Bamboo tube cutting machine

A cutting machine, bamboo tube technology, applied in mechanical equipment, sugarcane machining, rotary cutting tools, etc., can solve the problems of scrap, waste of resources, damage to moso bamboo, etc., and achieve the effect of high process efficiency and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

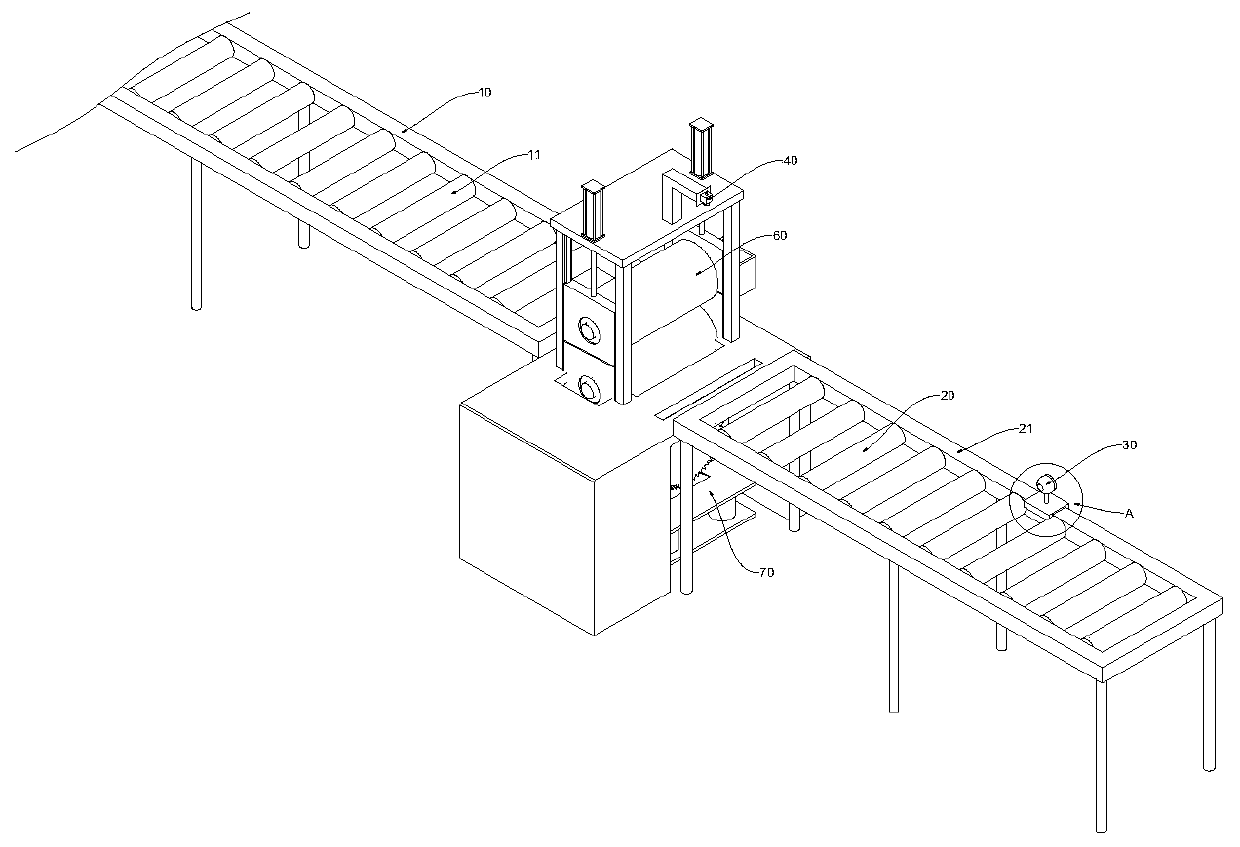

[0021] next combined with Figure 1-4 A specific embodiment of the present invention is described in detail.

