Automatic film pasting method and device applied to assembly line

A film sticking device and assembly line technology, applied in the field of automation, can solve the problems of reducing work efficiency, consuming labor, affecting spraying effect, etc., and achieving the effect of improving film sticking efficiency, avoiding waste of raw materials, and reducing labor for placing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

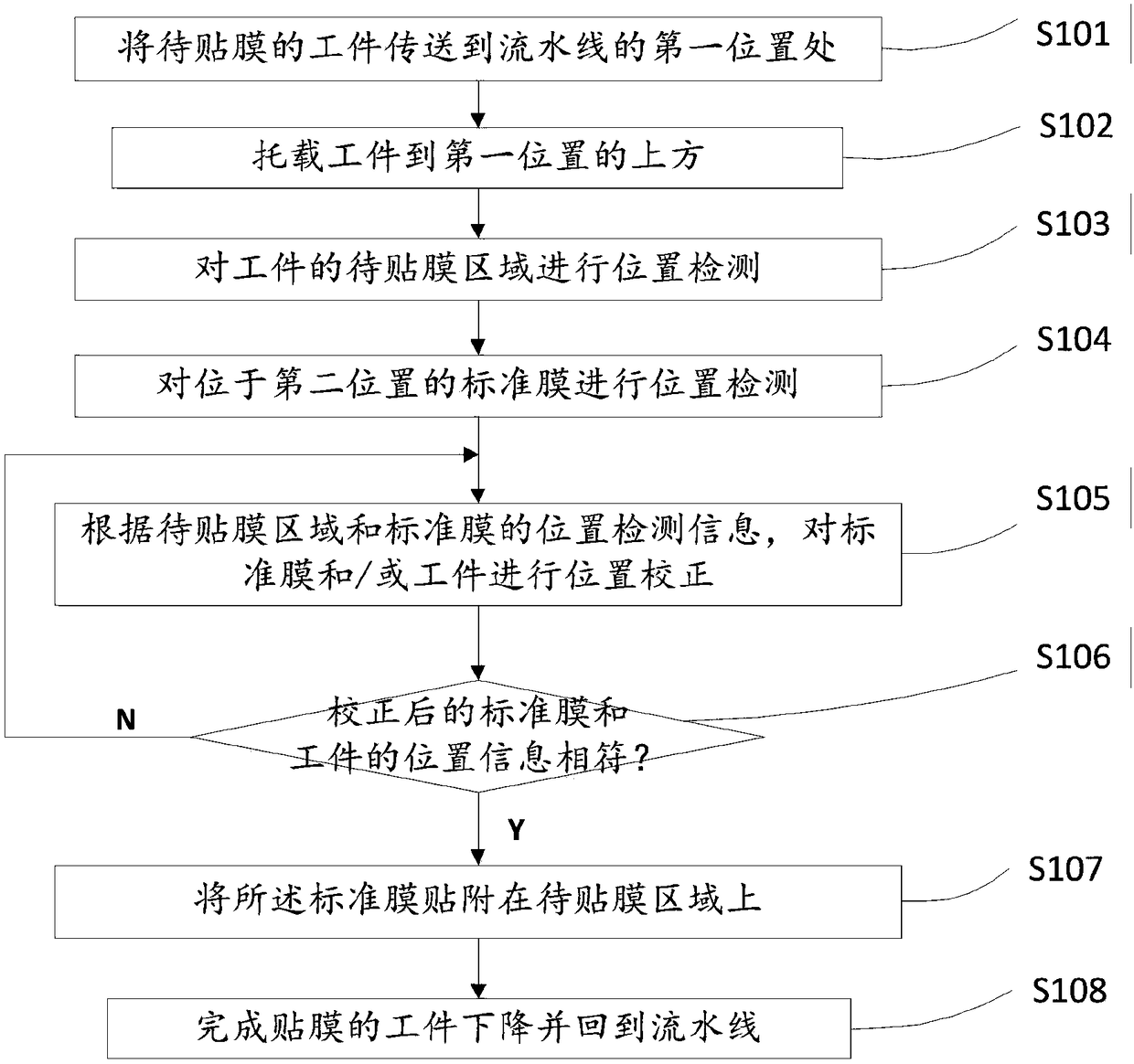

[0040] There is a finger touch area on the notebook. During the spraying process of the notebook shell, the finger touch area is prohibited from spraying. Therefore, before spraying the notebook shell, it is necessary to apply a film to the touch area to avoid The paint is sprayed to cover the touch area. In this application scenario, an embodiment of the present invention provides an automatic film sticking method applied to the assembly line. For details, see figure 1 , the method process includes:

[0041] S101. Transfer the workpiece to be film-attached to the first position of the assembly line.

[0042] The first position here is an absolute position that is stationary relative to the rack of the assembly line, rather than a position that moves with the transfer of the assembly line.

[0043] S102. Carrying the workpiece above the first position.

[0044] Specifically, the middle of the transmission track of the assembly line at the first position is up and down, and t...

