Patents

Literature

37results about How to "Realize cutting work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

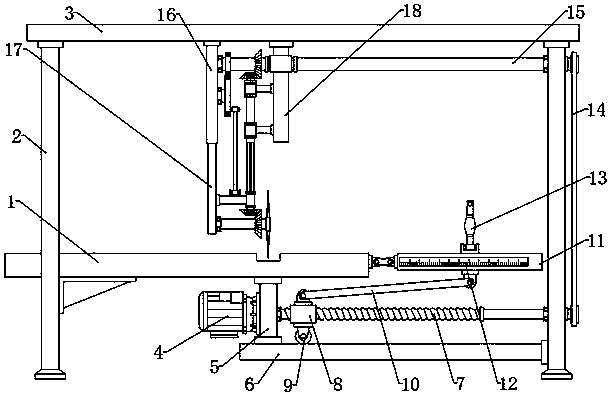

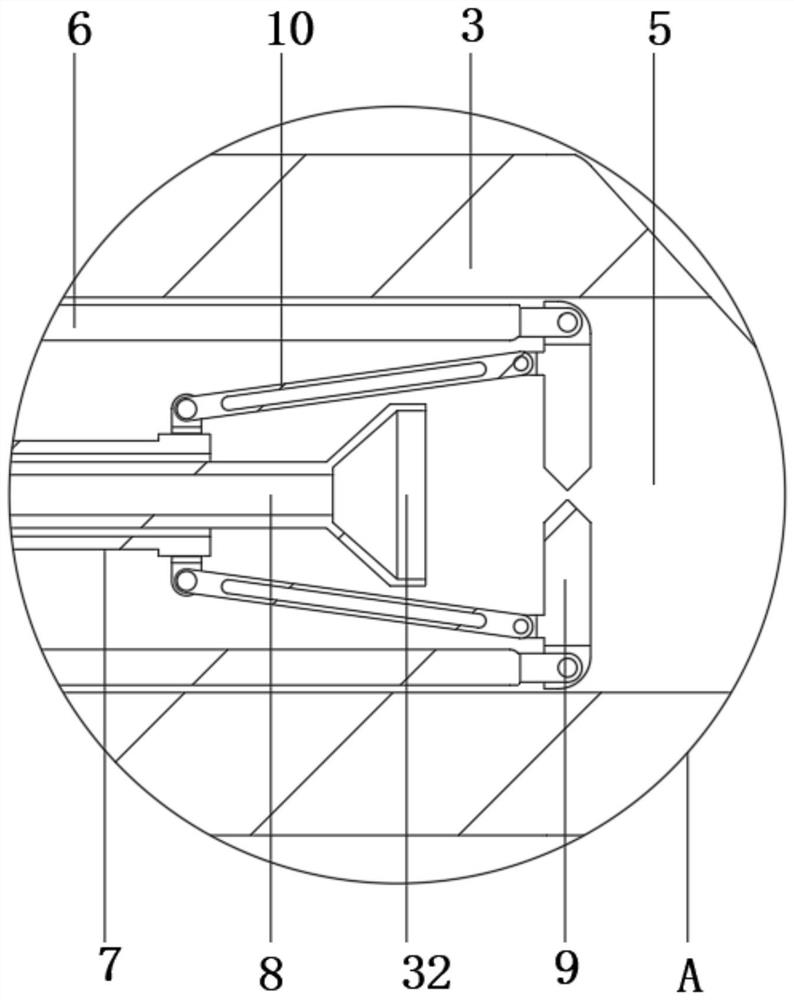

Connecting-rod-type pipe bending and cutting integrated device

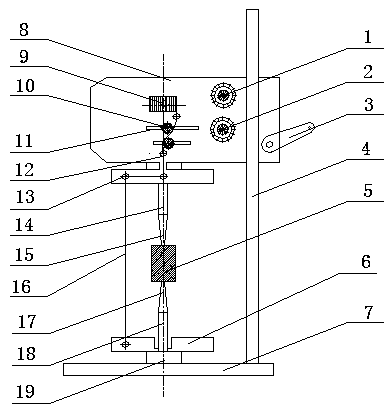

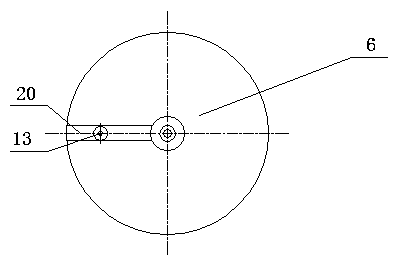

The invention discloses a connecting-rod-type pipe bending and cutting integrated device, and relates to equipment capable of synchronously bending and cutting a steel pipe. According to the connecting-rod-type pipe bending and cutting integrated device, a screw rod is brought by a motor to rotate, and then a threaded sleeve block is driven to move; a first connecting rod is brought by the threaded sleeve block to drive a moving plate to rotate and bend the steel pipe; meanwhile, a driven shaft is driven by the rotating screw rod through a synchronous belt to rotate; a small gear is driven bythe driven shaft to rotate when a first bevel gear is driven by the driven shaft to rotate; a second bevel gear and a sleeve are brought by the first bevel gear to rotate, and then a stepped shaft anda third bevel gear are brought to rotate; a fourth bevel gear, a rotating shaft and a cutting knife are brought by the third bevel gear to rotate; a large gear is brought by the small gear to drive asecond connecting rod to bring a baffle plate, the rotating shaft and the cutting knife to move up and down in a reciprocating manner; and consequently, the cutting operation on the steel pipe can beachieved.

Owner:HUNAN UNIV OF SCI & ENG

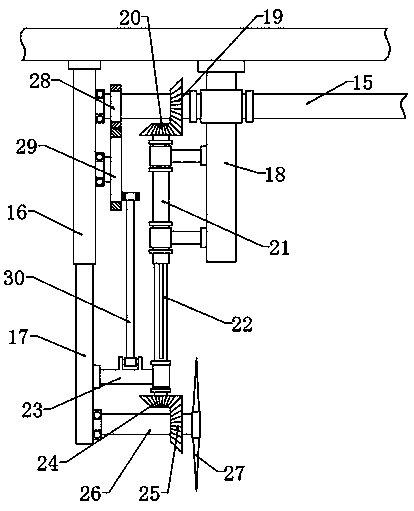

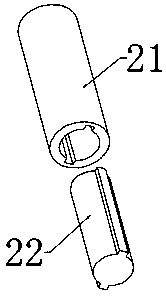

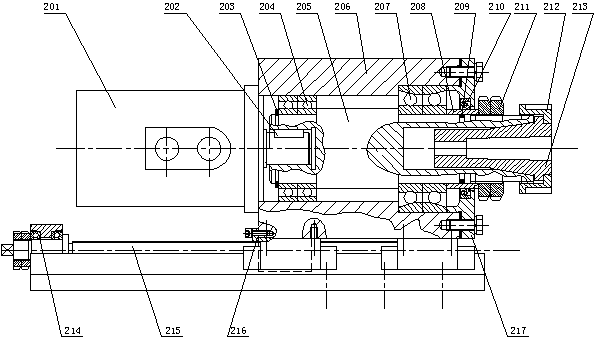

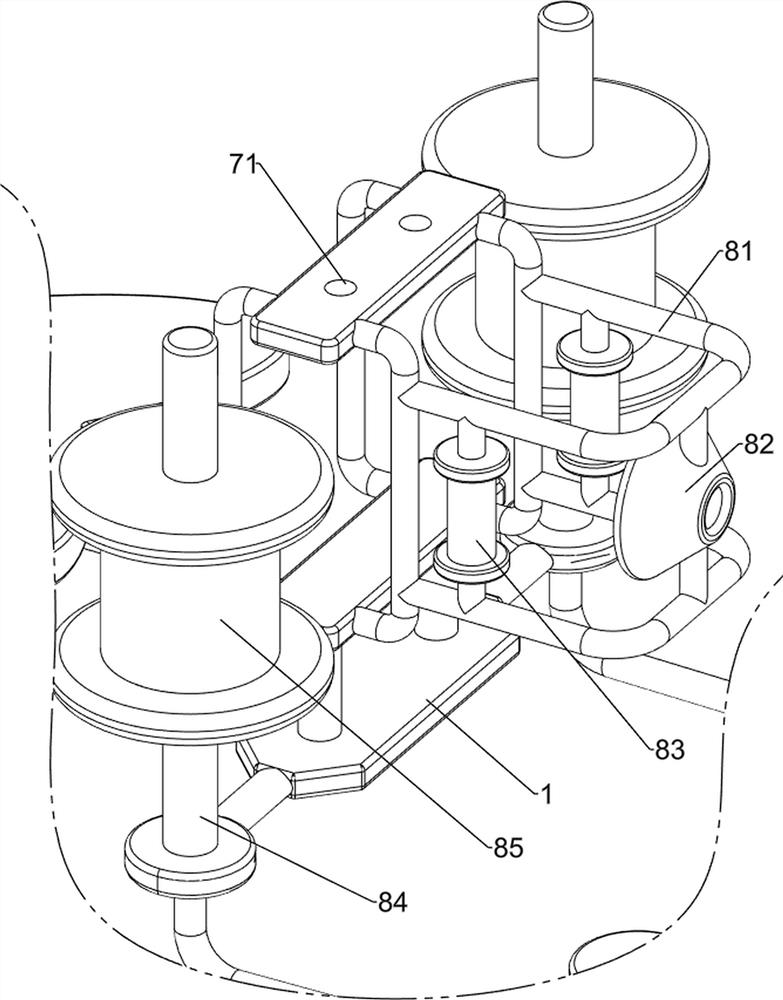

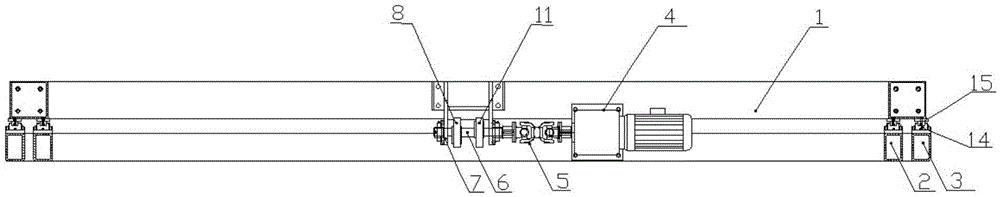

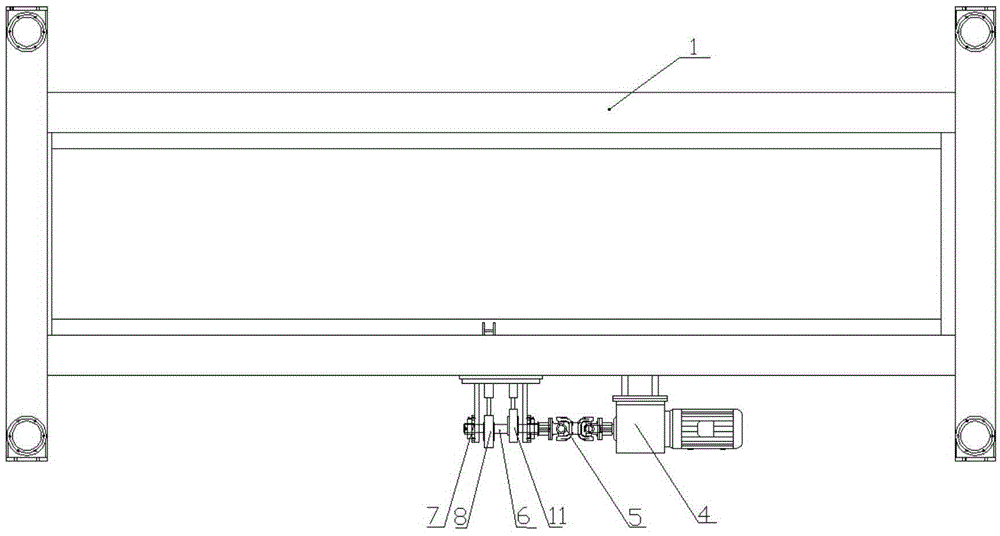

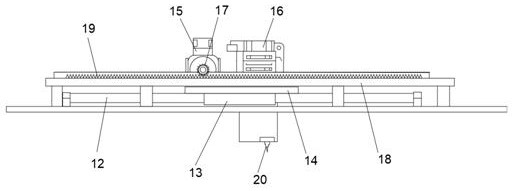

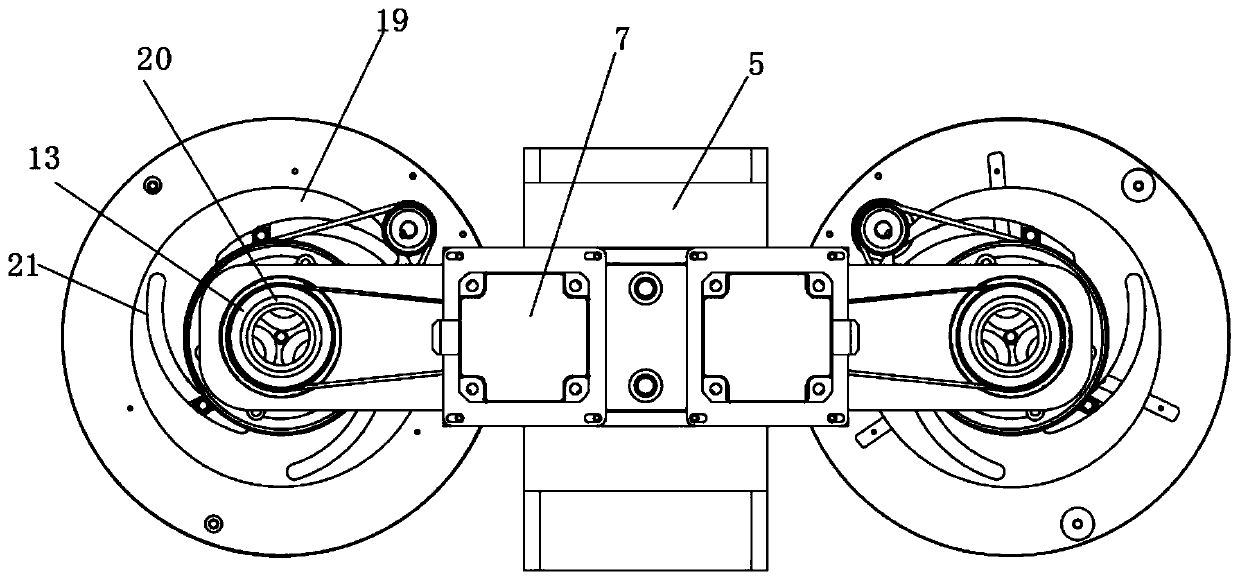

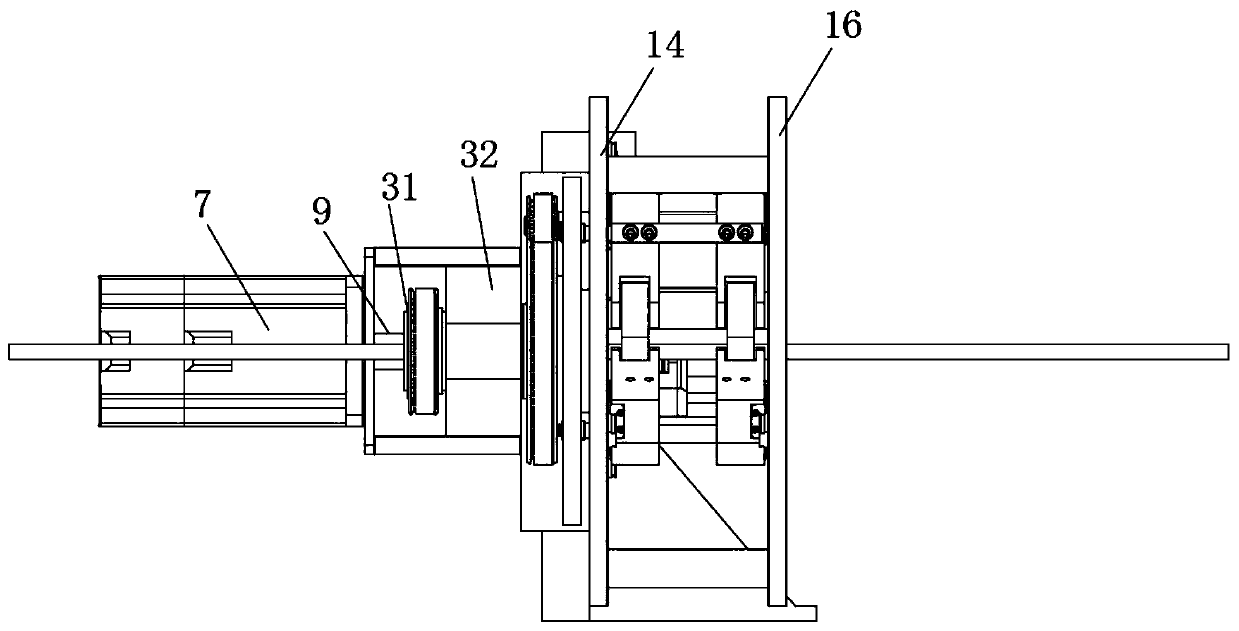

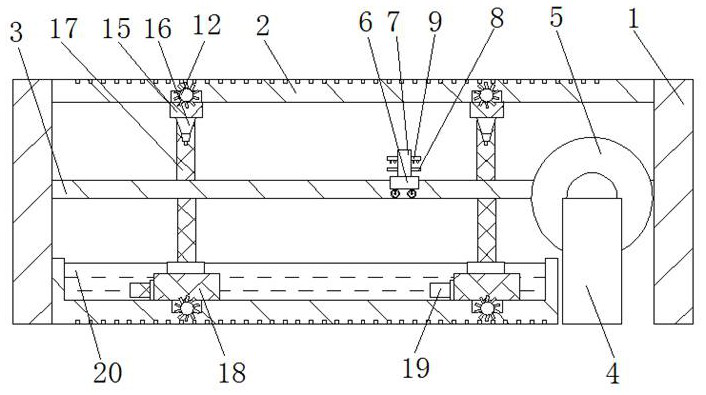

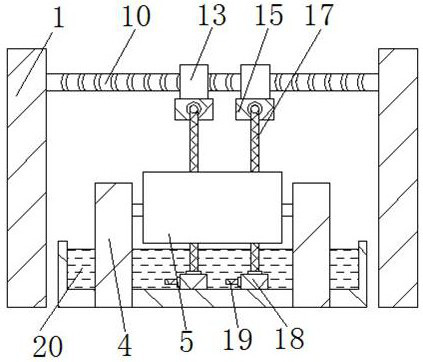

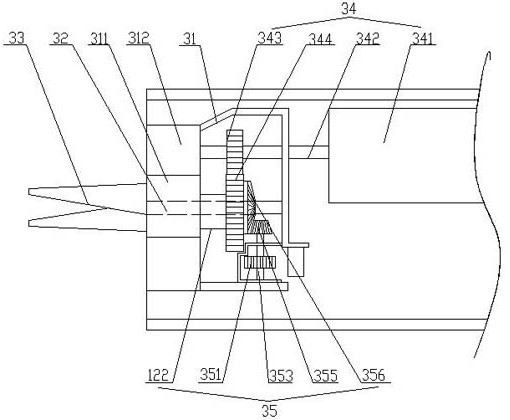

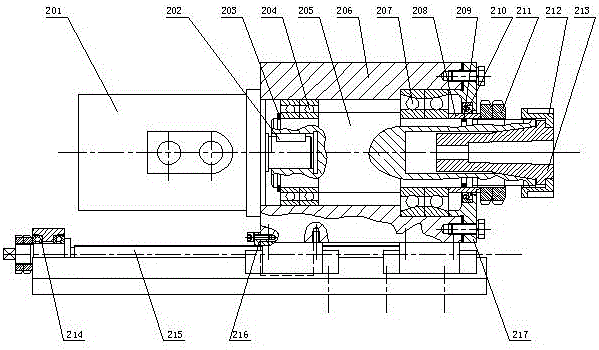

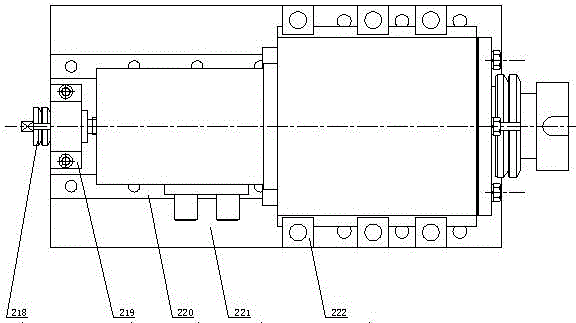

Power unit assembly of drill milling head

InactiveCN103659279ASimple structureEasy to implementFeeding apparatusOther manufacturing equipments/toolsMotor shaftPower unit

