Device for cutting track-like material as well as method for producing cross sections in a track-like material

A strip, cutting tool technology, applied in packaging, transportation and packaging, manufacturing of rigid/semi-rigid containers, etc., can solve problems such as short service life and achieve the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

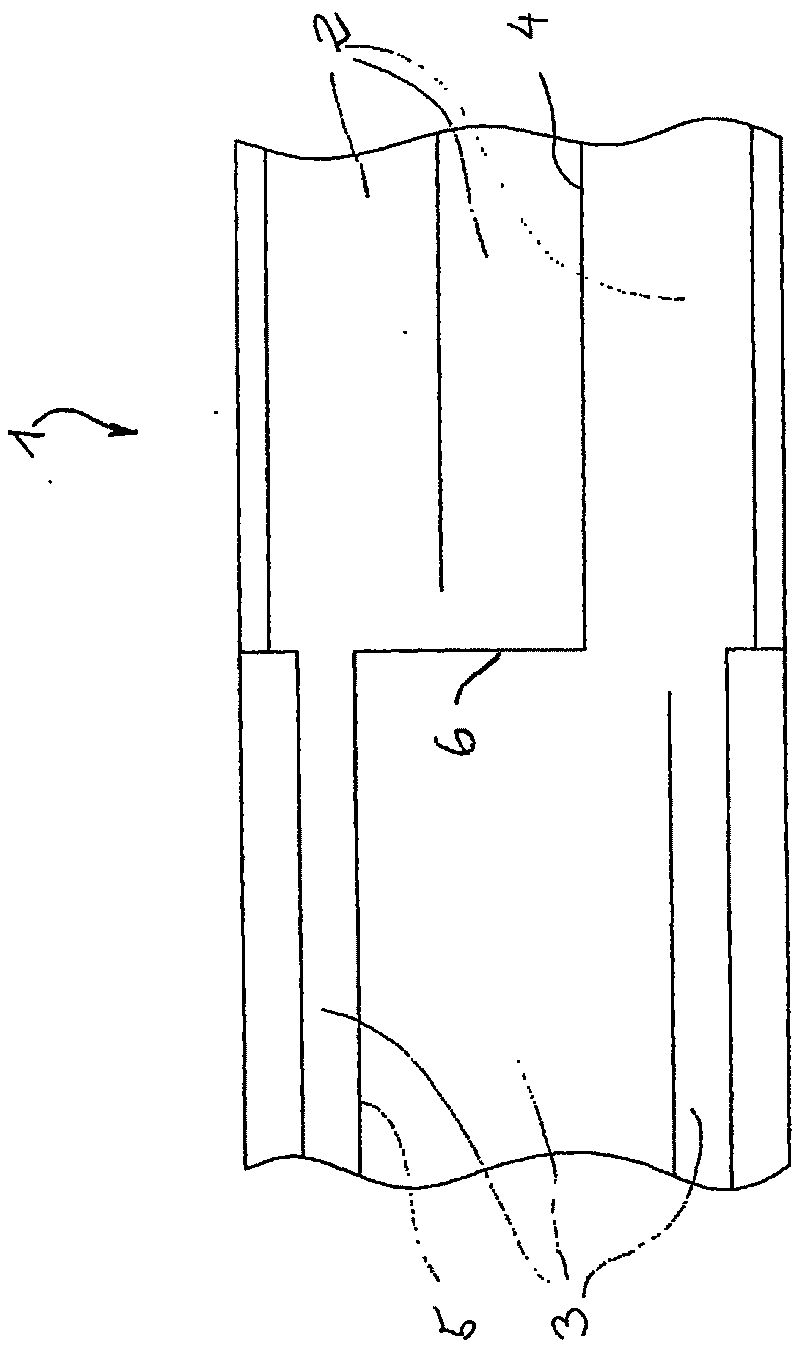

[0033] figure 1 Reference numeral 1 in represents a strip material, such as a corrugated cardboard, which is processed in a continuous process. For the simultaneous production of articles of different large dimensions (for example folding boxes of corrugated cardboard) the strip-like material 1 is divided by longitudinal slits 4 into a plurality of strips (“Nutzen”—used parts). exist figure 1 The right section of , shows a gauge width area with multiple strips (used portion) 2 . The first specification width area will pass through a (in figure 1 Not shown in the knife configuration structure cutting.

[0034] When changing the gauge width to a product of another size, the gauge width change from the first tape split to the second tape split with the use portion 3 is carried out by the knife arrangement, indicated by the cutting line 5 . The specification width change is also carried out in the continuous manufacturing process.

[0035] In order to ensure a trouble-free tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com