Synchronous multi-cutter fixed-distance cutting device for steel pipe

A technology for cutting devices and steel pipes, which is applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc. It can solve the problems of long time-consuming measurement of fixed distances, inconvenient fixed distances, and reduced work efficiency, etc., and achieves a reasonable structure , simple operation, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

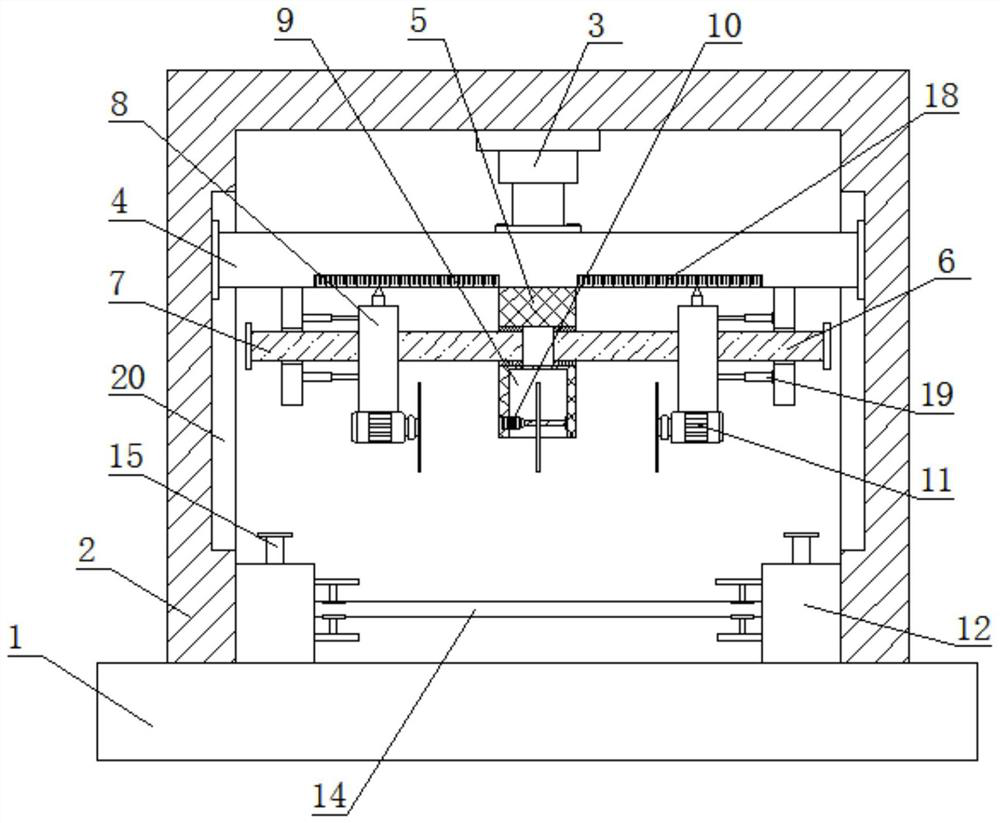

[0029] refer to Figure 1-4 , a synchronous multi-knife fixed-distance cutting device for steel pipes, including a base 1, the top of the base 1 is fixedly connected with a fixed frame 2, the top inner wall of the fixed frame 2 is fixedly connected with a top cylinder 3, and the output shaft of the top cylinder 3 is fixedly connected with a sliding plate 4, the bottom of the sliding plate 4 is fixedly connected with a fixed plate 5, and the bottom of the sliding plate 4 is symmetrically fixedly connected with two vertical plates 6, and one side of each vertical plate 6 is rotatably connected with a screw rod 7, and one end of the screw rod 7 through the fixed plate, and bearings are arranged on both sides of the fixed plate, the end of the screw rod is fixed at the center of the bearing, the other end of the screw rod 7 passes through the vertical plate, and is fixedly connected with a knob, and each screw rod 7 also runs through a Moving plate 8, in order to balance and stabi...

