Device for vertically cutting concrete pole in segmented mode

A cutting device and concrete technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of high labor intensity of workers, inability to ensure the direction of the poles toppling, and the length of the poles, etc., to improve the safety of cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

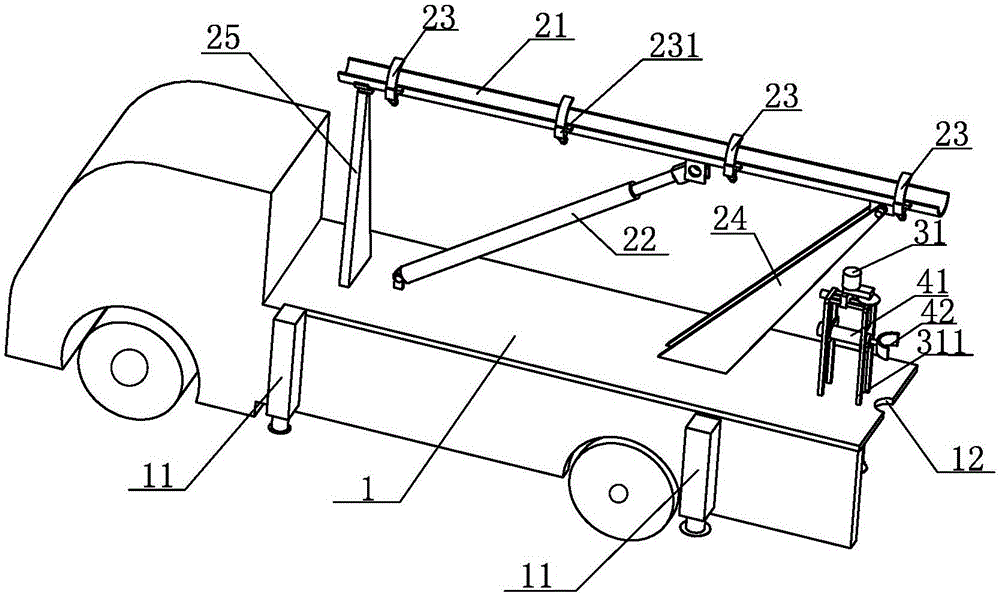

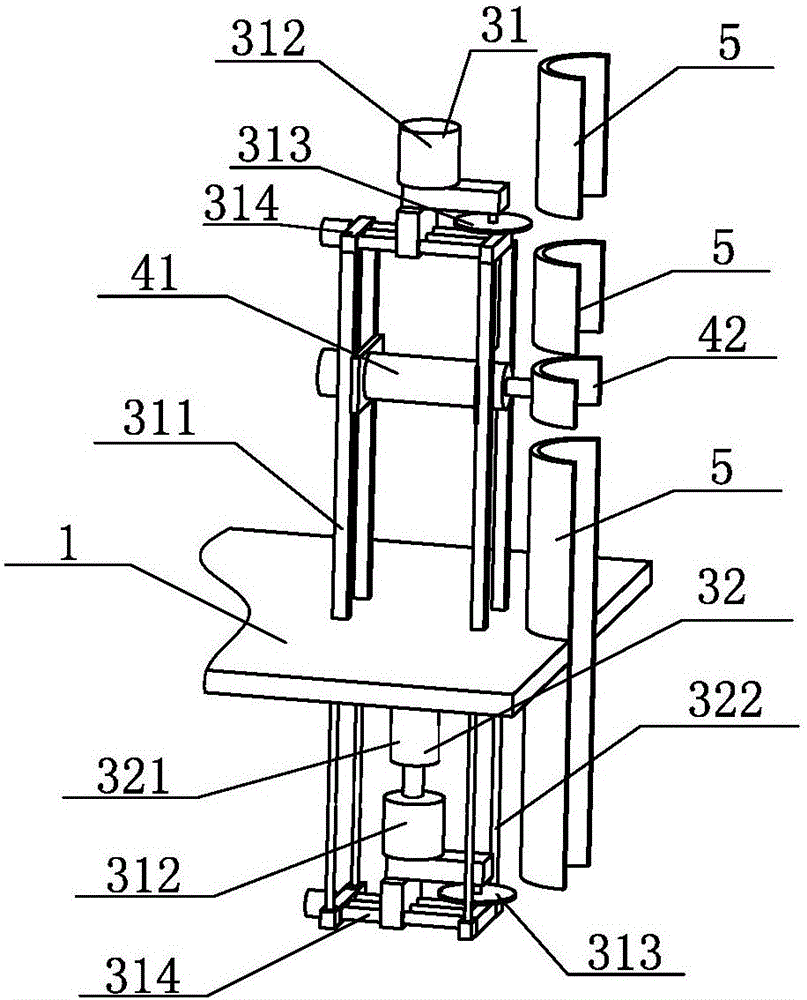

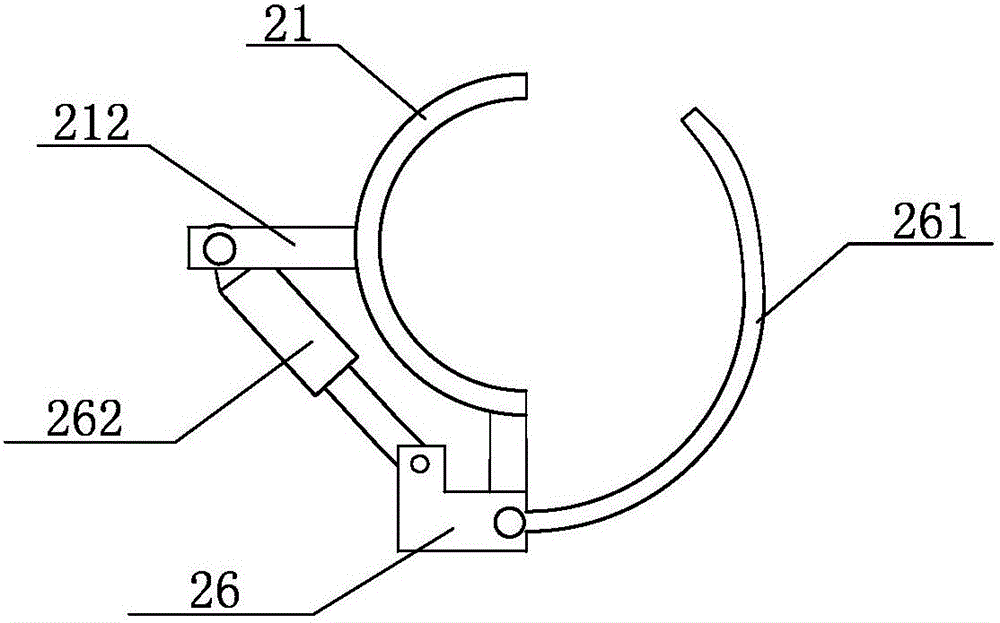

[0022] The following will combine specific embodiments and appendices Figure 1-5 The technical solutions in the embodiments of the present invention are described clearly and completely. Obviously, the described embodiments are only a part of the preferred embodiments of the present invention, rather than all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention. Therefore, the present invention is not limited by the specific embodiments disclosed below.

[0023] The invention provides a device for vertically segmented cutting concrete poles (such as figure 1 (Shown), including a vehicle-mounted chassis 1, an embracing device, and a cutting mechanism. On both sides of the vehicle-mounted chassis 1, there are telescopic hydraulic legs 11 opposite to each other. The vehicle-mounted chassis 1 can travel freely, and the hydraulic legs 11 are the same as the existing ones. The design principle of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com