Automatic film laminator

A film laminating machine, automatic technology, applied in the direction of packaging, web rotary wrapping, etc., can solve the problems of cumbersome operation and low efficiency, and achieve the effect of improving the efficiency of film laminating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

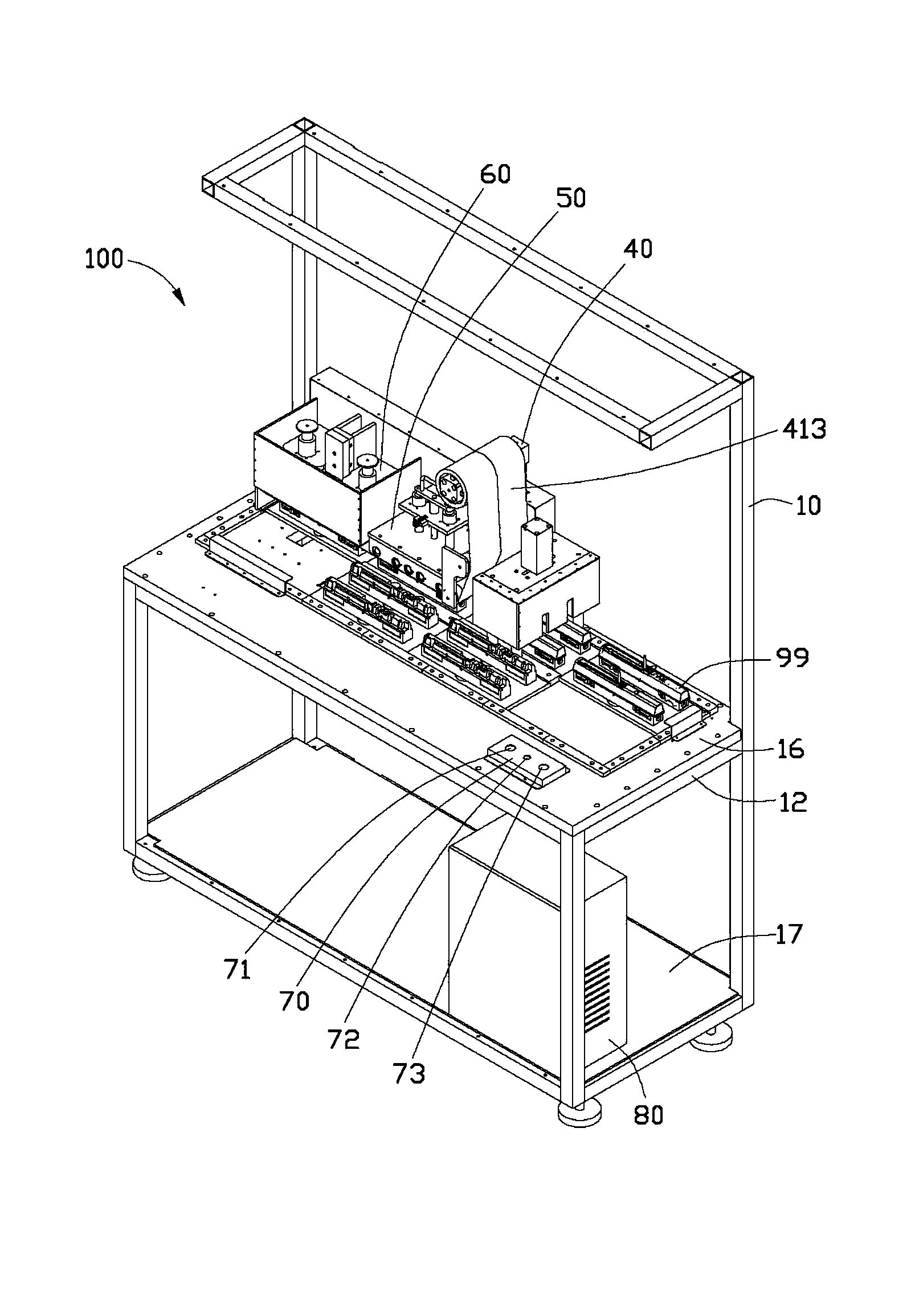

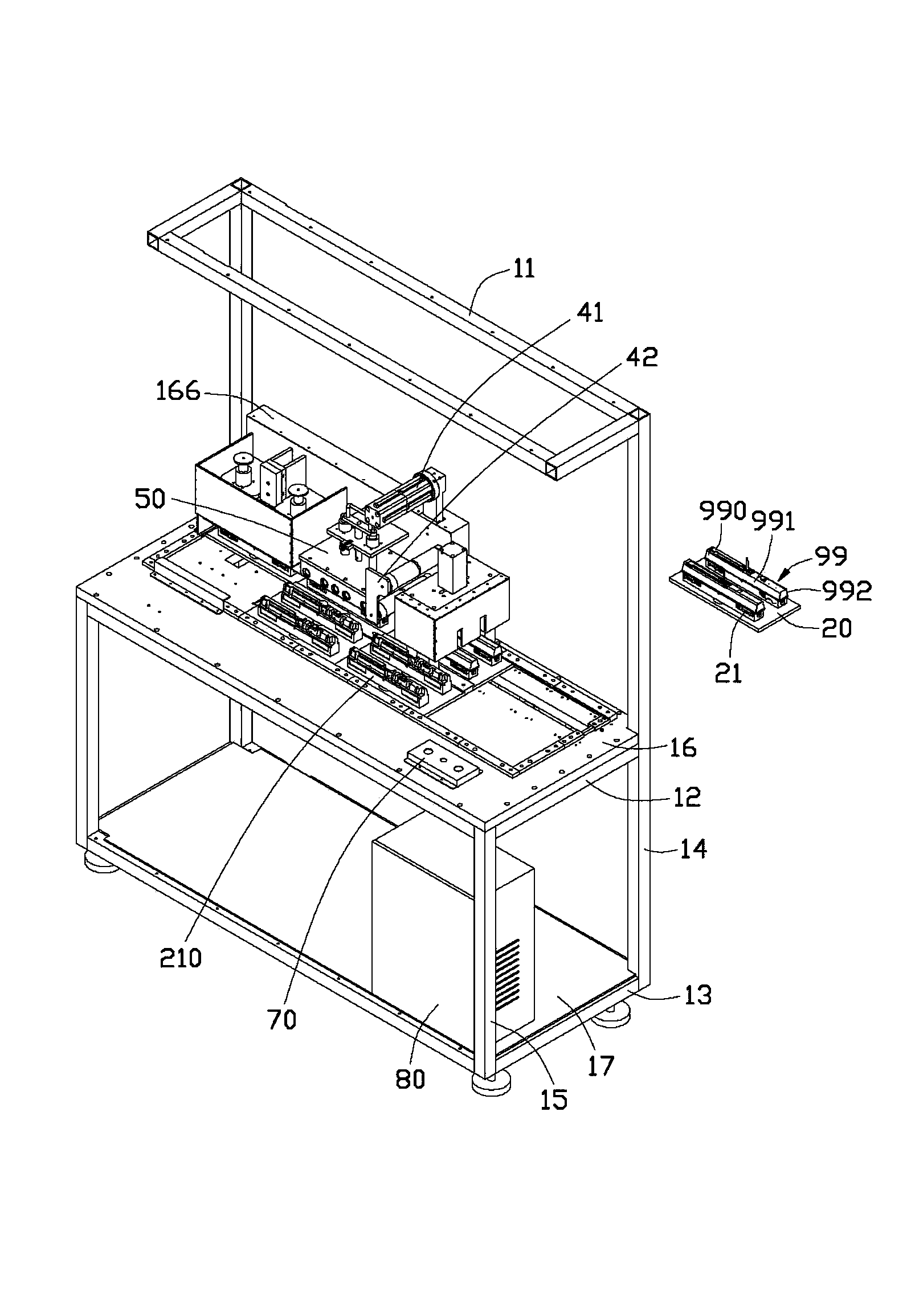

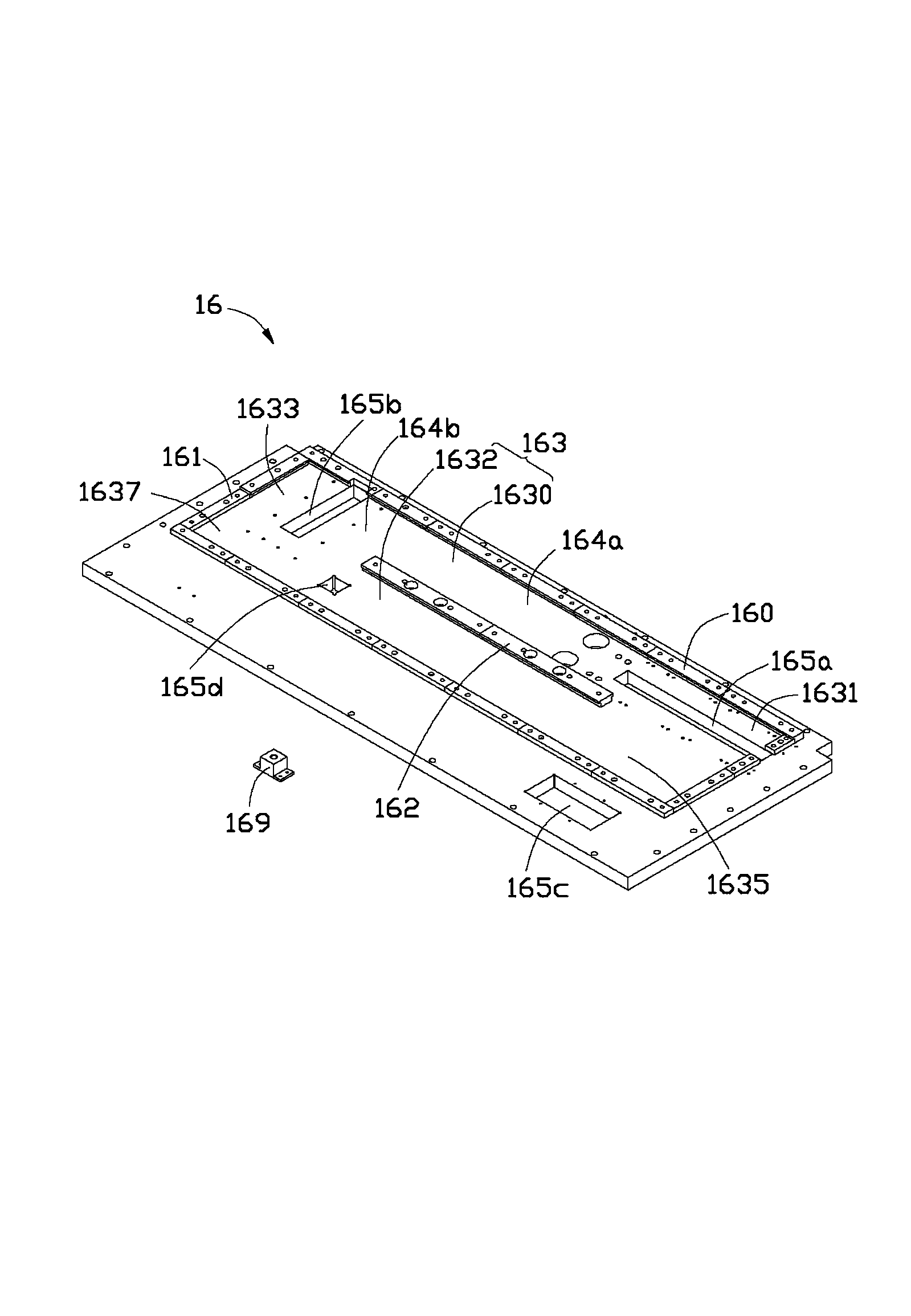

[0103] Please see figure 1 and figure 2, which is a three-dimensional view of the automatic film laminating machine. The automatic film sticking machine cuts and sticks films to the workpiece 99. The workpiece 99 includes a rectangular top surface 990, two parallel first side surfaces 991 and two parallel second side surfaces 992 extending from four edges of the top surface 990, and a top surface extending from one first side surface 991. Removed portion 993 outside surface 990. Wherein, the top surface 990, the first side surface 991 and the second side surface 992 need to be pasted with a film. The automatic film laminating machine includes a machine platform 10 , a carrier 20 placed on the machine platform 10 , a film hanging device 40 , a film sticking device 50 , a film cutting device 60 , an operation box 70 , and a control box 80 .

[0104] The carrier 20 is provided with two symmetrical positioning parts 21 side by side. Each positioning portion 21 is used to fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com