Coaxial connector with a cable gripping feature

A connector and cable technology, applied in the direction of conductive connection, connection, connection/disconnection of connecting parts, etc., can solve the problems of difficult sealing, inability to fully clamp coaxial shielded cables, etc., to avoid bending and firmly fix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

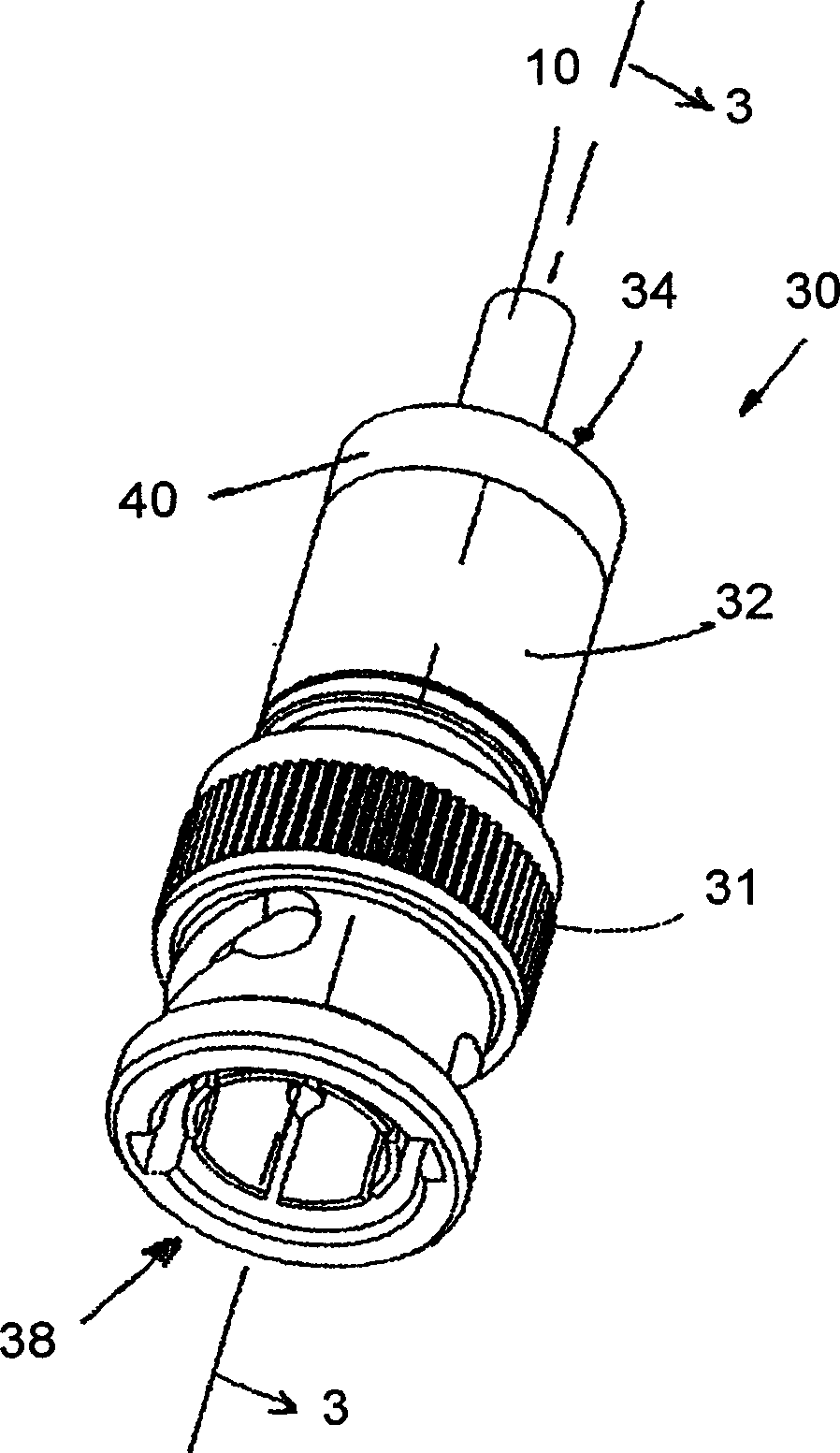

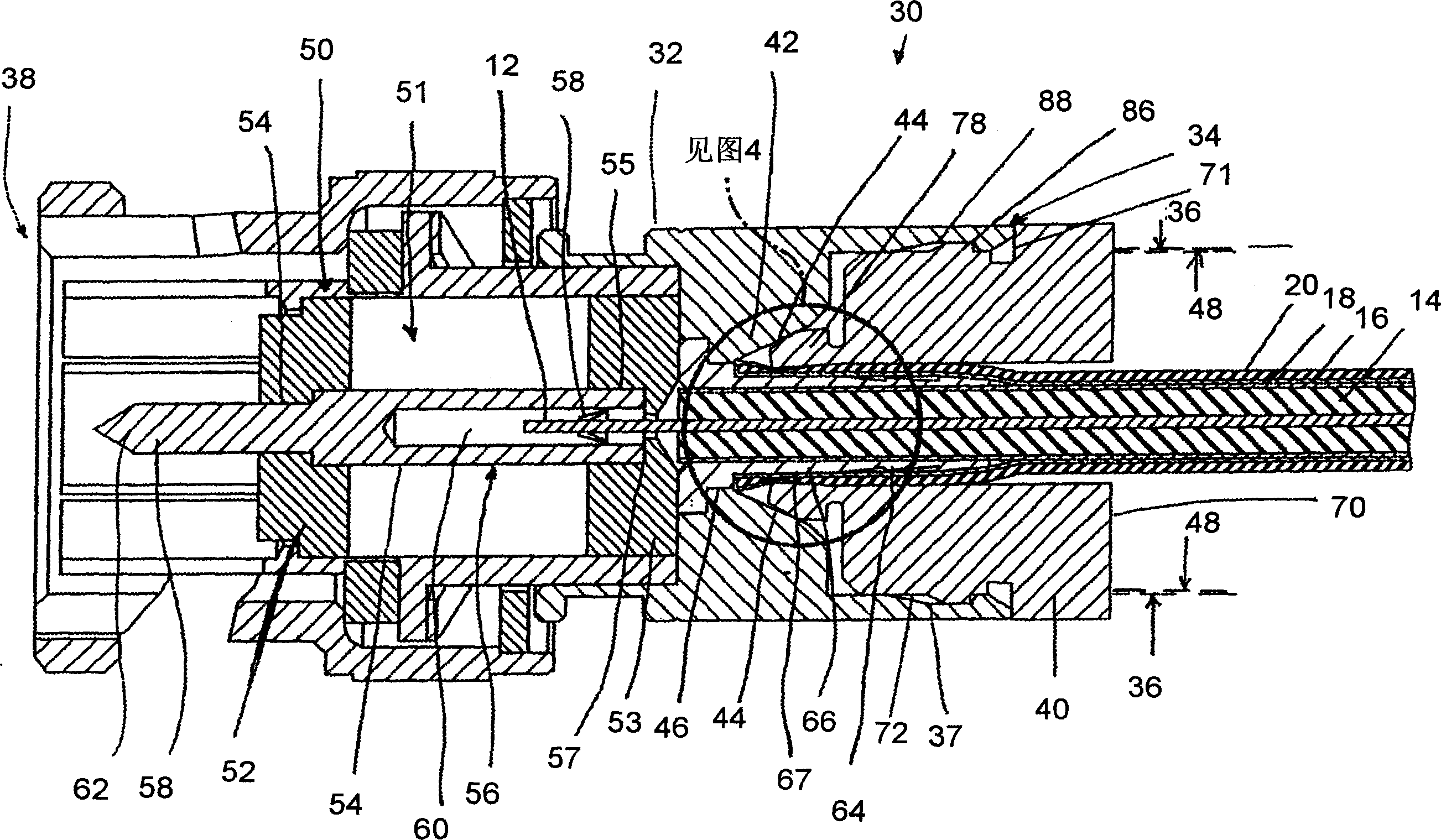

[0030] see figure 1 , which shows a coaxial connector 30 according to the present invention. Connector 30 has a housing 32 (sometimes referred to as a "connector body" or "sleeve") with a first end 34 and a sleeve 40 that receives a shielded coaxial cable. Located at the opposite end from the first end 