Underground concrete mixer for coal mine

A technology of concrete mixer and mixing mechanism, which is applied in cement mixing device, clay preparation device, mixing operation control, etc. It can solve the problems of uneconomical transportation of concrete, inability to adapt to construction operations, and low concrete quality ratio, so as to overcome the slow movement speed Stable, space-saving, and easy to carry and move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

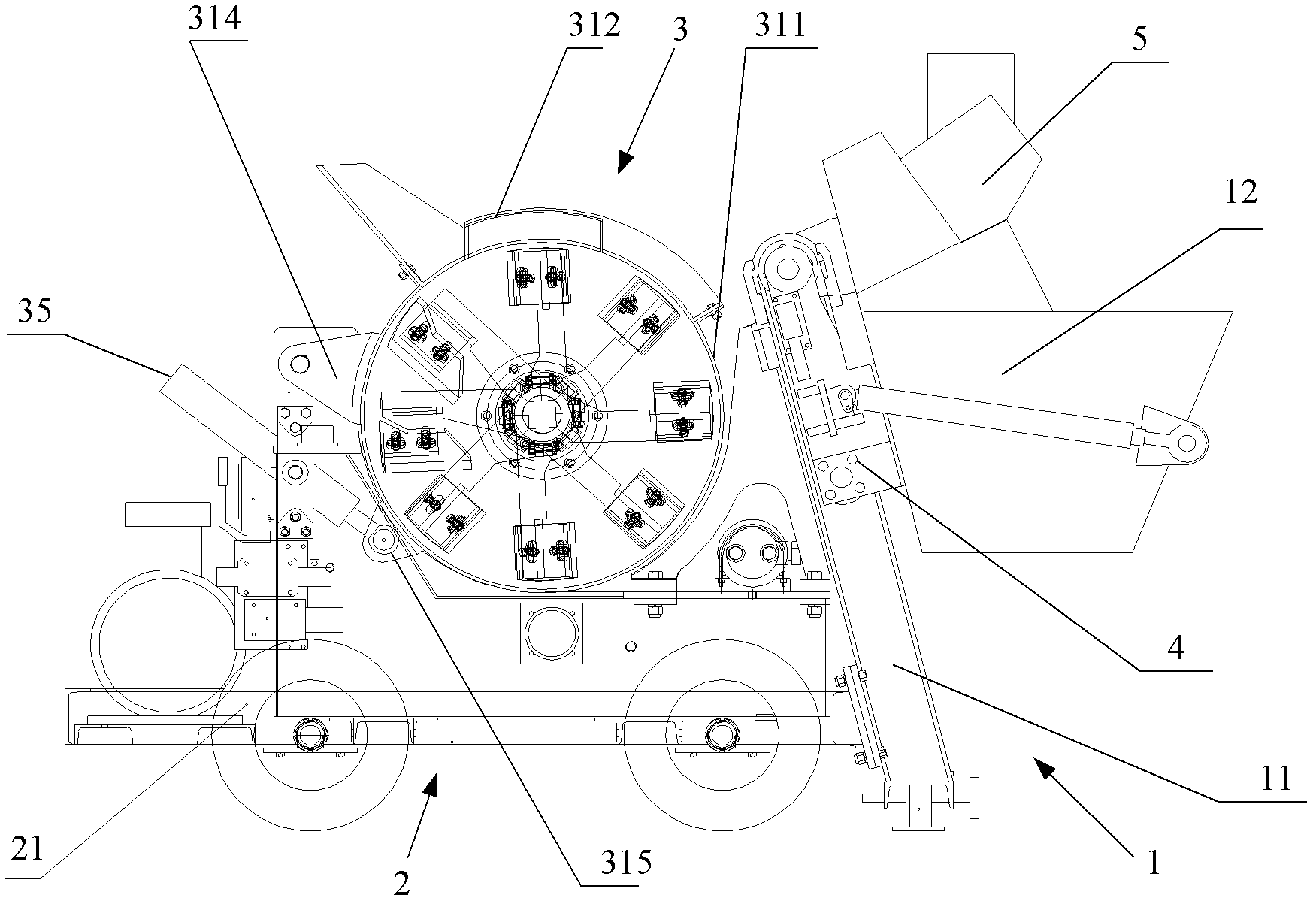