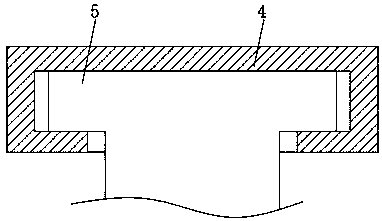

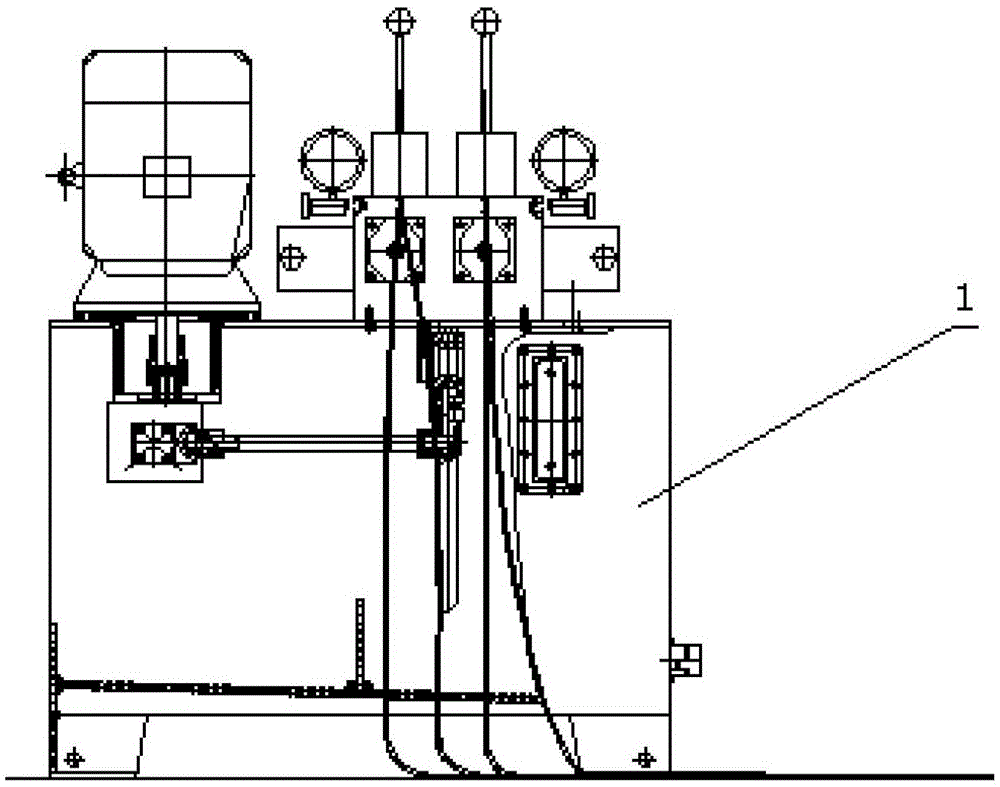

The invention discloses a power unit assembly of a drill milling head. The power unit assembly is mounted on a front end face of a pipe cutter movable plate through a bottom plate, two paralleling linear guide rails are fixedly mounted on the bottom plate, and a box body is fixedly mounted on the linear guide rails. A lead screw is mounted on the bottom plate through a supporting seat and forms a lead screw nut pair with the box body. The box body can move along the linear guide rails under the drive of the lead screw. A hydraulic motor is fixedly mounted on a rear end face of the box body through a square flange, a motor shaft extends into a cylindrical hole of a rear end of a main shaft, and the motor shaft and the main shaft are connected by keys. The main shaft is in a form of single-pivot and two-way fixing. A cutter is integrally connected with a collet. A tapered wedge cushion block is additionally mounted on the pipe cutter movable plate, the power unit assembly of the drill milling head is fixedly mounted on the tapered wedge cushion block, so that an inclination angle of the power unit assembly of the drill milling head is changed, the cutter inclines during milling, and a welding groove can be directly formed on an end face of a pipeline during pipeline cutting, and integral operation of a cutting pipe and the groove can be achieved. The power unit assembly of the drill milling head is simple in structure and easy to achieve.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

