Thermal processing apparatus

A technology of heat treatment device and heater, which is applied in the direction of post-processing device, post-processing, post-processing details, etc., can solve the problems of increasing the manufacturing cost of the vacuum insulation layer forming body, and achieve the effect of improving the bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

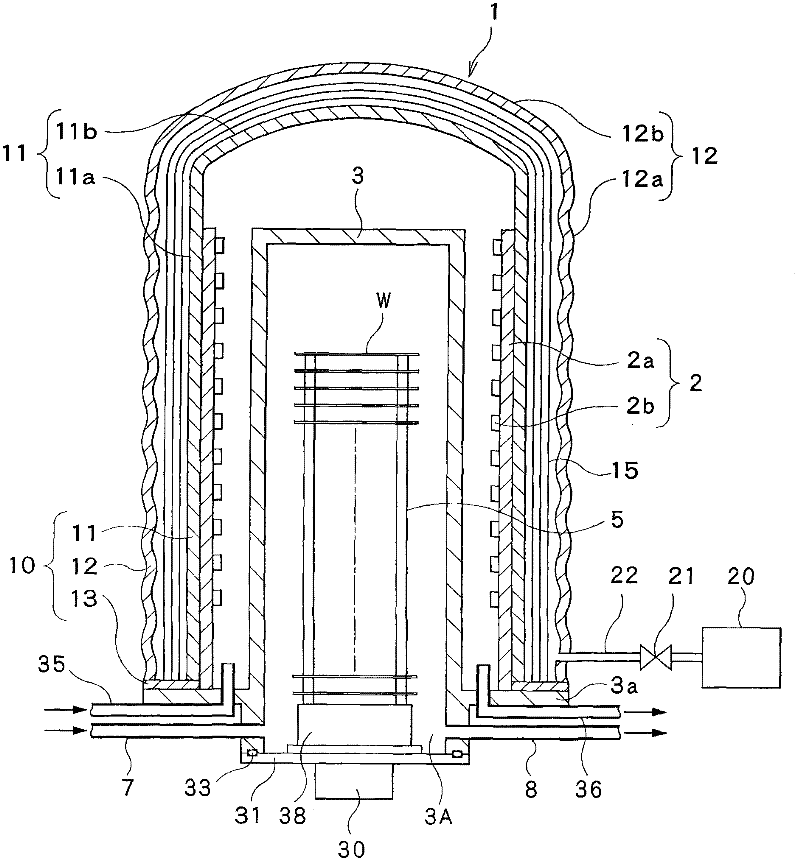

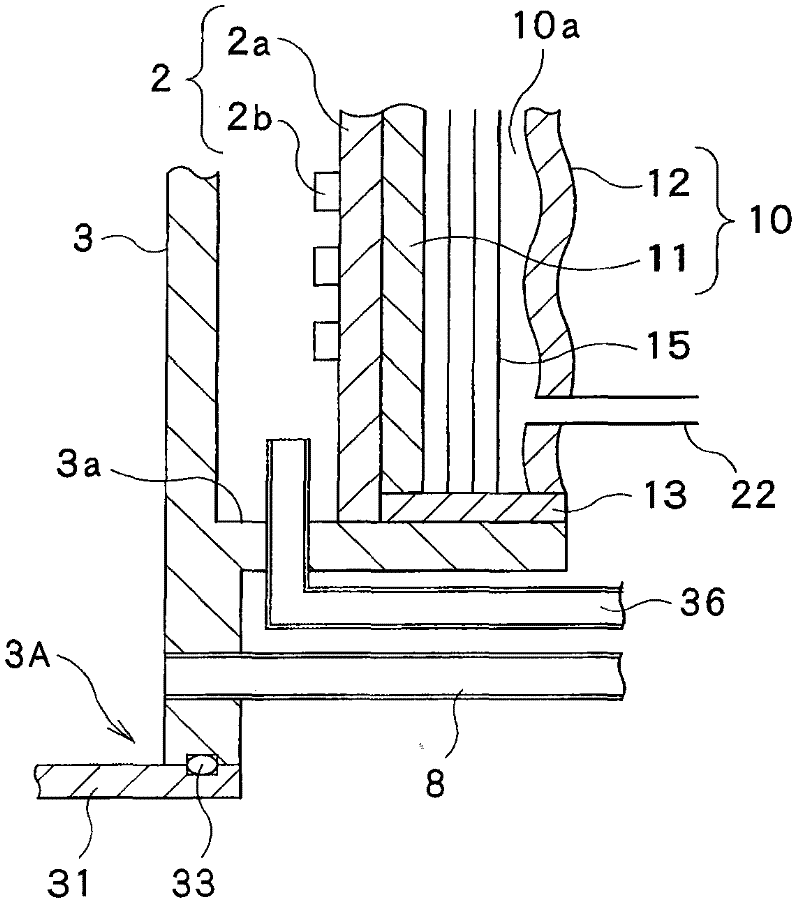

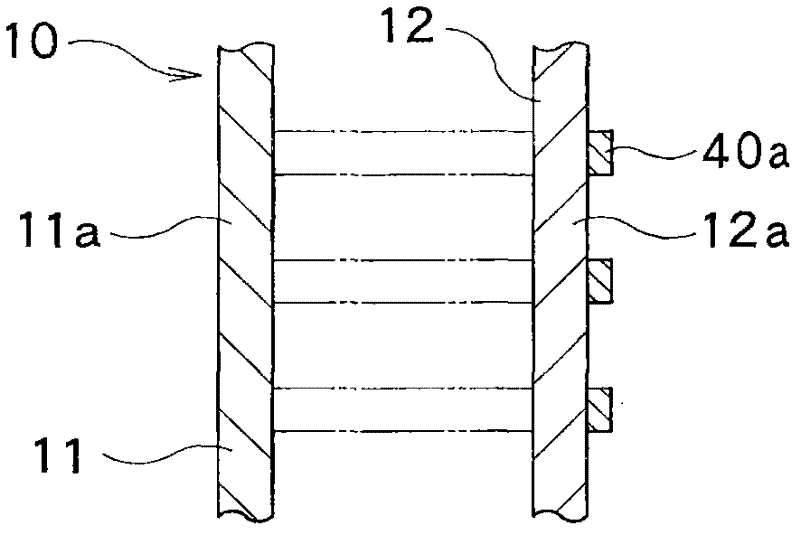

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings. here, figure 1 is a schematic cross-sectional view showing one embodiment of the heat treatment apparatus according to the present invention. figure 2 Yes figure 1 magnified view of .

[0026] like figure 1 As shown, the heat treatment apparatus of the present invention is composed of a vertical heat treatment apparatus 1, which includes: a cylindrical reaction tube 3 with an upper surface and a side surface integrally formed and an opening on the lower surface; a wafer W is loaded and accommodated in a The boat 5 in the reaction tube 3, the heater 2 surrounding the reaction tube 3 and used to heat the inside of the reaction tube 3, and the outer periphery of the heater 2 to cover the periphery and the upper surface of the reaction tube 3 The vacuum heat insulating layer forming body 10 is arranged so as to surround the side surface of the reaction tube 3 .

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com