Embodiment 2

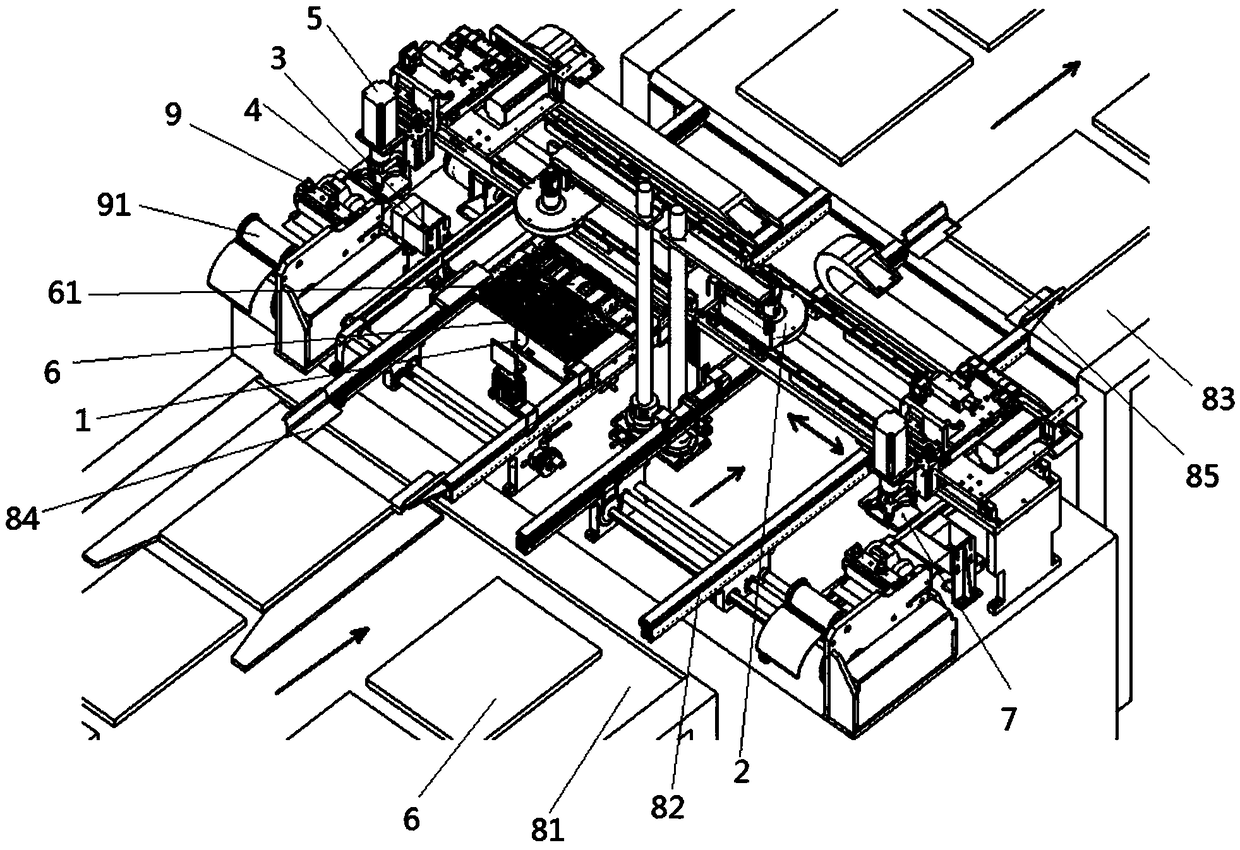

[0061] In one embodiment of the present invention, an automatic film sticking device applied to an assembly line is provided. For a schematic view of the structure, see figure 2 , the film sticking device includes a transmission mechanism, a lifting mechanism 1, a first sensing device 2, a second sensing device 3, a film carrying mechanism 4, a film gripping mechanism 5 and a controller,

[0062] The transmission mechanism is used to transfer the workpiece 6 to be film-attached to the first position, the lifting mechanism 1 is used to support the workpiece 6 so that it is located above the first position, and the first sensing device 2 is used for the workpiece 6 to be film-attached. Area 61 performs position detection;

[0063] The film carrying mechanism 4 is used to transfer the standard film 7 to a second position, and the second sensing device 3 is used to detect the position of the standard film 7;

[0064] According to the detection information of the first sensing de...

Embodiment 3

[0072] Different from Embodiment 2, in this embodiment, the film carrier mechanism 4 is moved according to the correction data, and the process of controlling the action of the film carrier mechanism 4 to correct the position of the standard film 7 is as follows: the carrier film Mechanism 4 is a mechanism that can move back and forth, left and right, and rotate on a plane. According to the detection information of the first sensing device 2 and the second sensing device 3, the position information of the area to be pasted by the first sensing device 2 is As a benchmark, calculate the gap between the detection information of the second sensing device 3 and the gap, the gap includes the displacement and rotation on the plane, and then according to the calculation results, according to the displacement and rotation, the film carrying mechanism 4. Carry out control and adjustment to make it reach the corresponding position, then the gripping mechanism 5 descends to absorb the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com