Method for manufacturing substrate of LED thin film chip and structure of substrate

A thin-film chip and substrate technology, which is applied in the field of preparation of LED thin-film chip substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

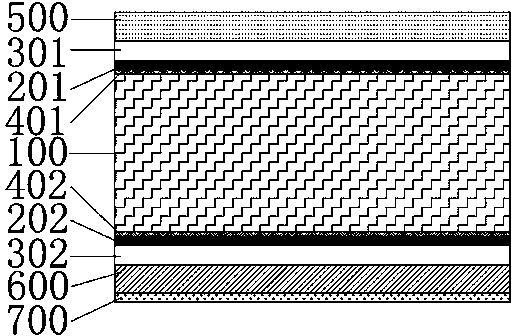

[0074] figure 1 and figure 2 ~7 describes the preparation method of a kind of LED thin film chip substrate of embodiment 1 of the present invention, and this preparation method comprises the following steps:

[0075] A, prepare a substrate support body 100, such as figure 2 shown, and its surface was cleaned; in this embodiment, a Si wafer with good thermal and electrical conductivity was selected as the substrate support, and its thickness was 250 μm.

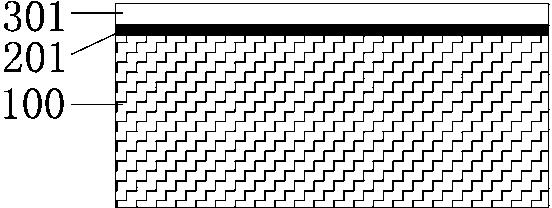

[0076] B. Forming the first alloy preparation layer 201 and the first substrate protection layer 301 sequentially on the front surface of the substrate support 100 by means of electron beam evaporation or sputtering, as shown in FIG. 3 ;

[0077] C. Forming a second alloy preparation layer 202 and a second substrate protection layer 302 sequentially on the reverse side of the substrate support 100, as shown in FIG. 4 ;

[0078] The materials of the second alloy preparation layer 201 and the second alloy preparation layer...

Embodiment 2

[0109] The difference from Embodiment 1 is that in Embodiment 2, the first substrate protection layer 301 and the second substrate protection layer 302 are respectively formed on the front surface of the substrate support 100 after the alloying process is completed. and the opposite side, while the structure of a LED thin film chip substrate obtained in Example 2 is exactly the same as that in Example 1.

[0110] A kind of preparation method of LED thin film chip substrate provided in embodiment 2, comprises the following steps:

[0111] A. Provide a substrate support body 100 with a clean surface;

[0112] B. A first alloy preparation layer 201 is sequentially formed on the front surface of the substrate support, and a second alloy preparation layer 202 is sequentially formed on the reverse surface of the substrate support, as shown in FIG. 8 ;

[0113] C. Carry out alloying, make the first alloy preparation layer 201, the second alloy preparation layer 201 and the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com