Intelligent anti-static stable tempered glass cutting equipment

A glass cutting and anti-static technology, used in stone processing equipment, work accessories, manufacturing tools, etc., can solve problems such as low practicability and scratches, and achieve the effect of increasing stability, increasing shear force, and avoiding movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

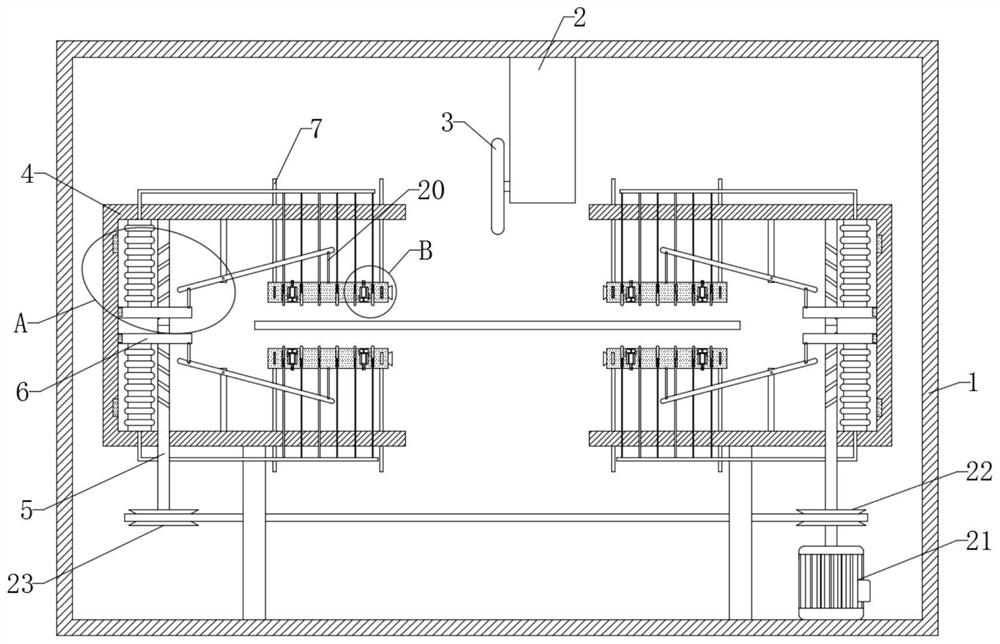

[0019] refer to Figure 1-3 , an intelligent anti-static and stable tempered glass cutting equipment, including a casing 1, a cutting knife 3 is installed on the top of the casing 1 through a control mechanism 2, it should be noted that the control mechanism 2 can control the cutting knife 3 to rotate and up and down Mobile, for existing technology.

