Integrated sealing elastic keyboard pad

A sealing elastic and integrated technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of resource waste, cumbersome operation, high material cost, etc., achieve the effect of simplifying the manufacturing process, overcoming the large number, and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

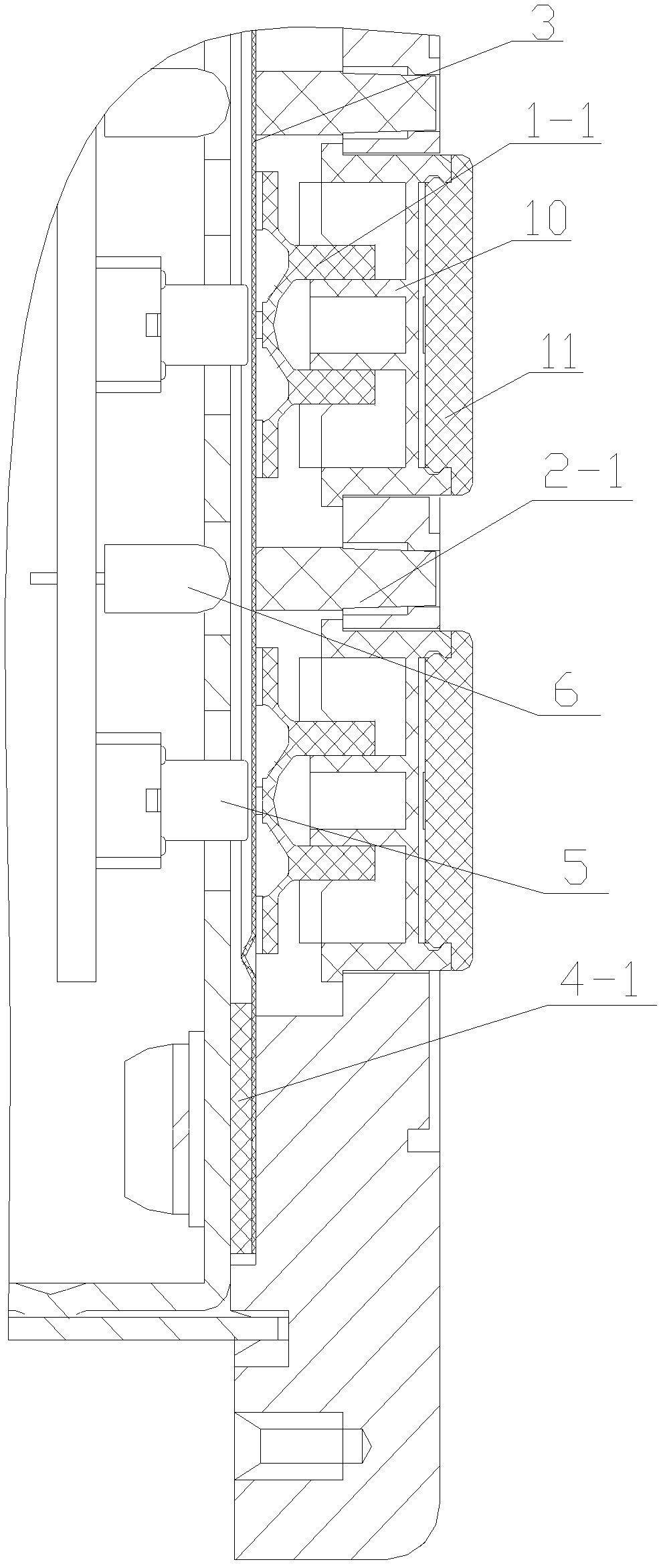

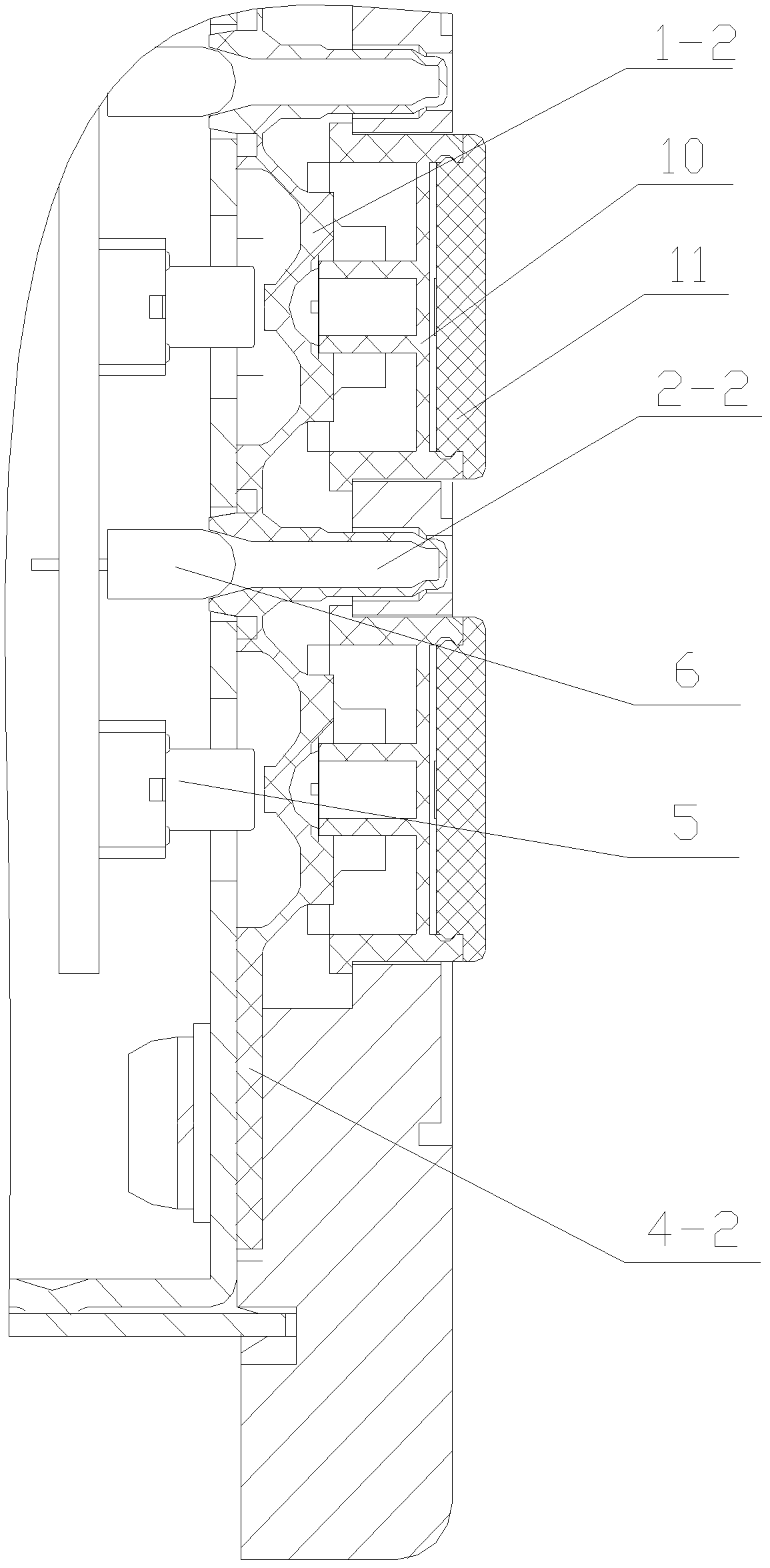

[0026] This embodiment is a kind of one-piece sealed elastic keyboard pad, its structure is as follows: figure 2 As shown, it includes a plurality of keypads 1-2 and a plurality of light guide columns 2-2, and a plurality of keypads and a plurality of light guide columns are combined into an integrated structure. Each keypad is located above the corresponding key 5 on the keyboard, and each light guide column It is located above the corresponding indicator light 6 on the keyboard.

