Atomization unit and atomization device

An atomization device and heating sheet technology, applied in the field of atomization, can solve the problems of dry burning of harmful substances, slow start of heat, uneven frame parts, etc., to achieve the effect of expanding the range of material selection, ensuring sufficient contact, and avoiding extrusion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

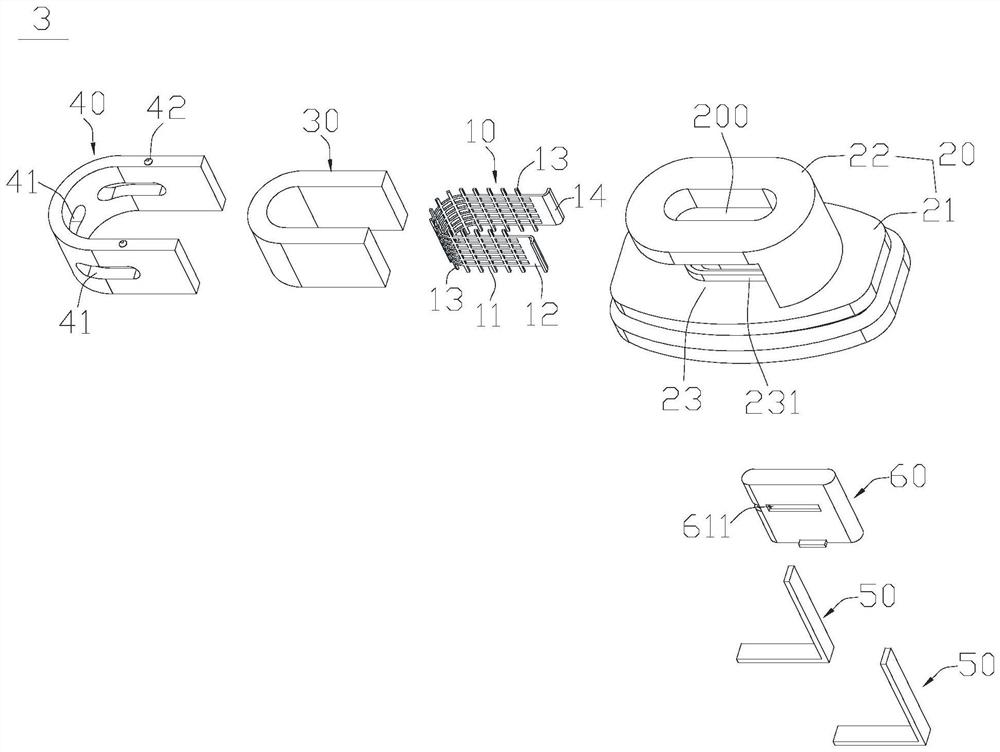

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

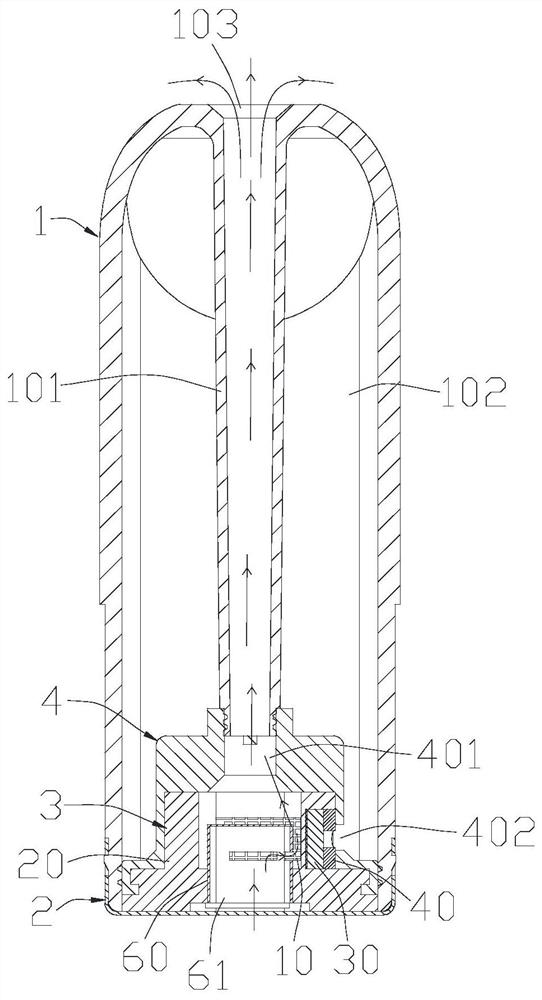

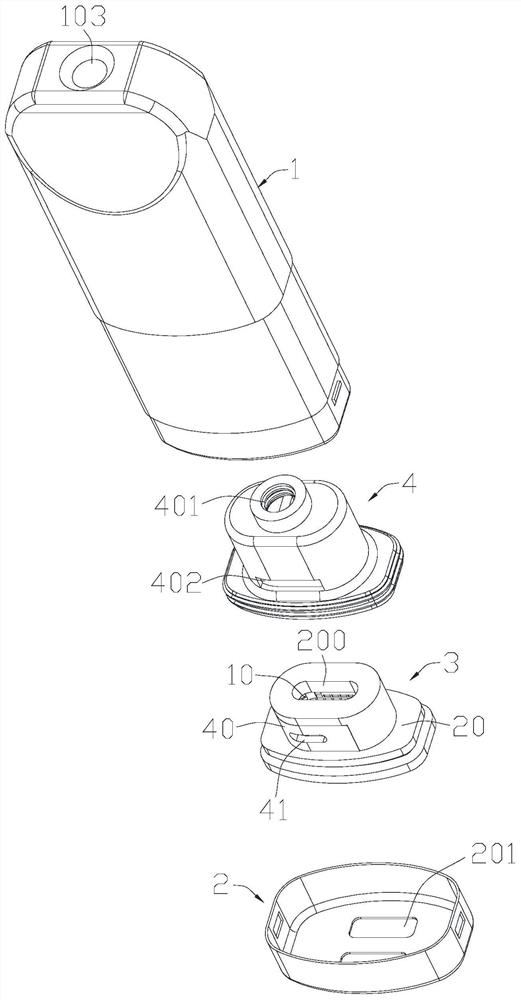

[0040] Such as figure 1 , 2 As shown, an atomizing device according to an embodiment of the present invention includes a housing 1 , a bottom shell 2 and an atomizing unit 3 .

[0041] The housing 1 is a hollow cylindrical structure and may include a first end and a second end opposite to each other. The housing 1 is provided with an isolated air duct 101 and a liquid storage tank 102. The air duct 101 is located in the middle of the housing 1 and extends along the length of the housing 1. The inner channel of the air duct 101 is an air duct. The liquid storage chamber 102 surrounds the outer periphery of the air duct 101 and is used for storing e-liquid. The first end of the shell 1 is provided with an air outlet 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com