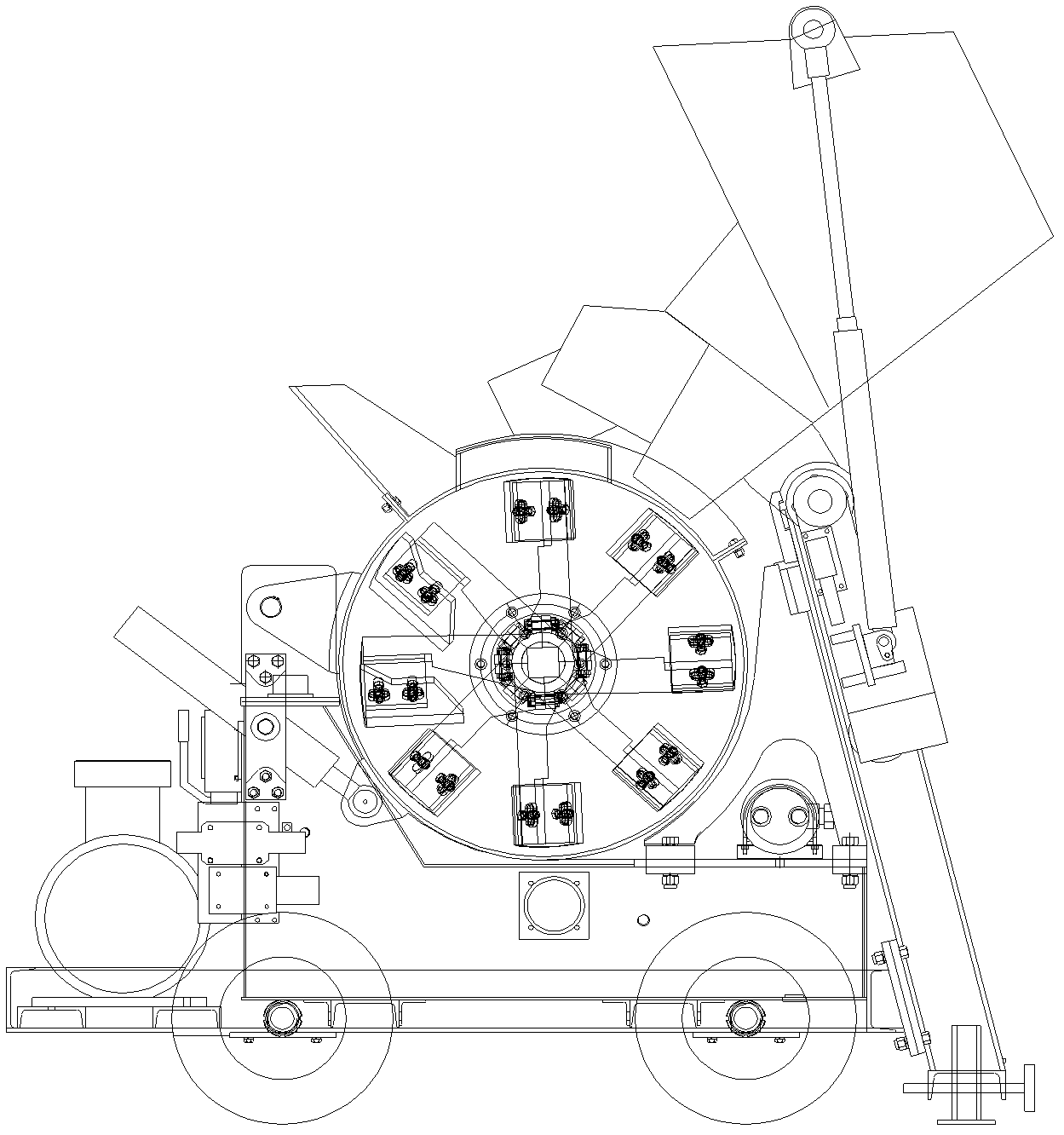

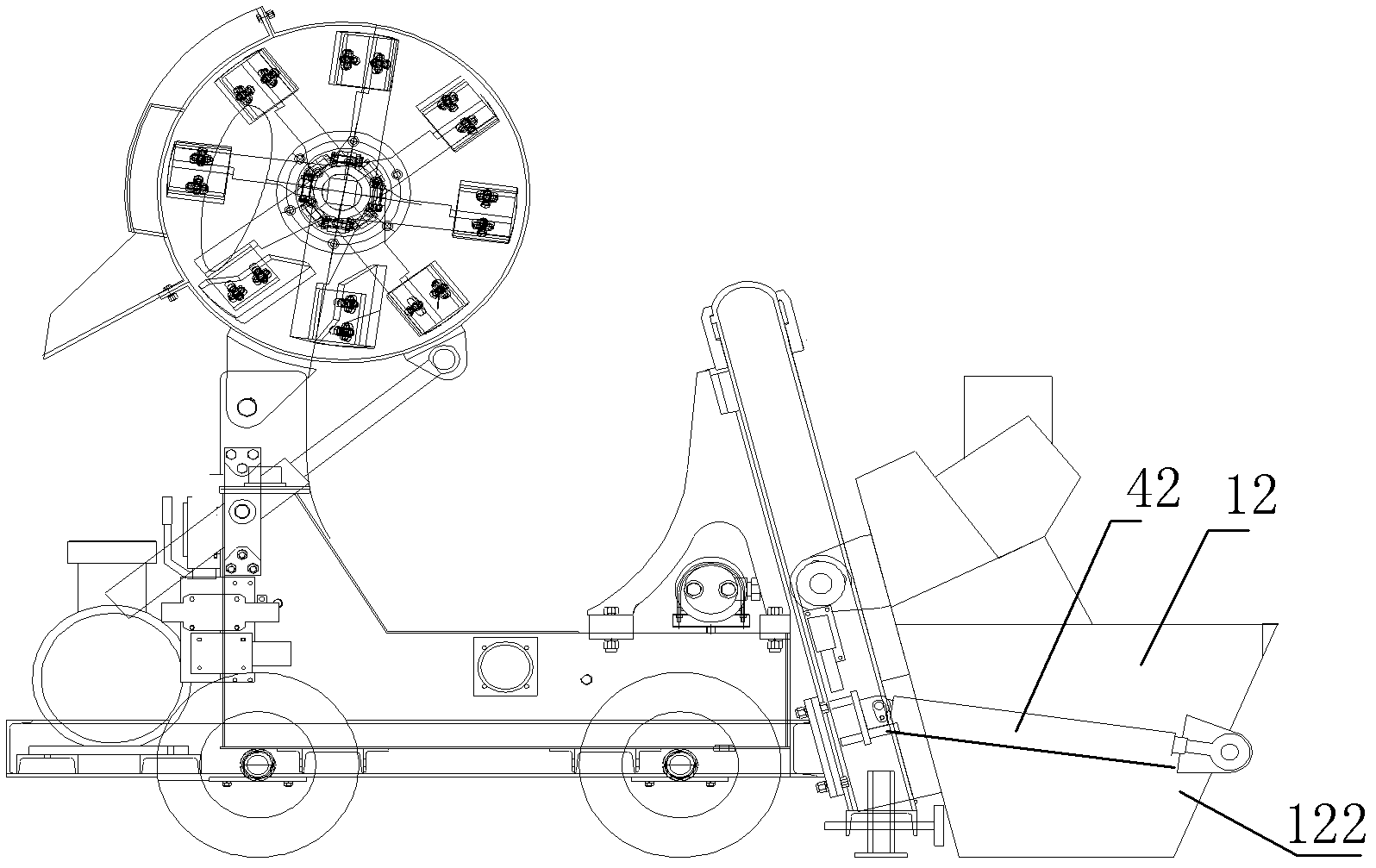

[0038] combine Figure 1 to Figure 8 , Coal mine underground concrete mixer, including frame 2, feeding mechanism 1 and mixing mechanism 3, feeding mechanism 1 is located at the front end of frame 2, and mixing mechanism 3 is located on frame 2.

[0039] The feeding mechanism 1 comprises a support 11, a hopper 12, a hydraulic cylinder 13, a first sprocket shaft 14, and a second sprocket shaft 15. The support 11 consists of a bottom beam 111, two H-shaped steels 112 erected above the bottom beam 111 and The upper beam 113 constitutes.

[0040] The front end of the piston rod of the hydraulic cylinder 13 is connected to the bottom beam 111, the front end of the cylinder barrel of the hydraulic cylinder 13 is connected to the first sprocket shaft 14, the rear end of the cylinder barrel of the hydraulic cylinder 13 is connected to the second sprocket shaft 15, and the first sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com