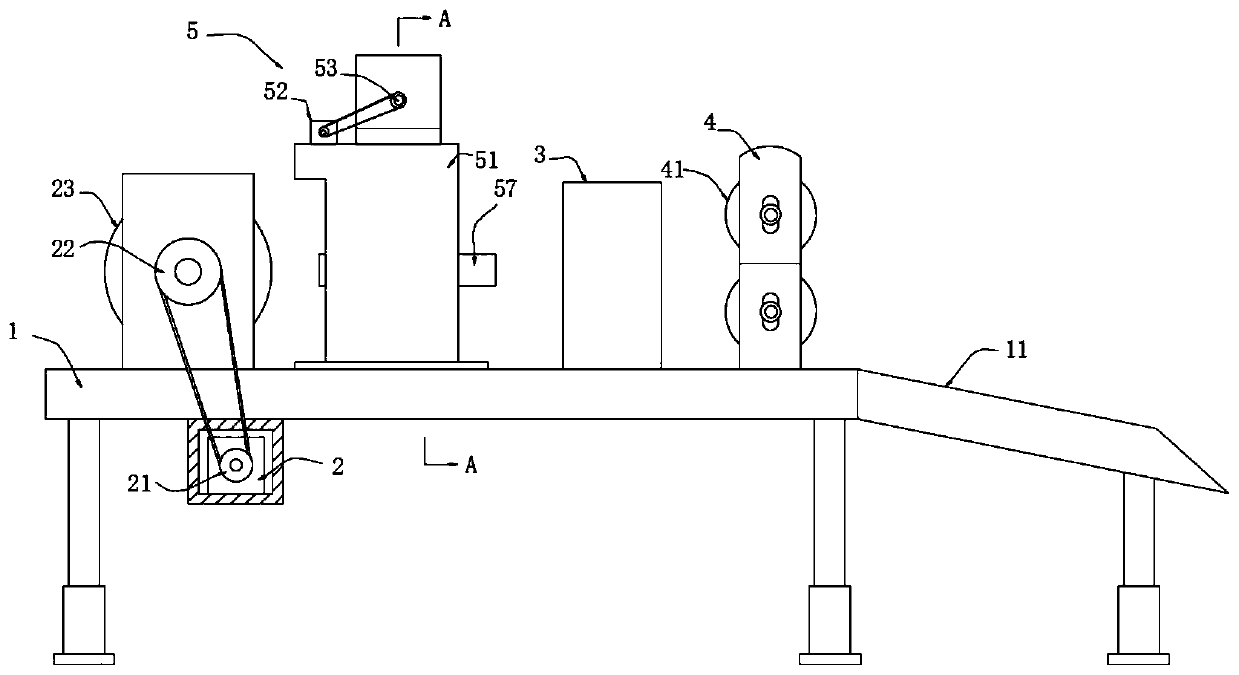

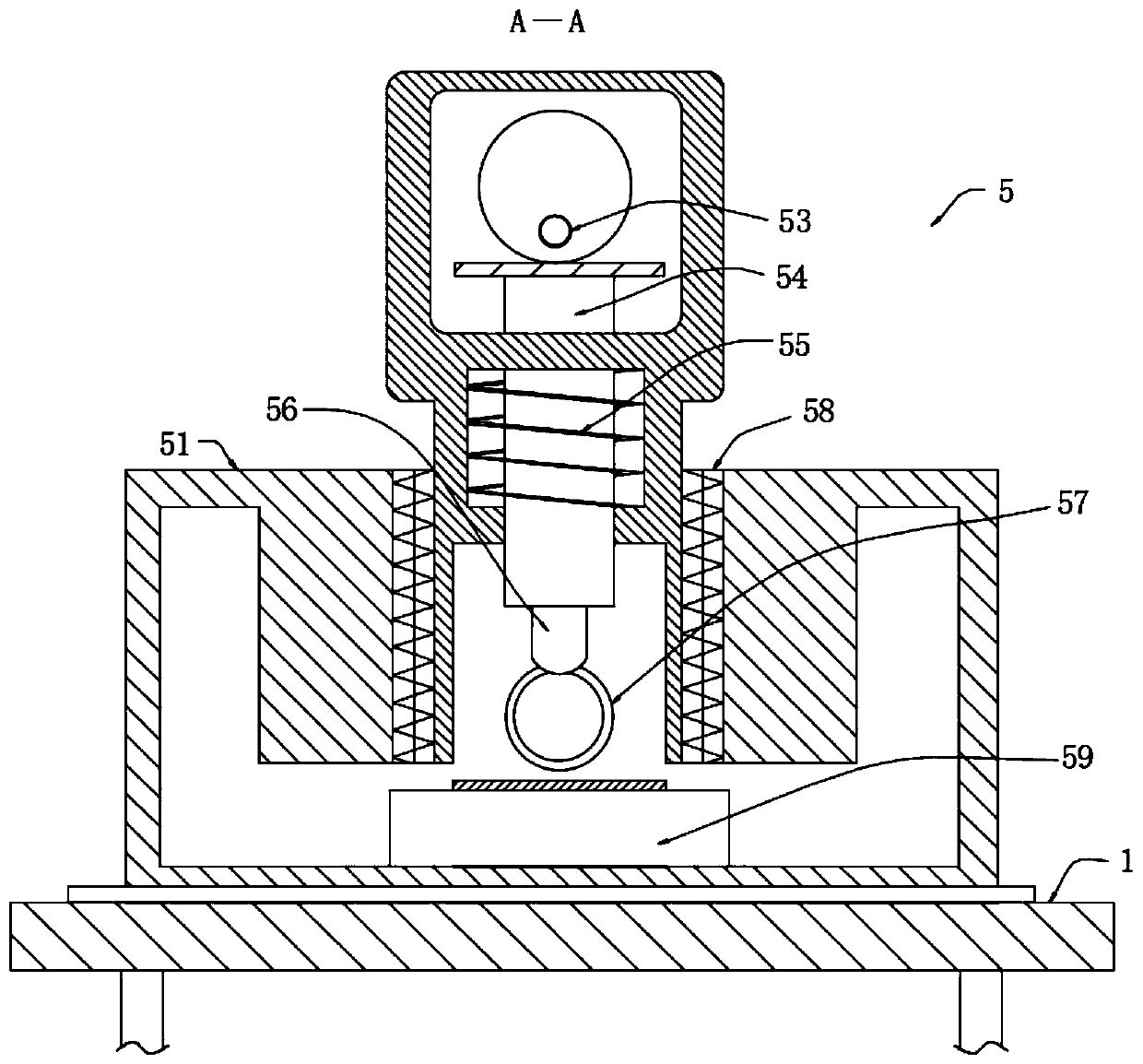

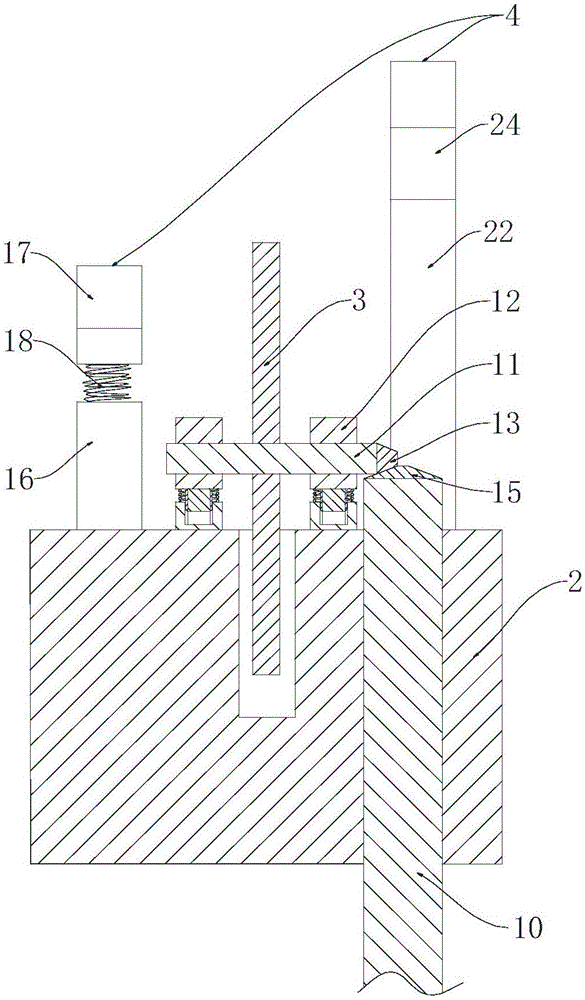

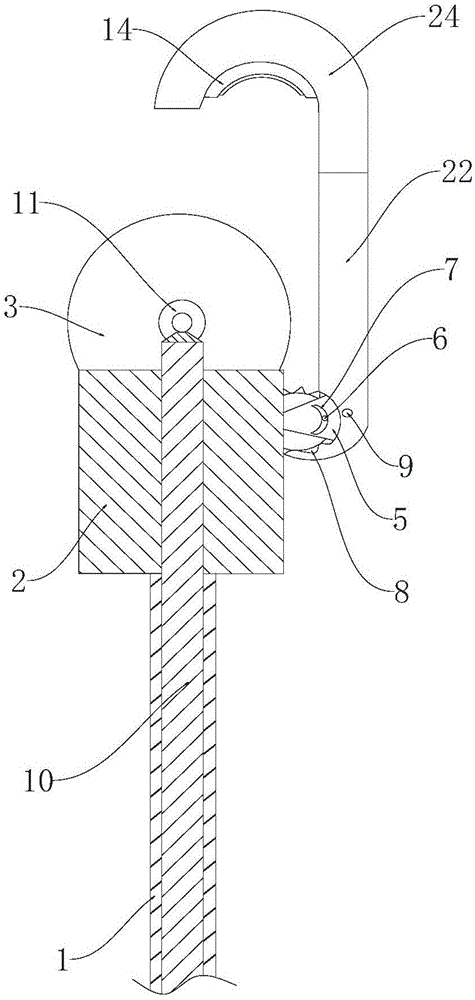

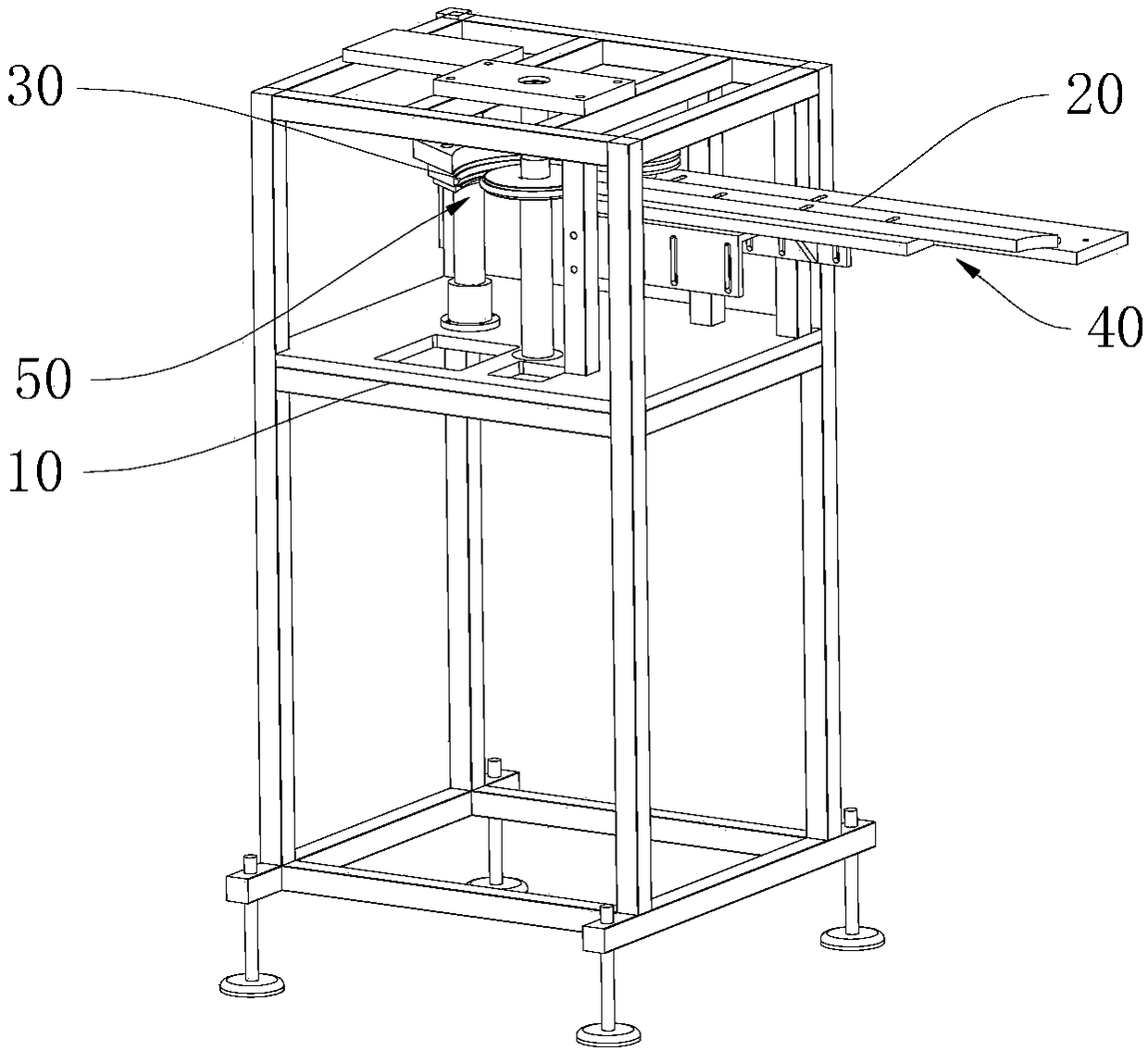

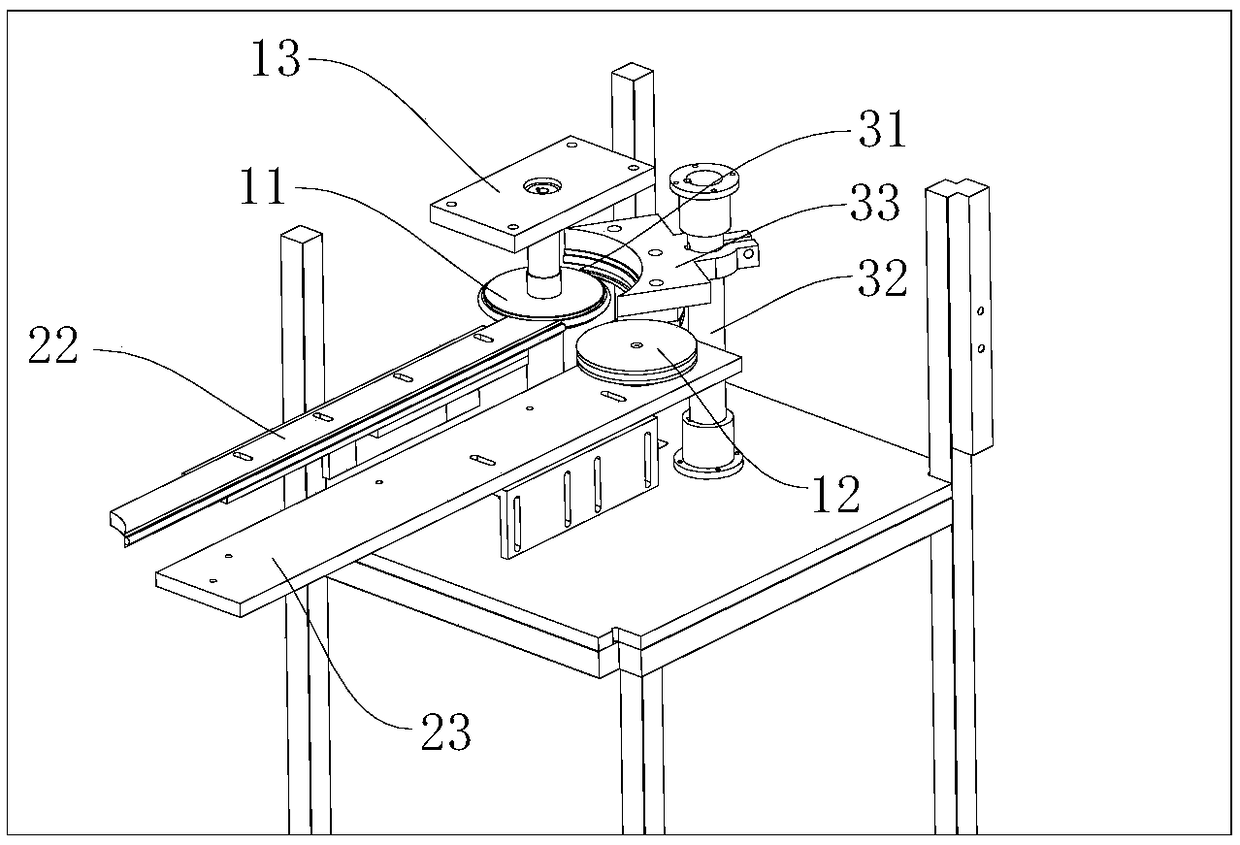

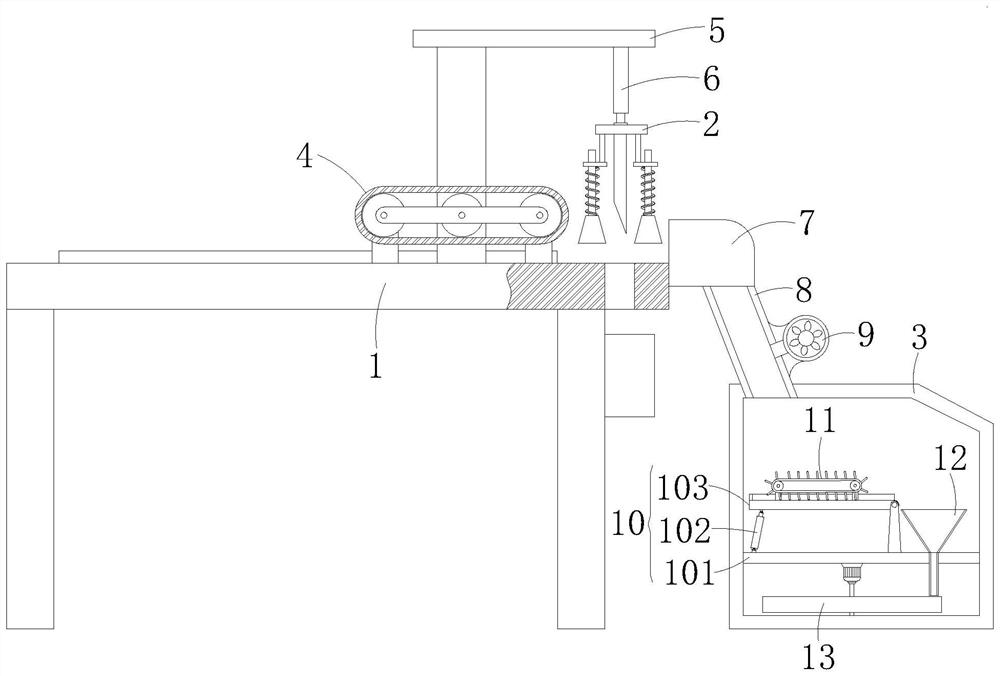

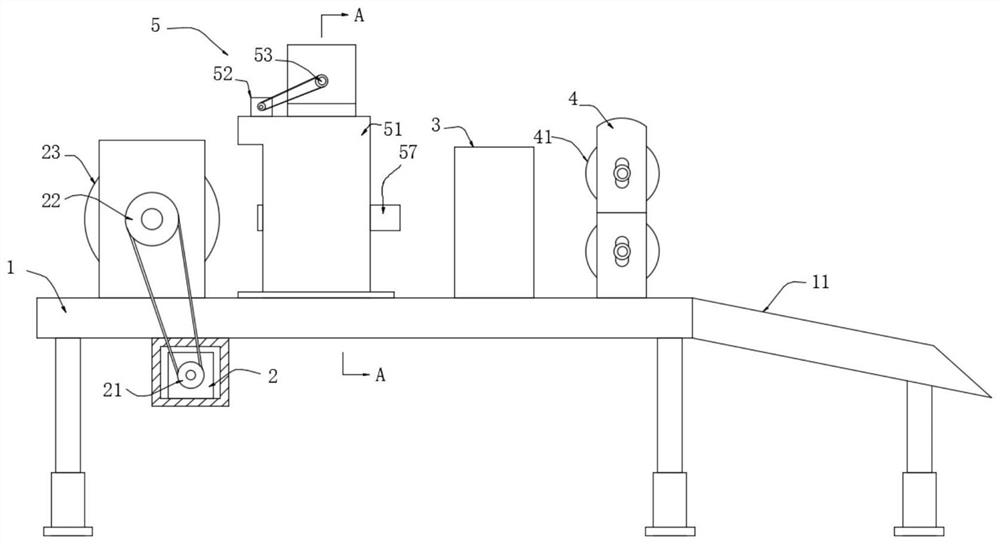

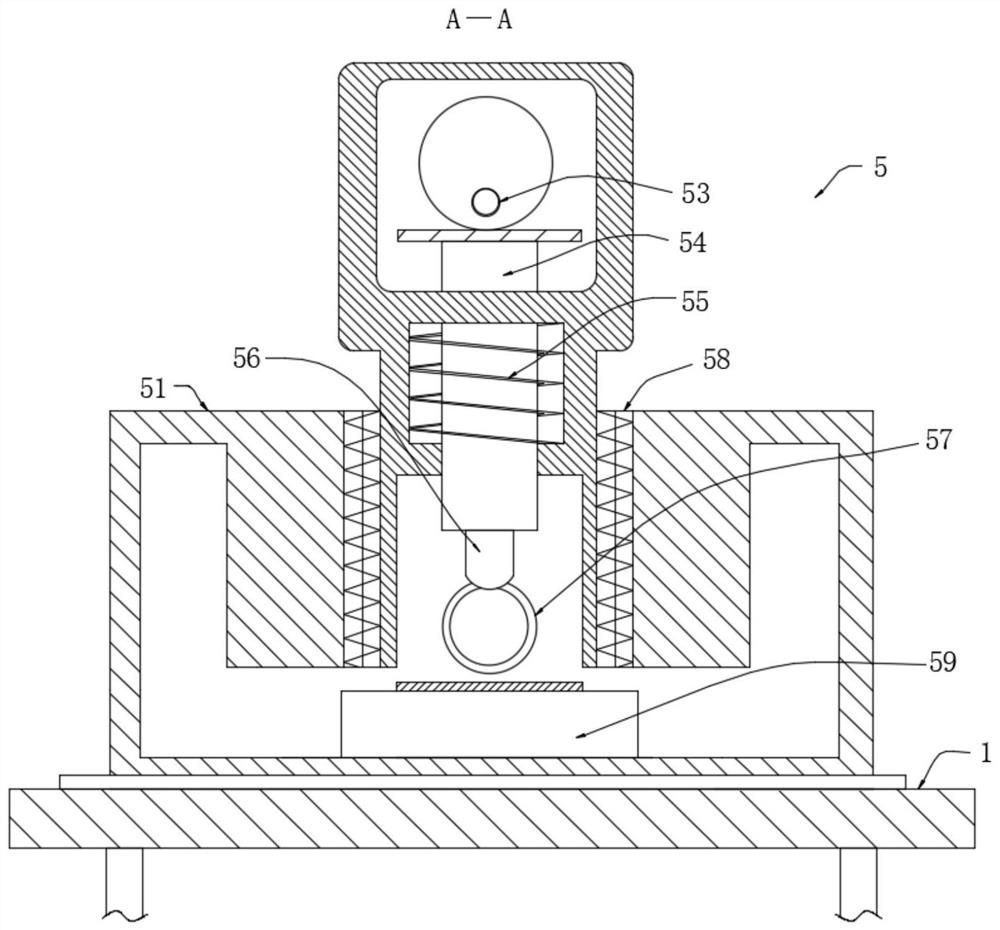

Cable stripping and cutting machining device

ActiveCN111049070AEasy to moveRealize cutting workApparatus for cutting/splicing cablesApparatus for removing/armouring cablesWire cuttingStructural engineering

The invention discloses a cable stripping and cutting machining device. The device comprises a mounting bracket, a wire stripping mechanism and a wire cutting mechanism; the wire stripping mechanism and the wire cutting mechanism are both installed on the mounting bracket; the wire stripping mechanism is arranged on the right side of the wire cutting mechanism; and a wire winding roller is arranged on the left side of the wire cutting mechanism. With the cable stripping and cutting machining device of the invention adopted, problems such as infirm fixation of a cable, failure to automaticallystrip or cut the cable, and failure to automatically wind the cable during existing cable stripping can be solved. The wire stripping mechanism is adopted; the wire stripping mechanism can perform automatic wire stripping on a cable; the wire stripping mechanism is reasonable in structural arrangement and firm in fixation; the stripped cable can enter the wire cutting mechanism; the cable can be cut off through the up-down reciprocating work of a cutter; and therefore, the machining efficiency of the cable is greatly improved, and tedious manual operation is avoided. The cable stripping and cutting machining device has high practicability and is convenient to use and popularize.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

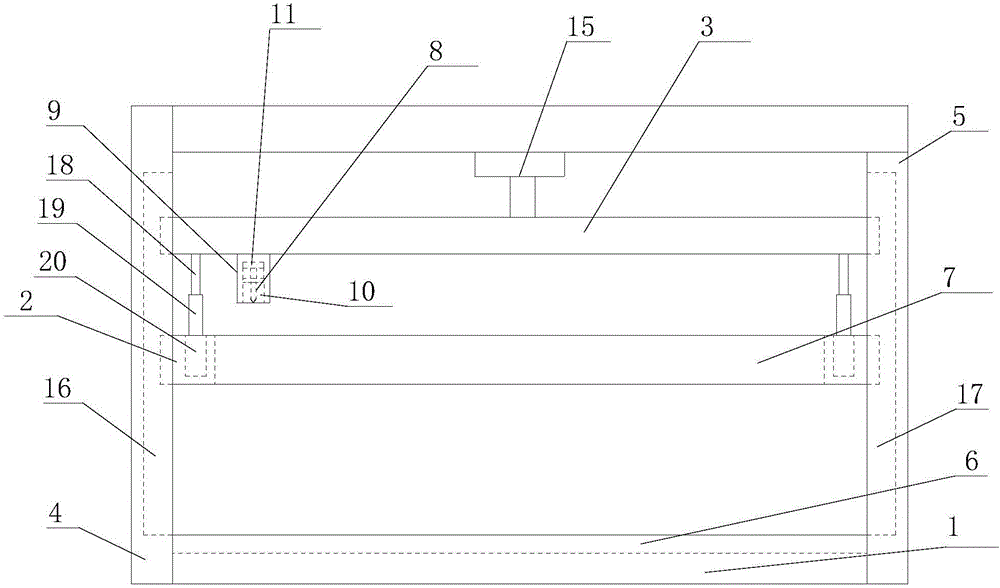

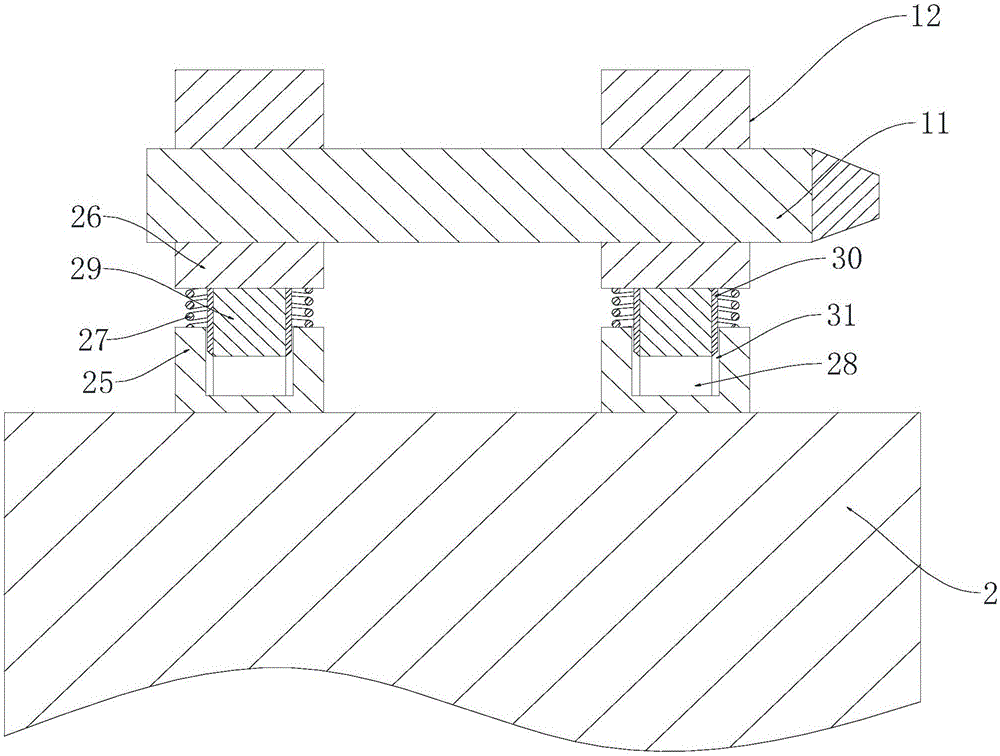

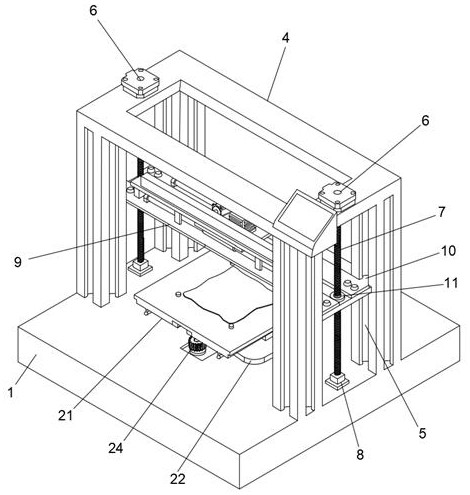

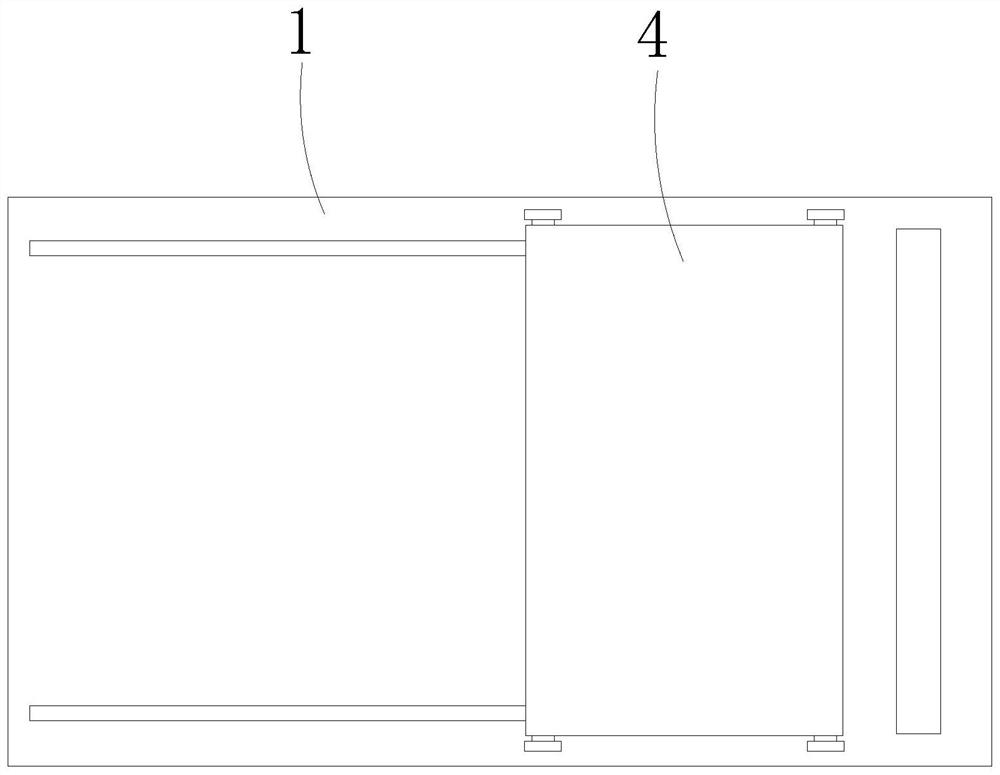

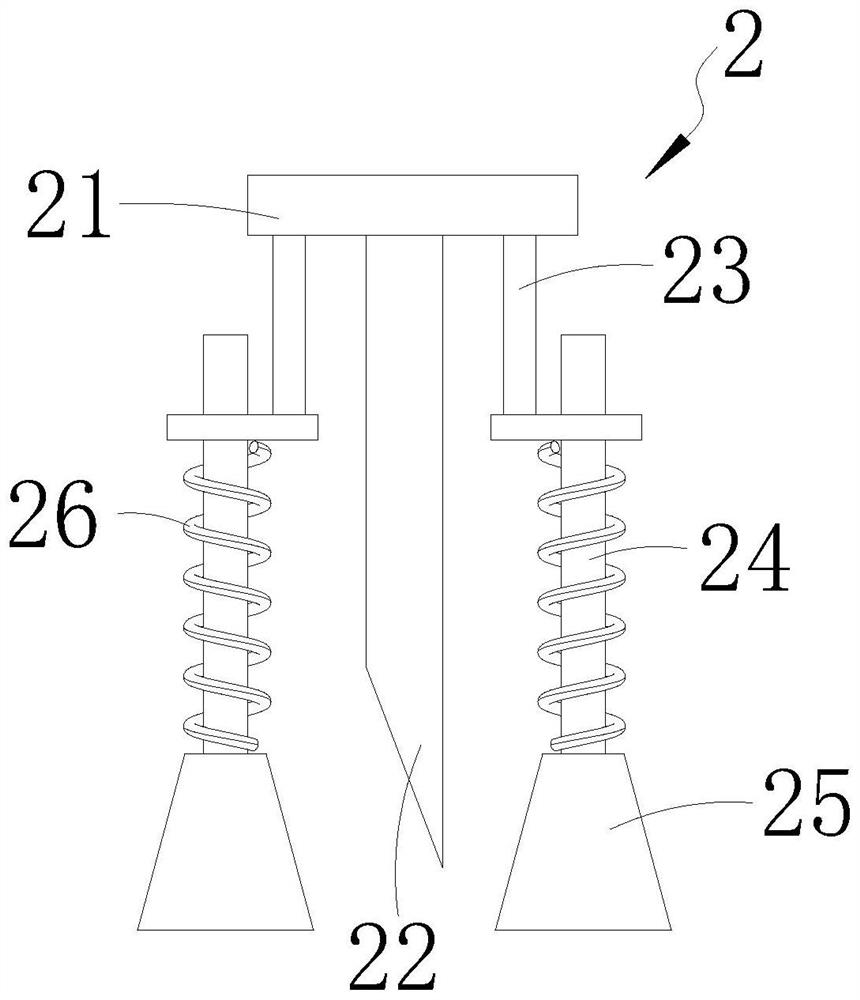

Multifunctional cutting device for printing paperboard

ActiveCN106042447ARealize cutting workMeet production needsMetal working apparatusContainer making machineryPaperboardEngineering

The invention provides a multifunctional cutting device for a printing paperboard. The multifunctional cutting device comprises a workbench, a pressing plate and an installation plate. A first side frame and a second side frame are oppositely arranged at the two ends of the workbench in the vertical direction. The workbench is provided with a plurality of cutter grooves side by side. The pressing plate is located above the workbench and parallel to the workbench. The two ends of the pressing plate are movably connected with the first side frame and the second side frame correspondingly. The pressing plate is provided with a plurality of first sliding grooves penetrating through the upper surface and the lower surface of the pressing plate side by side. The installation plate is located above the pressing plate and parallel to the pressing plate. The two ends of the installation plate are movably connected with the first side frame and the second side frame correspondingly. A plurality of cutter assemblies are arranged on the side, close to the pressing plate, of the installation plate side by side. Each cutter assembly comprises a cutter used for cutting the printing paperboard. According to the multifunctional cutting device for the printing paperboard, the workbench, the pressing plate, the installation plate and the cutter assemblies are matched with one another, so that the cutting work of the printing paperboard is completed; the cutting speed is high; the continuity is high; the production requirements for cutting with different sizes are met; the working efficiency is high; and the machining precision is high.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

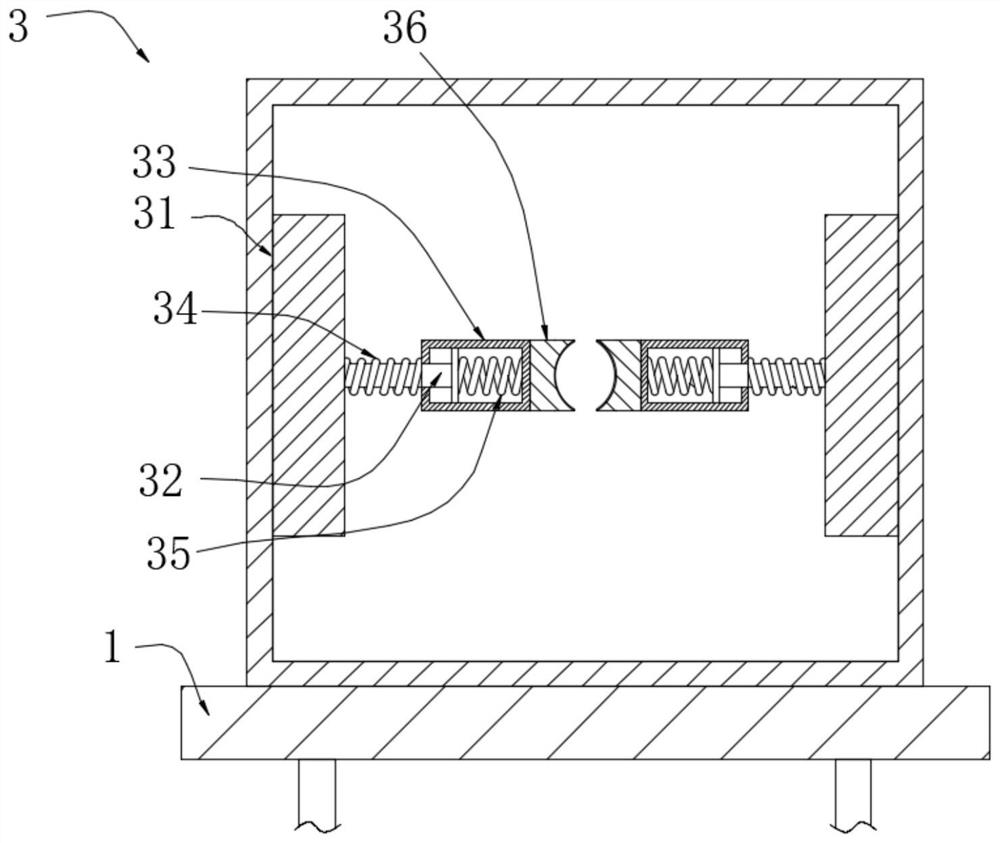

Rotary cutting type stainless steel round tube processing equipment

InactiveCN108788280AOvercoming elasticityAchieve fixationTube shearing machinesShearing machine accessoriesEngineeringSteel tube

The invention relates to rotary cutting type stainless steel round tube processing equipment. The rotary cutting type stainless steel round tube processing equipment comprises a base. A supporting column is fixedly arranged on the upper part of the right side of the base, a first groove opened upward is formed in the supporting column, the bottom in the first groove is fixedly connected to a firstspring, the top end of the first spring is fixedly connected to a moving column, the top end of the moving column is fixedly connected to a horizontal mounting plate, and a cutter is fixedly connected to the lower side of the left end of the horizontal mounting plate; a moving through slot is formed in the right side of the supporting column, a moving plate is fixedly connected to the side wall of the moving column, the moving plate is arranged by penetrating the moving through slot, a power driving device is fixedly connected to the right side wall of the supporting column, and the power driving deice is connected to the moving plate; a supporting rack is fixed to the upper side of the base, a steel tube is arranged on the supporting rack in a penetrating manner, and a clamping device isarranged in the steel tube. The rotary cutting type stainless steel round tube processing equipment provided by the invention has the advantages of being reasonable in structural design, convenient to use and convenient to cut steel tubes of large diameter dimensions, and has wide popularization and application value.

