Municipal road damaged asphalt pavement cutting and cleaning equipment

A technology for asphalt pavement and municipal road, applied in the field of cutting and cleaning equipment for damaged asphalt pavement on municipal roads, can solve the problems of affecting the connection of asphalt concrete, difficult to use flexibly, inconvenient to clean, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

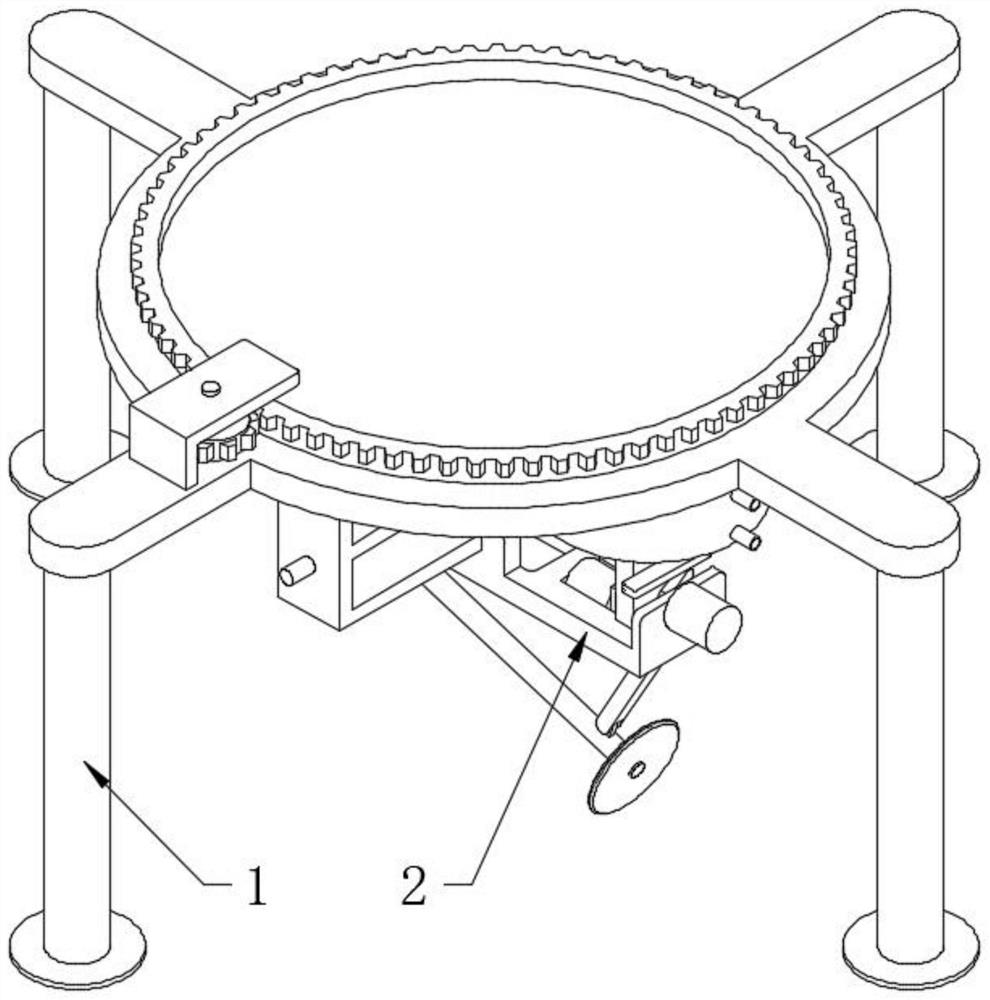

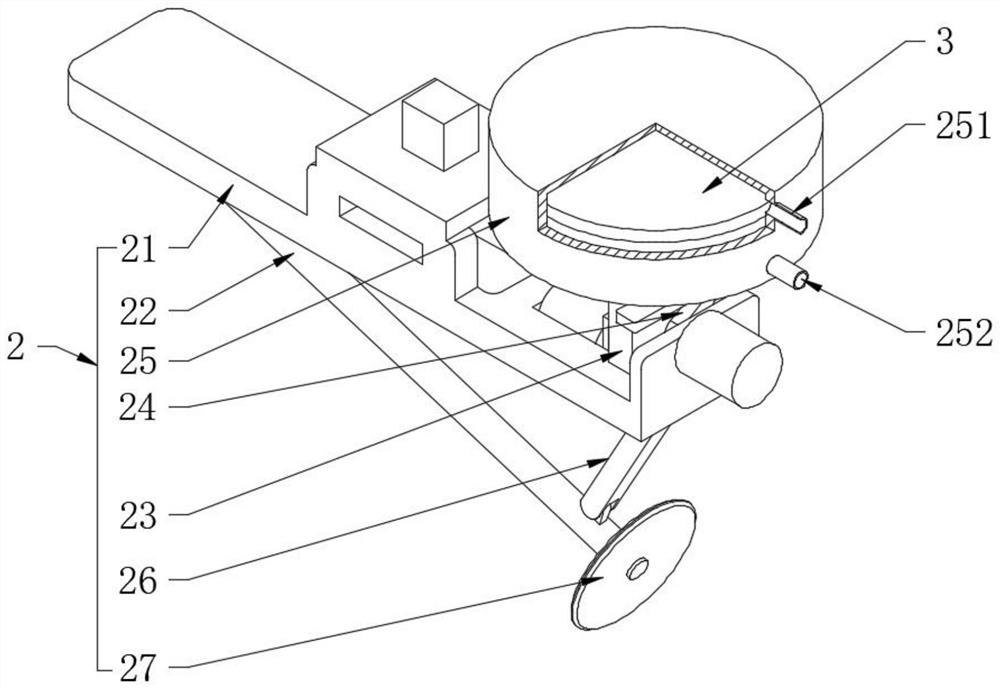

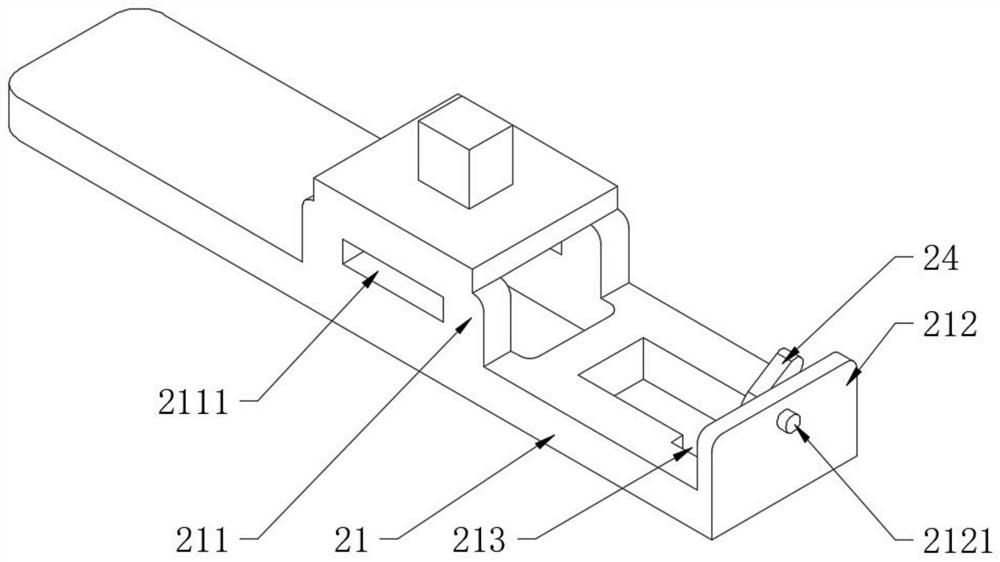

[0032] see Figure 1-5, a kind of municipal road damaged asphalt pavement cutting and cleaning equipment, comprising a cutting positioning seat 1 and a circular punching and rolling cutting device 2 arranged at the lower part of the cutting positioning seat 1, the cutting positioning seat 1 is used to control the rotation and rotation of the circulating punching and rolling cutting device 2 Linear movement, the function of the cutting positioning seat 1 is to fix the upper part of the damaged road surface, on which four legs with bottom nails can be set, the legs support the ground, and the upper part of the cutting positioning seat 1 can be equipped with common gear-driven Rotary disk, the bottom of the rotary disk is fixed with a rotating frame 11, and the rotating frame 11 is linearly slidably matched with the circulating punching and rolling cutting device 2; the circulating punching and rolling cutting device 2 includes a horizontally distributed rectangular bearing plate ...

Embodiment 2

