Wheel with suspension system

a technology of suspension system and wheel, which is applied in the direction of wheelchair/patient conveyance, transportation and packaging, ambulance service, etc., can solve the problems of uneven rotation of the wheel, different damping characteristics of compressing the damper, and the wheel may break, so as to increase the overall stability and/or strength of the entire construction, the effect of increasing the stroke length of the support member and the inner spring elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

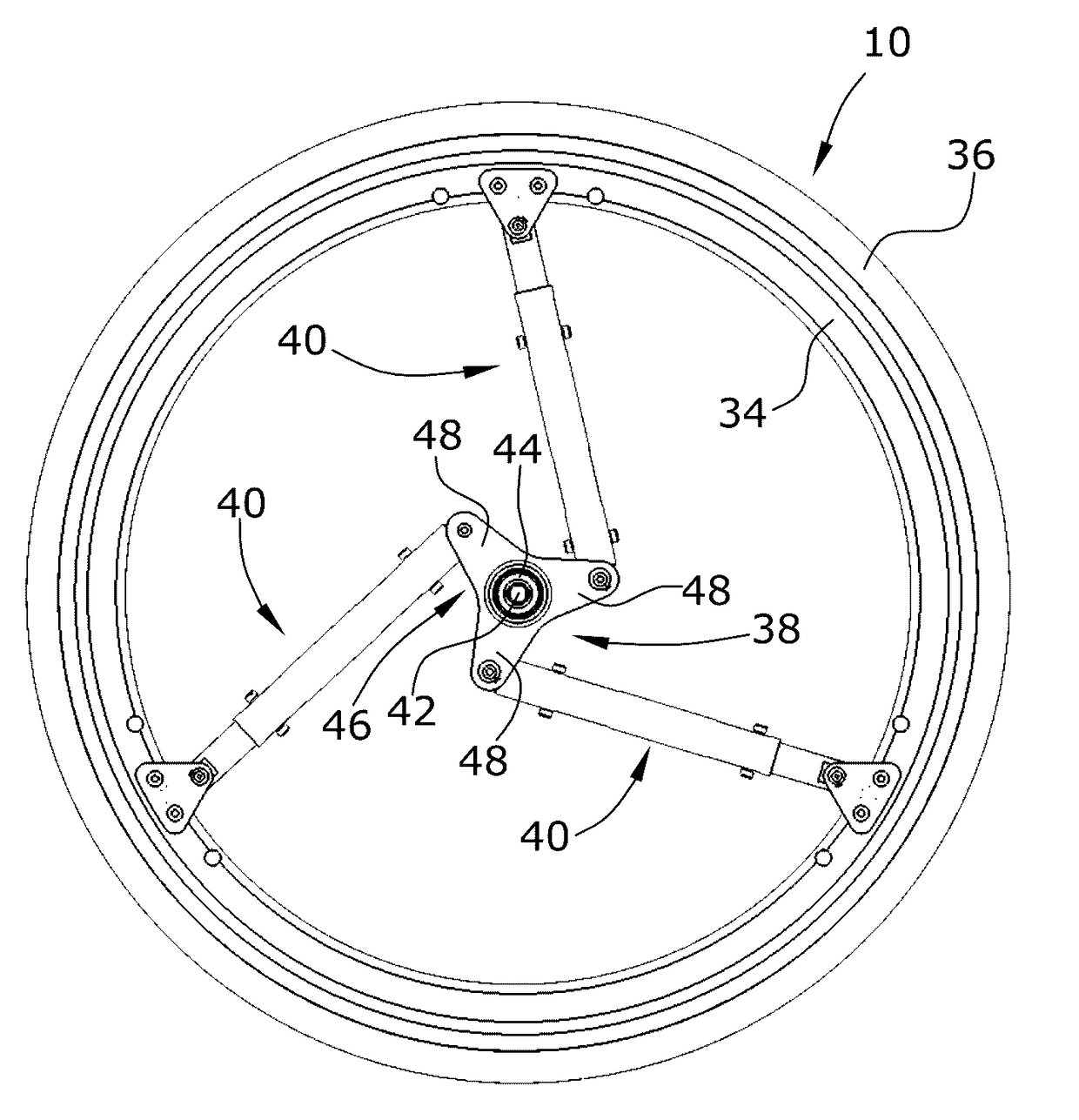

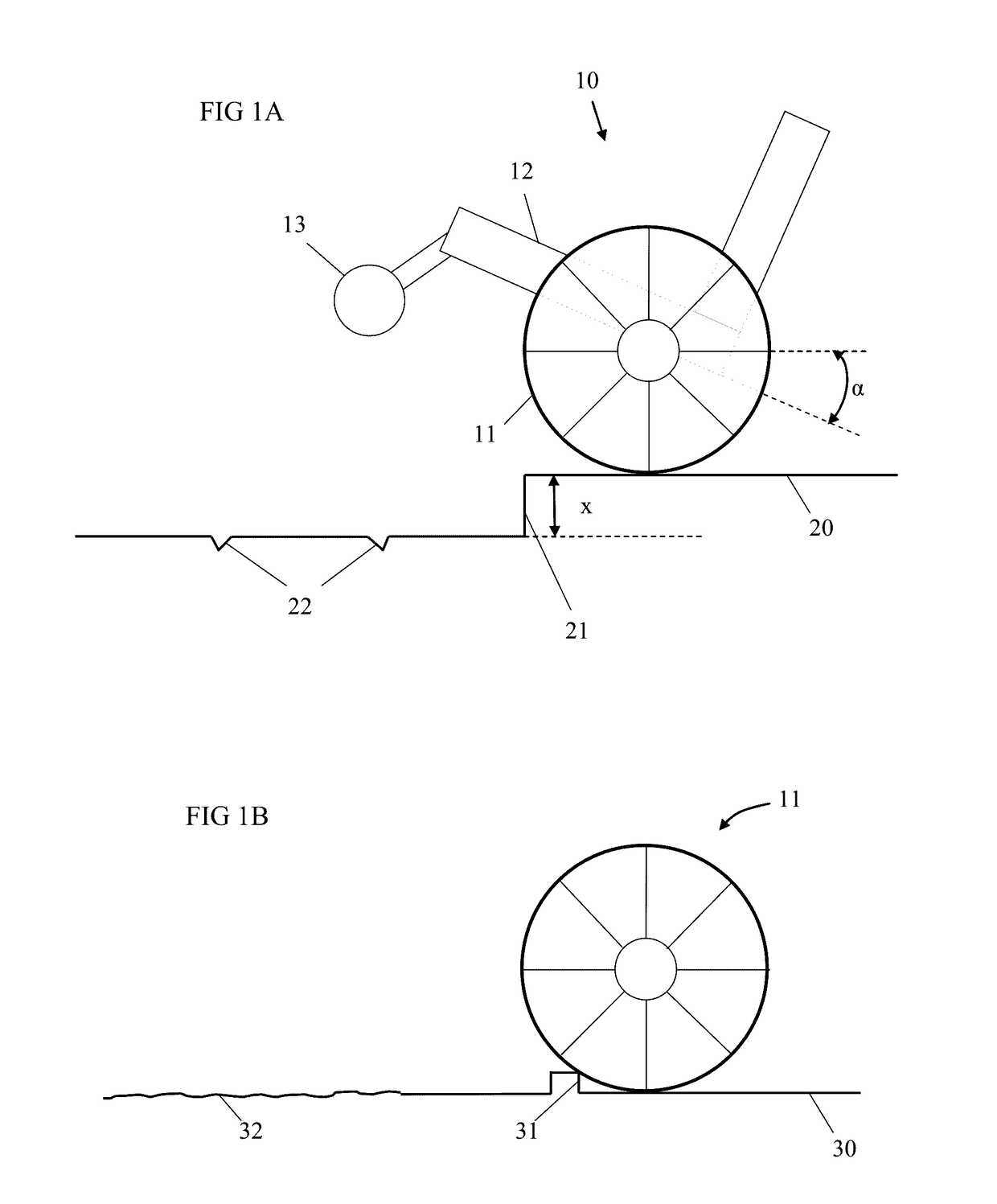

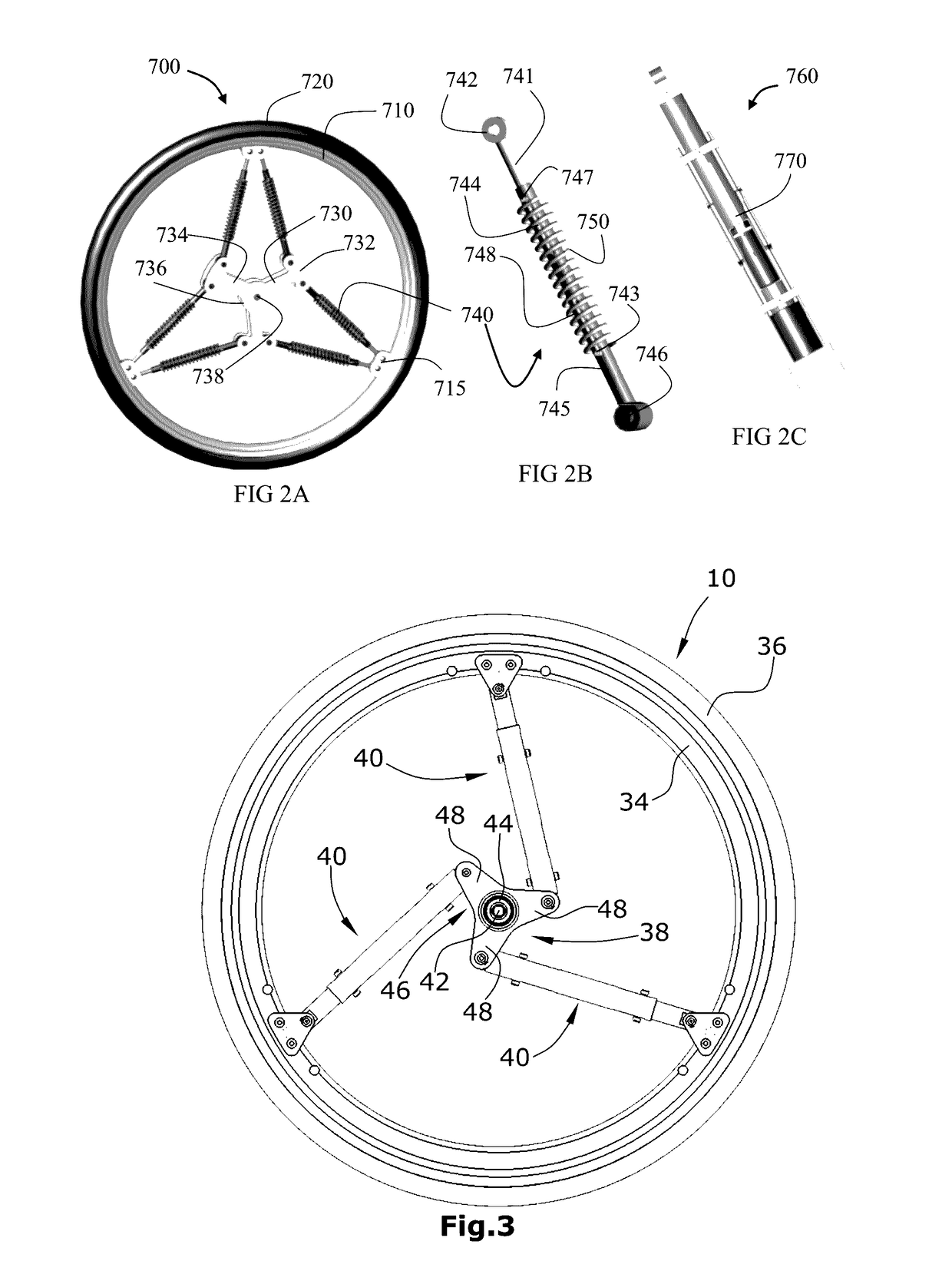

[0033]The following preferred embodiments may be described in the context of exemplary suspension mechanisms for wheelchairs, or other types of self-propelled vehicles, for ease of description and understanding. However, the invention is not limited to the specifically described devices, and may be adapted to various applications without departing from the overall scope of the invention. For example, devices including concepts described herein may be used for suspension of any rotatable mass including wheels of motorized or otherwise powered vehicles.

[0034]Common suspension systems are built to absorb interruptions and obstacles which cause deceleration and / or undesired vibration to the vehicle and / or aid the wheel in following the terrain and avoiding loss of contact with it, or grip. In doing so, the suspension systems are built to absorb and / or dissipate energy, including such that can be translated to effective kinetic energy. Furthermore, the common suspension systems (which in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com