Owner:安徽广美钢业有限公司

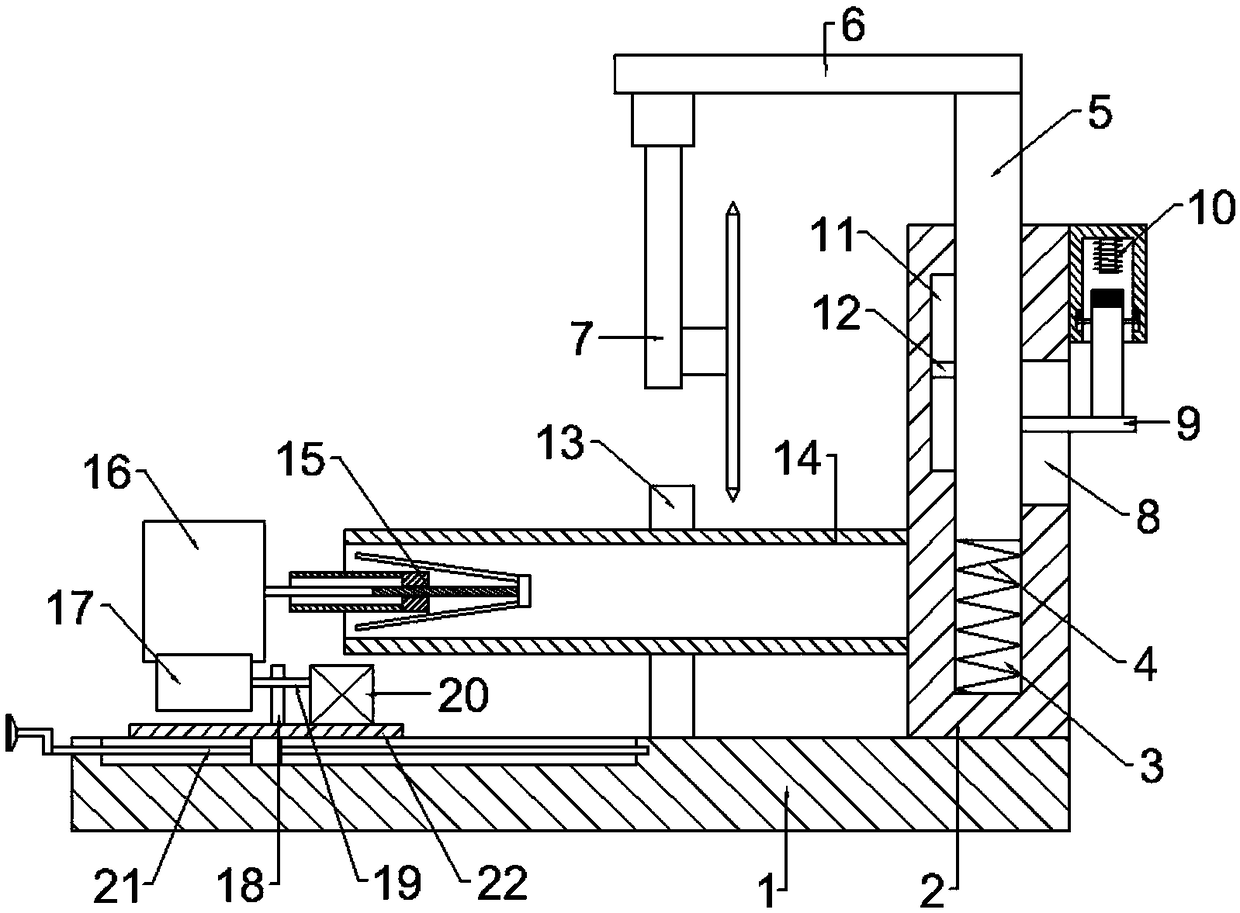

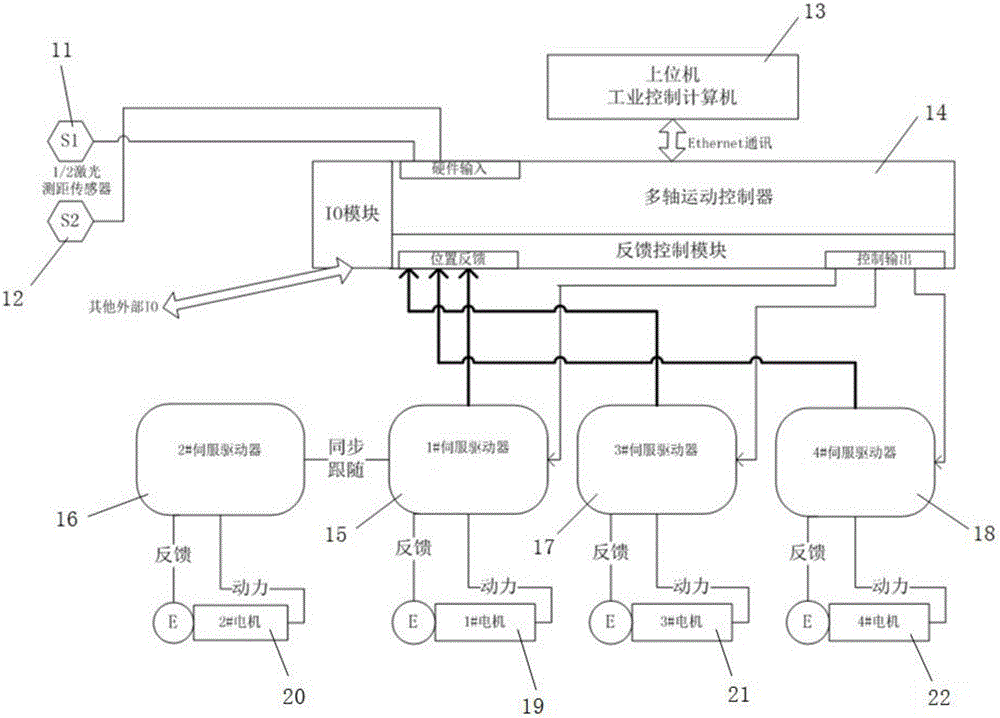

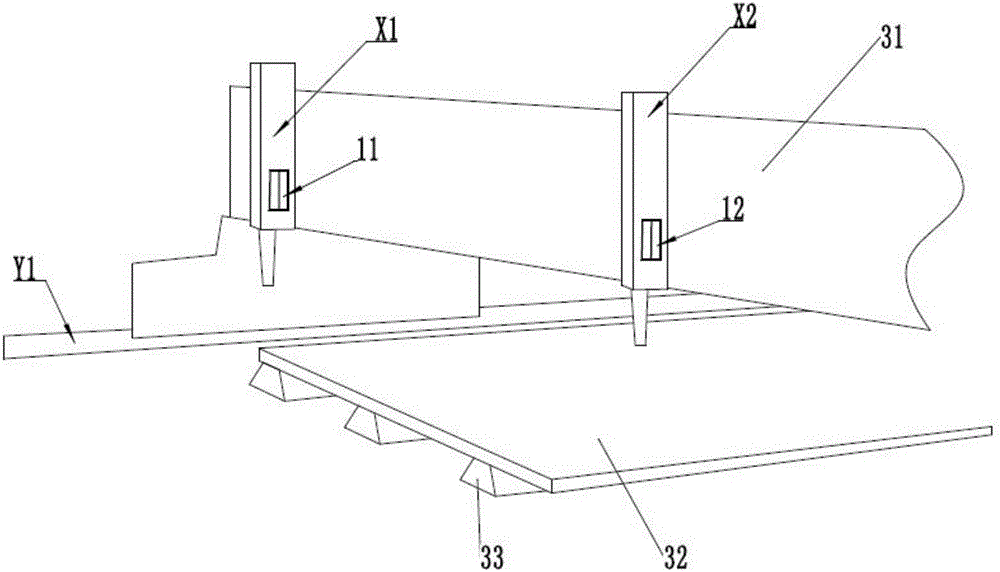

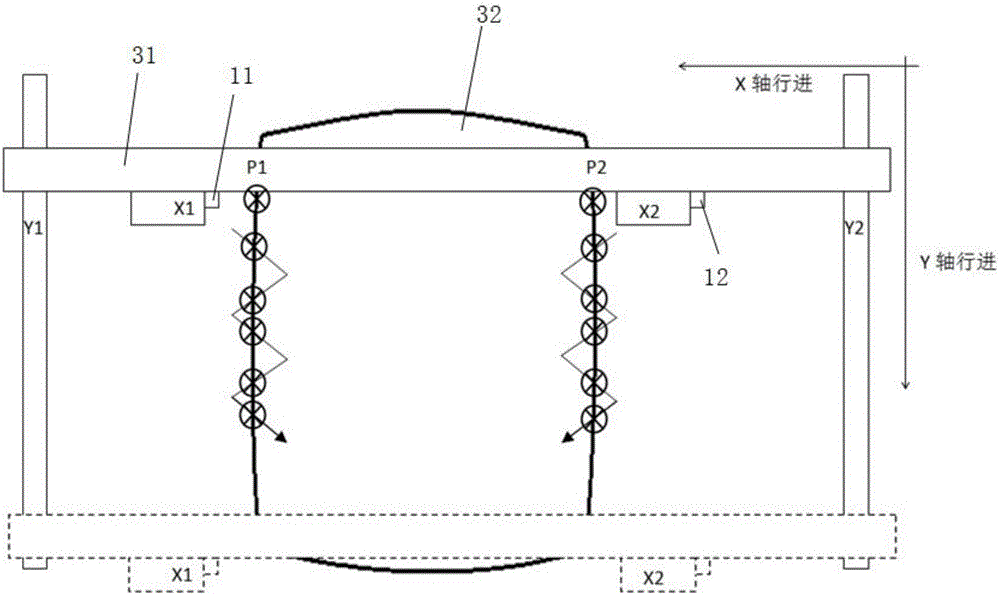

Steel plate edge scanning and cutting control system based on laser distance measuring sensors

ActiveCN106001847AAuto scanRealize cutting workWelding/soldering/cutting articlesMetal working apparatusLaser rangingControl system

The invention discloses a steel plate edge scanning and cutting control system based on laser distance measuring sensors. The steel plate edge scanning and cutting control system based on the laser distance measuring sensors comprises the first laser distance measuring sensor, the second laser distance measuring sensor, an upper computer industrial control computer, a multi-axis movement controller, a 1# servo driver, a 1# motor, a 3# servo driver, a 3# motor, a 4# servo driver and a 4# motor, wherein the first laser distance measuring sensor and the second laser distance measuring sensor are connected with the multi-axis movement controller; the upper computer industrial control computer is in communication connection with the multi-axis movement controller; the 1# motor is connected with the 1# servo driver; the 3# motor is connected with the 3# servo driver; the 4# motor is connected with the 4# servo driver; and the multi-axis movement controller is provided with a feedback control module, and the 1# servo driver, the 3# servo driver and the 4# servo driver are all connected with the feedback control module. The steel plate edge scanning and cutting control system based on the laser distance measuring sensors can carry out automatic scanning and cutting on steel plates, manpower is saved, and the precision and quality of the cut steel plates are high.

Owner:佛山市中菱智控科技有限公司

Waste cable recovery device for resource regeneration

ActiveCN112670038ARealize cutting workRealize the winding workBasic electric elementsApparatus for removing/armouring cablesEnvironmental engineeringElectric machine

The invention relates to a recovery device, in particular to a waste cable recovery device for resource regeneration. The invention provides a waste cable recovery device for resource regeneration, which can peel off a cable insulation protection layer, fix a cable and wind the cable insulation protection layer. The waste cable recovery device for resource regeneration comprises first supporting frames and second supporting frames connected between the first supporting frames, a motor fixed connected with the top ends of the second supporting frames through bolts, and reciprocating mechanisms rotationally arranged on the two parts of the first supporting frames. By arranging the reciprocating mechanisms, the reciprocating mechanisms are matched with a cutting mechanism, so that the cutting work of the cable can be realized; a rotating mechanism is matched with a peeling mechanism, so that the cable insulation protection layer can be peeled off; and a feeding mechanism is matched with the cutting mechanism and can push the cable towards the rear side, so that the stripping position of the cable is replaced.

Owner:无锡市黄浦电线电缆有限公司

Hanging pruning device

InactiveCN106550787AAvoid accidental damageImprove safety and reliabilityCuttersCutting implementsEngineeringMechanical engineering

The invention discloses a hanging pruning device comprising a screw, a cutting seat and a cutting assembly, and further comprising a hanger assembly; the cutting assembly comprises two supporting blocks and a rotating shaft; each supporting block comprises an upper portion, a lower portion and a first spring; and the hanger assembly comprises a short hanger rod, a long hanger rod, a first hanger head, and a second hanger head. According to the hanging pruning device, the cutting seat is hung through a residual part and a reservation part, so that the situation that the cutting seat falls down with cut trunks after cutting can be avoided, accidental damage to a structure is avoided, and safe reliability in the operating process is improved. In addition, in the whole cutting process, separate hanging is conducted through the arrangement of the long hanger rod and the short hanger rod, stable clamping to the branches and trunks is formed, and therefore, the situation that the cutting assembly works steadily on the branches and trunks can be further achieved.

Owner:CHONGQING LANXIN BEIER AGRI TECH CO LTD

Fretsaw cutting device for rock core samples and cutting method therefor

PendingCN109283030AAvoid damageSolve the problem of water expansion and deformationPreparing sample for investigationThroatRock core

The invention relates to a fretsaw cutting device for rock core samples and a cutting method therefor. The transmission integration mechanism of the fretsaw cutting device is arranged at the upper endof a supporting frame, and is provided with an emery wire winder, an emery wire motion adjuster, a transverse motion adjusting button, a circular motion adjusting button and an adjusting wrench. A rotating platform is consisting of an upper rotating platform and a lower rotating platform, and is arranged between the transmission integration mechanism and the supporting tray of the supporting frame, the upper rotating platform and the lower rotating platform are provided with clamping devices. The rock core sample is fixed between the two clamping devices, the upper rotating platform and the lower rotating platform are provided with transverse motion guide rails, each transverse motion guide rail is provided with an emery wire moving device, wherein the two emery wire moving devices are located on the same vertical line, and an emery wire moves up and down between the two emery wire moving devices. According to the fretsaw cutting device for rock core samples and the cutting method therefor, problem of damages to the pore throat structure of a rock body caused by the fracture of a fragile rock core sample during rotary drilling and coring is solved, and the original pore structureof the rock is retained to the maximum extent.

Owner:NORTHEAST GASOLINEEUM UNIV

Aerated concrete green body cutting and swinging mechanism

InactiveCN105397906ASolve the one-way forceCutting hidden damage is smallCeramic shaping apparatusDislocationMechanical engineering

The invention discloses an aerated concrete green body cutting and swinging mechanism which comprises a rack upper beam, inner and outer swinging frames and a drive mechanism for driving the inner and outer swinging frames to swing in a dislocation and reciprocating manner relative to the rack upper beam, wherein the inner and outer swinging frames are arranged in a dislocation manner; the inner swinging frame is arranged in front of the outer swinging frame; the drive mechanism is composed of a decelerating motor and a bearing seat which are fixed to the rack upper beam; the decelerating motor is connected with a rotation shaft arranged in the bearing seat through a universal coupling; first and second eccentric wheels are connected to the periphery of the rotation shaft in a sleeving manner in opposite eccentric directions; the eccentric direction of the first eccentric wheel is arranged at the front; the eccentric direction of the second eccentric wheel is arranged at the back; one ends of first and second rocker arms are respectively connected to the first and second eccentric wheels in the sleeving manner; the other ends of the first and second rocker arms are respectively hinged to one ends of first and second swinging connecting arms; and the other ends of the first and second swinging connecting arms are respectively fixed with the upper parts of the inner and outer swinging frames. The aerated concrete green body cutting and swinging mechanism is smooth in swinging and solves the problem that a green body is stressed in a single direction in the cutting process.