[0034] see figure 2 , and the difference from Embodiment 1 is that the counterweight body 25 is fixedly arranged on the top of the bearing vertical plate 232. The counterweight body 25 is a box structure, and one side thereof is screwed with a water inlet pipe 251 and a drain pipe 252. The gap in the counterweight body 25 is With the floating plate 3, the counterweight body 25 can be made into a water tank, and the size of the inertial impact force can be increased by installing and draining water, which has the ability to adjust the cutting force, and can discharge water when not in use, reducing the transfer weight and facilitating transfer; The floating plate 3 is used to reduce the shaking range of the water body in the water tank, and has high safety.

Embodiment 3

[0036] see Figure 6 , and the difference from Embodiment 1 is that the suspension tube 22 is rotatably connected with a positioning tube 221, and the outer wall of the positioning tube 221 is fixedly provided with a row of punches 2211. Since the suspension tube 22 is distributed obliquely, the arrangement direction of this row of punches 2211 Arrange along the axial direction of the suspension tube 22, and gradually lengthen along the direction away from the hob cutter 27; after cutting the ground, the positioning tube 221 can be rotated to ensure that a row of punches 2211 are in contact with the ground part downwards. In the example 1, the circular punching function can break the damaged road surface and fragment the damaged road surface for easy cleaning; the positioning pipe 221 is provided with a locking member 4, which is a bolt used in conjunction with the suspension pipe 22, The positioning pipe 221 is fixed by using a common structure of bolt rotation and shrinkage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com