Recyclable oil pipe bridge plug with high expansion ratio

An expansion ratio, tubing technology, applied in wellbore/well components, sealing/packaging, earth-moving drilling, etc., can solve the problems such as the inability to take out the bridge plug, the inability to guarantee the passability of the tool, and the inability to complete the operation. De-anchoring, enhanced slip resistance, reliable anchoring and de-anchoring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

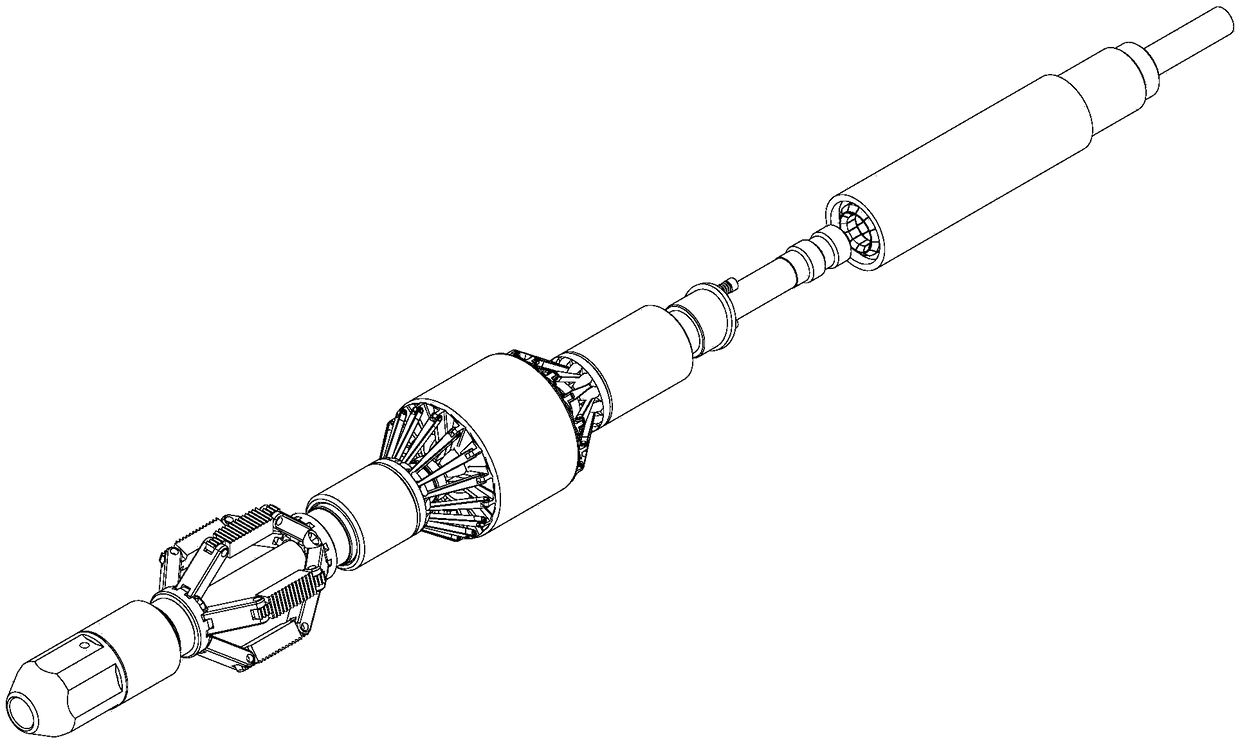

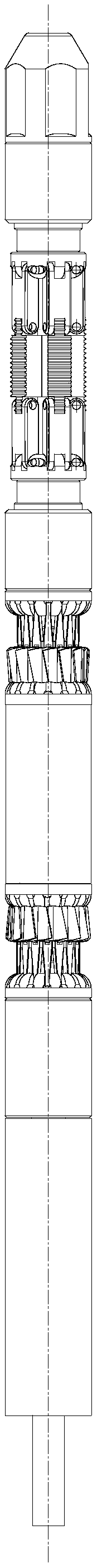

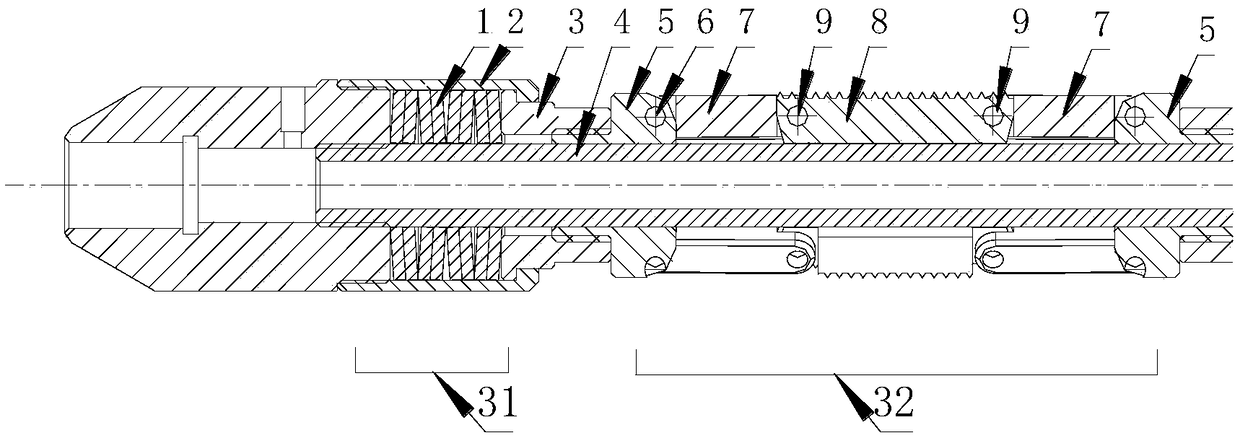

[0040] A retrievable oil pipe bridge plug with a high expansion ratio, the retrievable oil pipe bridge plug tool with a high expansion ratio is mainly composed of a combined stack spring assembly 31, a heavy-duty hinged slip assembly 32 arranged in a circular array, a combined stack Spring assembly 33, a pair of articulated link type anti-shock mechanism assembly 34,35, lock assembly 36, sending into composition such as throwing away assembly 37 that the circular array of mirror image symmetry arranges.

[0041] The combined lap spring assembly 31 is mainly composed of a group of stack springs 1, movable pressure sleeves 2, and push rings 3 that are arranged oppositely or in combination. When the push ring 3 compresses the stack spring 1 in the axial direction, a reliable restoring elastic force can be obtained. The elastic force of the overlapping spring is much larger than that of the annular spring, which can provide reliable pre-tightening force for the slip assembly and th...

Embodiment 2

[0050] This embodiment serves as a further optimization of Embodiment 1. On the basis of it, when it is necessary to unpack and propose the present invention, a standard overshot is lowered, and the description of the standard overshot is omitted here. The canister grabs the lock ring 19 and lifts it up, and the central tube 4 moves downward under the double action of the restoring force of the combined lap spring assembly 31 and the rubber tube 16, thereby driving the combined lap spring assembly 31 and the circular array arrangement. Heavy-duty hinged slip assembly 32, combined stacked spring assembly 33, articulated link type anti-shock mechanism assembly arranged in a circular array 34, articulated link type anti-shock mechanism assembly arranged in a circular array 35, lock assembly Cheng 36 returns to the initial state. The tool of the present invention can be taken out from downhole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com