Owner:JIANGSU DUOYUAN MACHINERY CO LTD

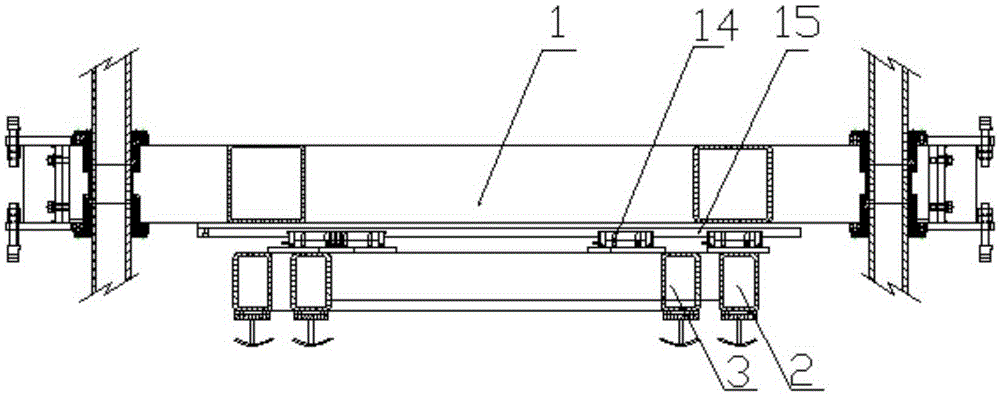

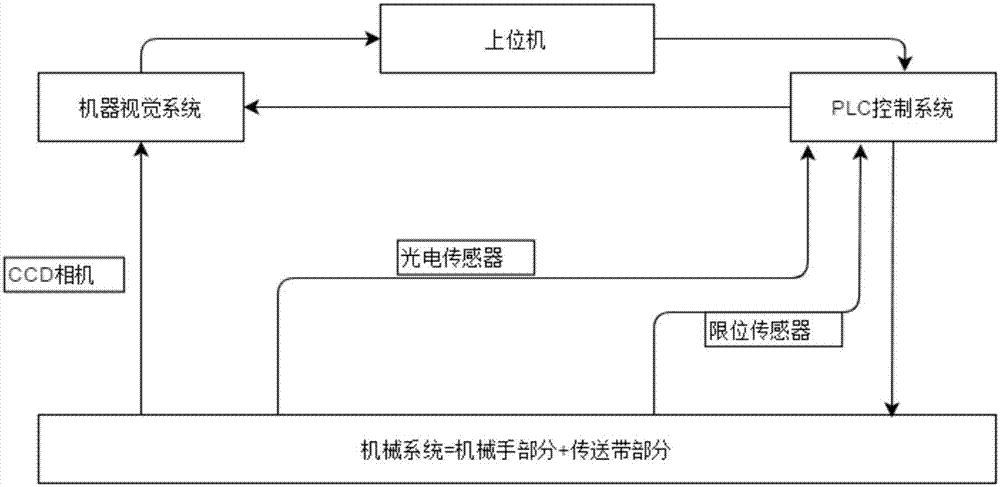

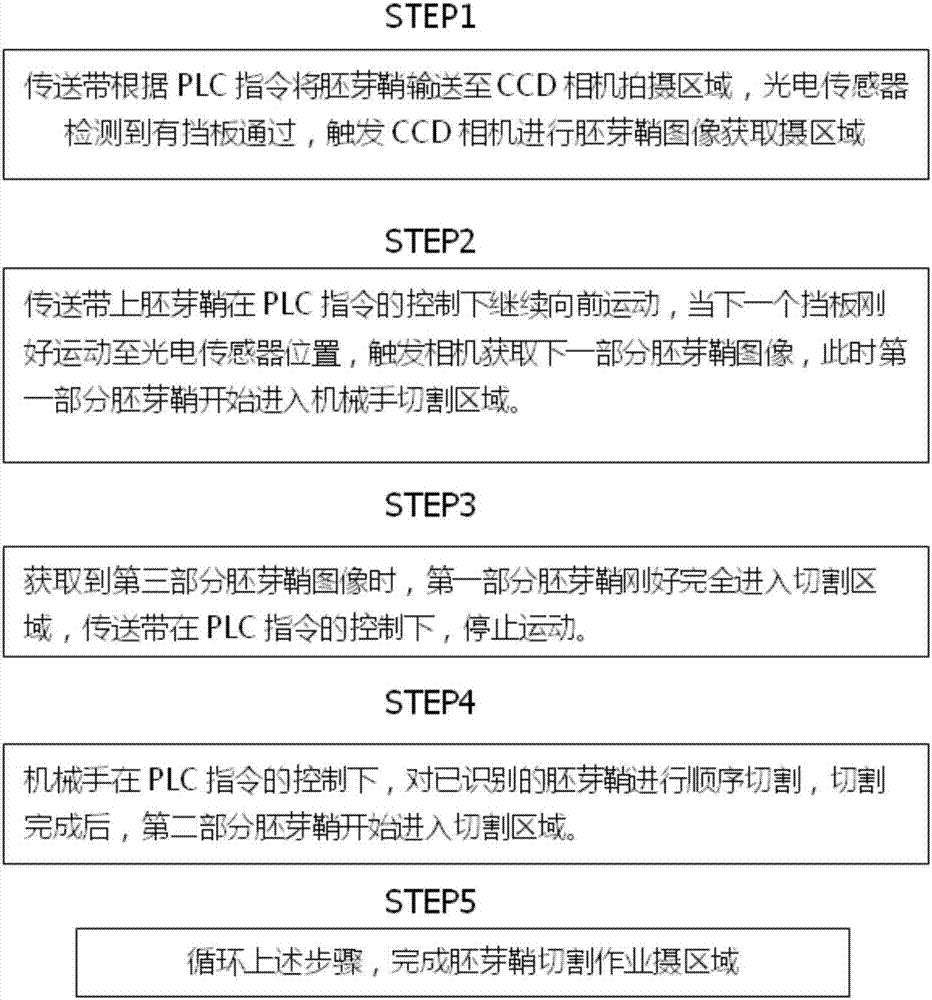

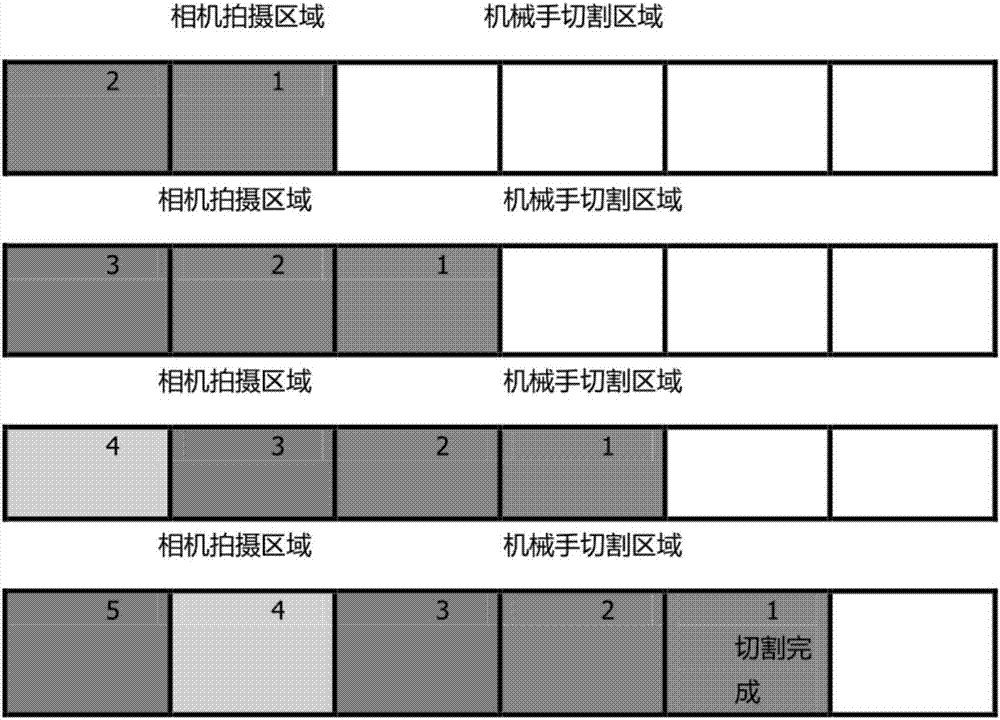

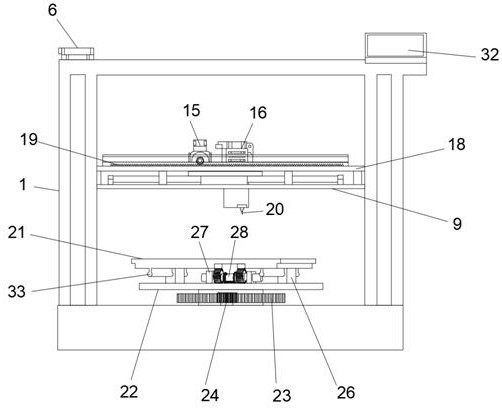

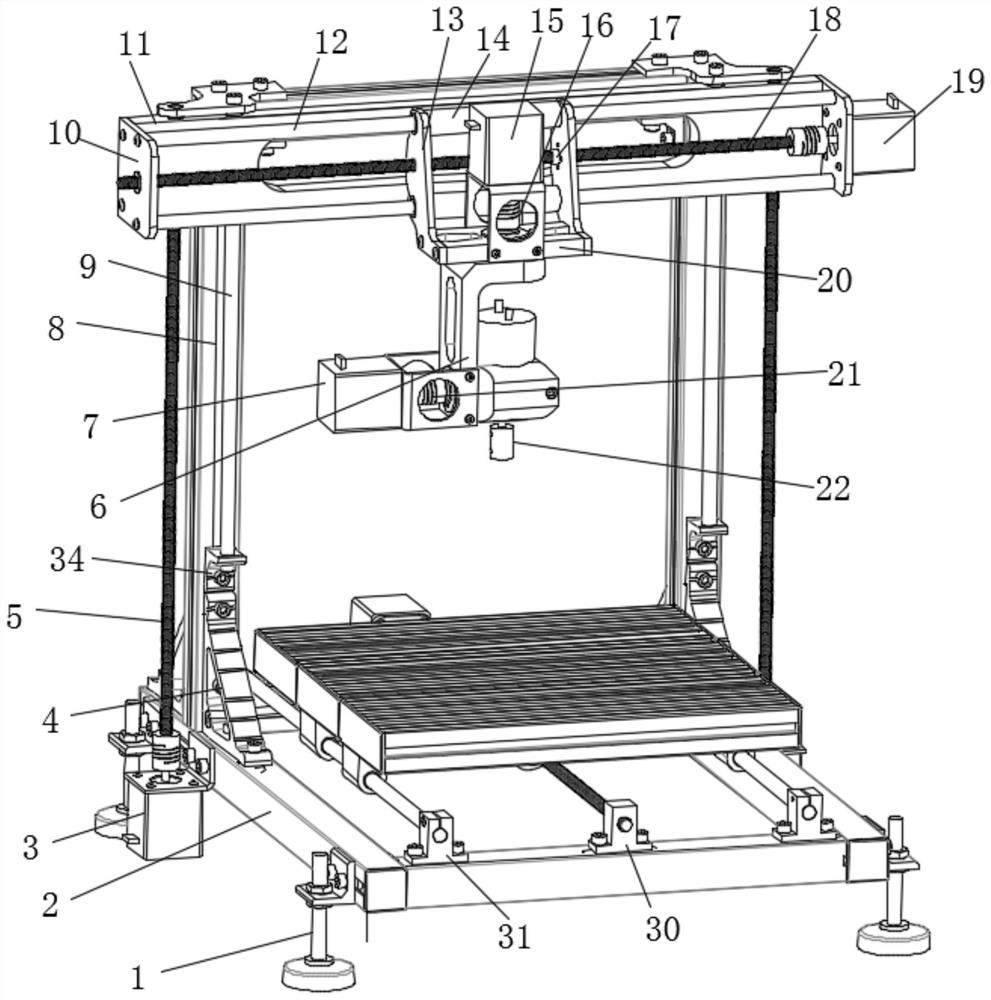

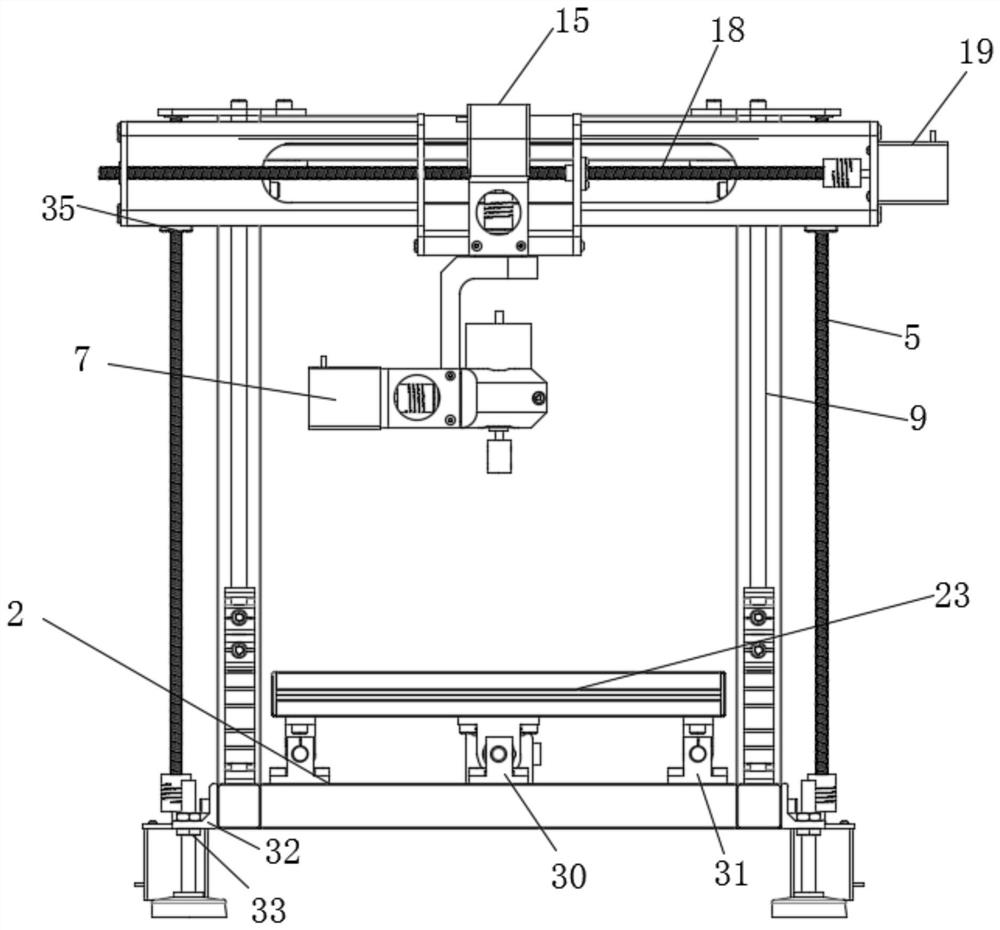

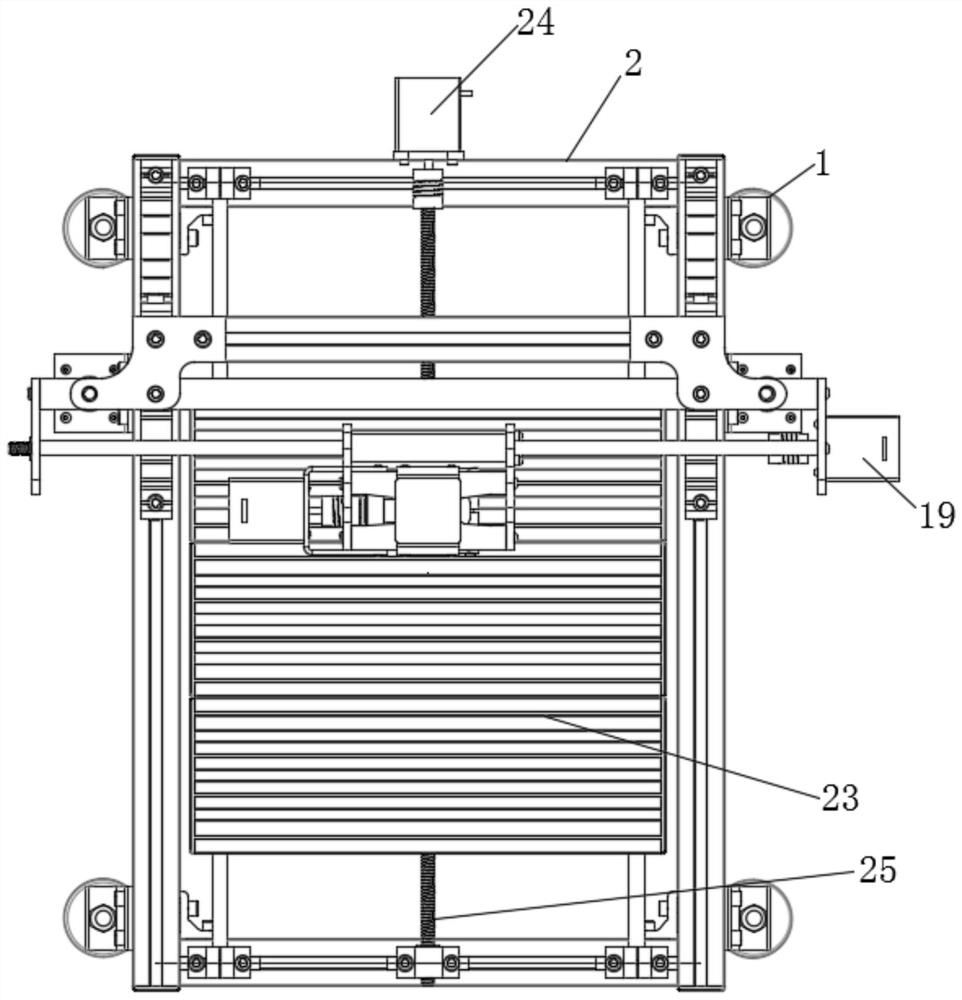

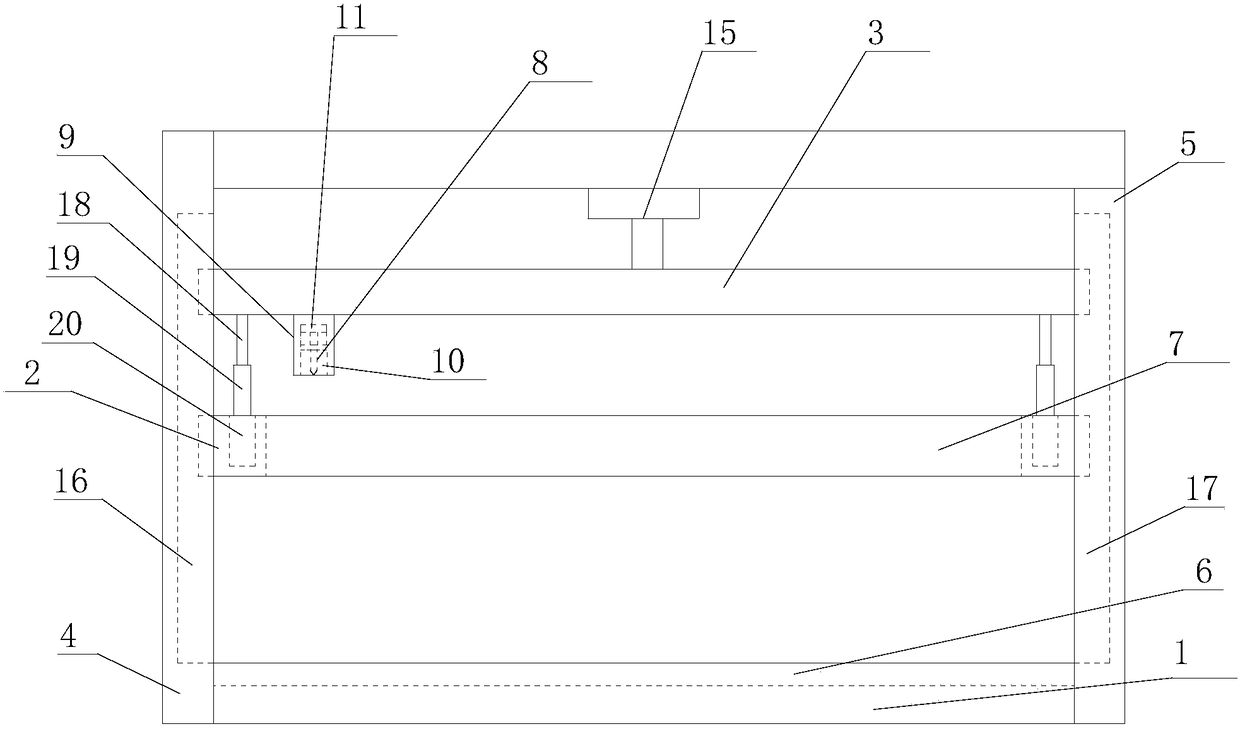

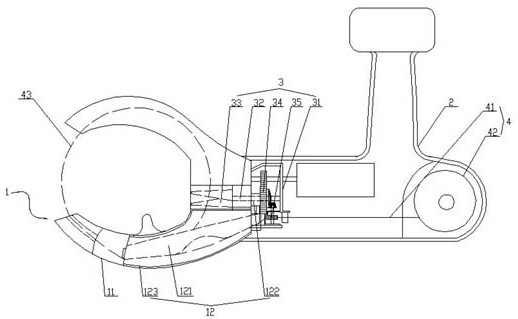

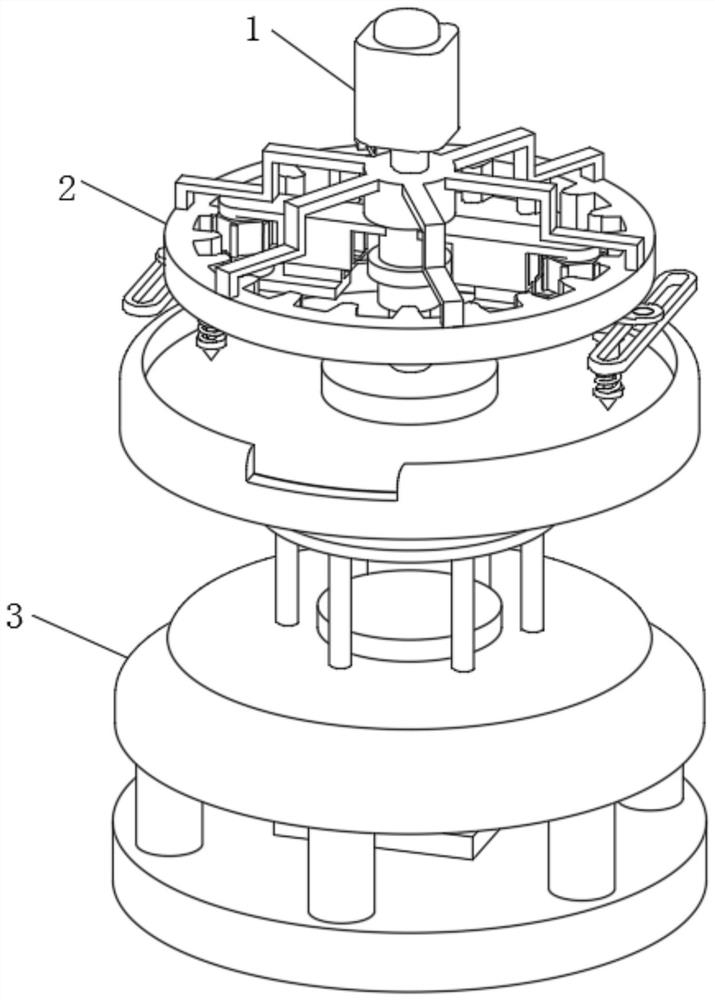

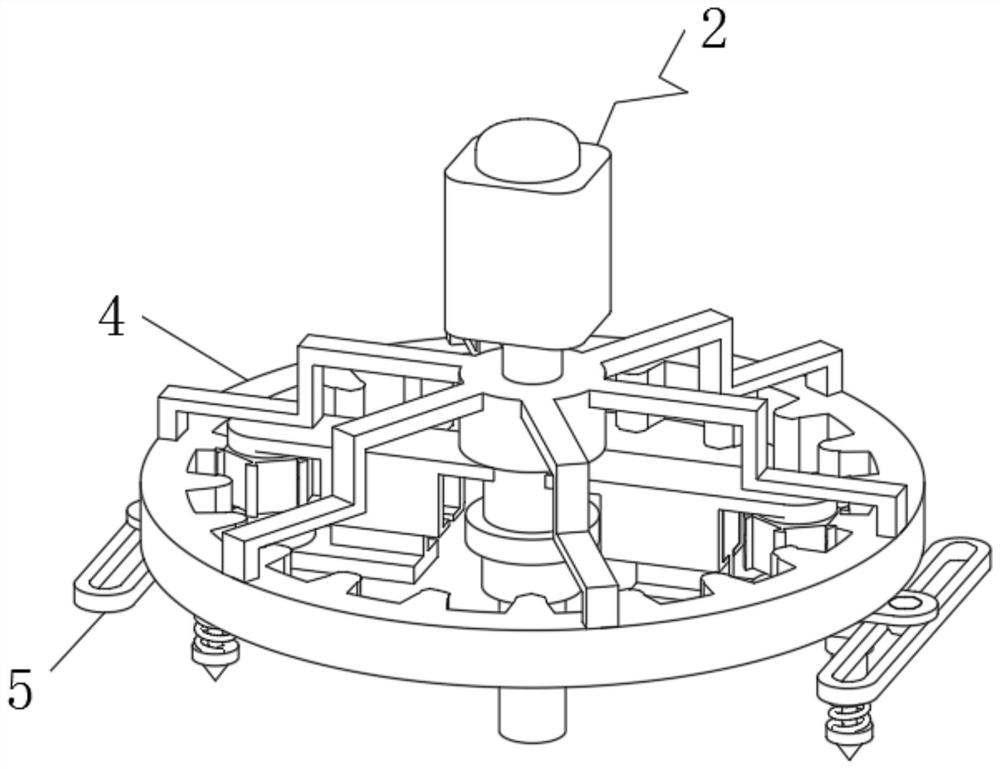

Coleoptile cutting system and method based on PLC control system

PendingCN107962616ARealize the identification workRealize cutting workMetal working apparatusControl systemControl engineering

The invention discloses a coleoptile cutting system based on a PLC control system. The coleoptile cutting system comprises a mechanical system, the PLC control system and a machine vision system; themechanical system comprises a manipulator (1) and a conveyer belt (3), the manipulator (1) is installed on the conveyer belt (3), and a hardware portion of the machine vision system (2) is installed on the conveyer belt (3); a photoelectric sensor (4) and a limiting sensor which are installed on the conveyer belt (3) are in wired connection with the PLC control system; the PLC control system is connected with an upper computer; and the machine vision system (2) is connected with the PLC control system and the upper computer. According to the coleoptile cutting system based on the PLC control system, the problems that an existing coleoptile cutting method is time-consuming, laboursome and low in efficiency, the existing coleoptile identification process relies on manpower and is low in identification efficiency, and the existing coleoptile cutting process relies on manpower and is low in cutting mechanization and automation are solved.

