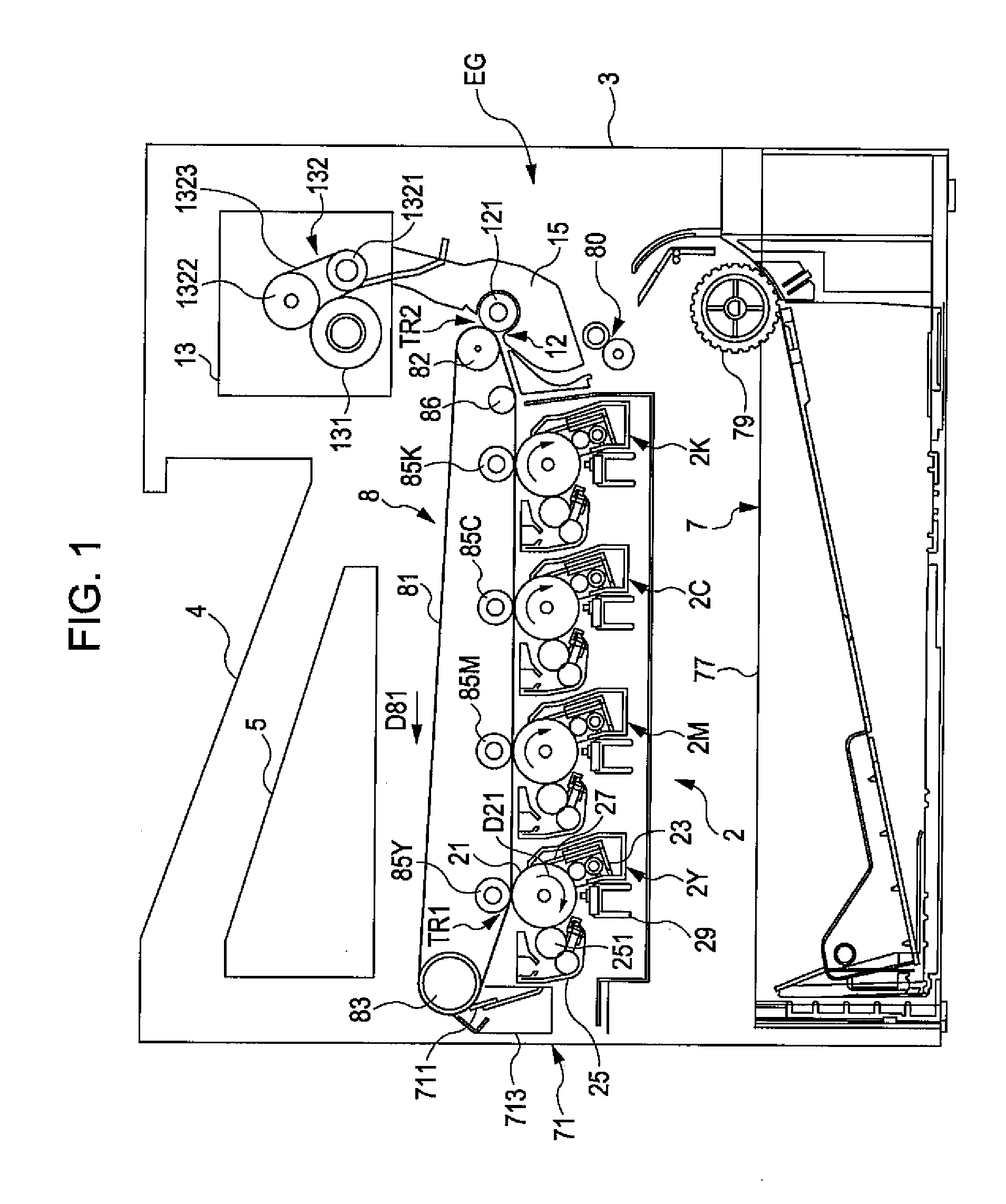

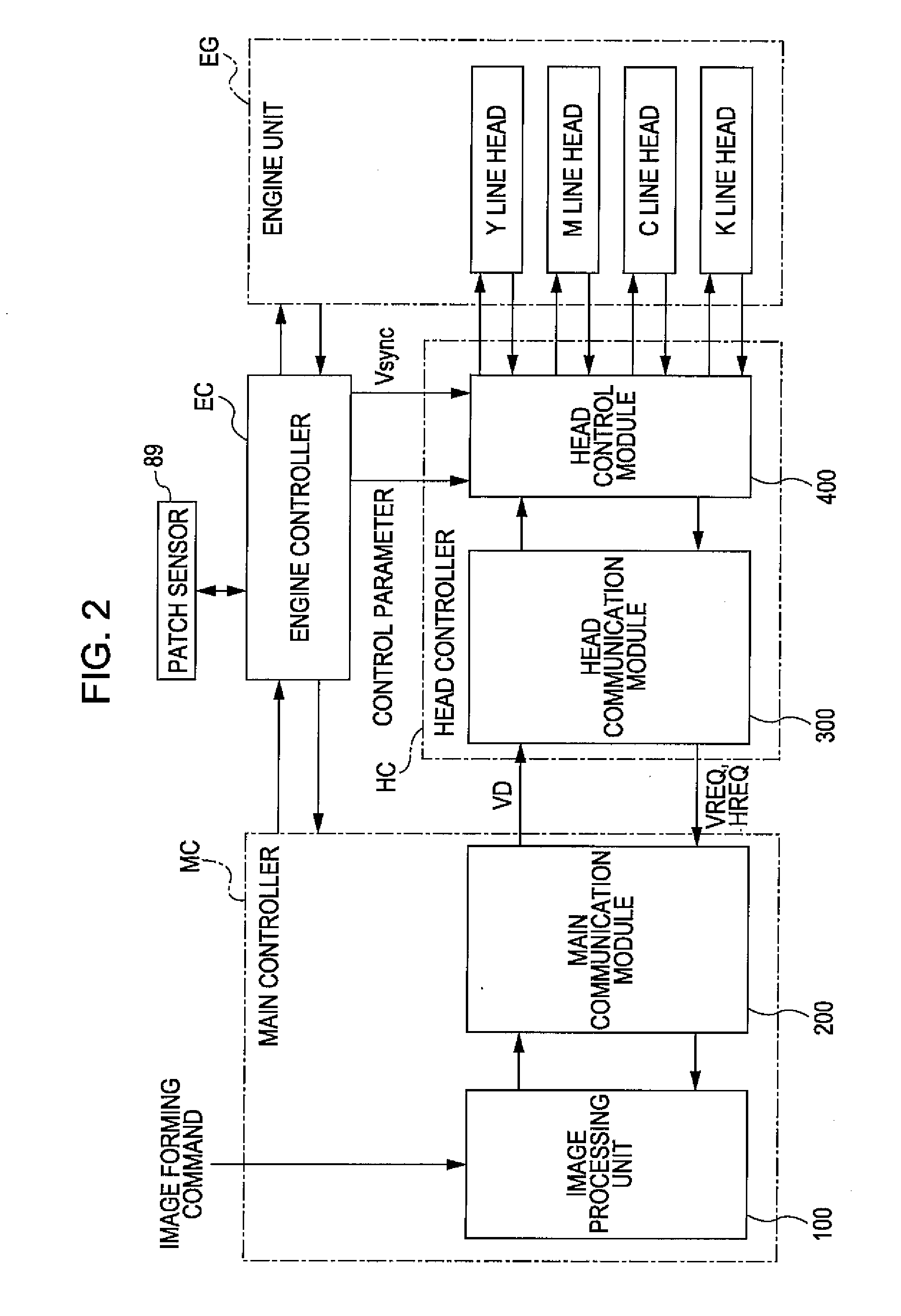

Exposure Head and Image Forming Device

InactiveUS20100086331A1Avoid deformationImprove support rigidityElectrographic process apparatusOptoelectronicsLens array

An exposure head includes a substrate through which light from light-emitting elements provided on a first surface of the substrate penetrates from the first surface to a second surface. A rod lens array is provided on the second surface of the substrate to image the light from the second surface. A light transparent member is provided between the substrate and the rod lens array and fixed to the second surface of the substrate and the rod lens array. A support member supports the first surface of the substrate.

