Near-isothermal forging method of TC17 biphase titanium alloy disc forge piece

A disc-shaped forging and isothermal forging technology, applied in the field of warm forging, can solve the problem of not giving the metallographic diagram of the mesh blue structure, and achieve the effects of uniform size, suitable size and sufficient recrystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] α+β type two-phase titanium alloy, such as:

[0024] The titanium alloy whose Chinese material grade is TC17, its main chemical element content (percentage by weight) is: Al content 4.50% ~ 5.50%, Sn content 1.60% ~ 2.40%, Zr content 1.60% ~ 2.40%, Mo content 3.50%~4.50%, Cr content 3.50%~4.50%, Fe content ≤0.30%, C content ≤0.05%, N content ≤0.05%, H content ≤0.0125%, O content ≤0.13%, The balance is Ti.

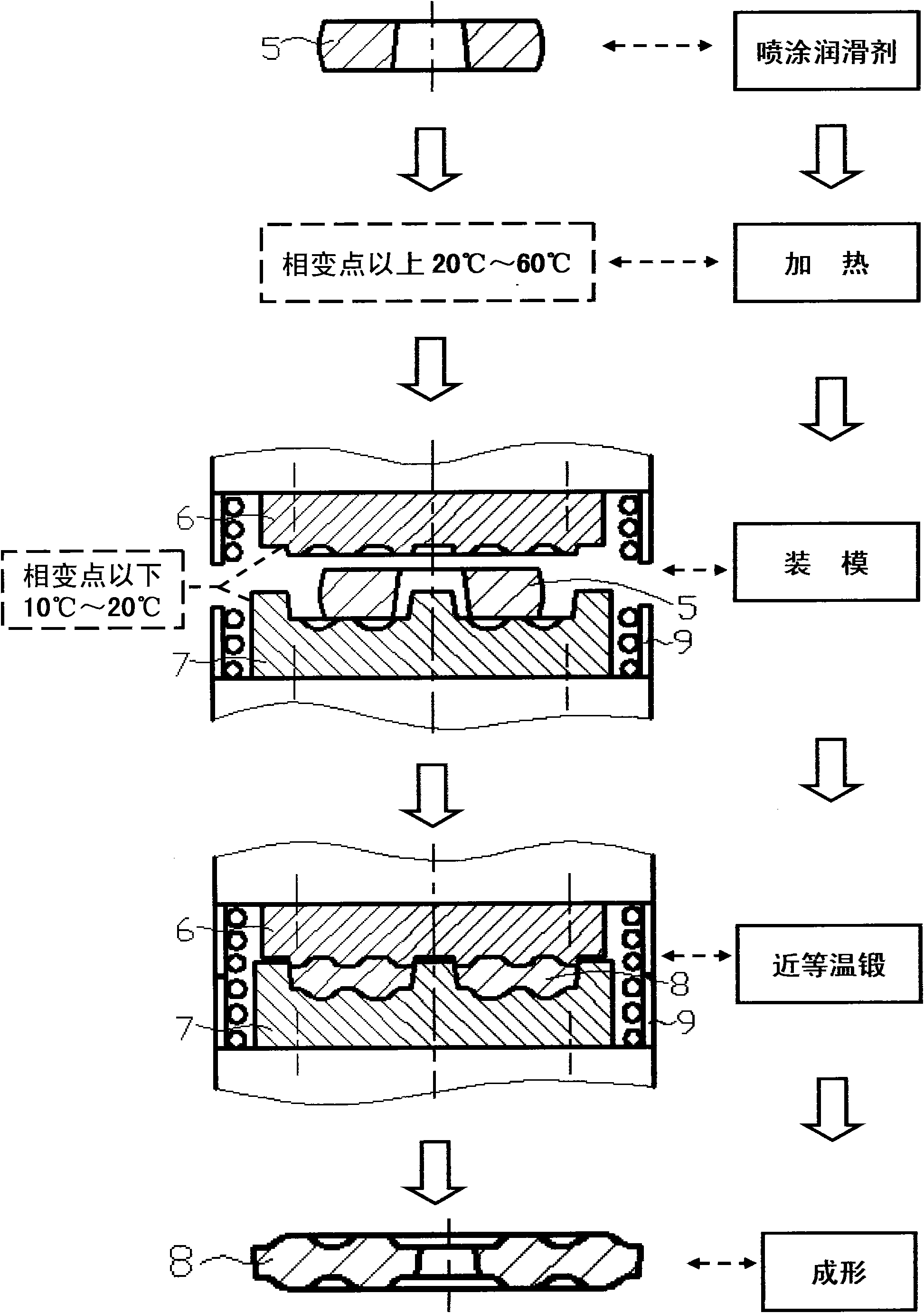

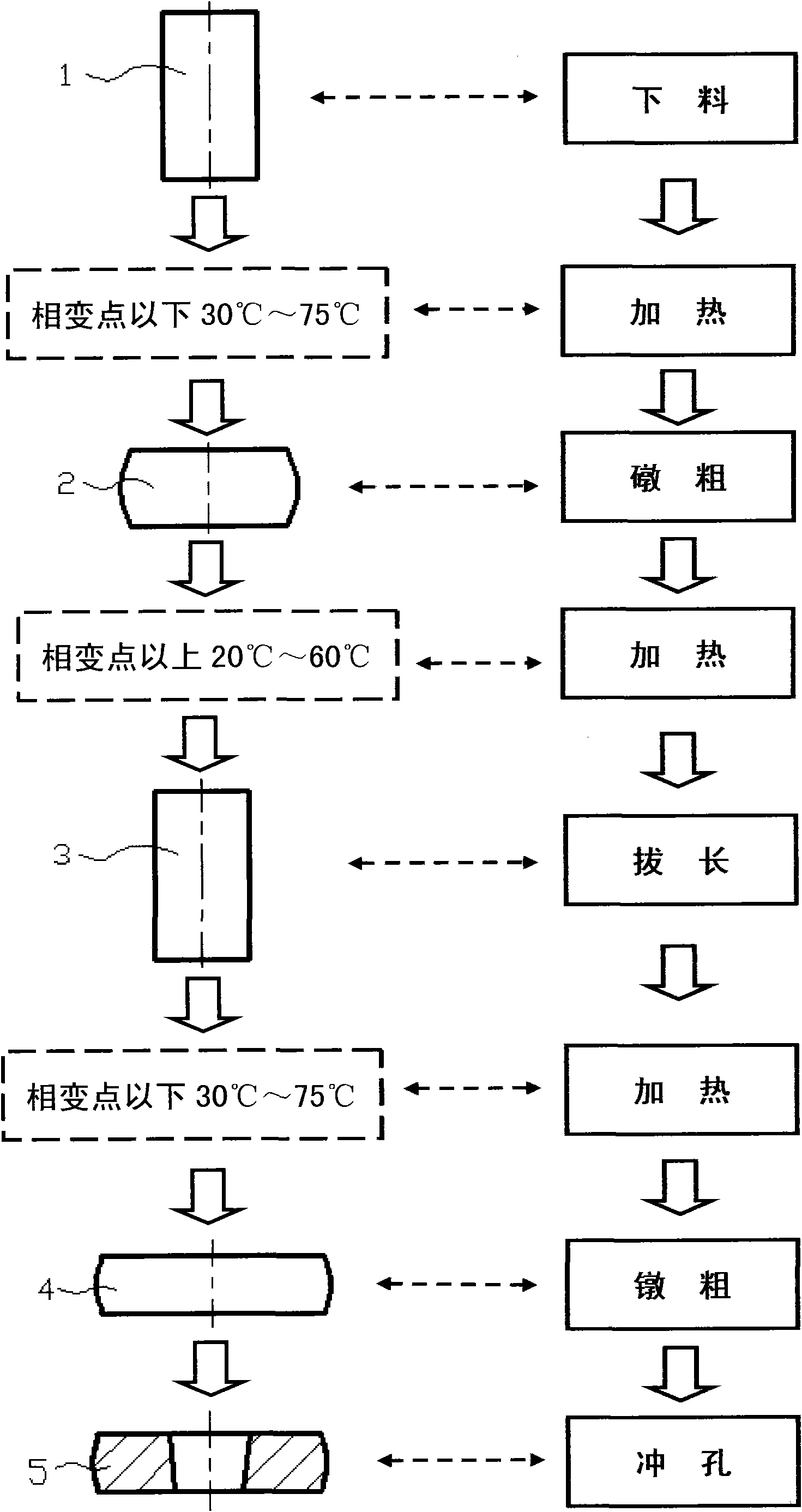

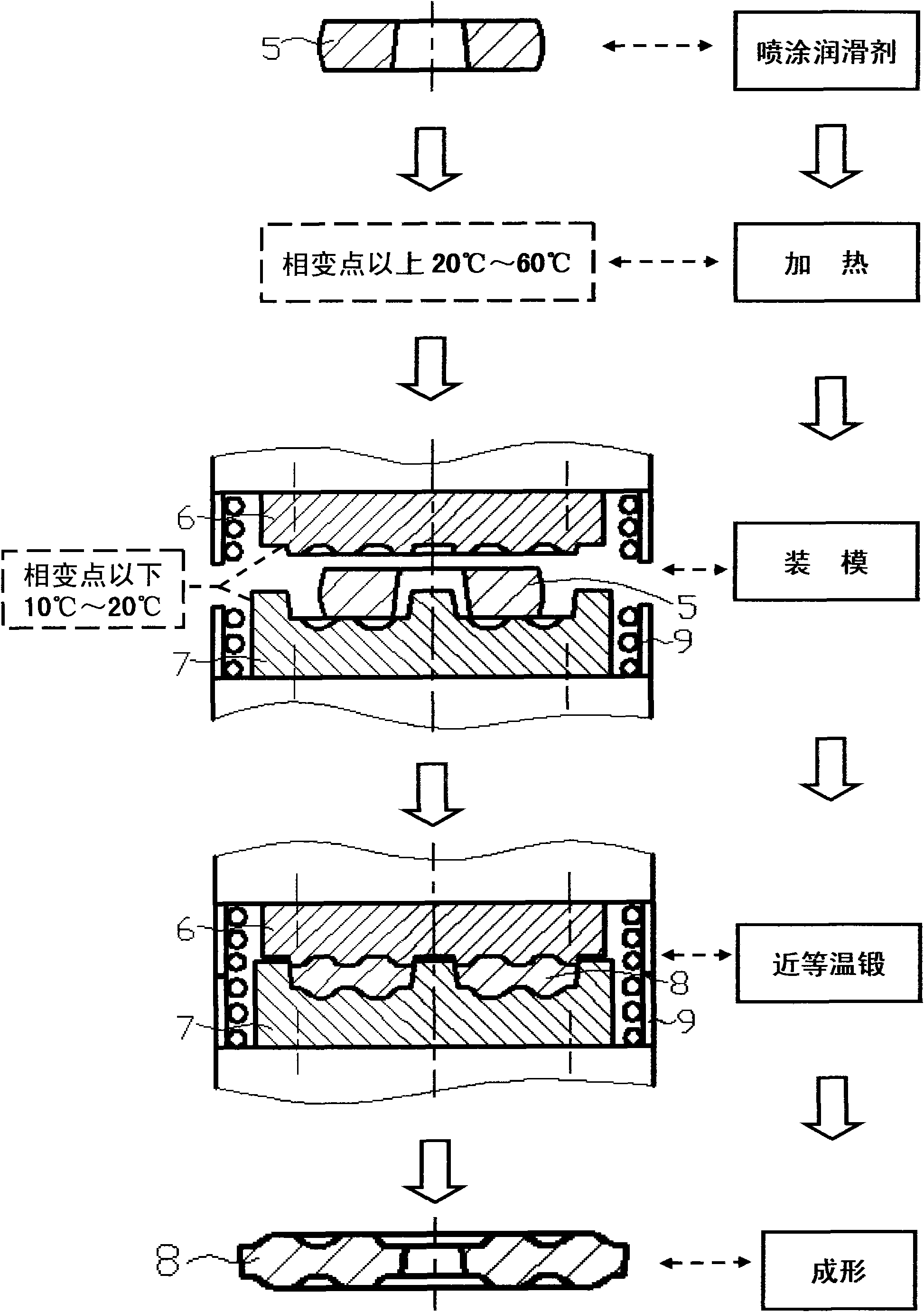

[0025] The process steps of the near-isothermal forging method for TC17 two-phase titanium alloy are given below:

[0026] Step 1: As shown in Figure 1, the TC17 titanium alloy round bar is cut according to the forging specification into a primary ingot 1, and then the primary ingot 1 is placed in a forging heating furnace and heated to 30°C below the phase transition point of the titanium alloy ~75°C, then heat preservation, the heat preservation time is calculated according to the thickness of the rod ingot 0.8 ~ 1min / mm.

[0027] Step 2: Take the primary ingot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com