Single straight tube Coriolis mass flowmeter

A mass flow meter, single straight tube technology, applied in the direction of direct mass flow meter, mass flow measurement device, etc., can solve the problems of unfavorable emptying and cleaning, large fluid pressure loss, heavy workbench, etc., to simplify the structure, reduce Fluid pressure loss, overall volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

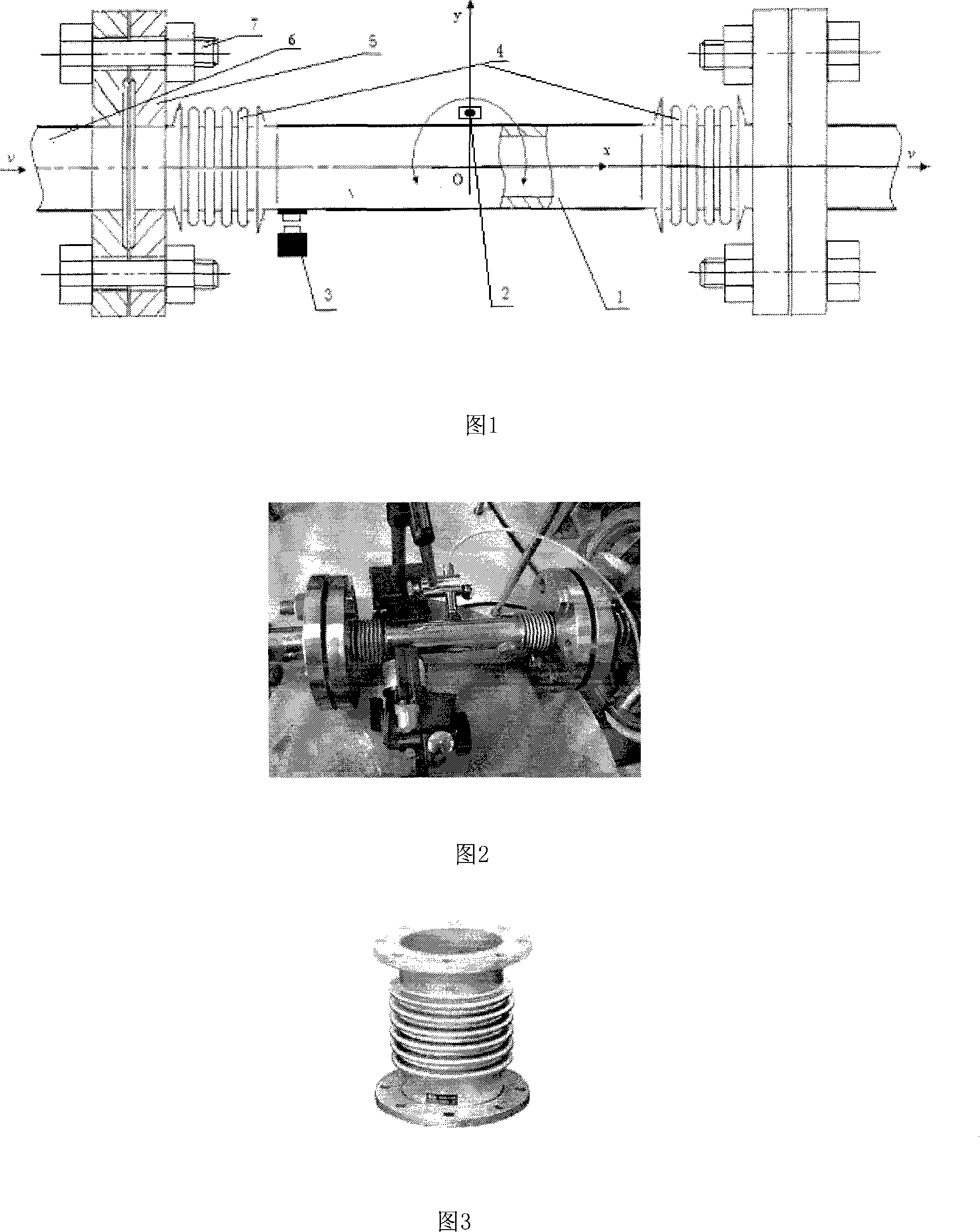

[0038] Embodiment 1, calibration experiment: the calibration method and process before the first use of the present invention.

[0039] As shown in Figure 2, the experimental parameters: the amplitude of the excitation signal is 10V; the amplification factor of the power amplifier is 7; the distance between the excitation coil and the magnet sheet is about 3mm; the distance between the displacement sensor probe and the copper sheet is about 3mm.

[0040] When the pipe is filled with still water, sweep frequency excitation. The mode shape of the system is obtained: the first natural frequency is 78Hz, the second natural frequency of the system is 138Hz, and the vibration amplitude of the center of the measuring tube (that is, the center of mass) is represented by an electrical signal as 12mv.

[0041] Experimental steps:

[0042] (1) Install and fix the flowmeter. Connect the flanges at both ends of the flowmeter to the water pipe under test, fix them with bolts, and check wh...

Embodiment 2

[0052] Embodiment 2, test example: use the present invention to measure the mass flow in the water pipe of a certain fluid experiment platform.

[0053]On the basis of the calibration experiment, start the switch of the exciter, set the excitation frequency of the system as the second-order natural frequency of the system, when the measured fluid passes through the flowmeter measuring tube with full load, after the system is stable, read The value of the detector is then measured.

[0054] Experimental steps:

[0055] (1) Connect and install the flowmeter, and check that the seal is intact.

[0056] (2) Adjust the excitation frequency of the flowmeter vibrator (3) to 138Hz.

[0057] (3) Open the valve of the delivery pipeline (6) of the fluid to be measured, so that the full load of water flows through the measuring tube.

[0058] (4) The vibration amplitude of the center of the measuring tube is measured, that is, the electrical signal is obtained from the oscilloscope of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com