Owner:SEIKO EPSON CORP

Slide block type multistage coupling parallel mechanism

PendingCN107932487AIncrease local degrees of freedomLarge expansion ratioProgramme-controlled manipulatorEngineeringCoupling constant

The invention discloses a slide block type multistage coupling parallel mechanism. The slide block type multistage coupling parallel mechanism comprises a fixed platform, a movable platform, a coupling platform, and three branched chains respectively connected with the fixed platform, the coupling platform and the movable platform and uniformly distributed along the periphery, wherein a first driving rod in the three branched chains for connecting the fixed platform with the coupling platform is connected with the fixed platform and one end of a first driven rod; the other end of the first driven rod is connected with the lower surface of the coupling platform; a first connecting rod is connected with the middle part of the first driven rod and the lower surface of a slide block arranged on the coupling platform; a second driving rod in the three branched chains for connecting the coupling platform with the movable platform is connected with the upper surface of the coupling platform and one end of a second driven rod; the other end of the second driven rod is connected with the lower surface of the movable platform; and a second connecting rod is connected with the middle part ofthe second driving rod and the upper surface of the slide block. The slide block type multistage coupling parallel mechanism increases an extension ratio of a single or multistage coupling parallel mechanism, enlarges working space, reduces the number of driving units, facilitates control during working, and improves rigidity thereof.

