Plate type ballastless track bed with reverse pressure device

A slab and track bed technology, applied in the field of rail transit, can solve the problems of strong vibration and radiated noise of the track structure, the overall decline of the slab ballastless track, and affecting the comfort of vehicles, so as to improve the effect of vibration reduction and noise reduction, and improve the comfort. and safety, the effect of improving integrity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

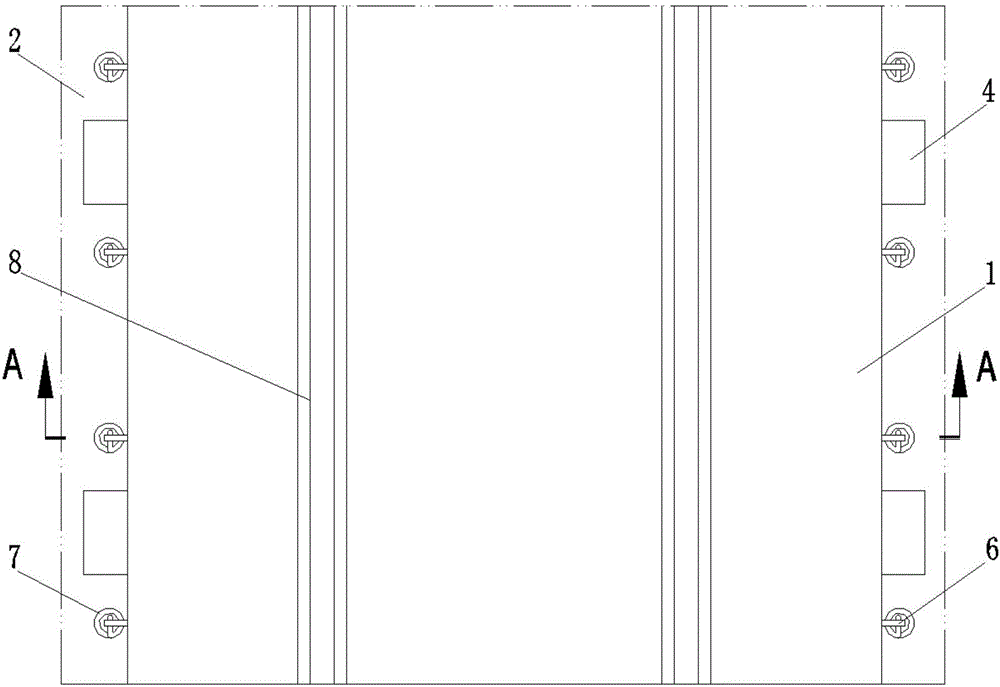

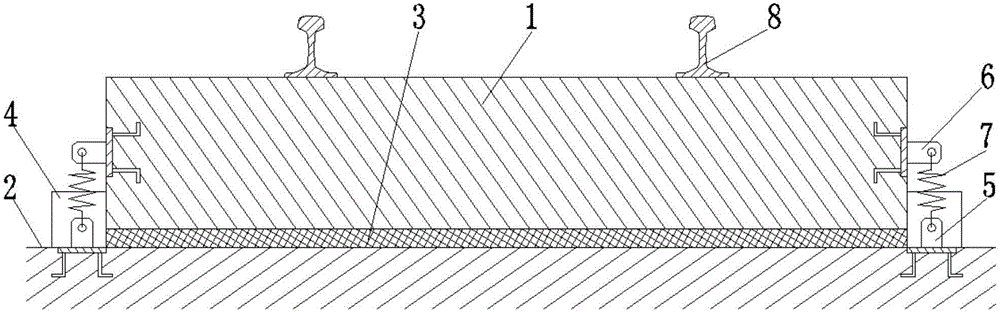

[0025] like figure 1 , figure 2 As shown, the plate-type ballastless ballast bed with back pressure device of the present invention includes a base 2, a track plate 1 is placed above the base 2, an under-slab filling layer 3 is provided between the track plate 1 and the base 2, and the under-slab filling layer 3 It is specifically composed of CA mortar material, and a limit structure 4 is also provided between the track plate 1 and the base 2, and the limit structure 4 is specifically a boss 12 integrated with the base 2; in addition, it also includes a counter pressure device, the counter The pressure device includes a back pressure elastic element 7, a connector 6 and an anchor 5. Specifically, the back pressure elastic element 7 is a tension-type helical steel spring, and both the connector 6 and the anchor 5 are ears with hook holes. plate, wherein the anchor piece 5 is fixedly arranged on the base 2 , the connecting piece 6 is fixedly arranged in the track plate 1 , and...

Embodiment 2

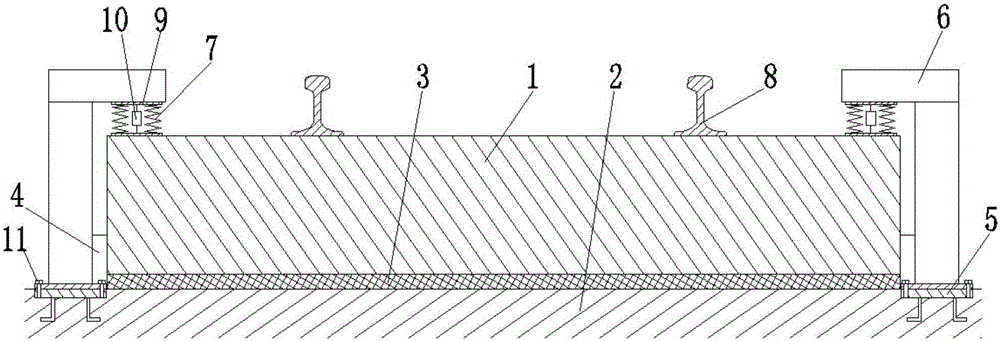

[0032] like image 3 The difference between the plate type ballastless ballast bed with a back pressure device shown in Embodiment 1 is that in the back pressure device of this example, the connecting piece 6 is specifically a bracket with a connecting flange, which consists of a connecting flange and a groove Correspondingly, the anchor piece 5 is a connecting flange fixed on the base 2 by using anchor ribs, and the connecting piece 6 and the anchor piece 5 are fixedly connected together by a fastener 11; in addition, the back pressure device The anti-pressure elastic element 7 includes a plurality of compressed helical steel springs. One end of the anti-pressure elastic element 7 acts on the track plate 1, and the other end acts on the connecting piece 6. The connecting piece 6 is connected to the base 2 through the anchor piece 5. Among them, in order to ensure that the multiple helical steel springs are evenly stressed, a pressure equalizing plate 9 is also provided in the...

Embodiment 3

[0037] like Figure 4 The plate type ballastless ballast bed with a back pressure device shown differs from the second embodiment in that a boss 12 is provided on the track plate 1; the back pressure elastic element 7 in the back pressure device consists of a single compression type Composed of spiral steel springs, one end of the back pressure elastic element 7 acts on the track plate 1, and the other end acts on the connecting piece 6, and the connecting piece 6 is connected to the base 2 through the anchor piece 5; in addition, the filling layer 3 under the plate is made of elastic polyurethane material The manufactured elastic damping pad is composed of no bonding between the under-board filling layer 3 and the track plate 1 .

[0038] Compared with Embodiment 2, the advantage of the technical solution described in this example is that, by setting the boss 12 on the track plate 1, the back pressure device is arranged at the boss 12, which does not occupy the limited space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com