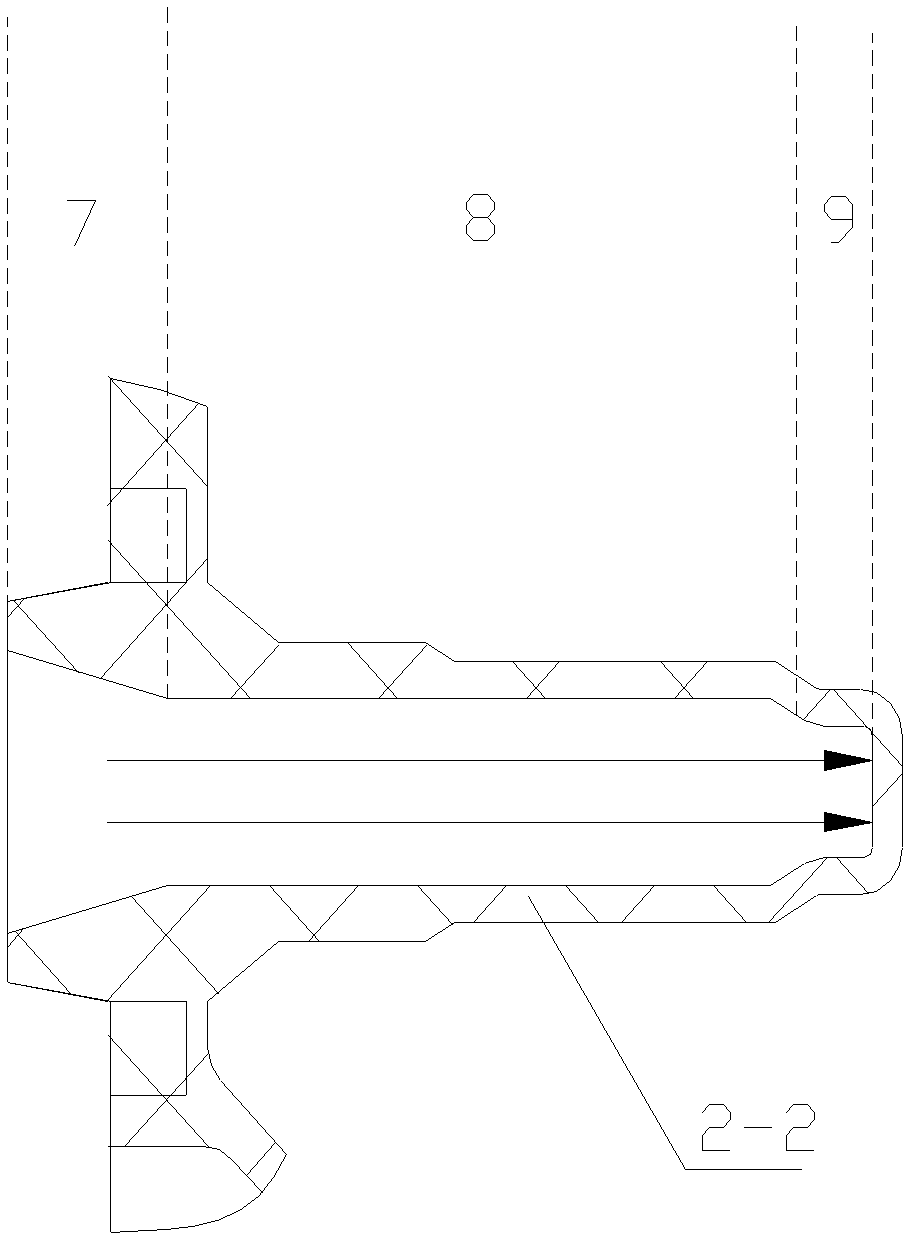

[0027] Among them, the light guide column is a hollow structure, see image 3 or Figure 4 , the end of the light guide column connected to the indicator light is an open end, and the other end of the light guide column is a closed end.

[0028] The end faces of the closed ends are planar.

[0029] The end surface thickness of the closed end of the light guide column is less than or equal to 0.8mm. In the case of ensuring that the closed end of the light guide column will not break due to being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com