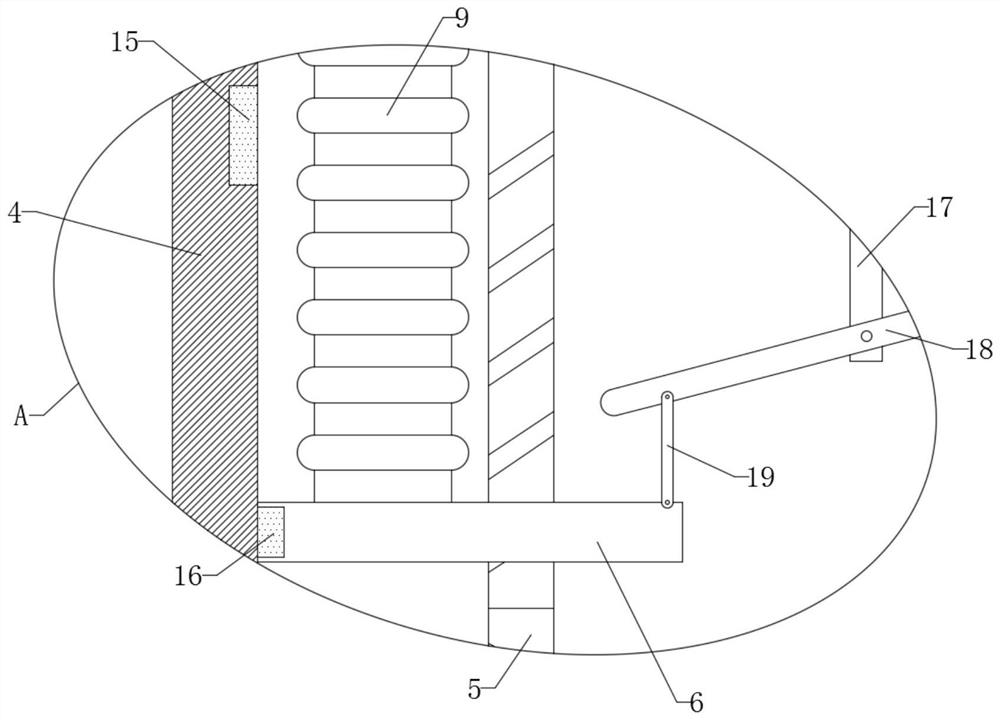

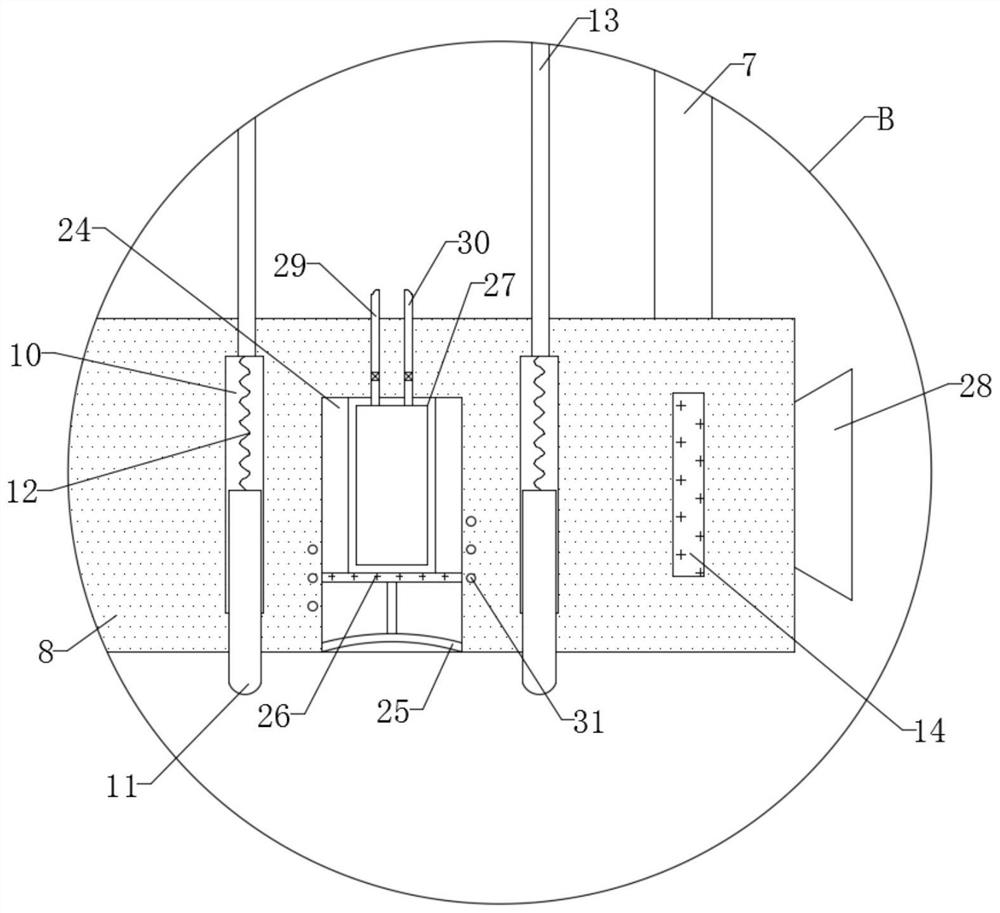

[0020] The housing 1 is provided with a stabilization mechanism. The stabilization mechanism includes two U-shaped plates 4 that are fixedly connected to the bottom of the housing 1 through two fixing rods. The inner walls of the two U-shaped plates 4 are respectively rotatably connected with two bidirectional lead screws 5 . Two sliding blocks 6 are threadedly connected to the side walls of the bidirectional screw 5. The side walls of the sliding blocks 6 are fitted with the side walls of the U-shaped plate 4. The top and bottom of the U-shaped plate 4 are connected with two horizontal plates 8 through a plurality of sliding rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com