Method for gluing quantum dot film and quantum dot films

A technology of colloidal quantum dots and quantum dots, applied in the field of quantum dots, can solve the problems of affecting the performance of quantum dots, many by-products, etc., and achieve the effects of short time consumption, low condition requirements, and expansion of the scope of application and material selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

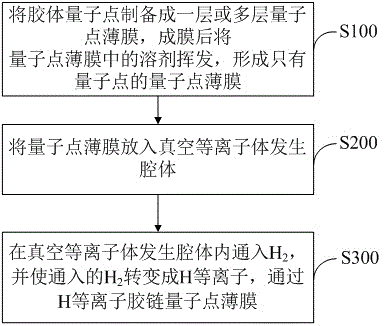

Method used

Image

Examples

Embodiment 1

[0038] A 10mg / ml quantum dot solution QD1 was prepared and spin-coated on a glass substrate in a nitrogen atmosphere. The spin-coating condition is 6000rpm, 60s, and a quantum dot film of about 10nm is formed. Transport the quantum dot film into the HHIC vacuum plasma generation chamber, and pump it to 1.5*10 -3 Under the working pressure of Torr, hydrogen gas of 20SCCM is introduced, the electron acceleration voltage is -100V, and the hysteresis voltage is +100V to -50V, and the sample is taken out after 40s of reaction. Once the sample is glued, it cannot be wiped off with the same solvent.

Embodiment 2

[0040]Prepare 30mg / ml quantum dot solution QD2, and use the same solvent as solution QD1. Spin-coat on the sample of QD1 above in a nitrogen atmosphere. The spin coating condition is 3000rpm for 60s to form a quantum dot film. Transport the quantum dot film into the HHIC vacuum plasma generation chamber, and pump it to 1.5*10 -2 Under the working pressure of Torr, hydrogen gas of 20SCCM is introduced, the electron acceleration voltage is -100V, and the hysteresis voltage is +100V to -50V, and the sample is taken out after 160s of reaction. The total thickness of the sample is 50nm. Cannot be cleaned with the same solvents.

Embodiment 3

[0042] Prepare quantum dot solutions: 40mg / ml quantum dot solution QD1 and 60mg / ml quantum dot solution QD2. Spin-coat on glass substrates under nitrogen atmosphere. The spin-coating condition is 2000rpm, 60s, and a 120nm quantum dot film is formed. Transport the quantum dot film into the HHIC vacuum plasma generation chamber, and pump it to 1.5*10 -1 Under the working pressure of Torr, 55 SCCM of hydrogen gas is introduced, the electron acceleration voltage is -100V, and the hysteresis voltage is from +100V to -50V, the sample is taken out after 400s of reaction. After the sample is glued, it cannot be cleaned by the same solvent.

[0043] In summary, the method and quantum dot film of a kind of adhesive chain quantum dot film provided by the present invention, the present invention adopts HHIC adhesive chain quantum dot film, and improves its technology, makes quantum dot film have better solvent resistance and The effect of mechanical force. The method for the HHIC adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com