Axial and radial stretching type tire molding drum

A technology of tire building drum and axial expansion, which is applied in the field of tire building, can solve the problems that the accuracy and quality cannot be well guaranteed, the production requirements cannot be well met, and the axial expansion and contraction of drum tiles cannot be realized, so as to achieve a simple structure , large expansion and contraction ratio, and the effect of reducing the weight of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

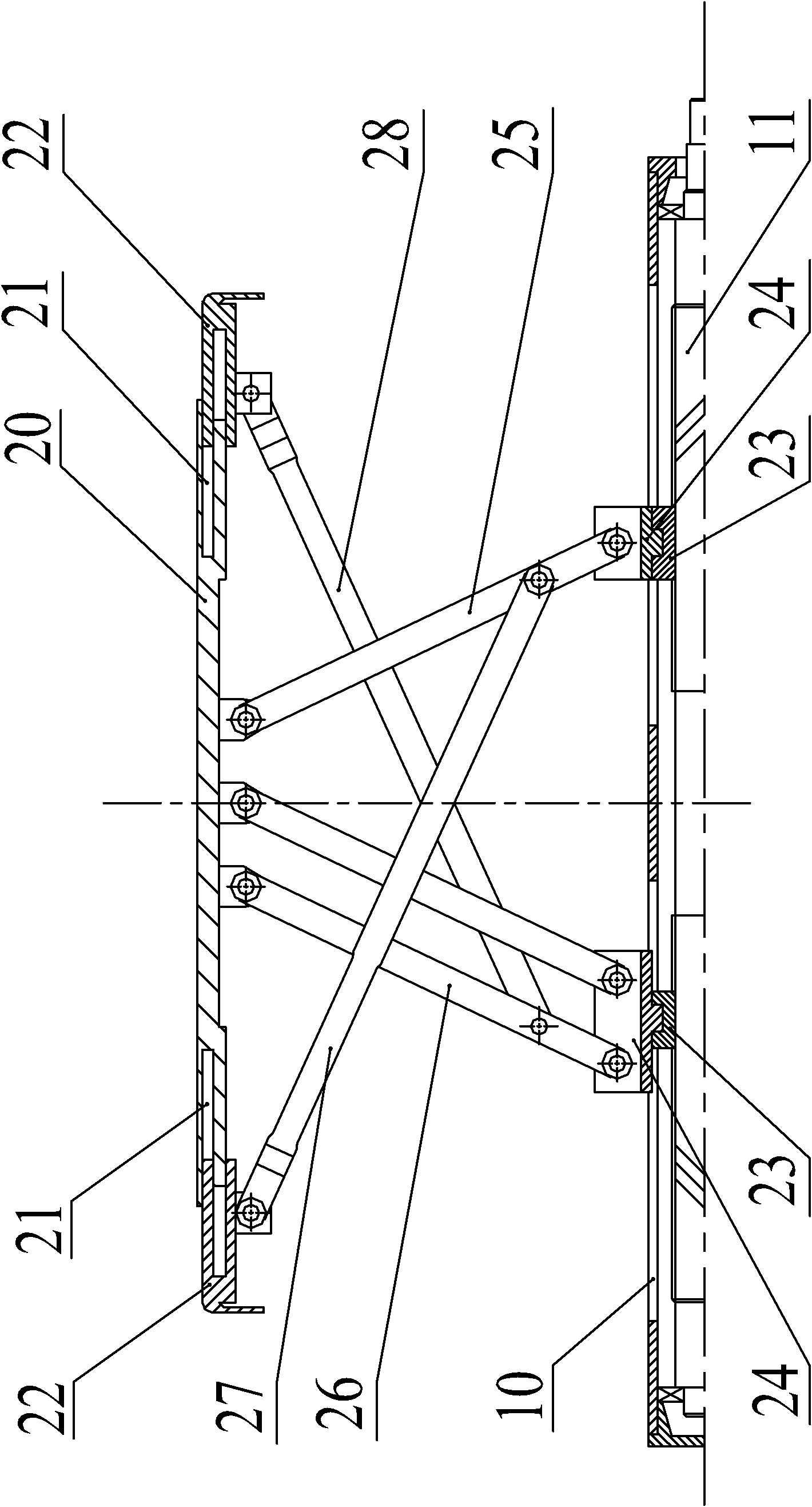

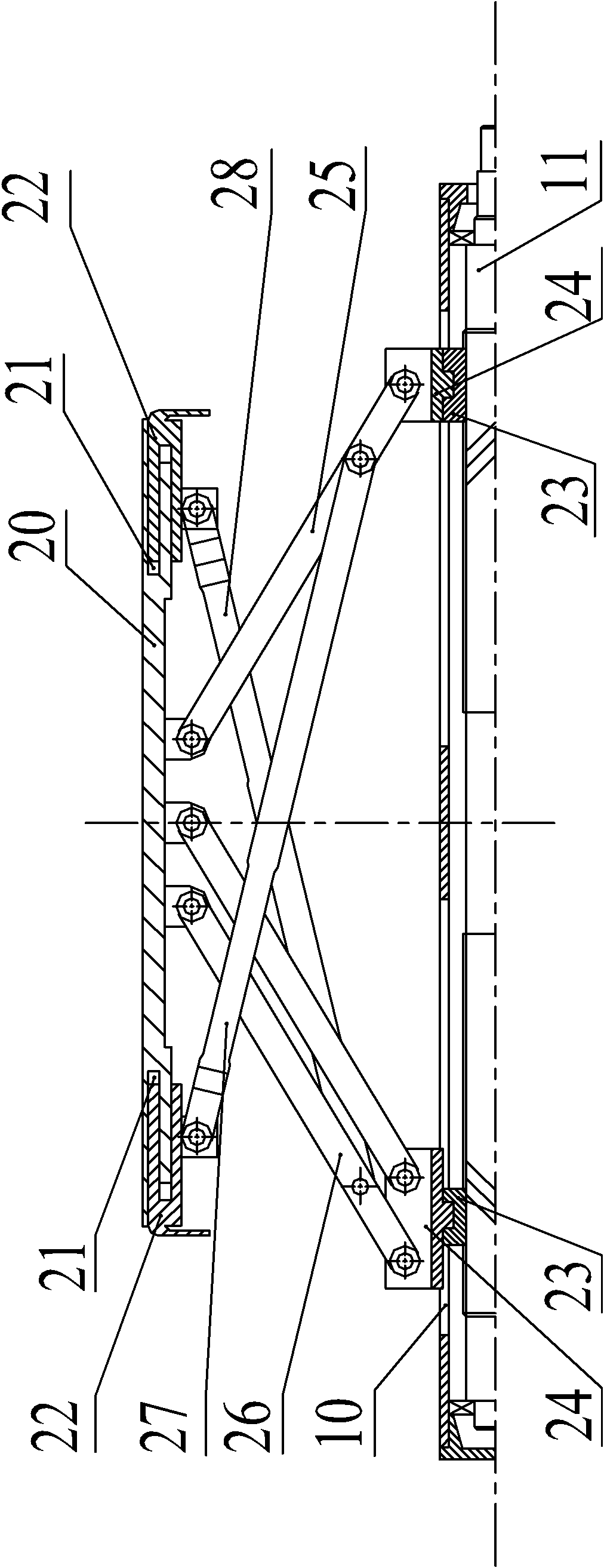

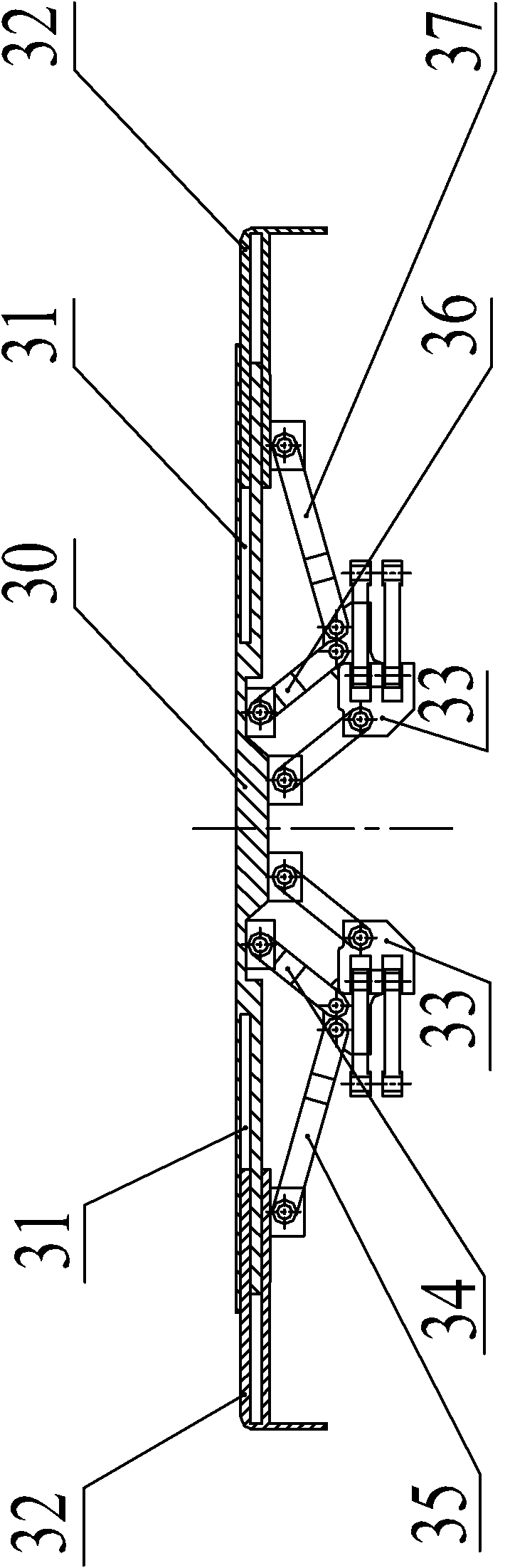

[0029] Such as Figure 7 and Figure 8 As shown, the axially and radially telescopic tire building drum of the present invention is composed of an inner tile 20 and an inner tile driving mechanism and an outer tile 30 and an outer tile driving mechanism.

[0030] Such as figure 1 As shown, the two axial ends of the inner tile 20 are provided with inner tile drum shoulders 22 that can move telescopically along the axial direction. 11. The two ends of the lead screw 11 are respectively provided with threads with the same pitch and opposite direction of rotation, and the hollow main shaft 10 is respectively provided with through grooves at positions aligned with the two sections of threads, and the two sections of threads are provided with Fitted with nuts 23 respectively, the two nuts 23 are respectively embedded in two through groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com