Owner:GUIZHOU UNIV

Novel skin graft rolling device

The invention discloses a novel skin graft rolling device. The device comprises a base, a skin graft rolling device body and a placing table, a portal frame is installed on the base, a lead screw motor is installed above the portal frame, and the lead screw motor is in transmission connection with a lead screw; the skin graft rolling device body comprises a movable bottom plate, the movable bottom plate is movably connected to the outer surface of the lead screw, guide rod frames and a rack frame are installed on the movable bottom plate, a movable frame is movably connected to the outer surfaces of the guide rod frames through sleeve rods, a first driving motor and a skin graft rolling machine are installed on the movable frame, and the driving motor is meshed with a rack on the rack frame through a first gear; and the driving end of the skin graft rolling machine penetrates through a strip-shaped groove and is connected with a cutting blade. The defects in the prior art are overcome, and a cutting blade is driven by the driving motor to move and cut in the Y-axis direction; and the rotating angle of the faulted skin graft on the horizontal plane is controlled through a second driving motor, and the whole placing plate is driven to axially move on the horizontal plane by controlling a third driving motor, so that the cutting work of the skin graft of different specifications or different sizes is realized.

Owner:RUIJIN HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

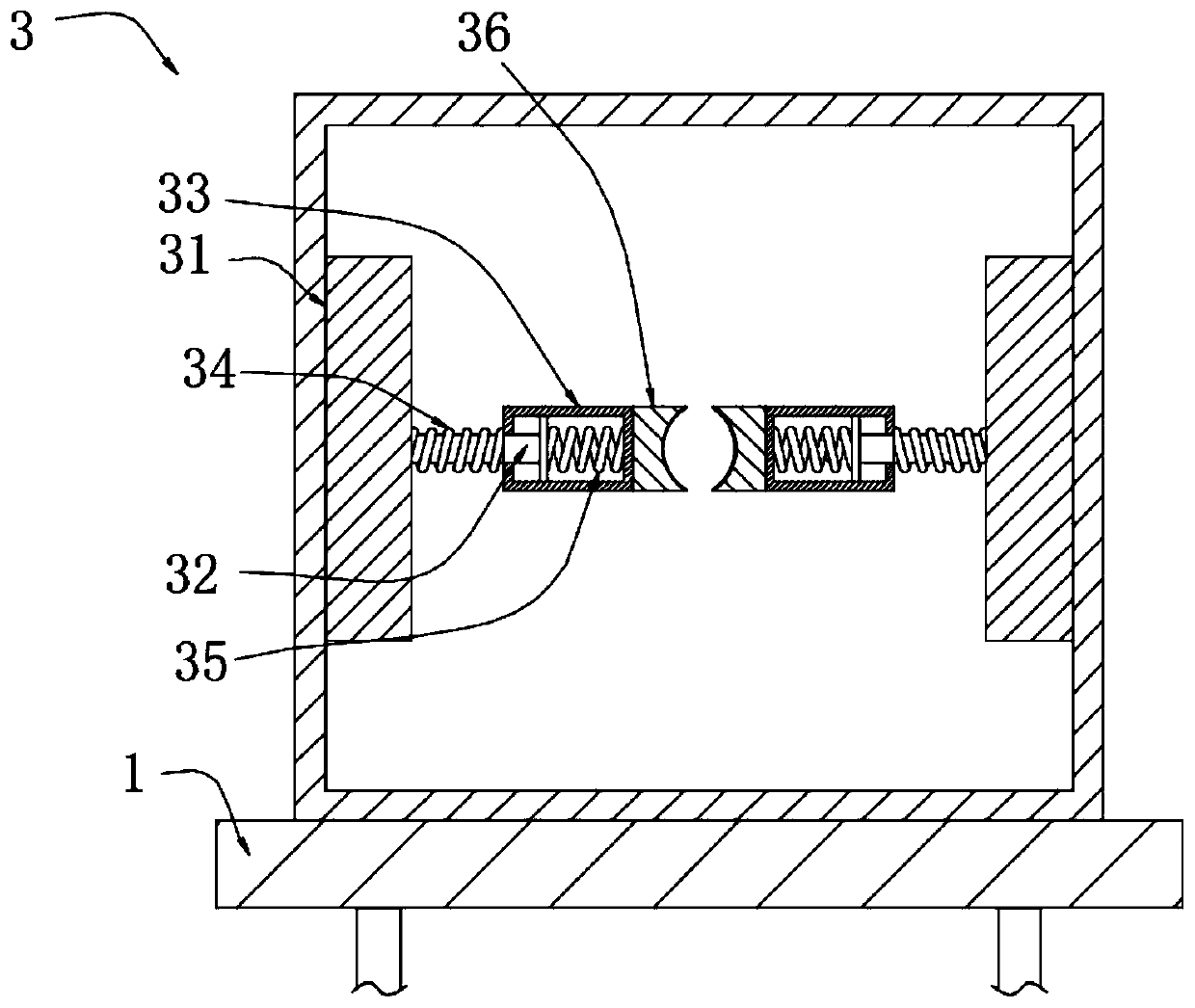

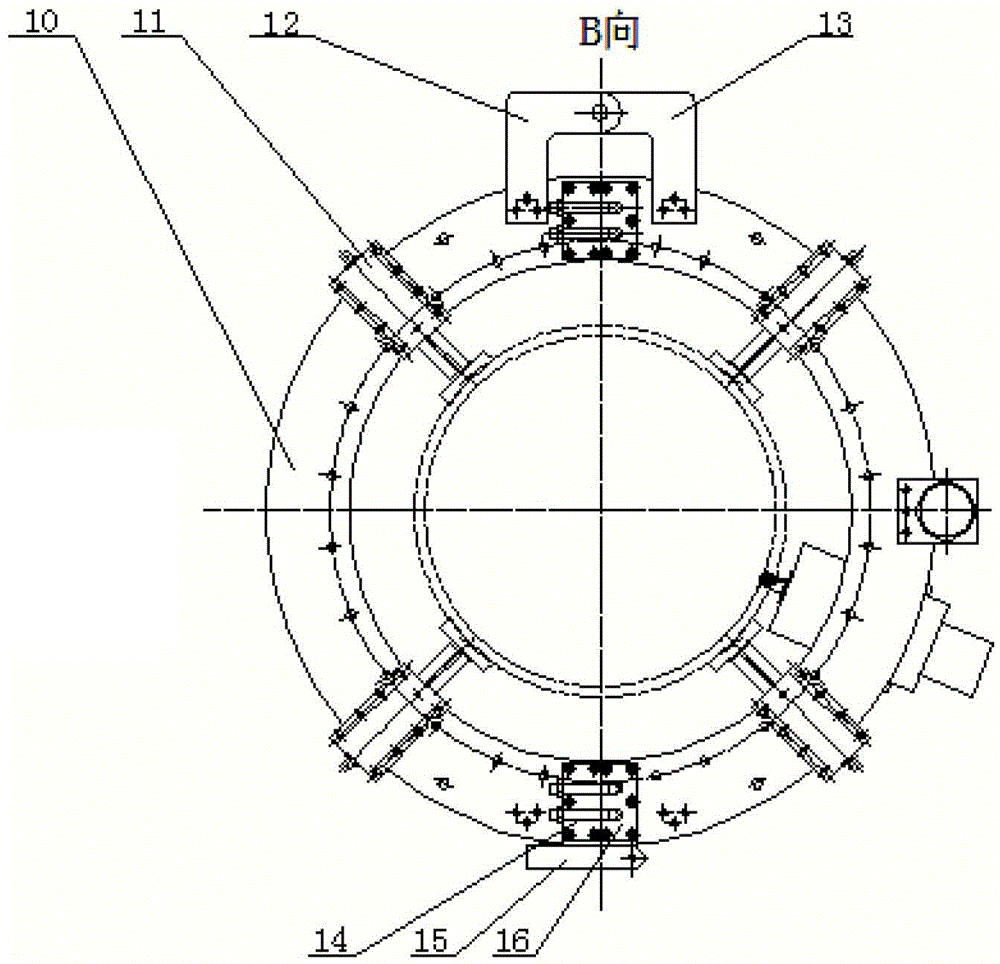

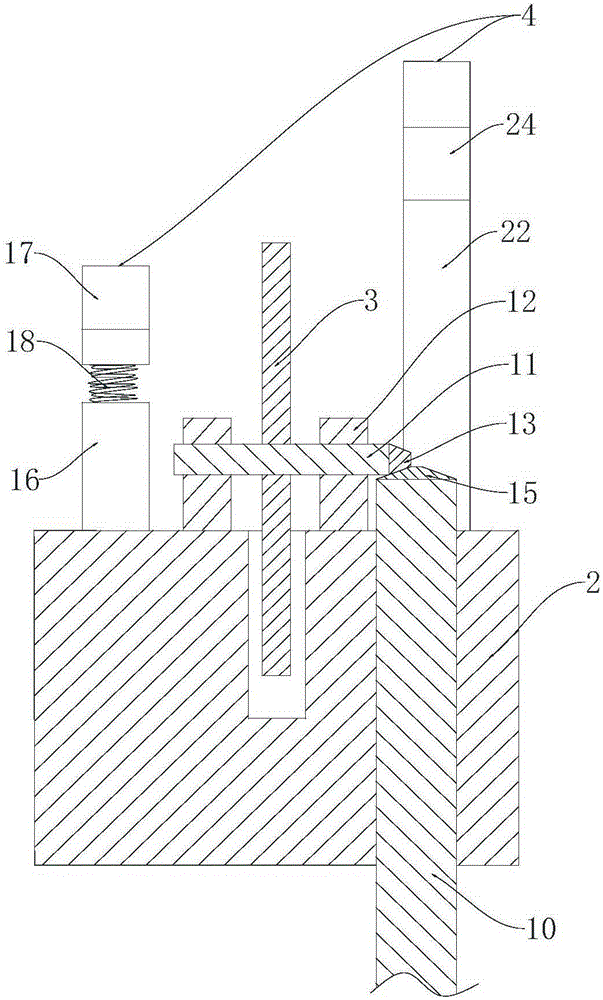

Cutting mechanism for beveling machine

InactiveCN111266649ARealize clamping and fixing workSmall footprintTube shearing machinesWorkpiece edge portionsElectric machineMachine

The invention discloses a cutting mechanism for a beveling machine. The cutting mechanism for the beveling machine comprises a bottom frame and a supporting plate, the supporting plate is arranged atthe top of the bottom frame, a sliding rail is arranged on the side wall of one side of the supporting plate, a sliding sleeve is arranged on the sliding rail, a transverse plate is fixedly arranged on the side wall of the side, opposite to the supporting plate, of the sliding rail, two motor bases are fixedly connected to one end of the transverse plate, a pipe is clamped by pliers to prevent rotation, a second rotating shaft is driven by the output end of a second motor to rotate, a second driving wheel is driven by the second rotating shaft to rotate, a second transmission wheel is driven by the second driving wheel to rotate through a chain, so that a sleeve rotates, then a working disc and a cover disc are driven to rotate, a blade on a mounting frame cuts the pipe in a surrounding mode, cutting work of the pipe is achieved, cutting is convenient, due to the fact that the blades conduct surrounding cutting, torsional force borne by the pipe is small, a worker can fix the pipe through common pliers, use is convenient, after cutting is completed, material taking is easy, and operation is easy.

Owner:LANZHOU CITY UNIV

Automatic cutting-off device for bottle mouth residual materials

The invention relates to the field of plastic molding, in particular to an automatic cutting-off device for bottle mouth residual materials. The automatic cutting-off device comprises a worktable, a conveying mechanism and a cutting mechanism; the conveying mechanism and the cutting mechanism are arranged on the worktable; the conveying mechanism comprises a first driving disk, a first baffle anda second baffle, the first baffle and the second baffle are arranged in the horizontal direction; a feeding channel is formed between the first baffle and the second baffle; the first driving disk isarranged at one end of the feeding channel and is spaced apart from the cutting mechanism; a cutting channel is defined by the cutting mechanism and the first driving disk; the cutting mechanism includes a blade extending into the cutting channel; the feeding channel is in communication with the cutting channel; and the first driving disk is configured to drive plastic bottles to move along the cutting channel. The automatic cutting-off device for the bottle mouth residual materials has the high degree of automation, can quickly realize the cutting work of the bottle mouth residual materials of a large number of plastic bottles, is stable in transmission and good in cutting-off effect, and has strong adaptability.

Owner:四川新升包装科技有限责任公司

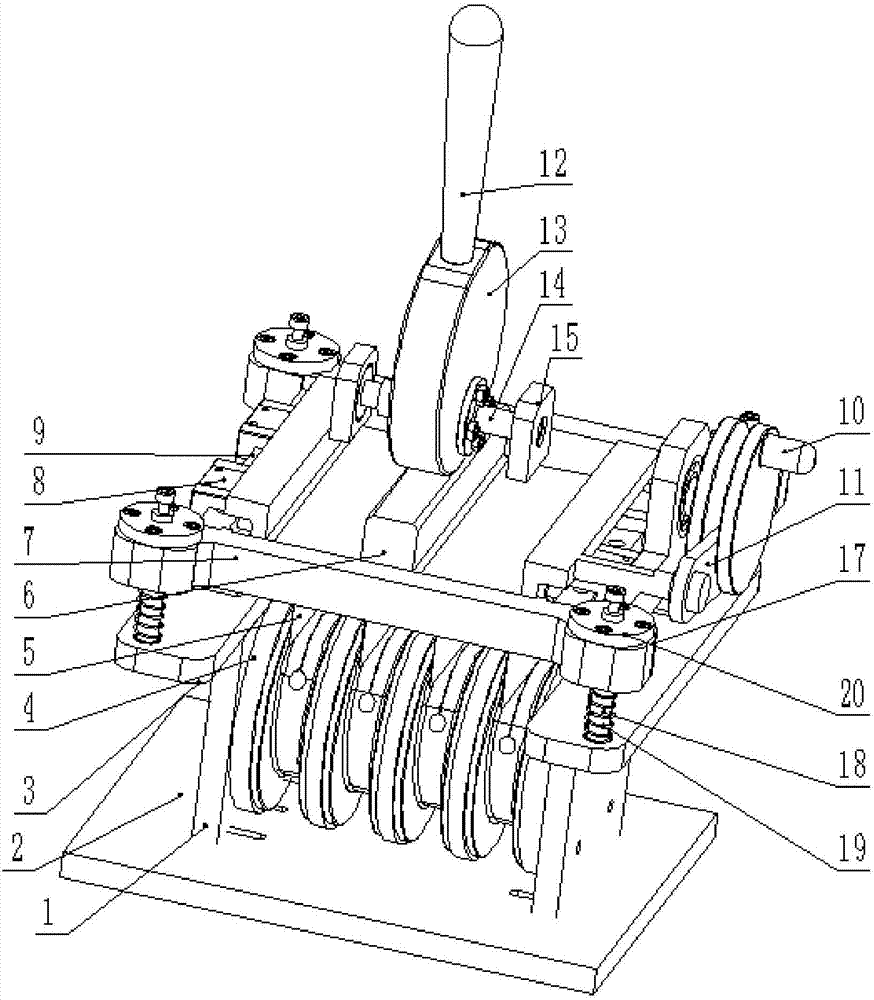

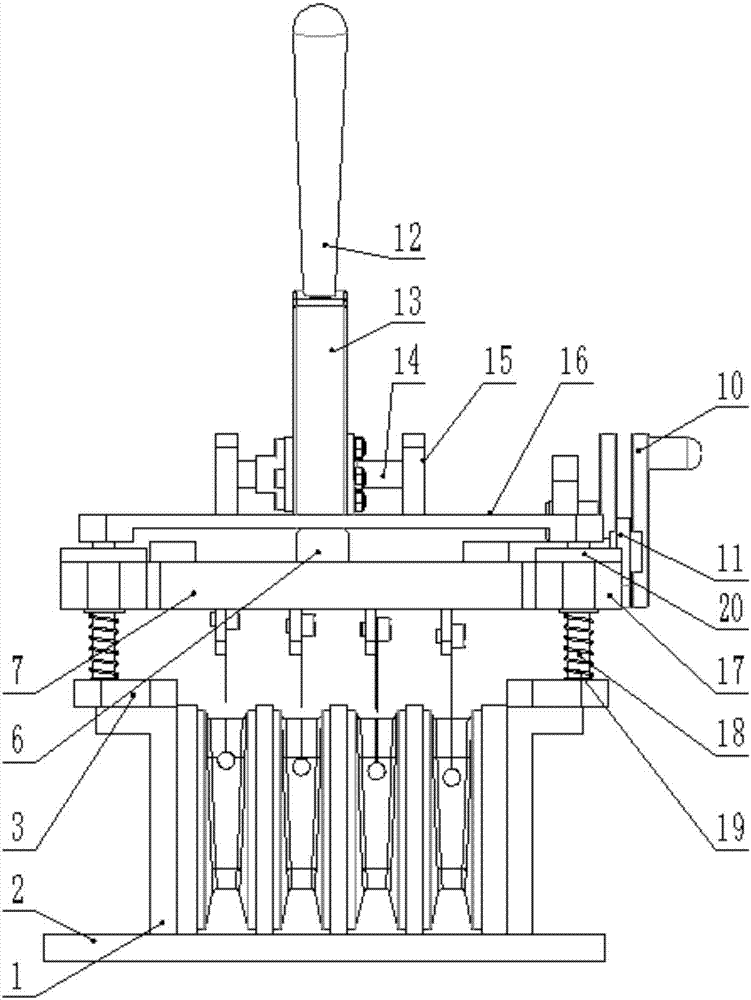

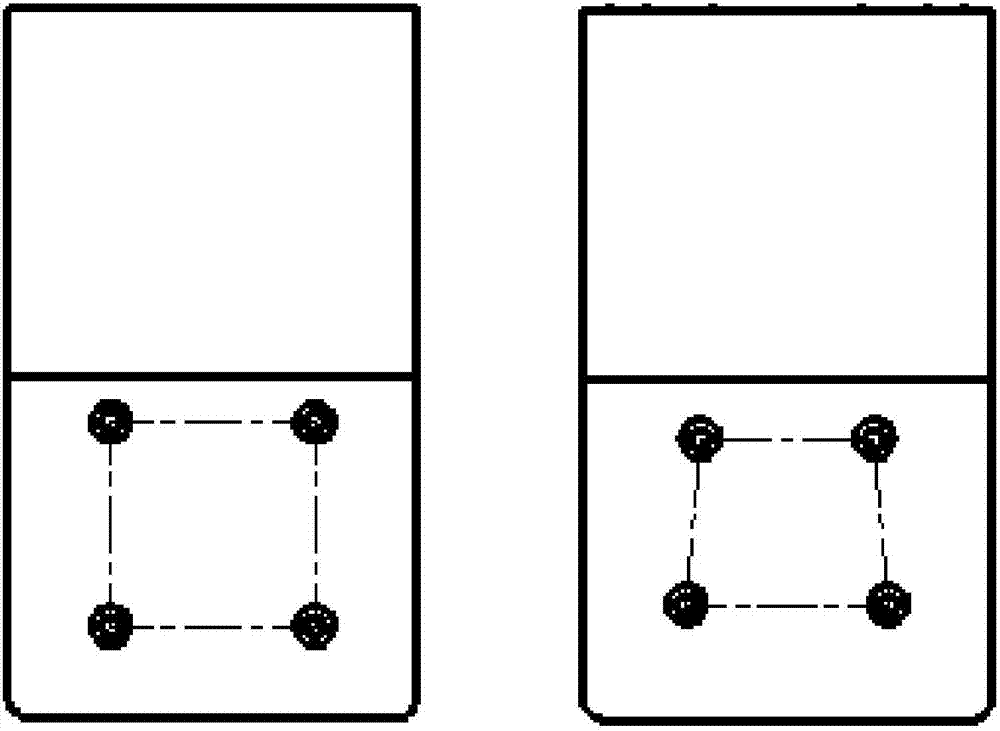

Dummy neck part notch special production device and cutting method

ActiveCN107053279ARealize cutting workImprove work efficiencyMetal working apparatusPhysical hard workNeck parts

The invention relates to a dummy neck part notch special production device and a cutting method. The device is composed of a neck positioning mechanism and a cutting mechanism. The neck positioning mechanism comprises neck positioning plates, a base bottom plate and adjustment bases. The neck positioning plates are used for being fixedly connected with neck parts. The cutting mechanism comprises a blade mounting structure, a cam structure and linear sliding sets. The blade mounting structure comprises blades, a blade holder and a blade holder supporting plate. The cam structure comprises a power assisting handle, an eccentric wheel, a cam supporting shaft, bearing pedestals and a base upper plate. A hole is formed in the position, under the eccentric wheel, of the base upper plate. The eccentric wheel can pass through the hole to press the blade holder tightly so as to driven the blades to cut neck parts. Each linear sliding set comprises a linear bearing, a cylindrical guide post and a reset spring, wherein the cylindrical guide post is sleeved with the reset spring. By adopting the dummy neck part notch special production device, the working efficiency is improved; the quality and performance of notches are substantially improved; the physical labor intensity of operators is greatly relieved; and the application range is wide.