34 is a second end 38 having a twistlock arrangement 31 for connecting the connector 30 with a desired mating arrangement (not shown). Connector 30 is shown as a fully assembled and compact structure. Housing 32 and sleeve 40 may have a cylindrical shape.

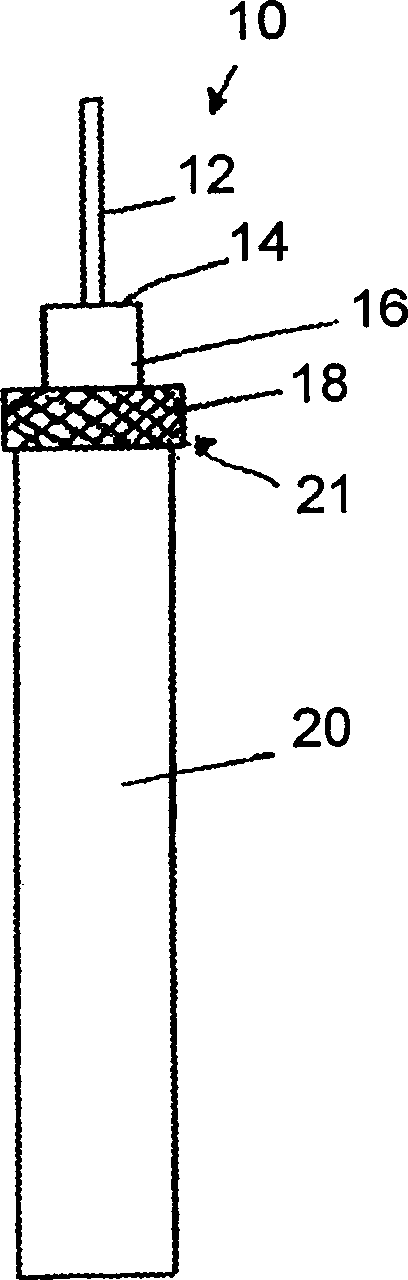

[0031] exist figure 1 and 3 A typical coaxial shielded cable 10 is shown in . The coaxial shielded cable 10 has a center conductor 12 surrounded by an insulating layer 14 . The insulating layer 14 is covered by a foil 16 and a metal braid 18 . The braid 18 is then covered by an outer layer 20, which may be plastic or other insulating material.

[0032] To prepare the shielded coaxial cable 10 for use with the connecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com