Owner:YANSHAN UNIV

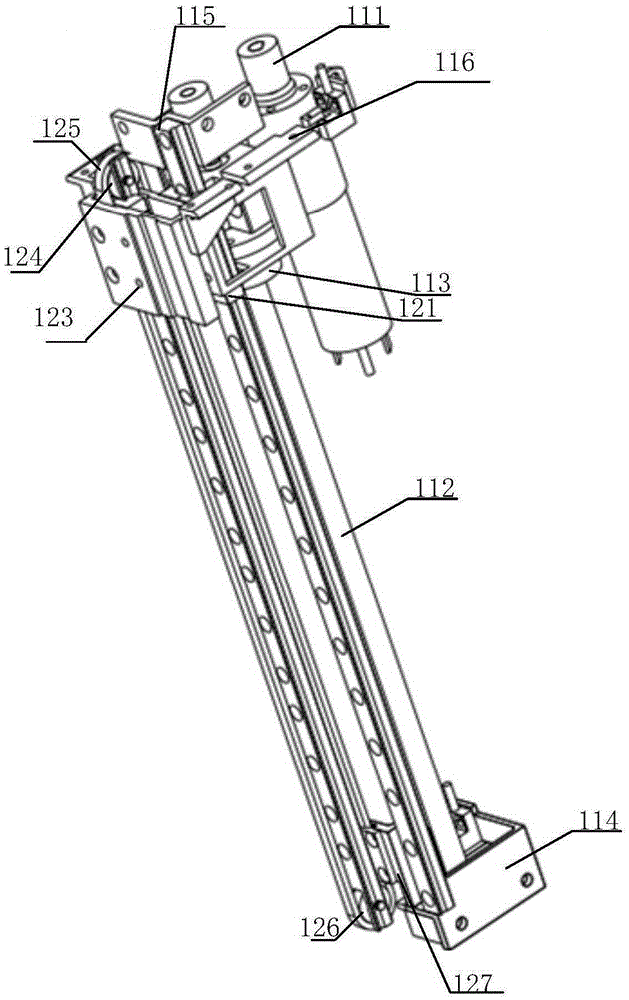

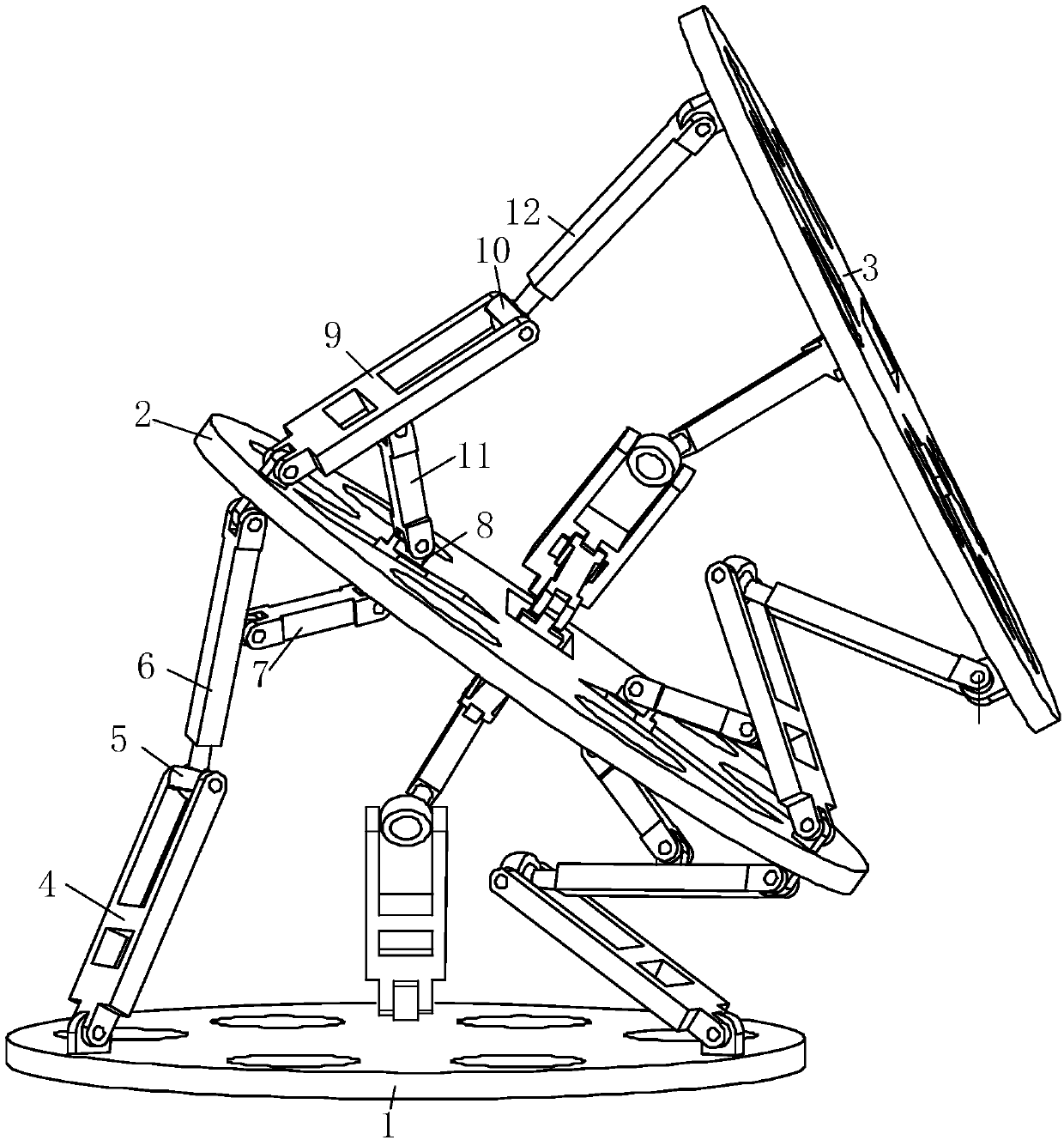

Lifting cradle head based on ball screw

The invention discloses a lifting cradle head based on a ball screw. The lifting cradle head comprises a support, the ball screw and a guide rod which are arranged on the support, a lead screw bearingmatched with the ball screw, a flange bearing in sliding fit with the guide rod, supporting rods, a lower plate, an upper plate and a stepping motor; the stepping motor is fixed on the support and isin driving connection with the ball screw; the lower plate is fixedly connected with the lead screw bearing and the flange bearing; one ends of the supporting rods are movably hinged to one end of the lower plate, and the other ends of the supporting rods are movably hinged to one end of one the upper plate; and the other end of the upper plate is movably hinged to one end of the support. According to the lifting cradle head, the ball screw and the stepping motor are combined to use so that the angle can be accurately adjusted; according to driving the stepping motor, pitching can be realizedby controlling the motor; and the lifting cradle head has the advantages that operation and structure are simple, the bearing force is large, the telescopic ratio is large, the occupied space is small, and a simple, practicable, fast and reliable pitch angle adjusting process can be realized on an object throwing robot.

