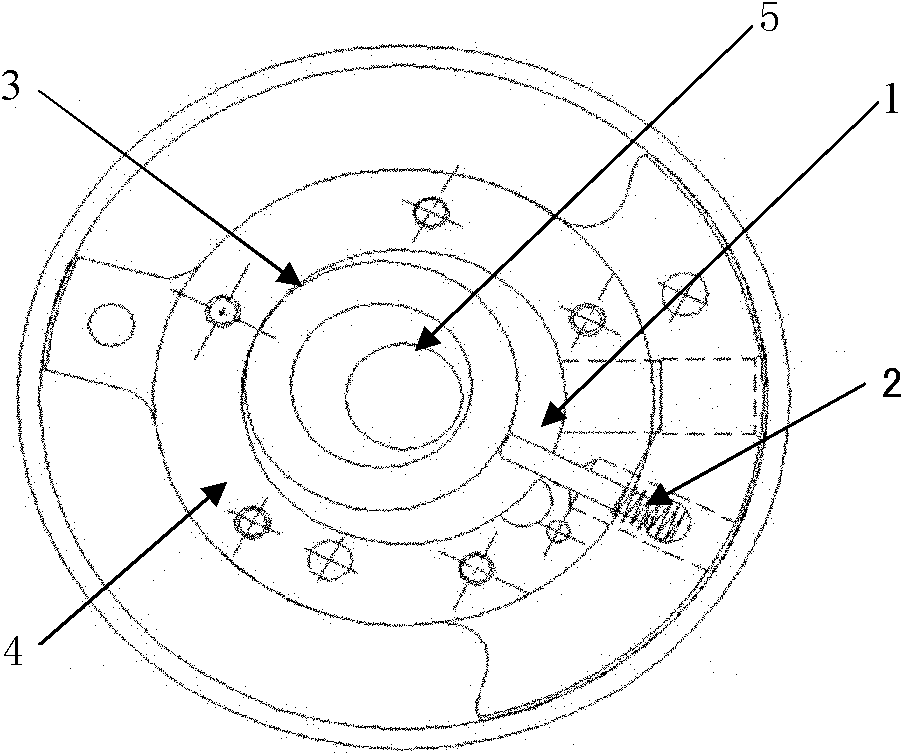

Slide block for rotary type compressor and manufacturing method thereof

A technology of a rotary compressor and a manufacturing method, which is applied in the field of compressors, can solve problems such as high raw material costs and complex manufacturing processes, and achieve the effects of reducing raw material costs, simple manufacturing processes, and low content of alloy elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) In this embodiment, the steel material with the chemical composition of GCr15 bearing steel is selected, which contains the following chemical compositions in terms of mass percentage: C: 0.95-1.05%, Si: 0.15-0.35%, Mn: 0.25-0.45%, Cr: 1.40-1.65 %, S: ≤0.025%, P: ≤0.025%, Ni: ≤0.30%, Mo: ≤0.10%, the balance is Fe and impurities that normally appear

[0037] (2) Carry out spheroidizing annealing treatment on the raw material before cold rolling, the annealing furnace temperature is 770±5°C, keep warm for 3hr, then slowly cool down to below 650°C with the furnace and leave the furnace for air cooling.

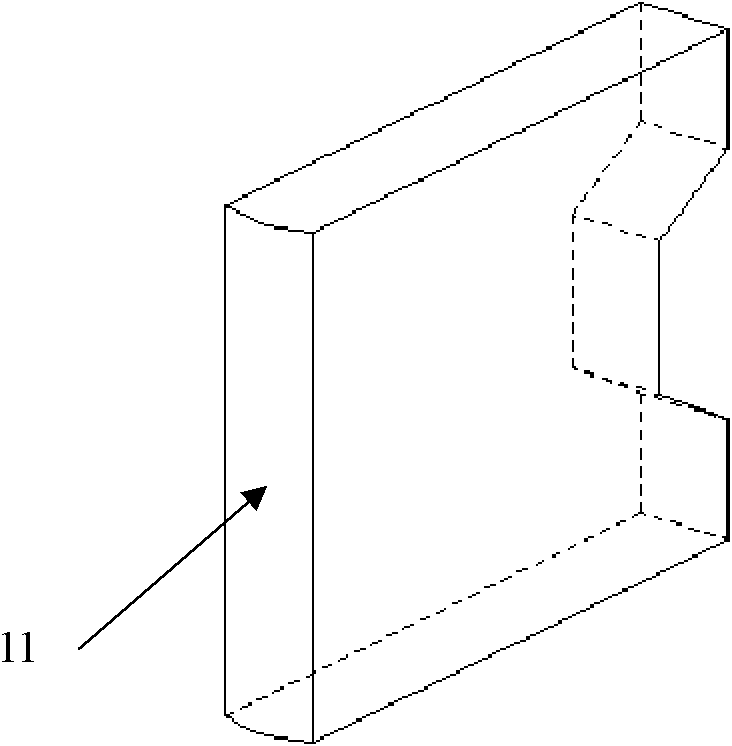

[0038] (3) Cold rolling is carried out according to the required precision of the slider width and height to obtain a flat plate;

[0039] (4) Cut the flat plate according to the length of the slider, and mill out the groove of the slider;

[0040] (5) Quenching, deep cooling and tempering are carried out sequentially on the cut slider.

[0041] ①Quenching treatment:...

Embodiment 2

[0057] (1) In this embodiment, the steel material with the chemical composition of GCr15SiMn bearing steel is selected, which contains the following chemical compositions in terms of mass percentage: C: 0.95-1.05%, Si: 0.45-0.75%, Mn: 0.95-1.25%, Cr: 1.40- 1.65%, S: ≤0.025%, P: ≤0.025%, Ni: ≤0.30%, Mo: ≤0.10%, and the balance is Fe and normally occurring impurities.

[0058] Steps (2)-(7) are the same as in Example 1, and a qualified slider for rotary compressors is obtained, which meets the current requirements for use of sliders for rotary compressors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com