Film adhesion device for film active release

A technology of a film sticking device and a driving device, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems such as the inability to clamp the adhesive film 103 smoothly, the direct stretching or shrinking of the wafer, and the waste in the width direction. The effect of saving film, improving film quality and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in detail below in conjunction with accompanying drawing:

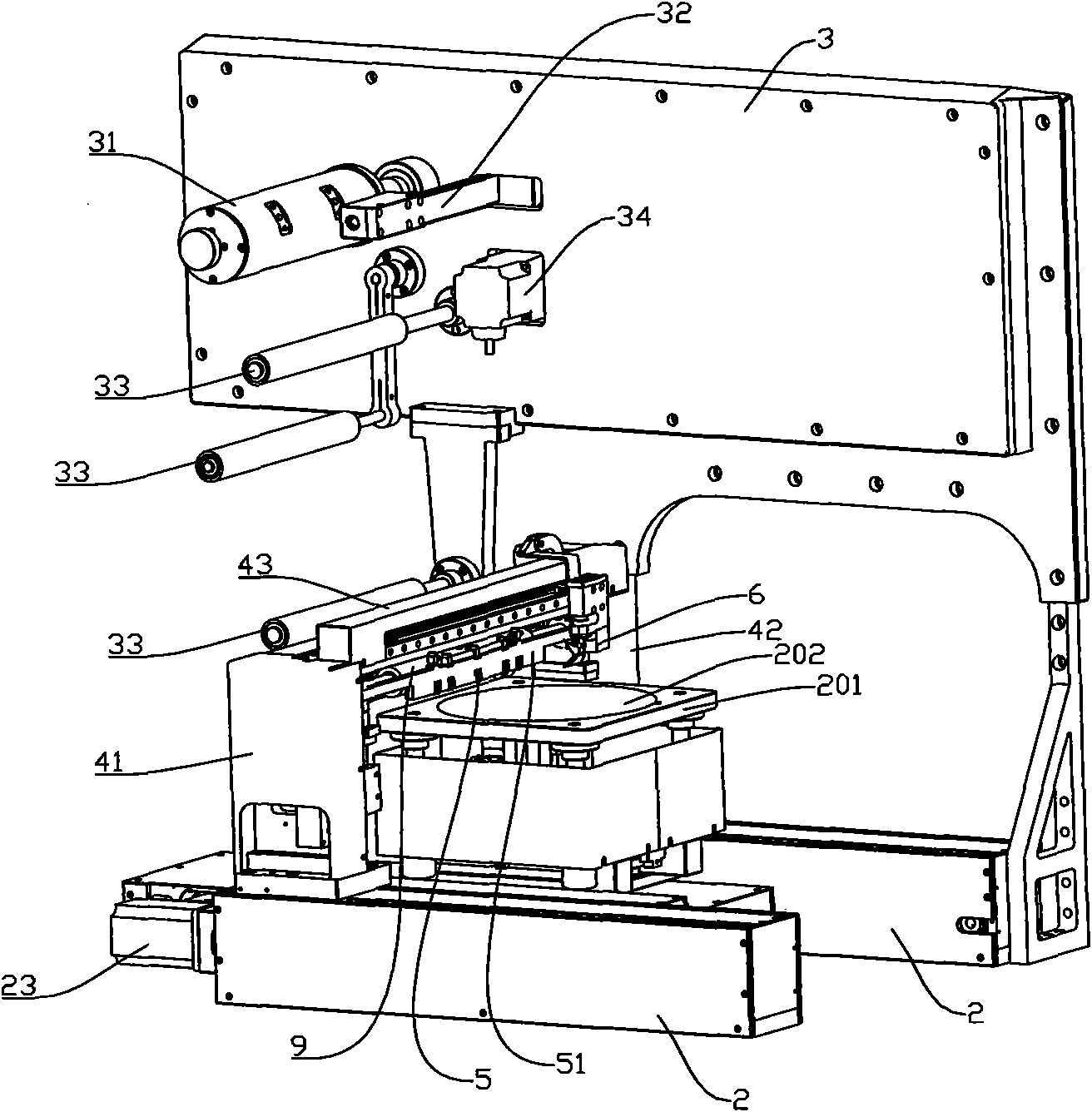

[0054] The film sticking device that releases the film actively, such as image 3 , Figure 5 As shown, it includes two bases 2, and a rack board (41, 42) is respectively arranged on the two bases 2. One of the bases 2 is provided with a motor 23 and a screw mandrel 24 . The output shaft of the motor 23 is connected with the screw mandrel 24, and the motor 23 can drive the screw mandrel 24 to rotate. The frame plate 41 is threadedly matched with the screw mandrel 24, and when the screw mandrel 24 rotates, the frame plate 41 can be driven to move. Specifically, a nut can be installed on the frame plate 41 , and the nut is sleeved on the screw mandrel 24 . The two frame plates (41, 42) are connected by a connecting rod 43, so that when the frame plate 41 is driven to move, it can drive the frame plate 42 to move synchronously.

[0055] The lower ends of the two rack plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com