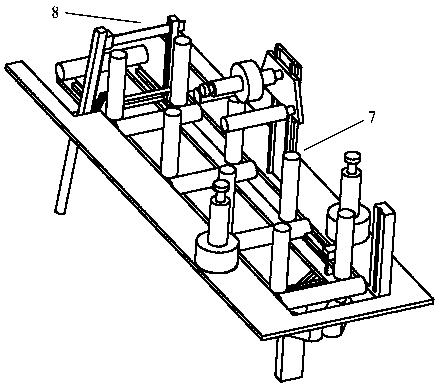

A fully automatic aluminum film sticking machine

A film laminating machine, fully automatic technology, applied in packaging and other directions, can solve the problems affecting the overall efficiency of aluminum film lamination, low cutting efficiency, etc., to achieve the effect of easy automatic cutting, wide application range and high lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

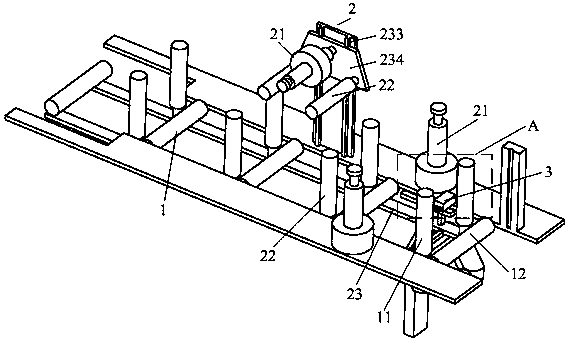

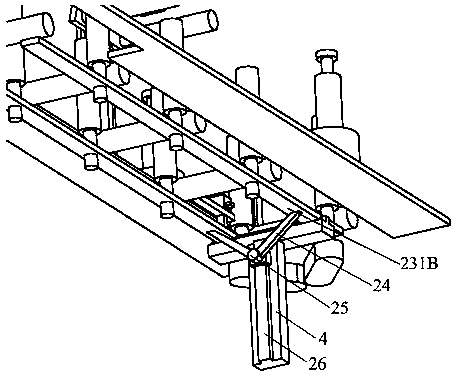

specific Embodiment approach

[0049] Such as Figure 6 and Figure 7 As shown, according to a specific embodiment of the present invention, the swivel 21 includes

[0050] The cylinder 211 is provided with an adjustment cavity inside and a bearing at the bottom, which can rotate relative to the fixed base;

[0051] The protective film bearing seat 212, which is sleeved on the column 211, includes a protective film support plate and a protective film fixing ring, for synchronously rotating the protective film and the column 211;

[0052] An adjustment screw 213 is provided in the adjustment cavity, and an adjustment nut 214 is arranged on the adjustment screw 213, and the adjustment nut 214 is fixedly connected with the protective film bearing seat 212 through a connector 215; The top of the body 211 protrudes, and an adjustment knob 216 is provided at the top; the adjustment screw 213 can rotate relative to the cylinder 211 to drive the adjustment nut 214 to rise or fall, thereby adjusting the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com