Owner:SOUTH CHINA UNIV OF TECH

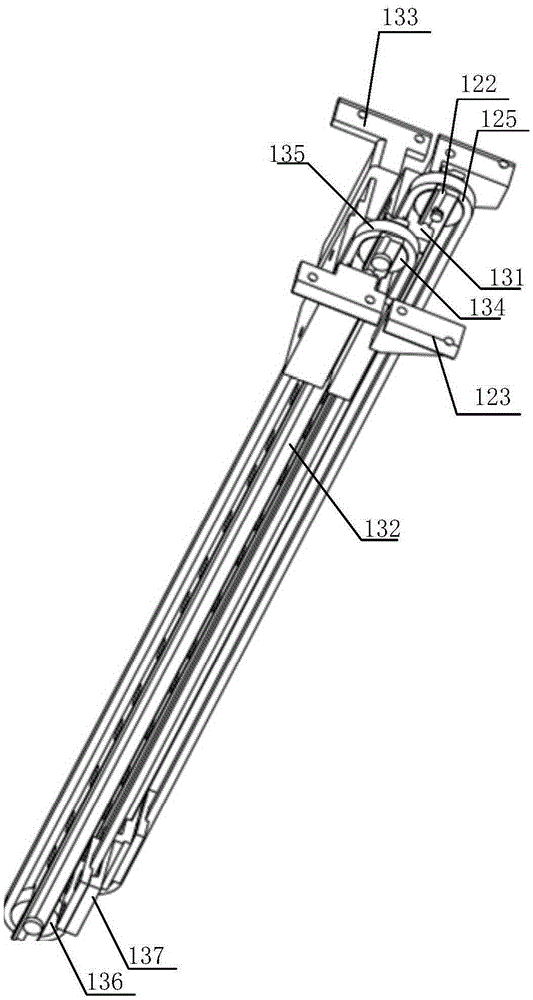

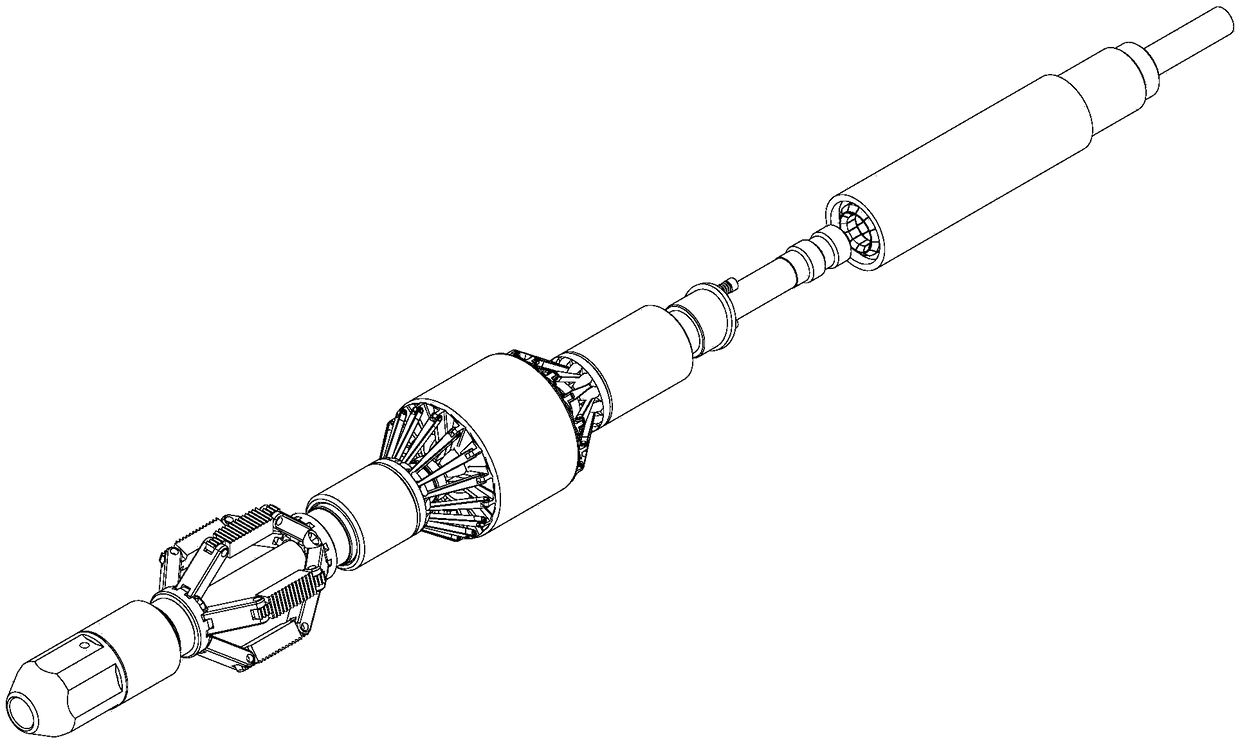

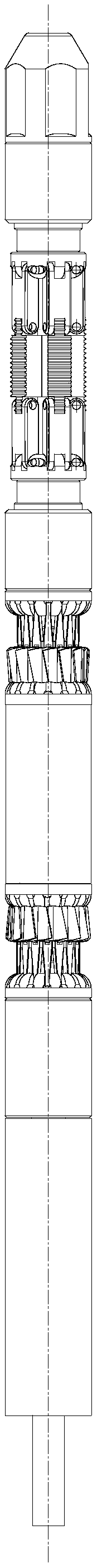

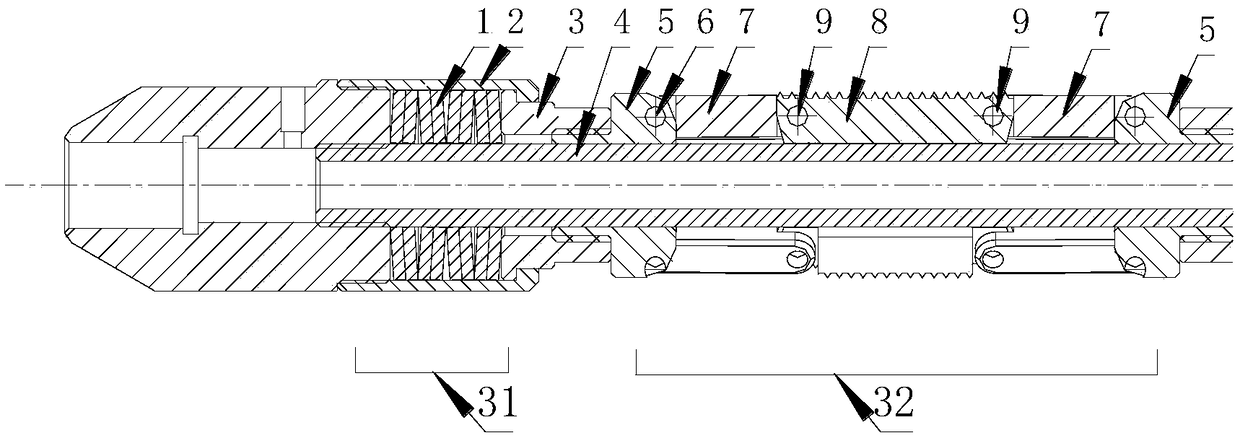

Recyclable oil pipe bridge plug with high expansion ratio

The invention relates to technological devices for well completion, oil extraction and gas production of oil and gas fields, in particular to a recyclable oil pipe bridge plug tool with a high expansion ratio. The oil pipe bridge plug comprises a first combined laminated spring assembly, a heavy hinged slip assembly, a second combined laminated spring assembly, a first joint-type and link-type anti-outburst mechanism assembly, a second joint-type and link-type anti-outburst mechanism assembly, a lock assembly and a feed-in release assembly; a central pipe is arranged in the middle of the oil pipe bridge plug; the first combined laminated spring assembly, the heavy hinged slip assembly arranged in a circular array mode, the second combined laminated spring assembly, the first joint-type andlink-type anti-outburst mechanism assembly, the second joint-type and link-type anti-outburst mechanism assembly, the lock assembly and the feed-in release assembly are mounted on the central pipe ina sleeved mode. The recyclable oil pipe bridge plug has the advantages that a piston only needs a small stroke through a crank connecting rod mechanism, and the high expansion ratio can be achieved.