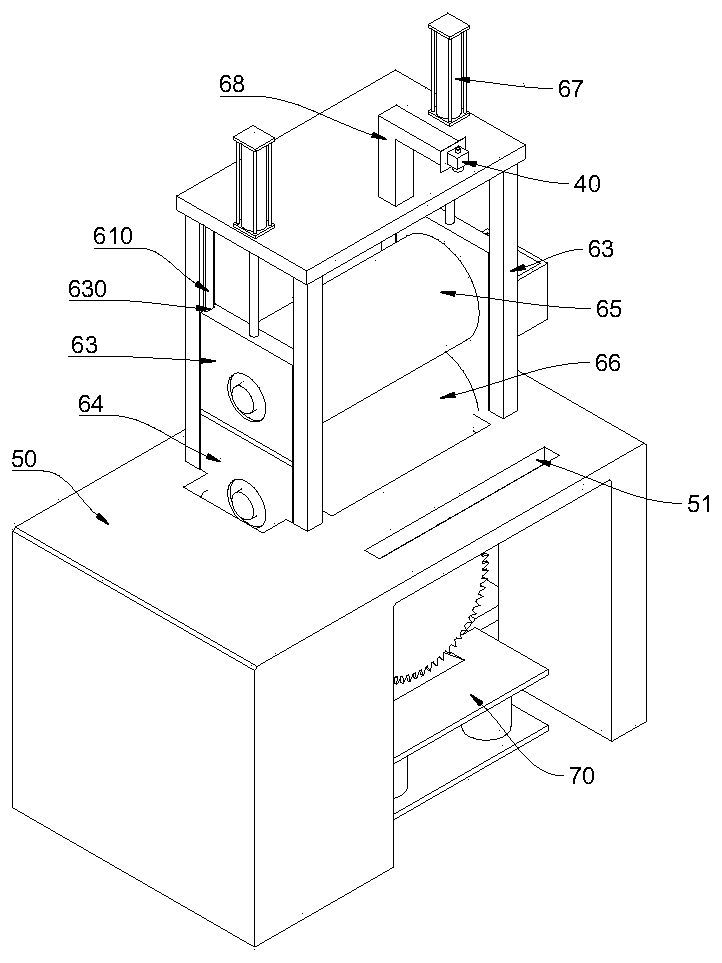

[0022] A bamboo tube cutting machine is used for cutting bamboo tubes, including a feeding platform 10, a discharging platform 20, a sensor sliding platform 30, a camera 40, a cutting structure and a console 80, and the bamboo tubes to be cut are placed on the feeding platform 10 , one end of which is held on the cutting structure, under the clamping of the cutting structure, advances to the other end of the cutting structure to a predetermined position, is photographed by the camera 40 to determine whether to implement avoidance measures, is then cut by the cutting structure, and falls into the discharge table 20 on.

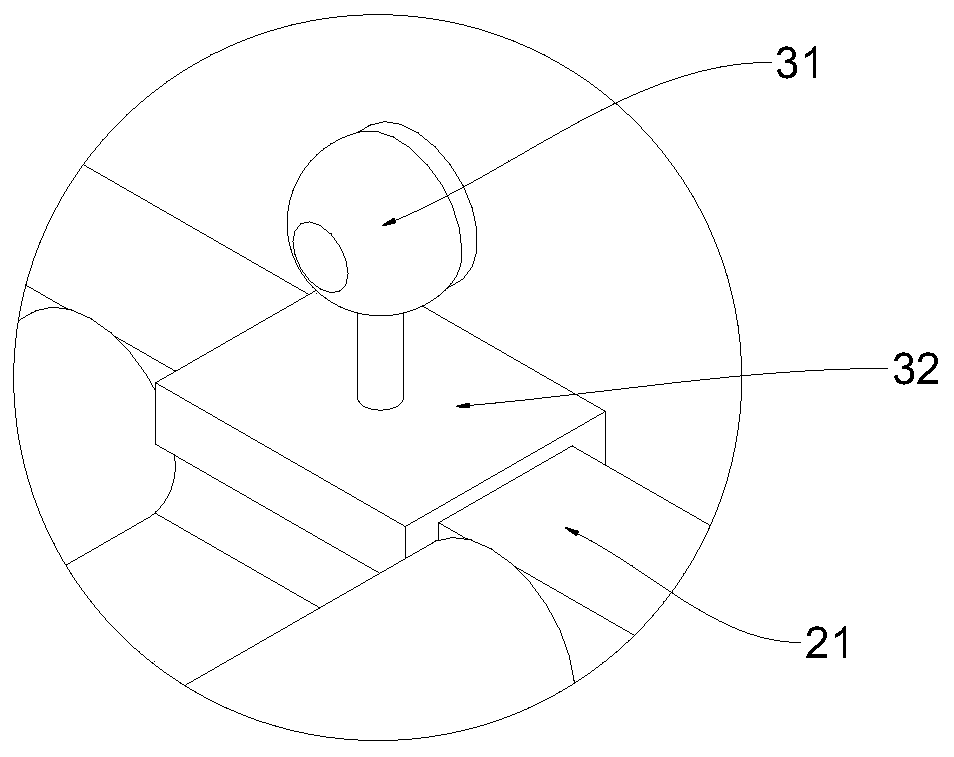

[0023] The tops of the feed table 10 and the discharge table 20 are at the same level, and movable rollers 11 are arranged on their surfaces. The sensor slide table 30 is arranged on the discharge table 20 and includes a sensor probe 31 and a slider 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com