Web spreading method and device for preparation of filament non-woven fabric through wet spinning technique

A filament non-woven fabric and wet spinning technology, which is applied in the direction of non-woven fabrics, textiles, and papermaking, can solve the problem of non-specific disclosure, uneven laying of filament fibers, and inability to use wet spinning long Issues in the field of silk fiber spunlace reinforcement, etc., to achieve consistent strength, ensure overall thickness, and overall uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

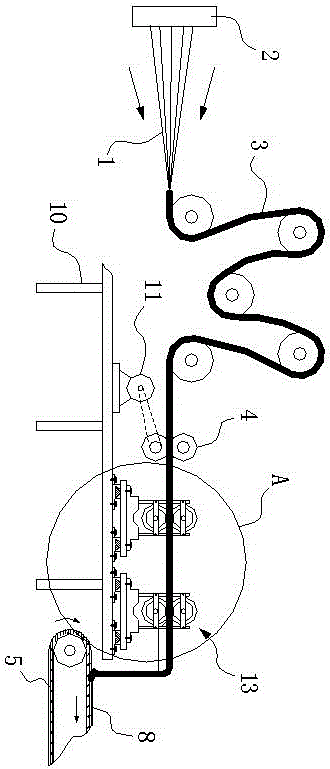

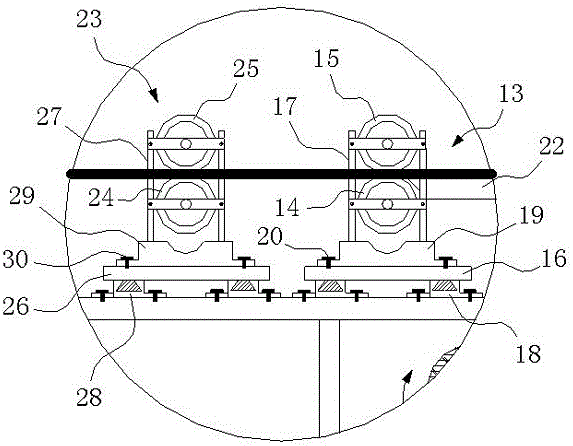

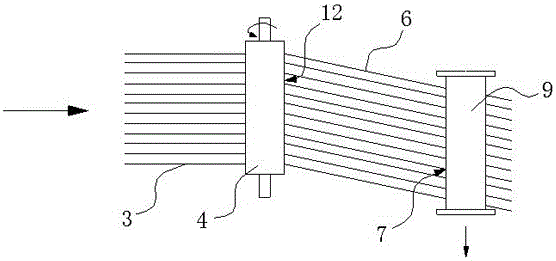

[0030]Such as figure 1 , 2 , 3, 4, and 5, a method for laying a filament non-woven fabric prepared by a wet spinning technique comprises the steps:

[0031] (1) Preparation of filament fiber tow 1: the spinning liquid is sprayed out through the spinneret 2, and the filament fiber tow 1 is output after being reacted in a coagulation bath;

[0032] (2), drafting of filament fiber tow 1: according to the use of the filament non-woven fabric, select the strength data of the filament fiber, and perform directional stretching on the output filament fiber tow 1;

[0033] (3) Formation of sheet-like uniform fiber tows 3: arranging a bundle of stretched filament fibers to form sheet-like uniform fiber tows 3;

[0034] (4), conveying of sheet-like uniform fiber tow 3: the formed sheet-like uniform fiber tow 3 is conveyed to the direction of net curtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com