Stable-switching ball screw type inerter device

A ball screw type, inertial container technology, applied in the field of inertial containers, can solve the problems of inertial container performance impact, time delay, inertial force generation, etc., and achieve the effects of weakening the time delay effect, reducing nonlinear factors, and eliminating impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

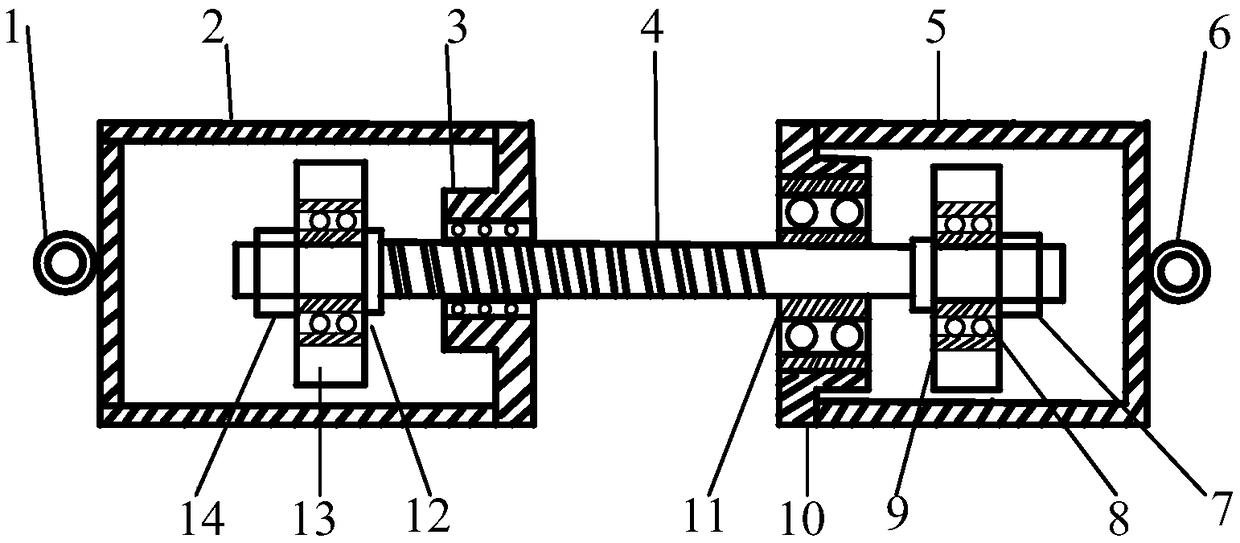

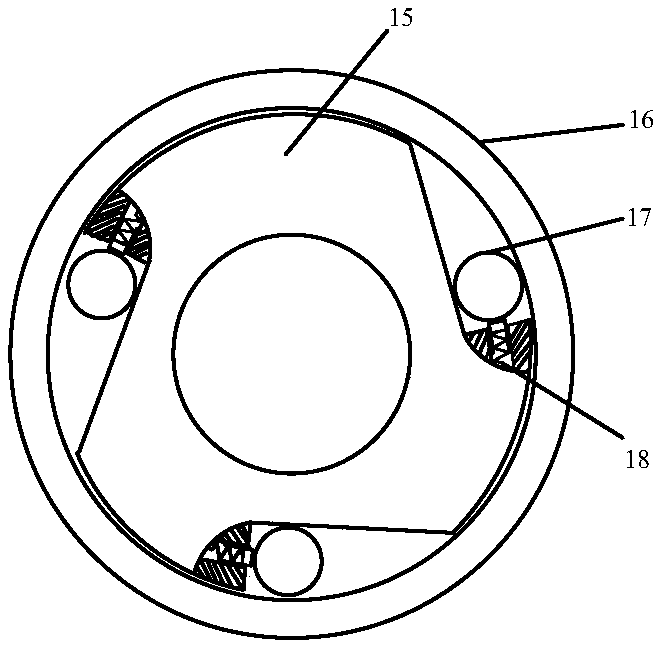

[0029] Such as figure 1 As shown, the ball screw type inerter device for steady state switching includes a left lug (1), a right lug (6), a first cylinder (2), a second cylinder (5), Lead screw nut (3), lead screw (4), bearing housing (10), bearing (11), flywheel A (13), flywheel B (9), roller type one-way clutch A (12), roller type One-way clutch B (8), pre-tightening nut A (14), pre-tightening nut B (7), the flywheel A (13) is installed on the lead screw (4) through the roller type one-way clutch A (12) At the left end, the flywheel B (9) is installed on the right end of the lead screw (4) through the roller type one-way clutch B (8), and the lead screw nut (3) is installed on the lead screw extending out of the first cylinder (2 ), and solidified together with the right end of the first cylinder (2), the bearing block (10) is solidified on the second cylinder (5), the inner ring of the bearing (11) and the lead screw (4) Consolidate together, the outer ring is installed o...

Embodiment 2

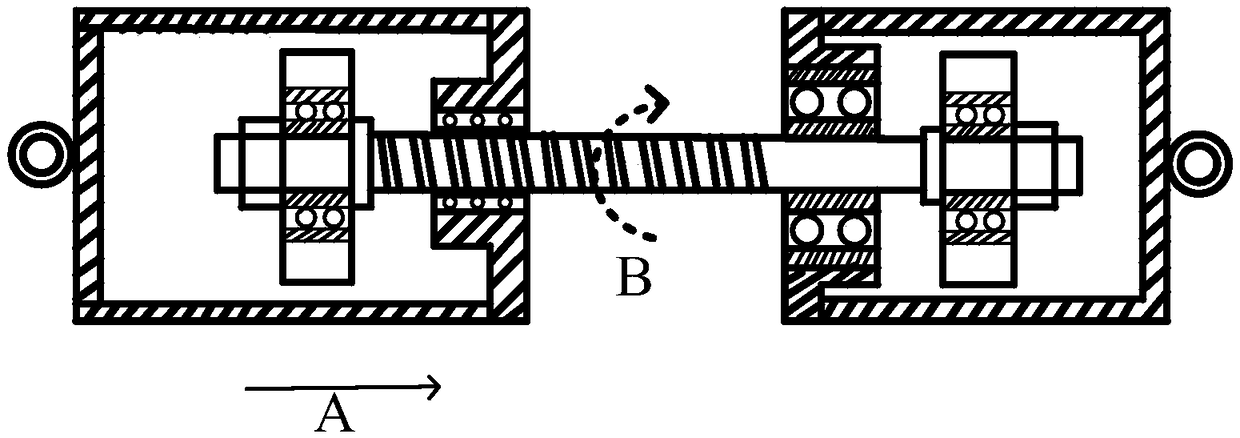

[0037] Such as Figure 5 As shown, the ball screw type inerter device for steady state switching includes a left lug (1), a right lug (6), a first cylinder (2), a second cylinder (5), Lead screw nut (3), lead screw (4), bearing housing (10), bearing (11), flywheel A (13), flywheel B (9), roller type one-way clutch A (12), roller type One-way clutch B (8), pre-tightening nut A (14), pre-tightening nut B (7), the flywheel A (13), flywheel B (9) through the roller type one-way clutch A (12), roller The column type one-way clutch B (8) is installed on the right end of the lead screw (4), and the lead screw nut (3) is installed at the position where the lead screw extends out of the first cylinder (2), and is connected with the first cylinder ( 2) the right ends are consolidated together, the bearing seat (10) is consolidated on the second cylinder (5), the inner ring of the bearing (11) is consolidated with the lead screw (4), and the outer ring is installed On the bearing seat,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com