Polymer nanocomposite optical material and preparation method thereof

An optical material and nanocomposite technology, which is applied in the field of polymer nanocomposite optical materials and its preparation, can solve the problems of cumbersome preparation process, high cost, and difficulty in obtaining optical quality, etc., and achieve simple preparation process, convenient operation and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

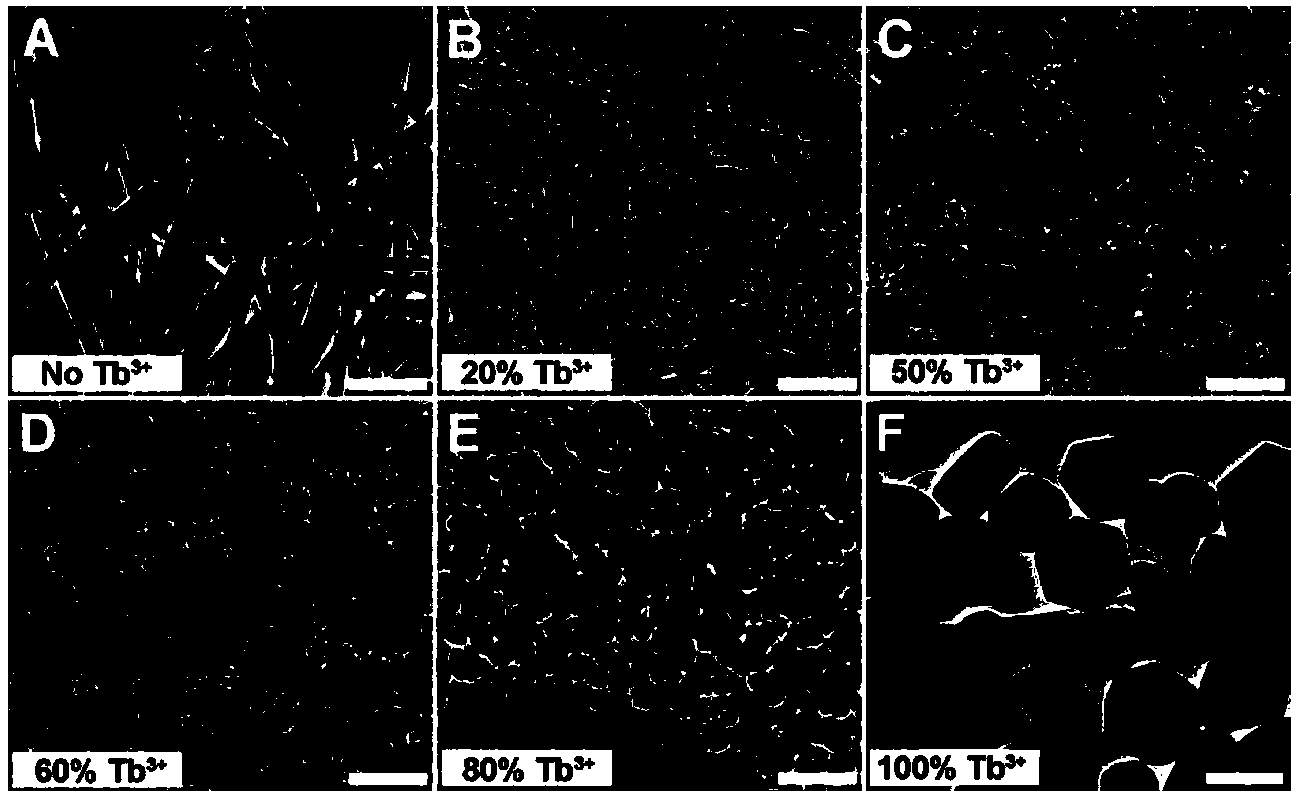

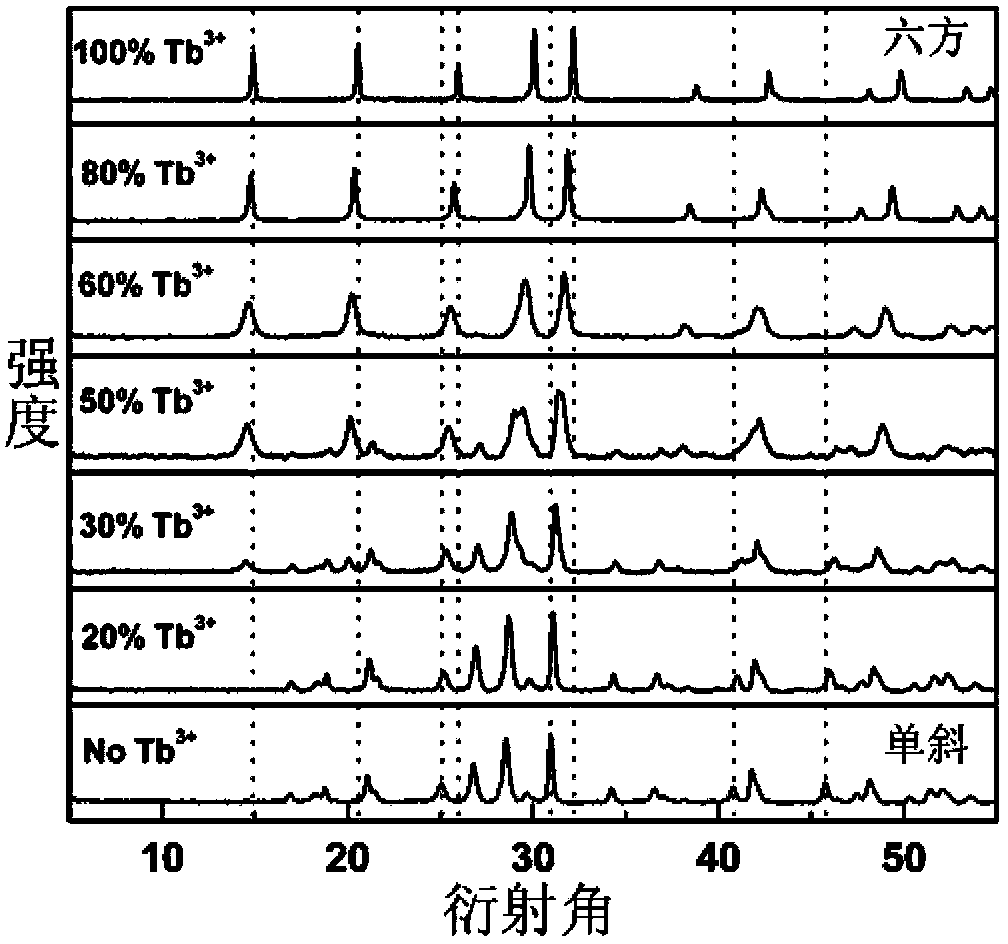

[0065] Example 1 Controllable preparation of rare earth phosphate nanoparticles with different shapes and sizes

[0066] 10 milliliters of 0.1mol / L lanthanum nitrate (La(NO 3 ) 3 ) solution was added to 10 ml of water, stirred and mixed. Another 2 mmol of citric acid was added to the solution, and vigorous stirring was continued for 30 minutes. Add 1 mmol of sodium dihydrogen phosphate (NaH 2 PO 4 ), and stirred for another 40 minutes. The solution was then transferred to a hydrothermal kettle and sealed. Heating to 150 degrees Celsius in an oven for 20 hours. After the hydrothermal kettle after the reaction was cooled to room temperature, a white precipitate could be obtained. The samples were centrifuged, washed, and finally dried in a vacuum oven at 60°C overnight. Finally got LaPO 4 Nanoparticles.

[0067] 8 milliliters of 0.1mol / L lanthanum nitrate (La(NO 3 ) 3 ) solution and 2 ml of 0.1mol / L terbium nitrate (Tb(NO 3 ) 3 ) into 10 ml of water, and stir to mi...