Owner:HUNAN UNIV

Building cutting device for construction site

InactiveCN111168862AAchieve horizontal movementRealize cutting workWorking accessoriesStone-like material working toolsArchitectural engineeringSlide plate

The invention discloses a building cutting device for a construction site. The building cutting device for the construction site comprises a base; a supporting plate is vertically arranged at the upper end of the base; the upper end of the supporting plate is fixedly connected with a first fixed plate; a moving mechanism is arranged at the lower end of the first fixed plate; the lower end of the moving mechanism is fixedly connected with a telescopic mechanism; a cutting machine is fixed to the lower end of the telescopic mechanism; two fixing mechanisms are symmetrically arranged at the upperend of the base; a pipe to be cut is arranged between the two fixing mechanisms; the moving mechanism comprises a fixed groove formed in the lower end of the first fixed plate; a strip-shaped plate is arranged in the fixed groove; a T-shaped chute is formed in the lower end of the strip-shaped plate; the interior of the T-shaped chute is connected with a T-shaped sliding plate in a sliding manner; and the lower end of the first fixed plate is fixedly connected with a first connecting plate and a second connecting plate. The building cutting device for the construction site is reasonable in structural design, can eliminate a potential safety hazard, and moreover, can improve the cutting efficiency.

Owner:徐州康纳高新材料科技有限公司

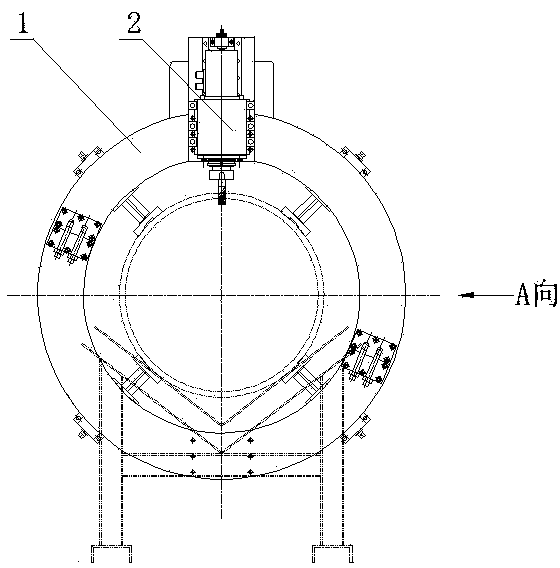

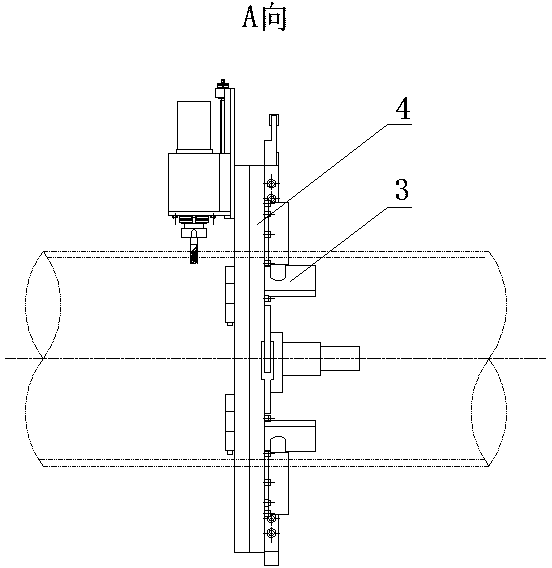

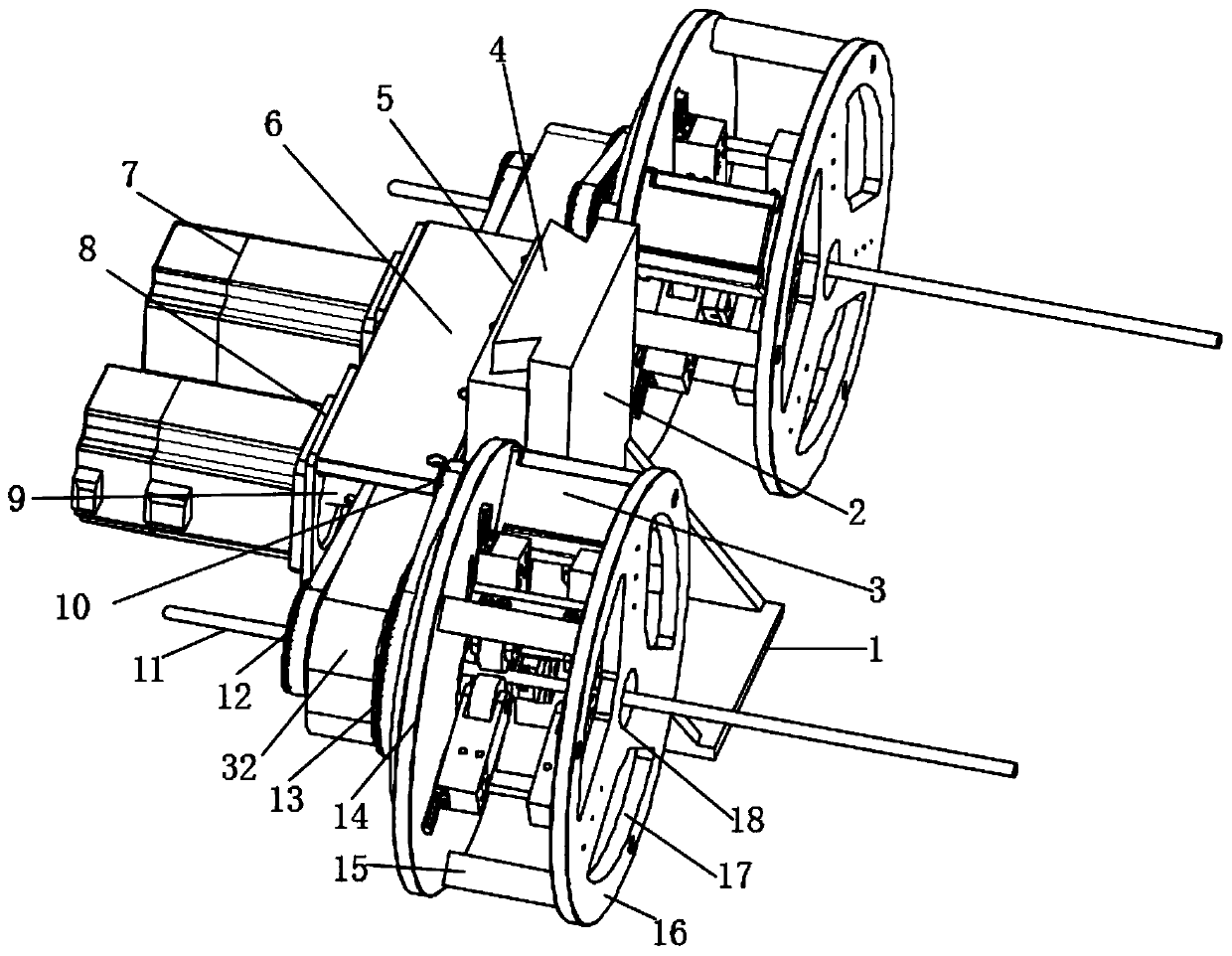

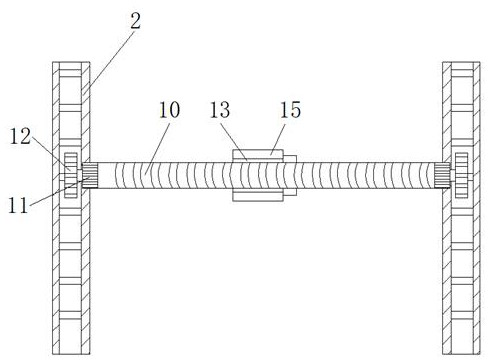

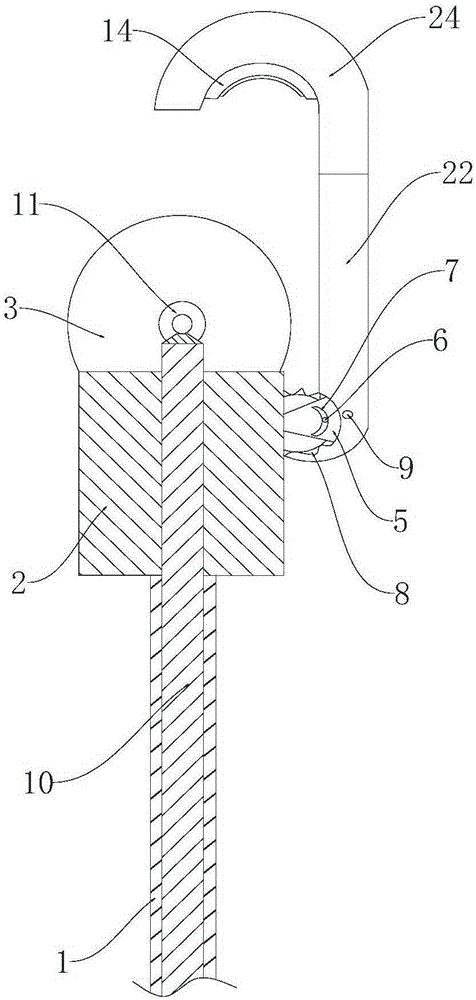

A Split Drilling Milling Pipe Cutting Machine

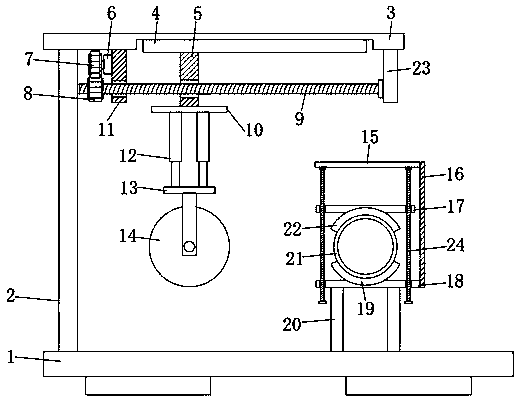

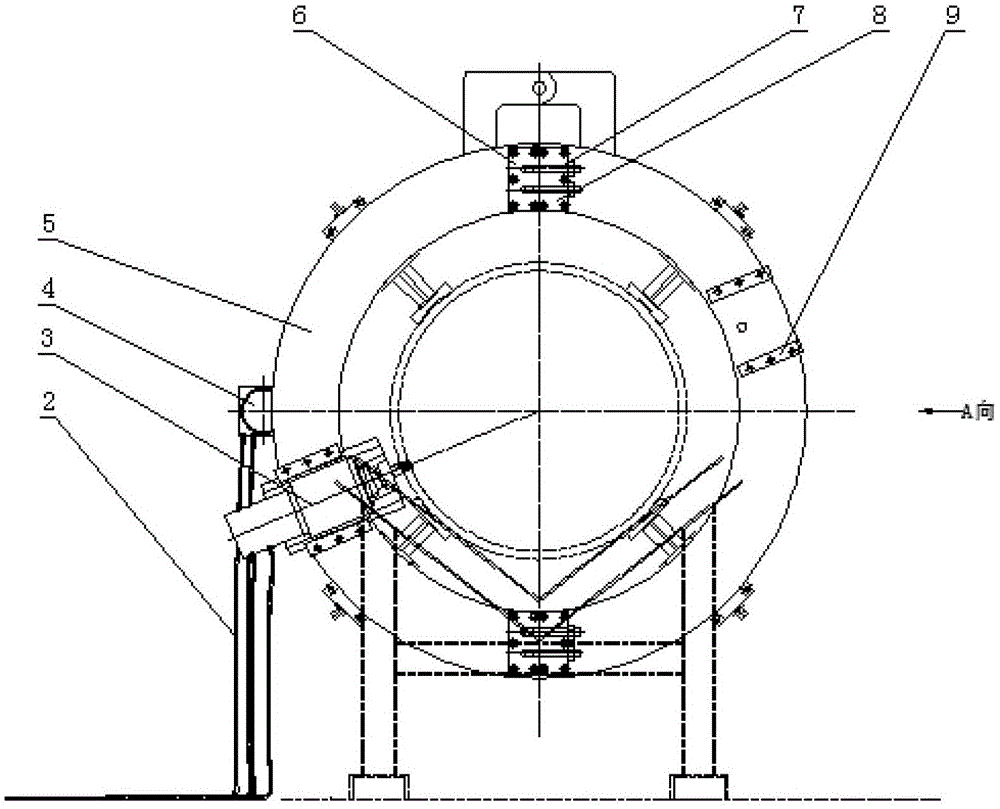

InactiveCN103567511BFast cutting speedSimple structureFeeding apparatusLarge fixed membersMilling cutterFeed drive

The invention relates to a split drilling and milling pipe cutting machine. The outriggers are fixed on the outer wall of the pipe to be cut; the movable seat is a split structure, and is rotationally connected with the front end of the fixed seat through a rolling device; the circular feed drive part is installed on the outer edge of the fixed seat, and is connected by transmission with the movable seat The drilling and milling head part is installed on the front end of the movable seat. The milling cutter is installed on the drilling and milling head part and drives the milling cutter to perform the main movement of rotating cutting and the radial feeding movement along the radial direction of the pipeline; the power source drives the circular feed Drilling and milling pipe operations are completed for the drive unit and the drilling and milling head unit. The present invention is simple in structure and easy to implement. The milling cutter only needs to cut once around the pipe circumference to complete the pipe cutting work. Cutting work for strength steel pipes.

Owner:SHENYANG LIAOHAI PETROLEUM & CHEM ENG

Cutting equipment for cutting water-soluble film through high-speed cutting water jet cutter

InactiveCN112824070ARealize cutting workAchieve recyclingMetal working apparatusSoluble FilmGear wheel

The invention relates to the technical field of water-soluble films, and discloses cutting equipment for cutting a water-soluble film through a high-speed cutting water jet cutter. The cutting equipment comprises a supporting frame, wherein a sliding rail is fixedly connected to the interior of the supporting frame. According to the cutting equipment for cutting the water-soluble film through the high-speed cutting water jet cutter disclosed by the invention, a transmission gear at a sliding lead screw and a meshing block at a sliding rail are matched with each other, so that the transmission gear can drive the sliding lead screw and a sliding block to transversely move on the sliding rail together; a rotating block in the sliding block can freely move on a spiral slot in the sliding lead screw when rotating, so that the rotating block can drive the sliding block to freely and longitudinally move on the sliding lead screw together; a water jet nozzle is fixedly connected to the bottom end of a water pressure pump, and under the dual effects of water supply of a water suction pump and pressure supply of a water pressure cavity, the water jet nozzle can spray out a high-speed cutting water jet, so that cutting work of the water-soluble film is realized. Due to the fact that the water pressure pump and the water suction pump are both fixedly connected into a sliding mechanism, so that the cutting equipment can achieve cutting work of complex patterns.

Owner:HUNAN UNIV OF TECH

A fully automatic stone cutting device capable of recycling sewage

ActiveCN110587832BEasy cutting workImprove stabilityAbrasive feedersWorking accessoriesHydraulic cylinderElectric machinery

The invention discloses a fully automatic stone cutting device capable of recovering sewage, which comprises a bottom box, a column and a moving plate. Two columns are respectively arranged at the two sides of the top end of the bottom box, and the two columns are connected to the bottom box. The top surface is vertical, and the second screw is driven to rotate through the output end of the second motor. When the second screw rotates, because the second screw is connected with the two second nut seats through threads, the moving plate moves laterally to complete the cutting of the stone. When working, when encountering stones of different thicknesses, the second hydraulic rod inside is controlled by the second hydraulic cylinder to move downwards, so that the fixed plate moves downwards, and the water gun moves downwards to achieve stone cuttings of different thicknesses; When the stones are of different sizes, the first hydraulic cylinder controls the downward movement of the first hydraulic rod inside to realize the fine adjustment of the position of the water gun, realize the cutting work of stones of different sizes, meet the high-precision cutting work of stones of different sizes, and improve the applicability of the device scope.

Owner:东宸环保装备制造有限公司

A multi-functional cutting device for printed cardboard

ActiveCN106042447BRealize cutting workMeet production needsBox making operationsPaper-makingCardboardMultiple function

The invention provides a multifunctional cutting device for a printing paperboard. The multifunctional cutting device comprises a workbench, a pressing plate and an installation plate. A first side frame and a second side frame are oppositely arranged at the two ends of the workbench in the vertical direction. The workbench is provided with a plurality of cutter grooves side by side. The pressing plate is located above the workbench and parallel to the workbench. The two ends of the pressing plate are movably connected with the first side frame and the second side frame correspondingly. The pressing plate is provided with a plurality of first sliding grooves penetrating through the upper surface and the lower surface of the pressing plate side by side. The installation plate is located above the pressing plate and parallel to the pressing plate. The two ends of the installation plate are movably connected with the first side frame and the second side frame correspondingly. A plurality of cutter assemblies are arranged on the side, close to the pressing plate, of the installation plate side by side. Each cutter assembly comprises a cutter used for cutting the printing paperboard. According to the multifunctional cutting device for the printing paperboard, the workbench, the pressing plate, the installation plate and the cutter assemblies are matched with one another, so that the cutting work of the printing paperboard is completed; the cutting speed is high; the continuity is high; the production requirements for cutting with different sizes are met; the working efficiency is high; and the machining precision is high.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

