Automatic reset two-directional clamping-type grinder

An automatic reset and clamping technology, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding the edge of workpieces, can solve the problem of inability to grasp the intensity of surface marking force, uncontrollable degree of pressing force, and inconvenient operation and other issues, to achieve a wide range of market application prospects, improve cutting safety, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

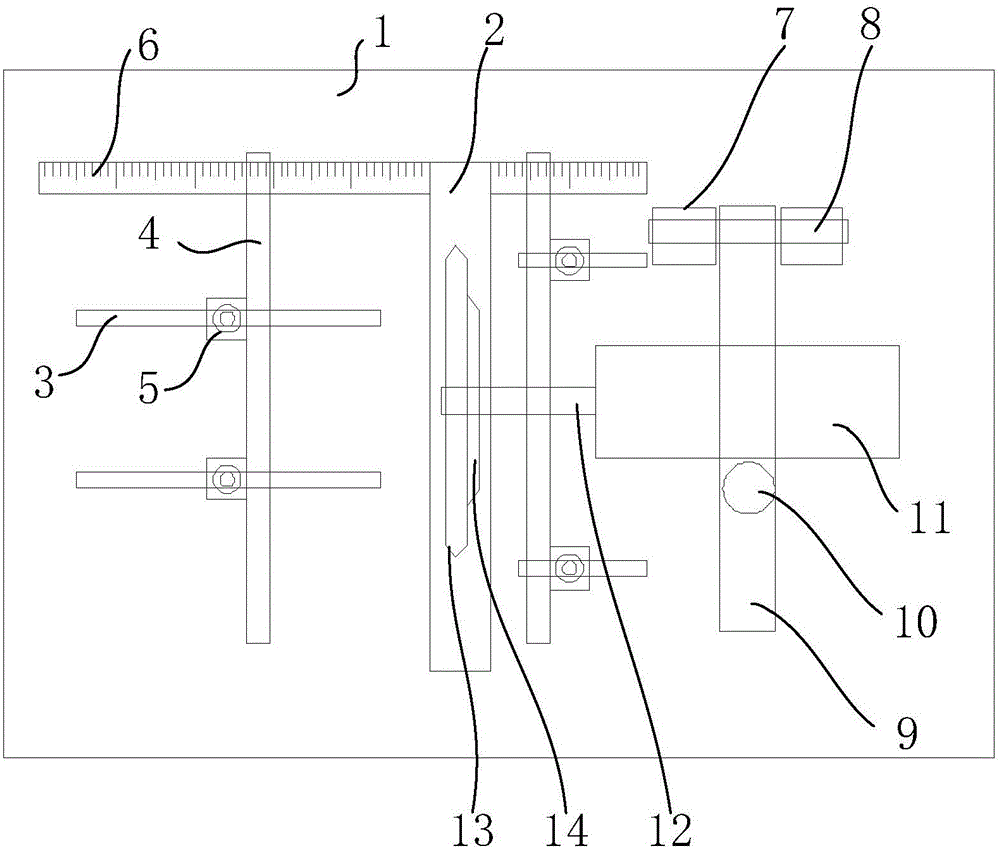

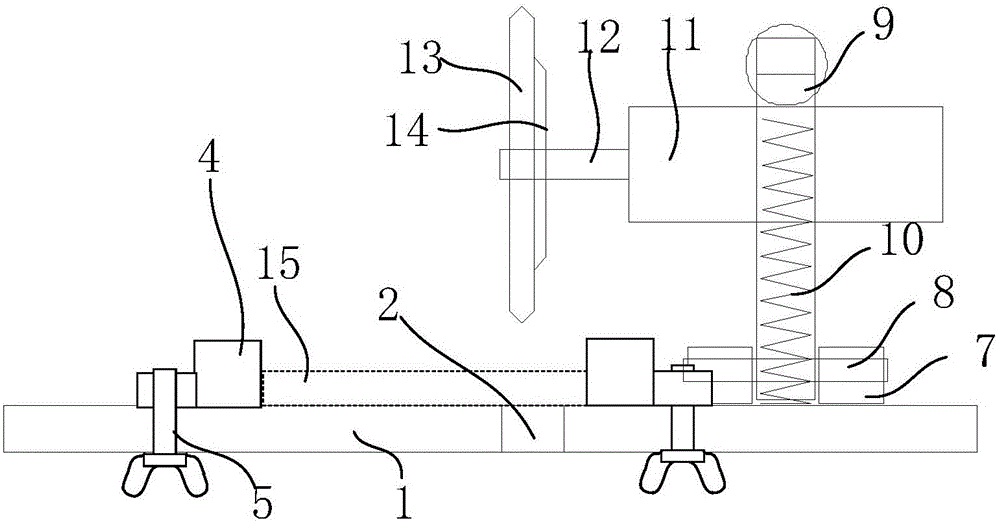

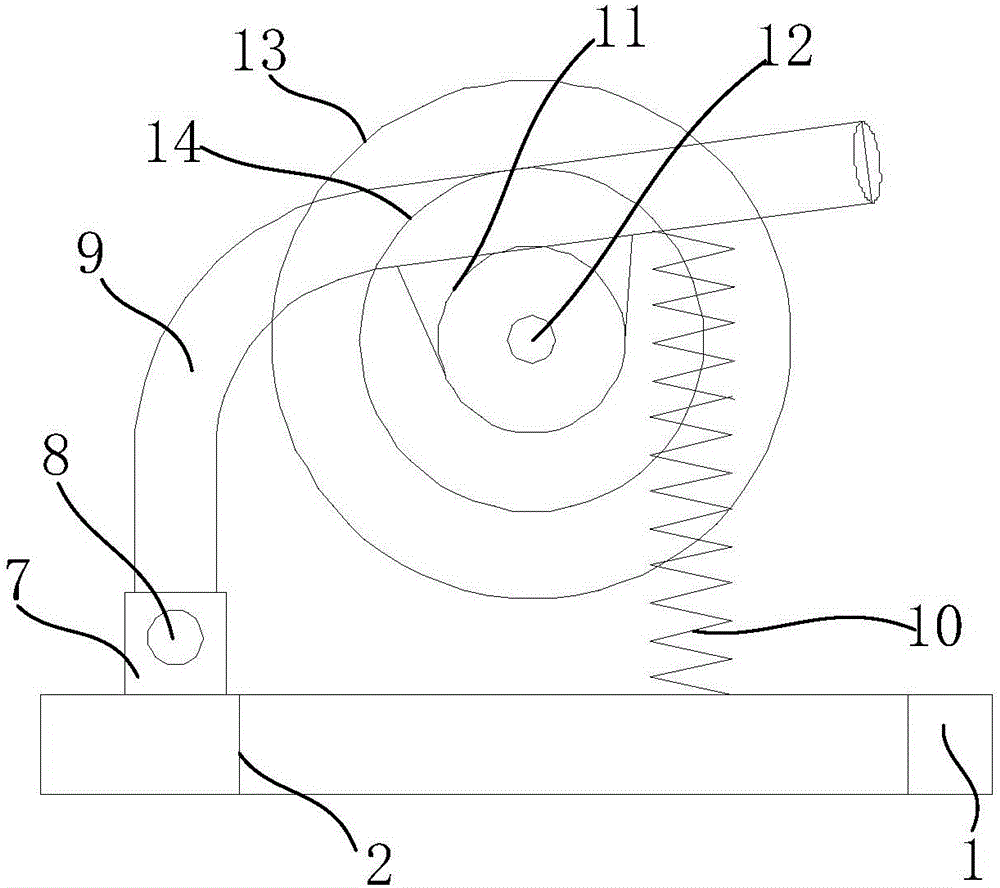

[0012] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0013] Such as Figure 1 to Figure 3 As shown, the self-resetting two-way clamping grinder includes two tables 1 with cutting grooves, at least two clamping guide grooves set on the table surfaces on both sides of the cutting grooves and perpendicular to the direction of the cutting grooves 3. The clamping bar 4 straddling all the clamping guide grooves on the same side of the cutting groove, passing through each clamping guide groove and the adjusting screw 5 connected with the corresponding clamping bar, and setting along the direction of the clamping guide groove The scale 6 is set on the fixed shaft frame 7 next to the cutting groove on the table, the rocker arm frame 9 connected with the fixed shaft frame through the rotating shaft 8, and the Weili spring 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com