Laser cutting tooling and laser cutting production line for soft pack battery tabs

A technology of laser cutting and pouch battery, applied in battery pack parts, laser welding equipment, welding/welding/cutting items, etc. Diversified requirements and safety requirements for battery-packed tab cutting to improve cutting safety and prevent splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

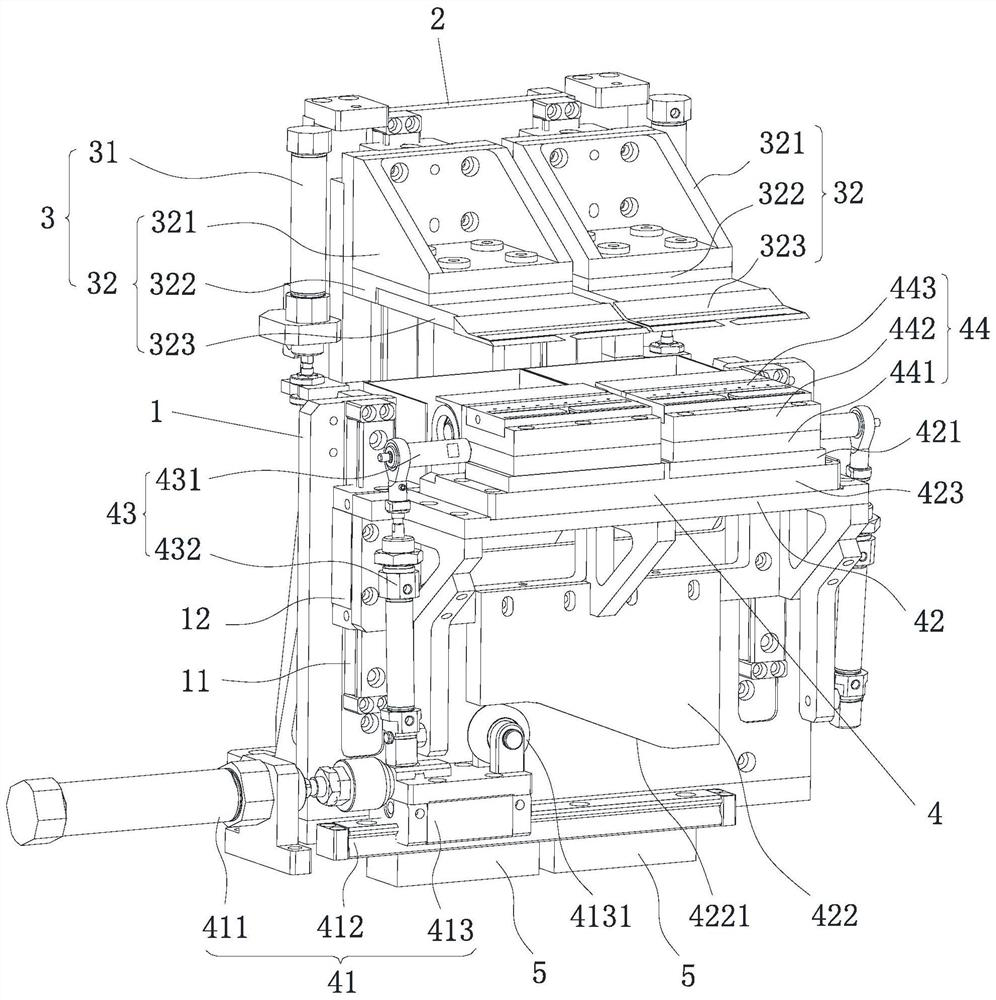

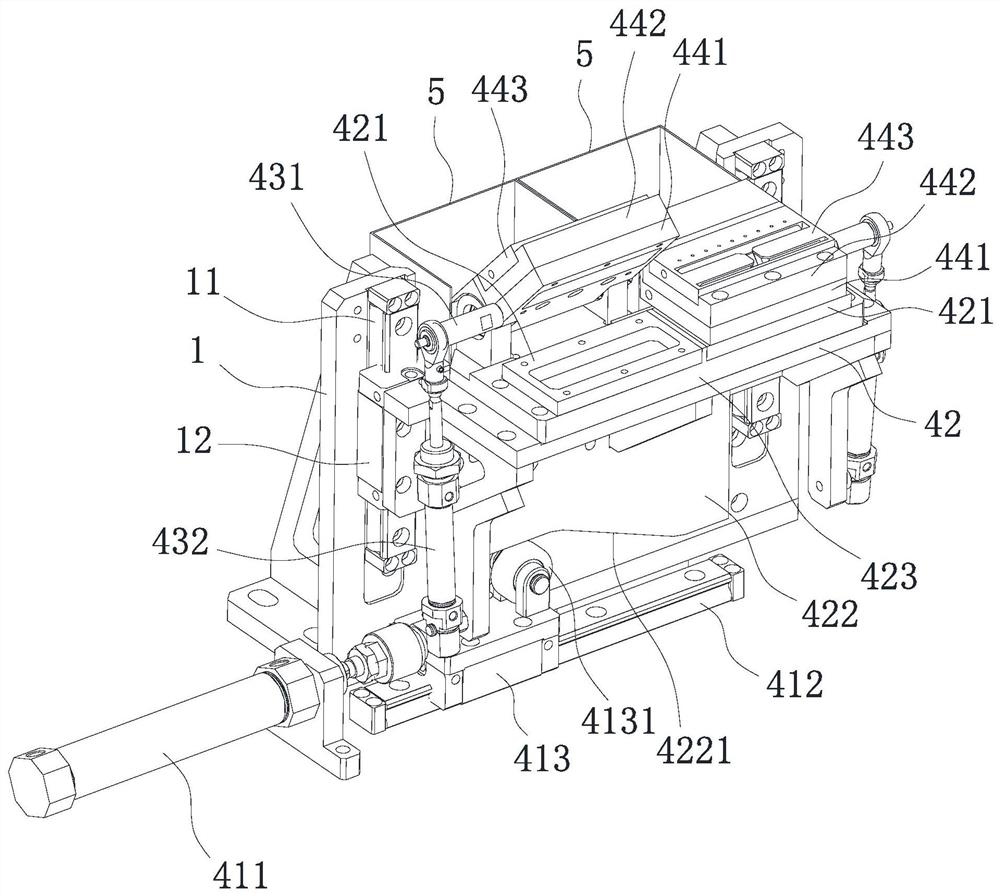

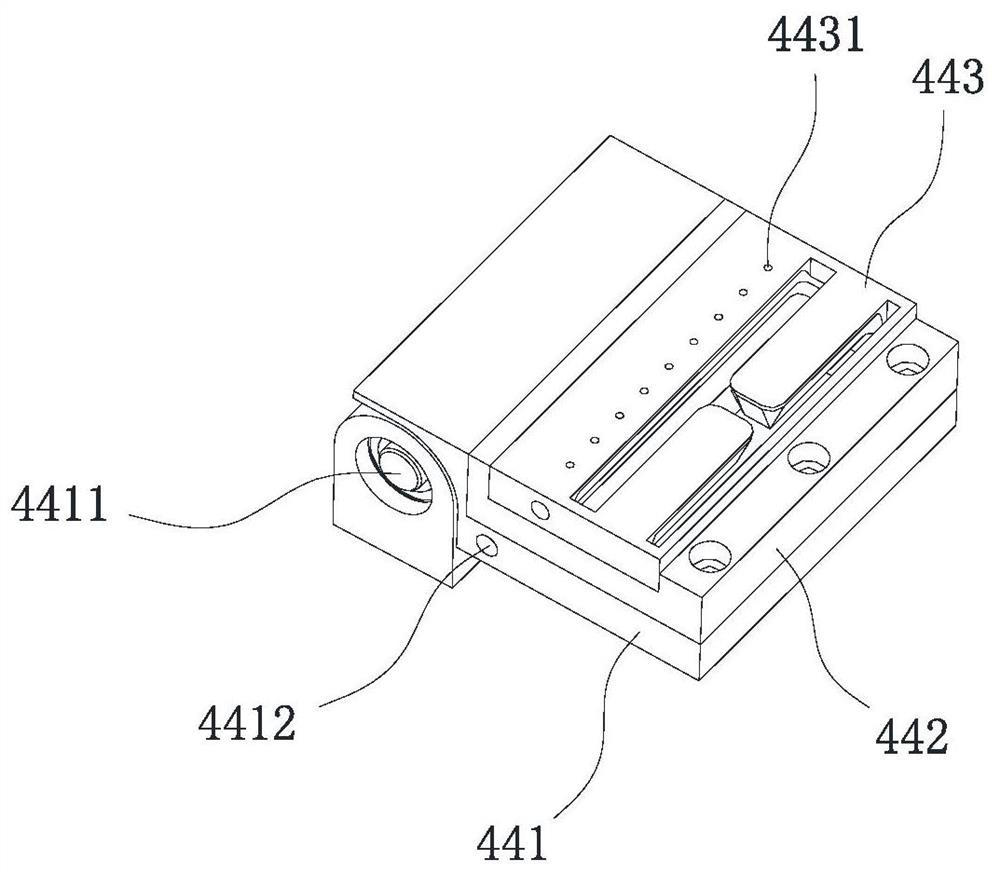

[0025] In this example, if Figure 1-6 As shown, the laser cutting production line (not shown) includes a laser cutting tool for the tab of the pouch battery, wherein the laser cutting tool for the tab of the pouch battery includes: a first fixing seat 1, a second fixing seat 2, and an upper pressing assembly 3 and the pressing assembly 4; the first fixed seat 1 and the second fixed seat 2 are all fixed with the laser cutting production line, and the pressing assembly 4 includes a first driving mechanism 41, a movable seat 42, an overturning driving mechanism 43 and a movable pressing block 44. The seat 42 is slidingly assembled on the first fixed seat 1, the first drive mechanism 41 is assembled on the laser cutting production line and connected with the movable seat 42, and the first drive mechanism 41 can drive the movable seat 42 along the first fixed seat 1 in the height direction Move, the movable briquetting block 44 and the movable seat 42 are rotated and assembled, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com