Owner:弗润联科(北京)石油科技有限公司

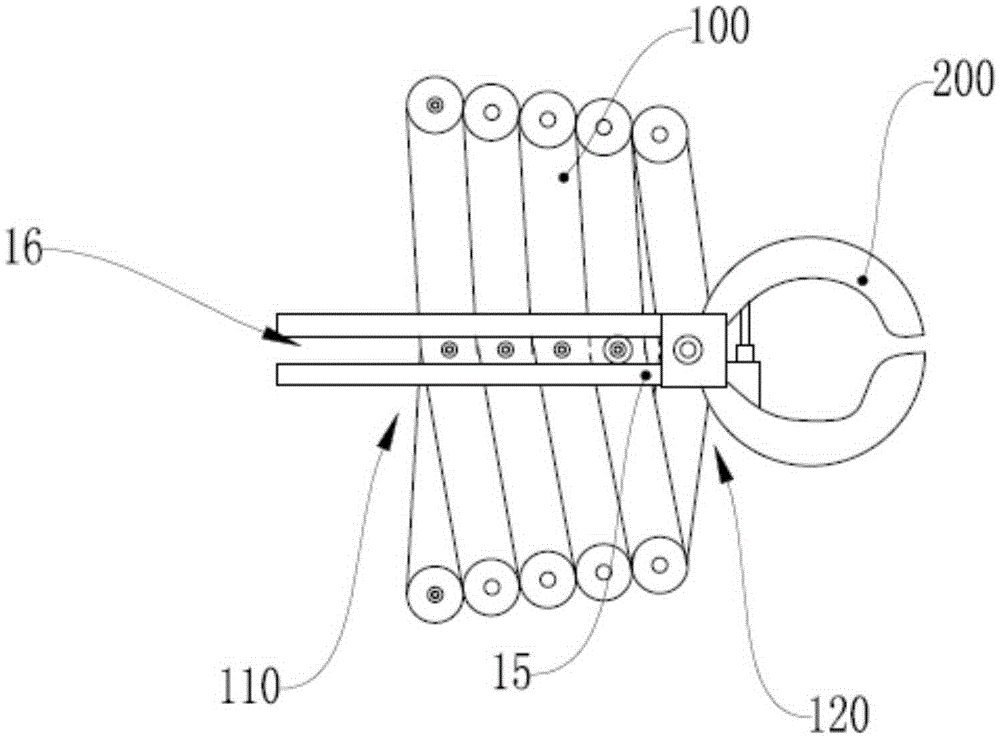

Multi-arm robot

InactiveCN106607887AImprove job stabilitySmooth telescopic movementProgramme-controlled manipulatorArmsEngineeringIndustrial machine

The invention relates to the field of industrial machines, in particular to a multi-arm robot. The multi-arm robot comprises two telescopic booms which are installed on the side face of a rack and terminal working mechanisms installed at one ends of the telescopic booms. Each telescopic boom is formed by hinging a plurality of shears-fork type units in sequence. The terminal working mechanisms are arranged at the working ends. Hinged arms of the shears-fork type units arranged at the driving ends of the telescopic booms are longer than hinged arms at the working ends, so that the widths of the driving ends are larger than those of the working ends when the telescopic booms are in a stretched or folded state. The multi-arm robot is provided, the dimensions of the working ends of the telescopic booms arranged on the multi-arm robot are smaller than those of the driving ends, so that the weight of each working end is low, the working ends after stretching are not likely to shake, and thus using is made more stable. In addition, due to the fact that the dimensions of the working ends are smaller, the multi-arm robot can be suitable for narrow and small space for working.

Owner:FOSHAN HECAI TECH SERVICE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com