Embodiment 2

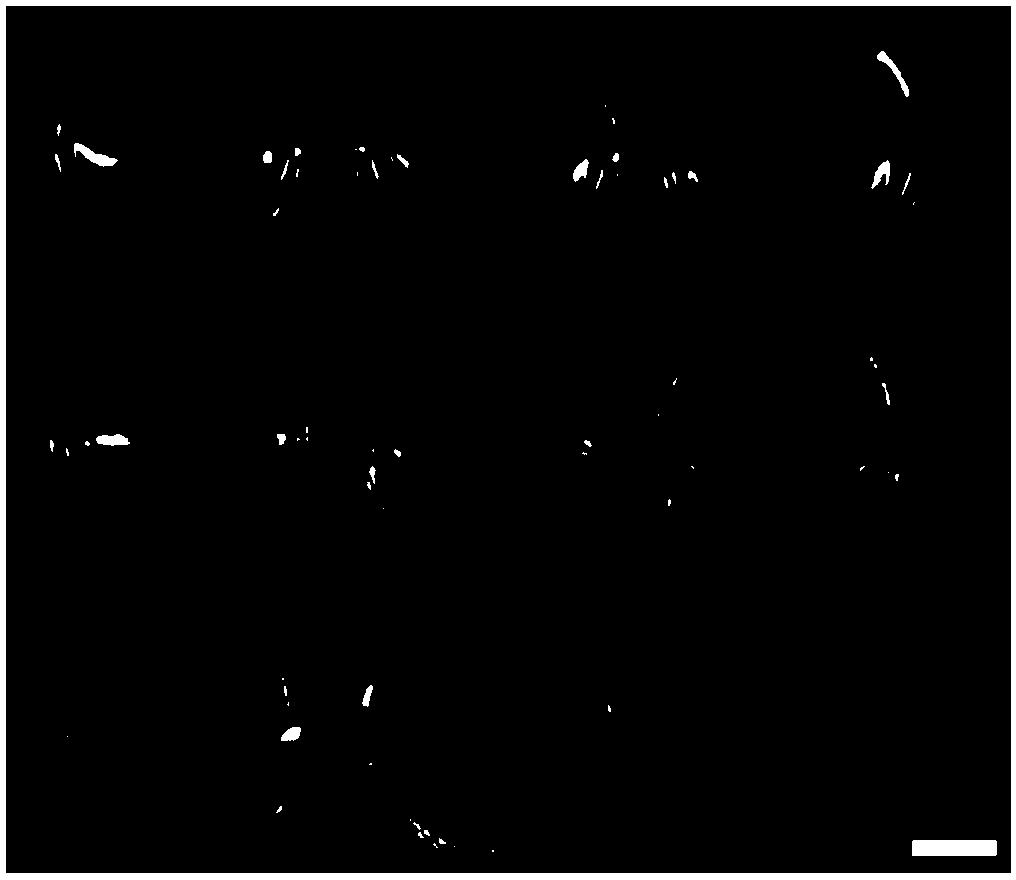

[0074] Example 2 Dispersion of Rare Earth Phosphate Nanoparticles in Trimethylolpropane Trimethacrylate Monomer and Its Free Radical Polymerization

[0075] A certain amount of La obtained in Example 1 0.5 Tb 0.5 PO 4 Nanoparticles were added to 300 microliters of organic solvent tetrahydrofuran, and the solution was stirred for 50 minutes under airtight conditions, and then ultrasonically dispersed for 30 minutes to form a dispersed nanoparticle solution. Under vigorous stirring, 1 ml of trimethylolpropane trimethacrylate monomer was added dropwise and ultrasonicated for 60 minutes to obtain a stable nanoparticle polymer monomer solution. A certain amount of benzoyl peroxide compound is added to the solution, and ultrasonic waves are used for 10 minutes to dissolve the benzoyl peroxide and form a stable solution. Next, fill the obtained mixed solution into a suitable glass mold, then put it in a vacuum oven, and remove the organic solvent tetrahydrofuran in the solution at...

Embodiment 3

[0077] Example 3 Dispersion of rare earth phosphate nanoparticles in methyl methacrylate monomer and its free radical polymerization.

[0078] A certain amount of La obtained in Example 1 0.5 Tb 0.5 PO 4 Nanoparticles were added to 300 microliters of organic solvent tetrahydrofuran, and the solution was stirred for 50 minutes under airtight conditions, and then ultrasonically dispersed for 30 minutes to form a dispersed nanoparticle solution. Under vigorous stirring, 1 ml of methyl methacrylate monomer was added dropwise, and ultrasonicated for 60 minutes to obtain a stable nanoparticle polymer monomer solution. A certain amount of azobisisobutyrocyanide compound is added to the solution, and the azobisisobutyrocyanide compound is ultrasonicated for 10 minutes to dissolve the azobisisobutyrocyanide compound and form a stable solution. Next, fill the obtained mixed solution into a suitable glass mold, then put it in a vacuum oven, and remove the organic solvent tetrahydrofur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com