Conveying and cutting mechanism for pesticide processing and production

A technology of cutting mechanism and conveying mechanism, which is applied in the direction of conveyor, transportation and packaging, grain processing, etc., can solve the problems of simple structure and single function, and achieve the effect of improving cutting efficiency, improving the degree of function integration, and avoiding splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

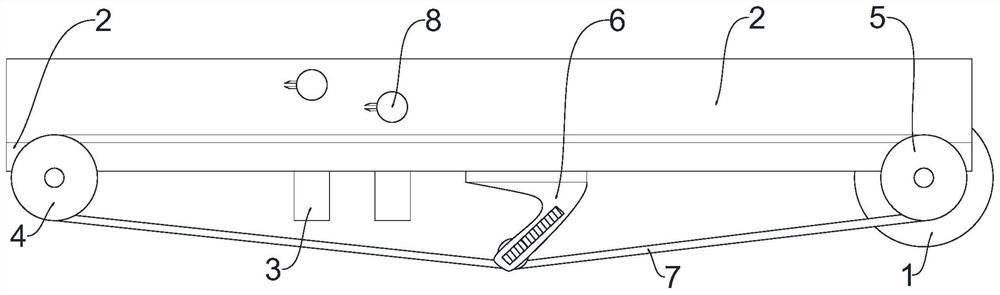

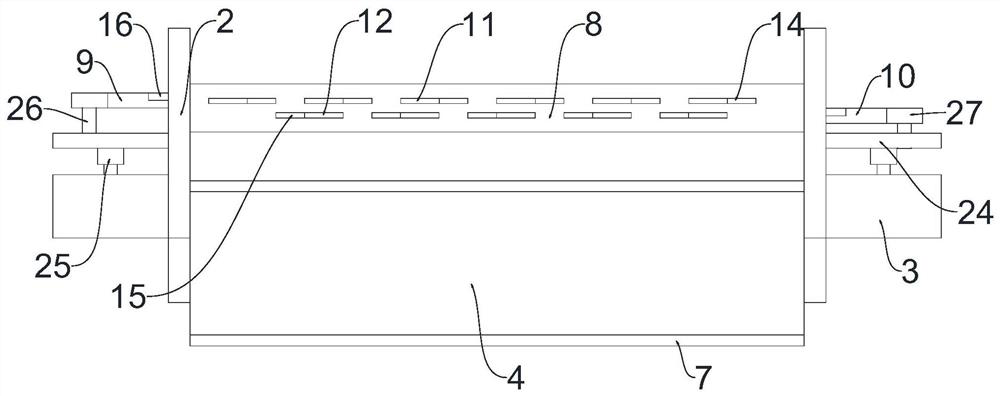

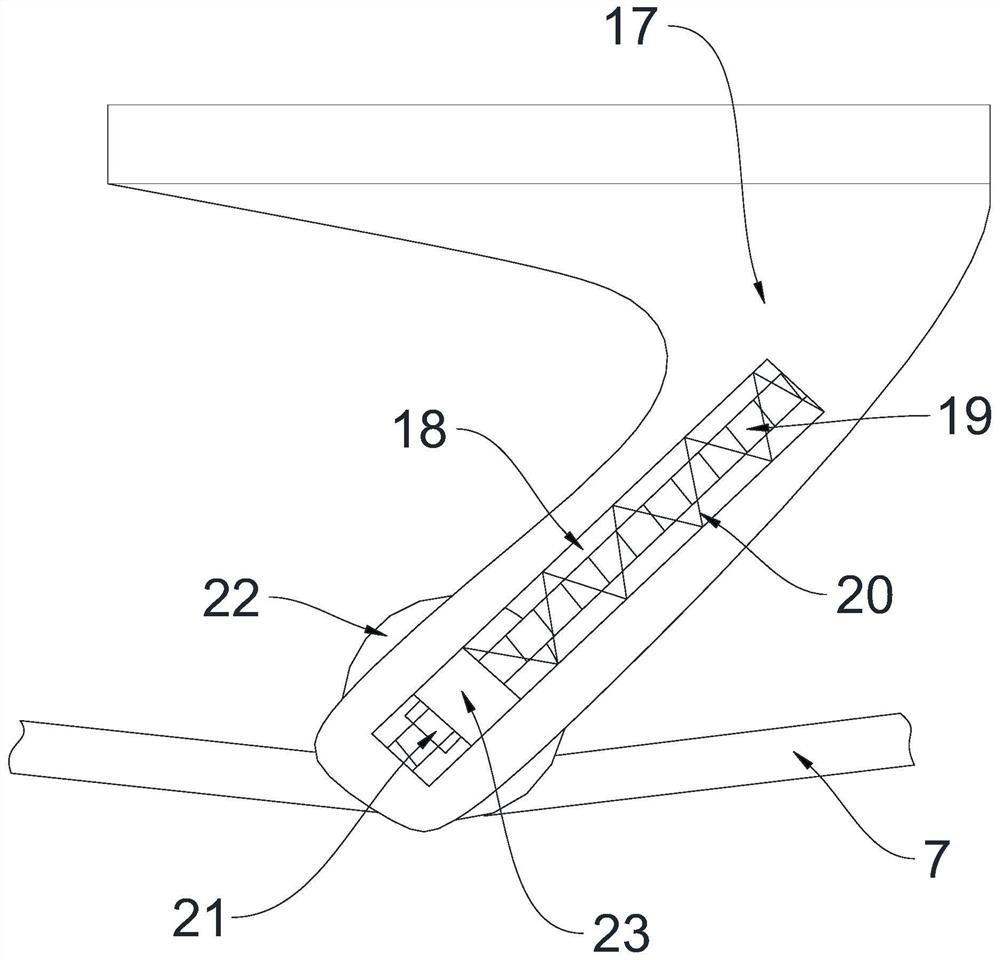

[0023] Embodiment: The conveying motor 1 is fixed on the outer surface of the transverse guide rail 2 by transverse bolts, and is axially connected with the drive roller at one end of the internal conveying mechanism. The specific drive roller can be selected according to the actual position, and the entire interior is driven by driving the drive roller at one end The conveying mechanism is running; the adjusting motor 3 is longitudinally fixed on the outside of the transverse guide rail 2 through the fixed mounting bracket on the outer surface of the transverse guide rail 2, and the circular adjustment plate 24 is driven to rotate, and the internal cutting mechanism is driven to translate forward and backward through the rotation of the circular adjustment plate 24. The adjustment motor 3 is installed on both sides of the transverse guide rail 2 respectively by a plurality of motors, and is installed symmetrically.

[0024] The internal conveying mechanism includes a left driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com