Automatic inspecting and packaging equipment for electric connectors

A technology of automation equipment and electrical connectors, applied in the field of mechanical equipment, can solve the problems of high false detection rate, many packaging quality problems, unstable quality, etc., to achieve a high degree of automation, reduce labor costs and false detection rates, product filming and good packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

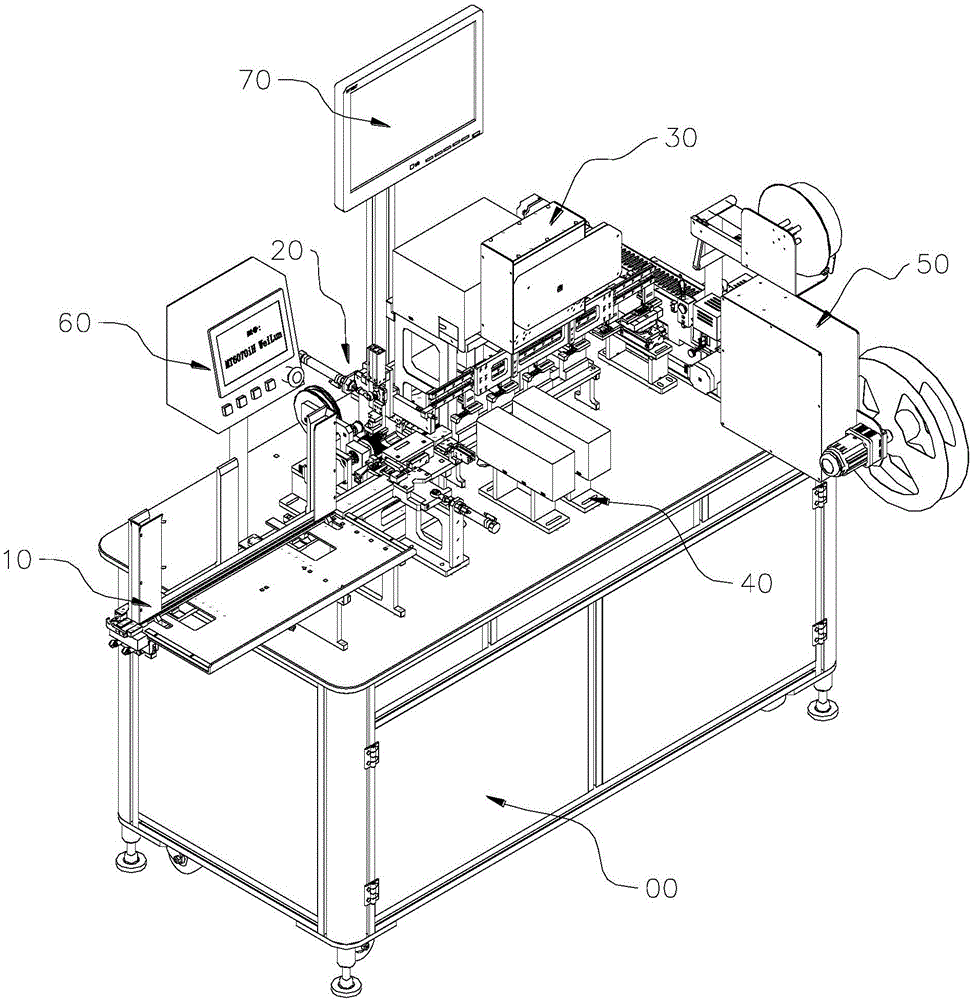

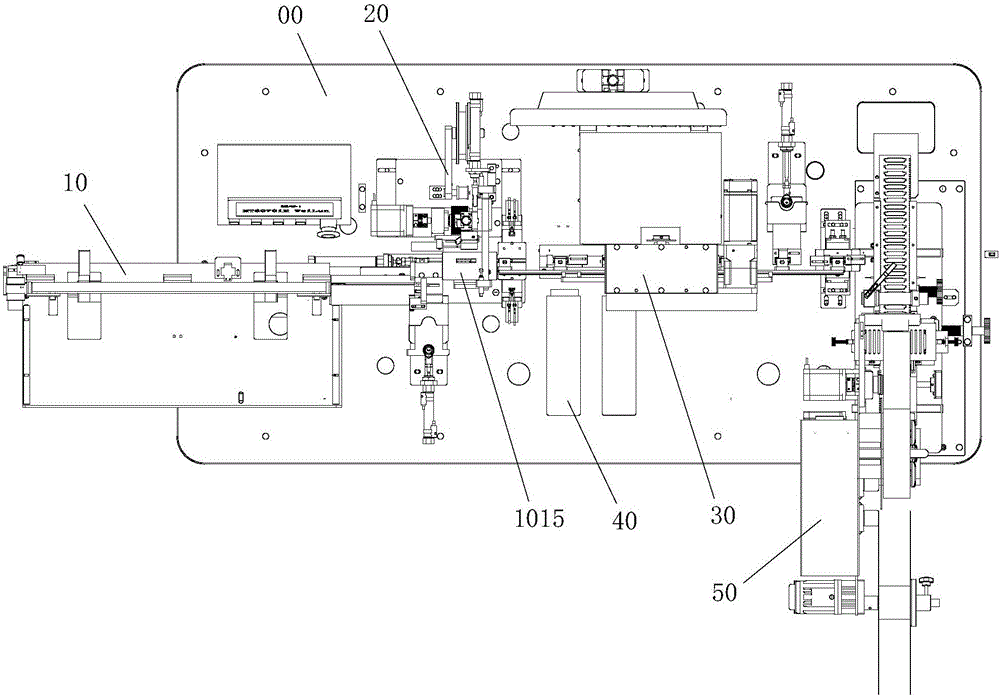

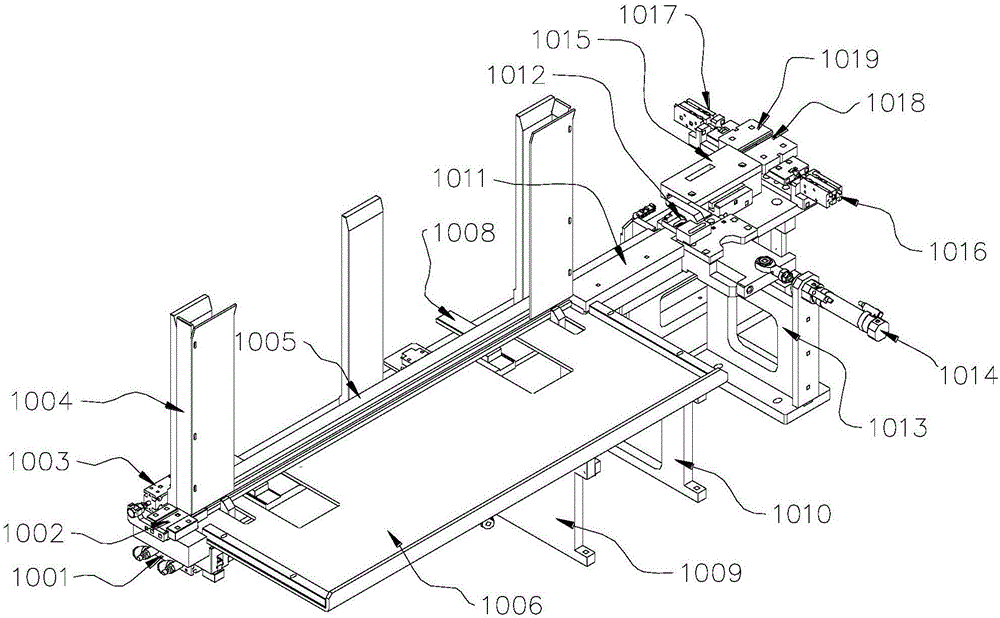

[0070] In this example, refer to figure 1 , figure 2 , Figure 5 and Image 6 , the electrical connector inspection and packaging automation equipment, including a power supply mechanism, a control mechanism and a frame 00, and a tube device 10 installed on the frame 00, an adhesive film device 20, a CCD detection device 40, and a material transfer device And packaging device 50, the pipe discharge device is located at the head end, the adhesive film device is docked with the pipe discharge device, the CCD detection device is docked with the adhesive film device, the packaging device is located at the end of the process, and the material transfer device is located between the adhesive film device and the CCD detection device and between the CCD detection device and the packaging device; the adhesive film device 20 includes a structural support 2001, and a stepper motor 2002 installed on the structural support, an adhesive film fixing plate 2005, a pushing cylinder, and a bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com