Embodiment 2

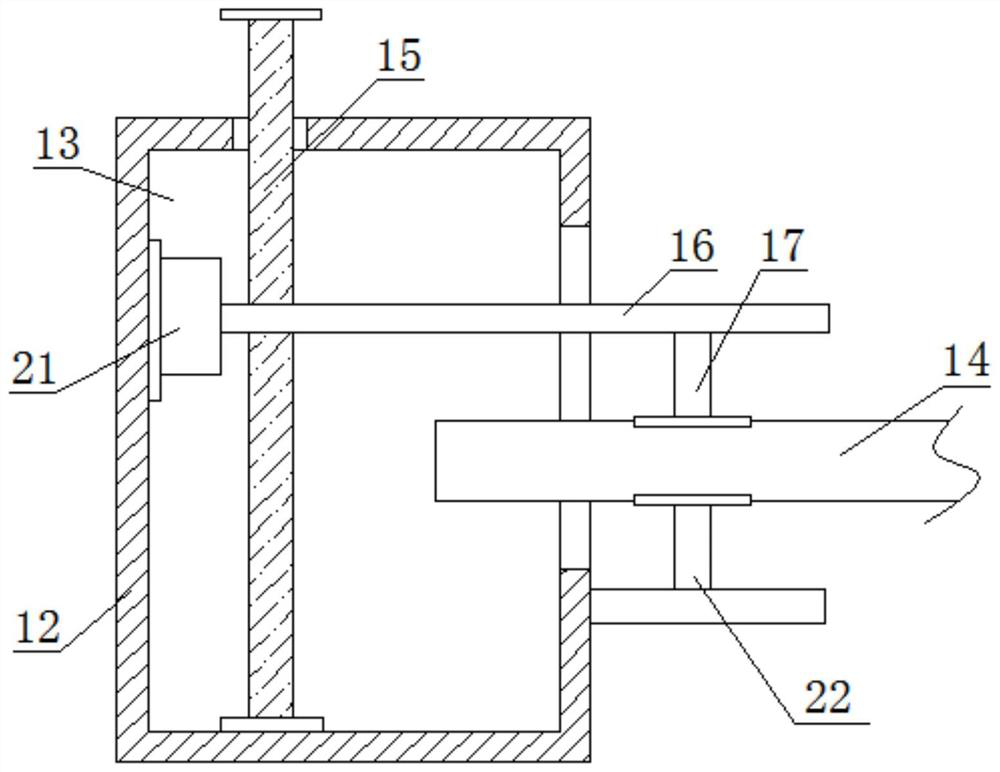

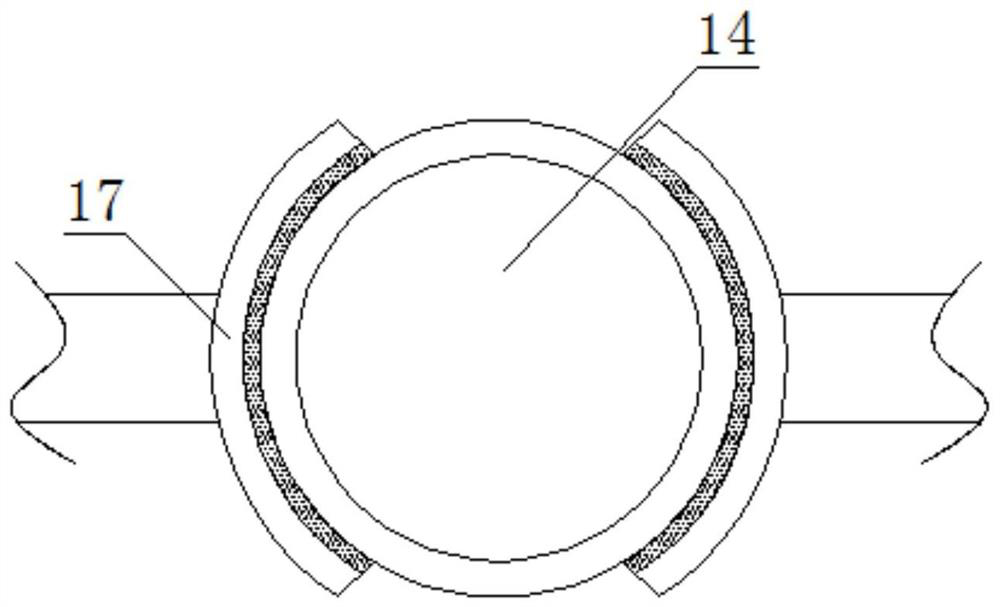

[0034] In the present invention, the clamping assembly includes a threaded shaft 15 that is rotatably connected to the inner wall of the bottom of the fixed chamber 13. The top end of the threaded shaft 15 extends above the top of the fixed base 12 and is fixedly connected with a handle. The threaded shaft 15 is threaded with a threaded plate 16. The sides of the two fixed seats 12 close to each other are fixedly connected with the support plate 22, one side of the threaded plate 16 extends to one side of the fixed seat 12, and the sides of the threaded plate 16 and the support plate 22 close to each other are fixed An arc splint 17 is connected, and the sides of the two arc splints 17 close to each other are closely attached to the top and bottom of the steel pipe body 14, and the threaded plate 16 can drive the arc on the threaded plate 16 through the rotation of the threaded shaft 15. Clamping plate 17 moves downwards, and then can make two arc-shaped splints 17 clamp and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com