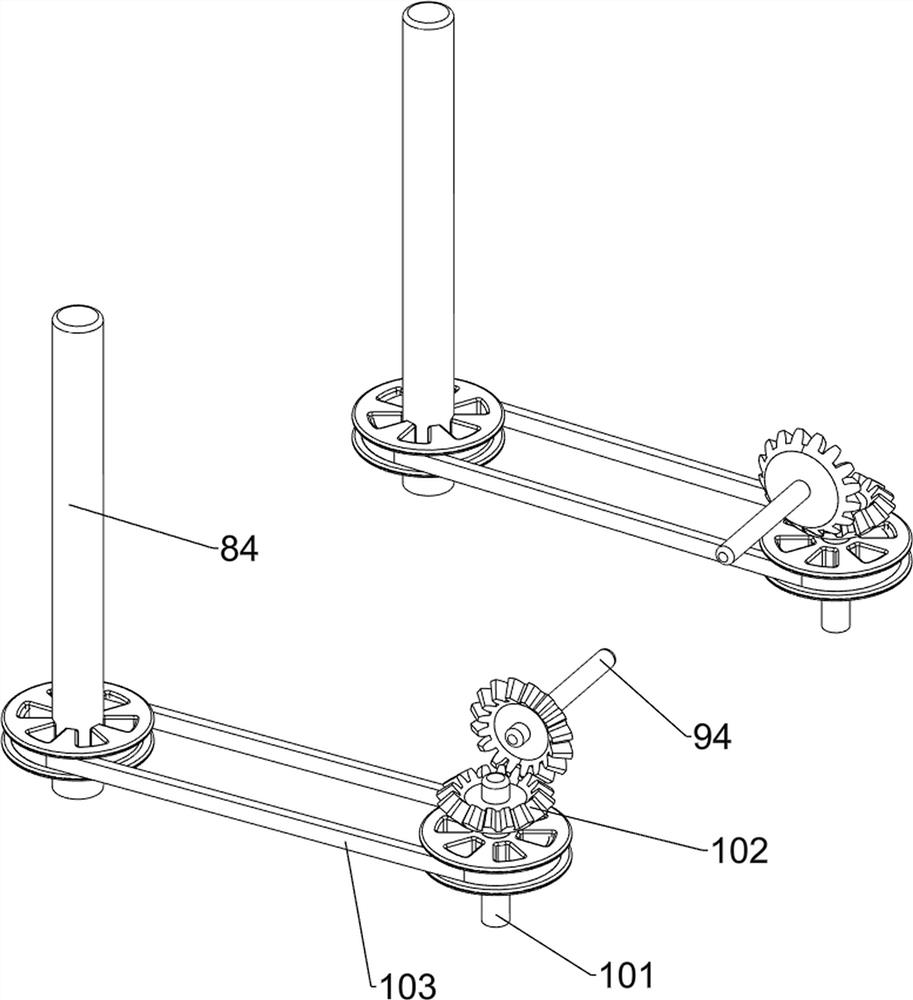

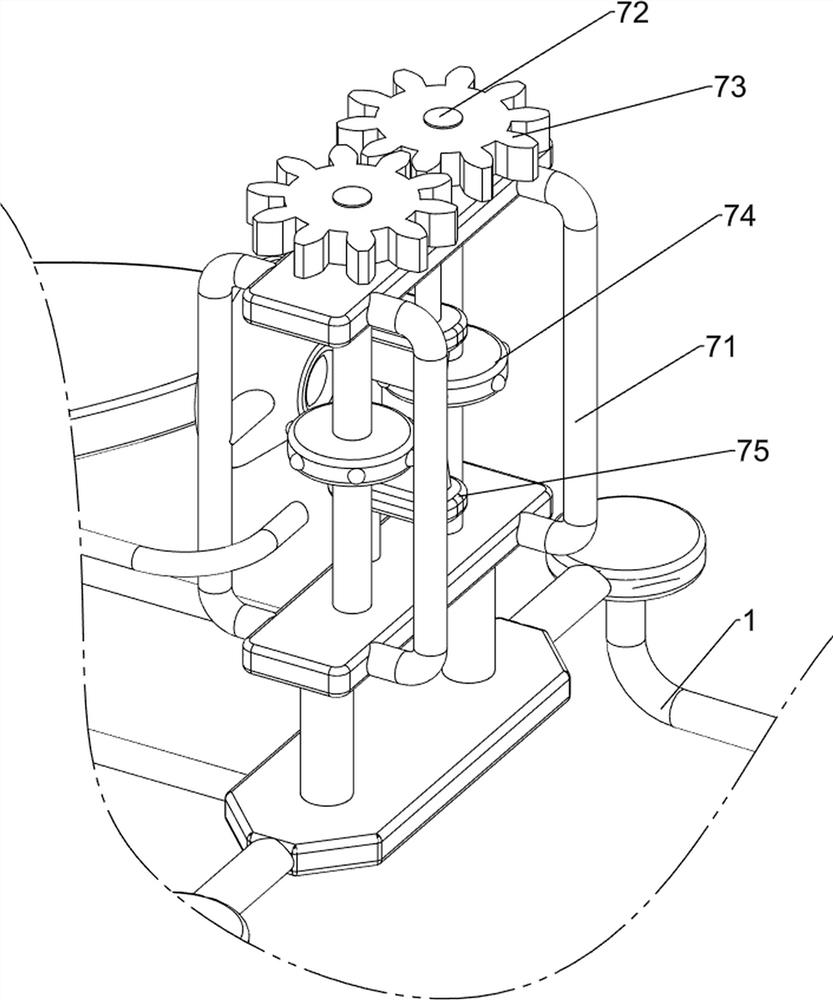

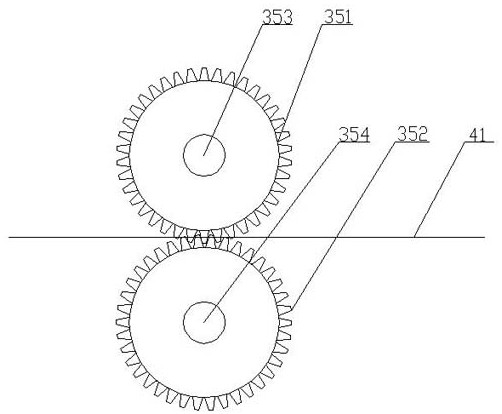

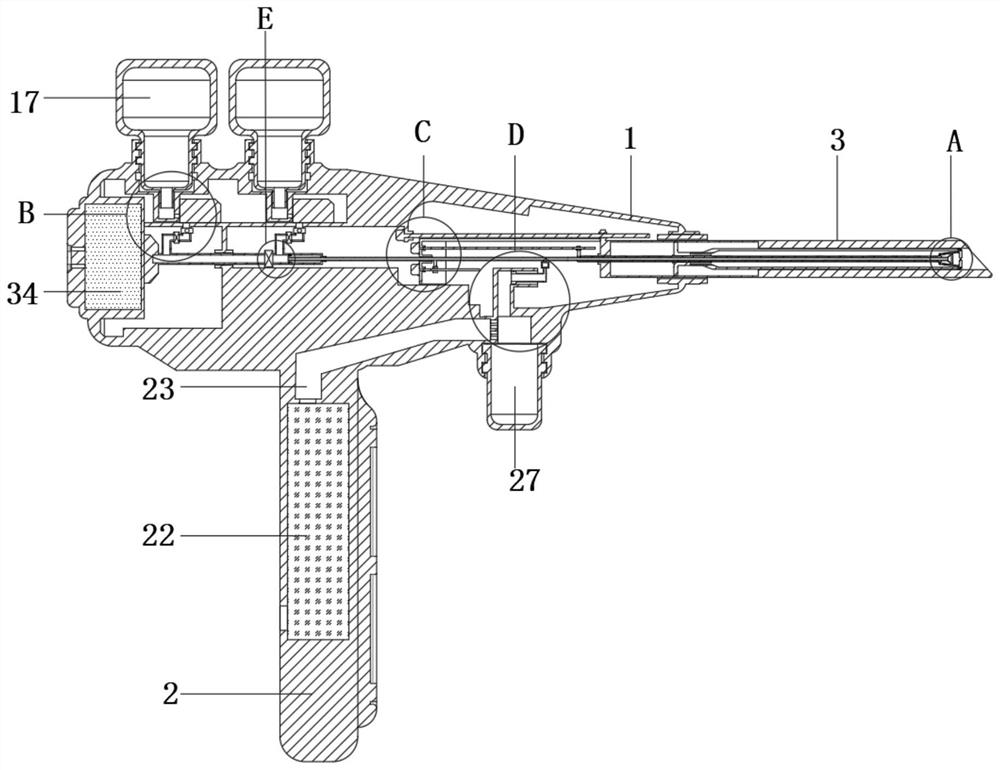

Electric branch binding machine

PendingCN112640724ARealize cutting workCompact internal structureCultivating equipmentsGear wheelElectric machinery

The invention relates to an electric branch binding machine. The electric branch binding machine comprises a machine shell, a driving structure, a wire feeding structure and a wire feeding and cutting bracket structure, an iron wire on the wire feeding structure forms multiple circles of iron rings into the wire feeding and cutting bracket structure along with transmission of the driving structure, and the wire feeding and cutting bracket structure cuts off the multiple circles of iron rings; and one end of the driving structure is sleeved with a connecting piece, the connecting piece is detachably connected with the wire feeding and cutting bracket structure, a shift rail penetrates through the central direction of the connecting piece and is connected with the wire feeding cutting bracket structure, shifting forks are arranged at the two ends, close to the side end face of the wire feeding and cutting bracket structure, of the shift rail, when the shift rail rotates along with driving of a gear motor, a first bevel gear and a second bevel gear are driven to be in meshed transmission, and therefore an upper gear and a lower gear are meshed and drive the iron wire to be conveyed. The electric branch binding machine has the following advantages that the driving stability and synchronism are improved, the split bracket serves as a wire feeding rail, wire running is not likely to happen, and mounting, dismounting and later maintenance are convenient.

Owner:南通捷顺电动工具有限公司

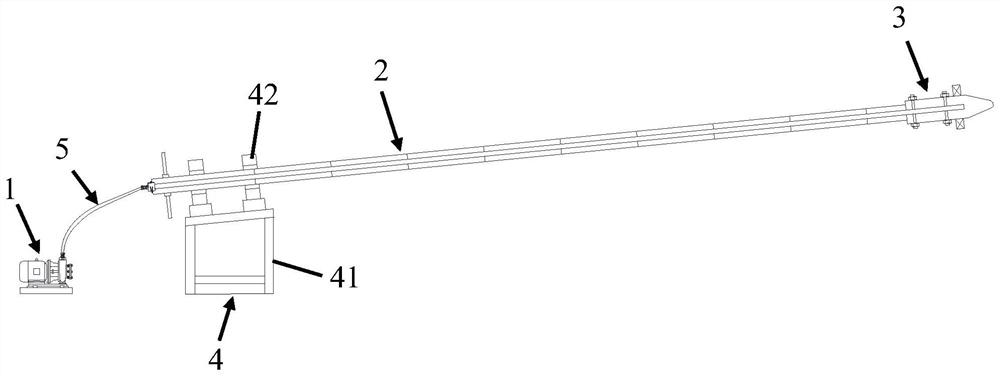

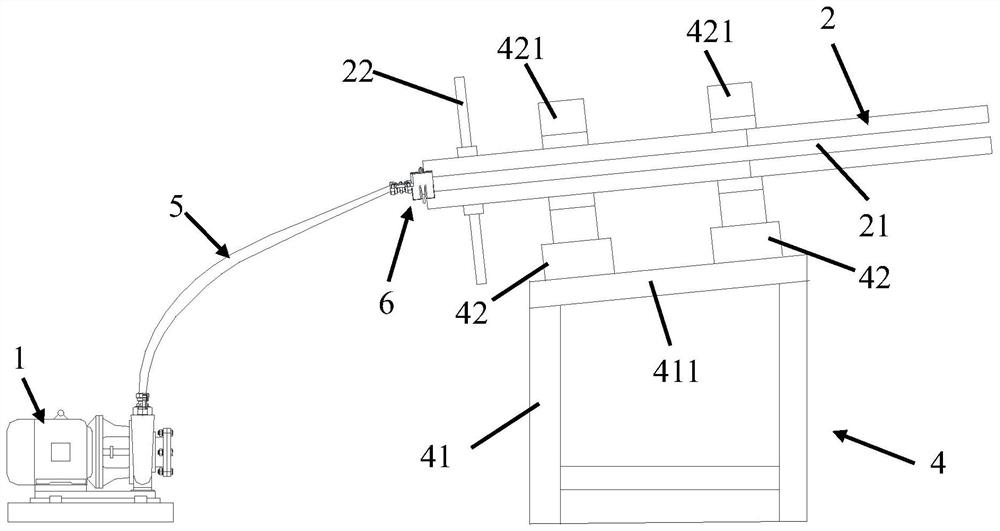

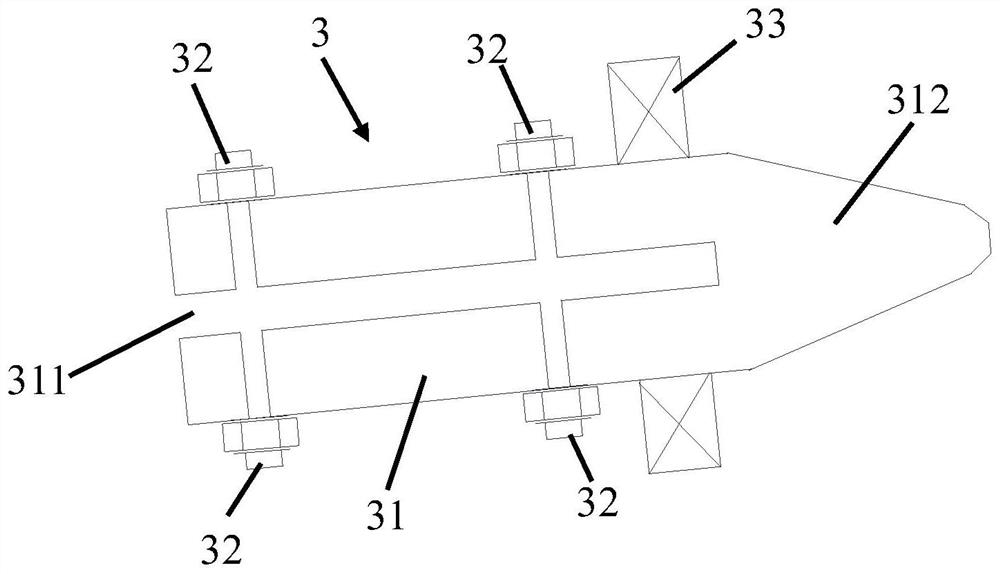

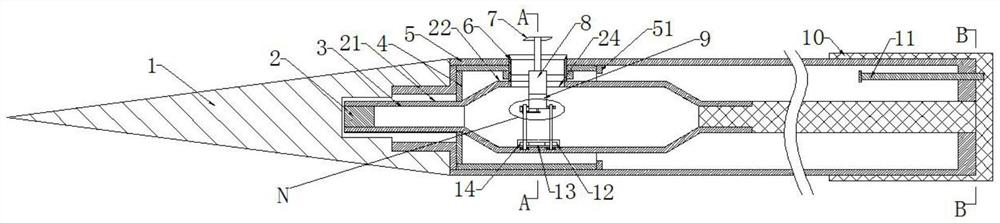

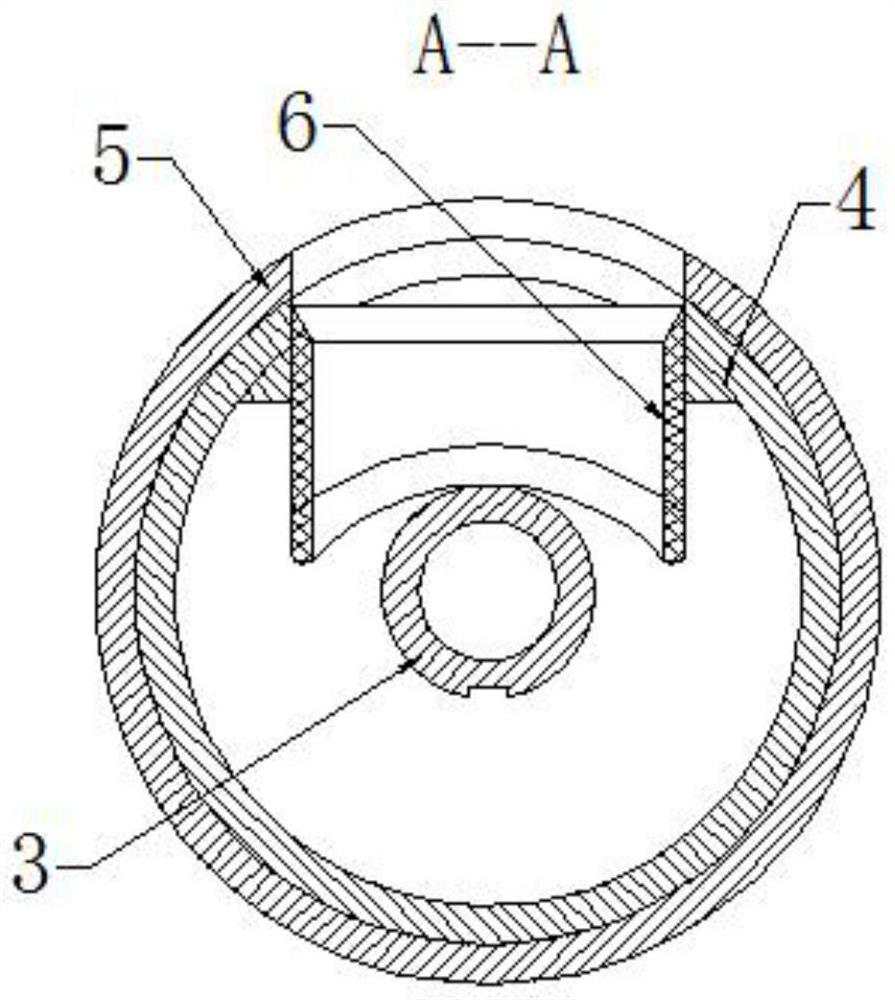

Hydraulic cutting device and gas extraction pipe cutting method

ActiveCN113931590ARealize cutting workEasy to dig outGas removalBorehole/well accessoriesRolling-element bearingStructural engineering

The invention discloses a hydraulic cutting device and a gas extraction pipe cutting method. The hydraulic cutting device comprises a high-pressure water pump, a drill rod used for being inserted into a gas extraction pipe, a hydraulic cutting head detachably connected with the head of the drill rod and a supporting base used for supporting the tail of the drill rod. The hydraulic cutting head comprises a cutting head shell, a nozzle and a rolling bearing used for being supported between the cutting head shell and the gas extraction pipe. According to the hydraulic cutting device and the gas extraction pipe cutting method, the hydraulic cutting head can be driven by the drill rod to rotate in the gas extraction pipe, high-pressure water is supplied to the hydraulic cutting head through the high-pressure water pump, the high-pressure water is sprayed out from the nozzle of the hydraulic cutting head, and therefore the annular pipe wall of the gas extraction pipe can be annularly cut; the device is simple, convenient and fast to operate, effectively realizes the cutting work of the gas extraction pipe in the coal seam, and is convenient for the heading machine to dig out the second crossheading (small coal pillar crossheading) of the coal pillar.

Owner:SHENHUA SHENDONG COAL GRP +1

Bristling cutting mechanism of industrial brush

The invention relates to the technical field of short brush filament cutting, and discloses an industrial brush bristle cutting mechanism which comprises a cutting table, a cutting mechanism and a collecting box, a vertically-through cutting groove is formed in the top of the cutting position of the cutting table, and a conveying pressing belt used for conveying brush filaments is arranged at the position, close to the cutting groove, of the top of the cutting table. A transverse fixing plate is fixed to the top of the cutting table through a support, the lower surface of the front end of the fixing plate is in transmission connection with a cutting mechanism through an air cylinder, a material suction cover is attached to the vertical face of the cutting end of the cutting table, and the diagonal bottom of a material suction opening of the material suction cover communicates with one corner of the top of the collecting box through a guide pipe. And an exhaust fan for sucking internal airflow outwards is arranged at the lower end of the outer side wall of the material suction cover. The problem that cut short brush filaments are inconvenient to collect, and consequently the later-period arrangement workload is large is solved.

Owner:QIANSHAN FUDA RUBBER BRUSH IND PROD FACTORY

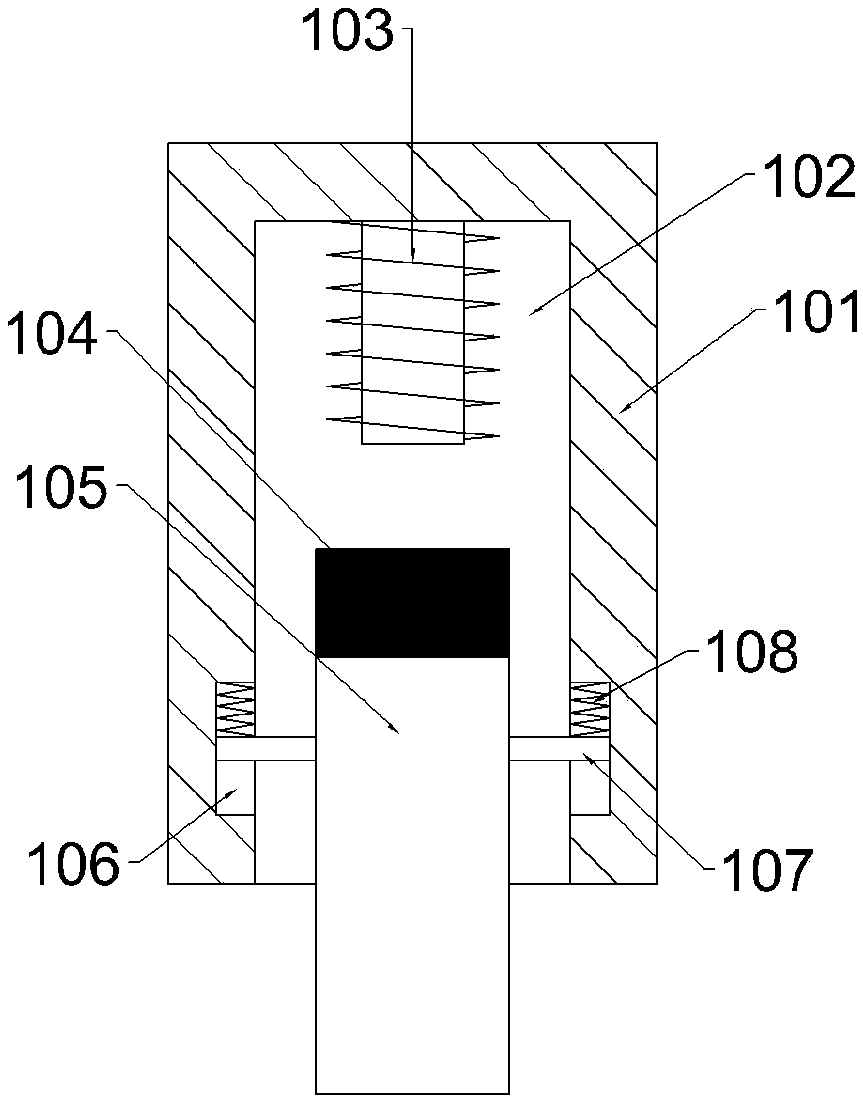

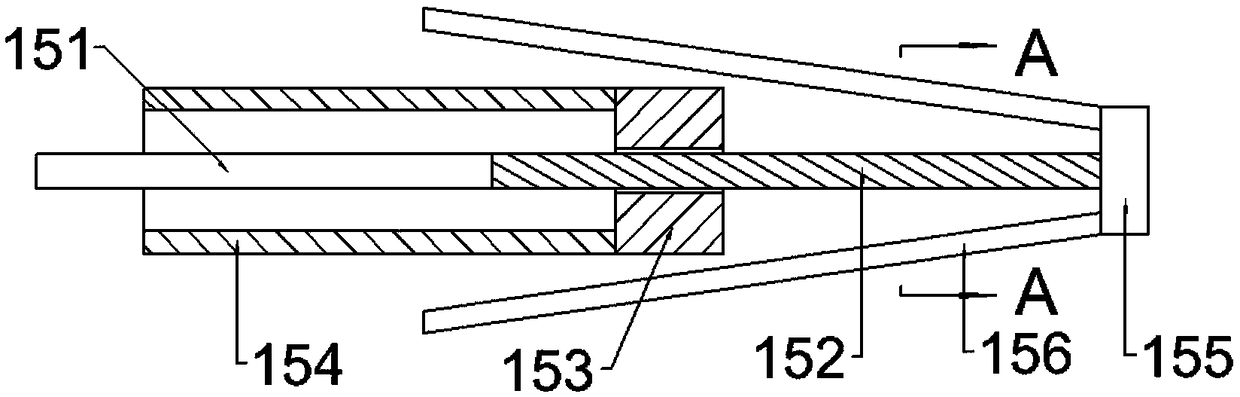

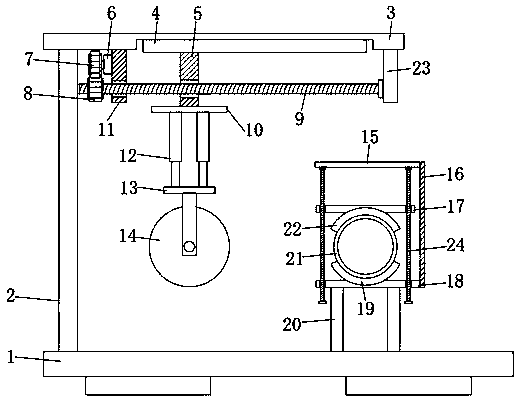

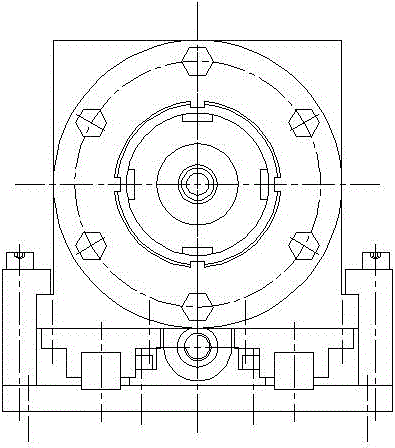

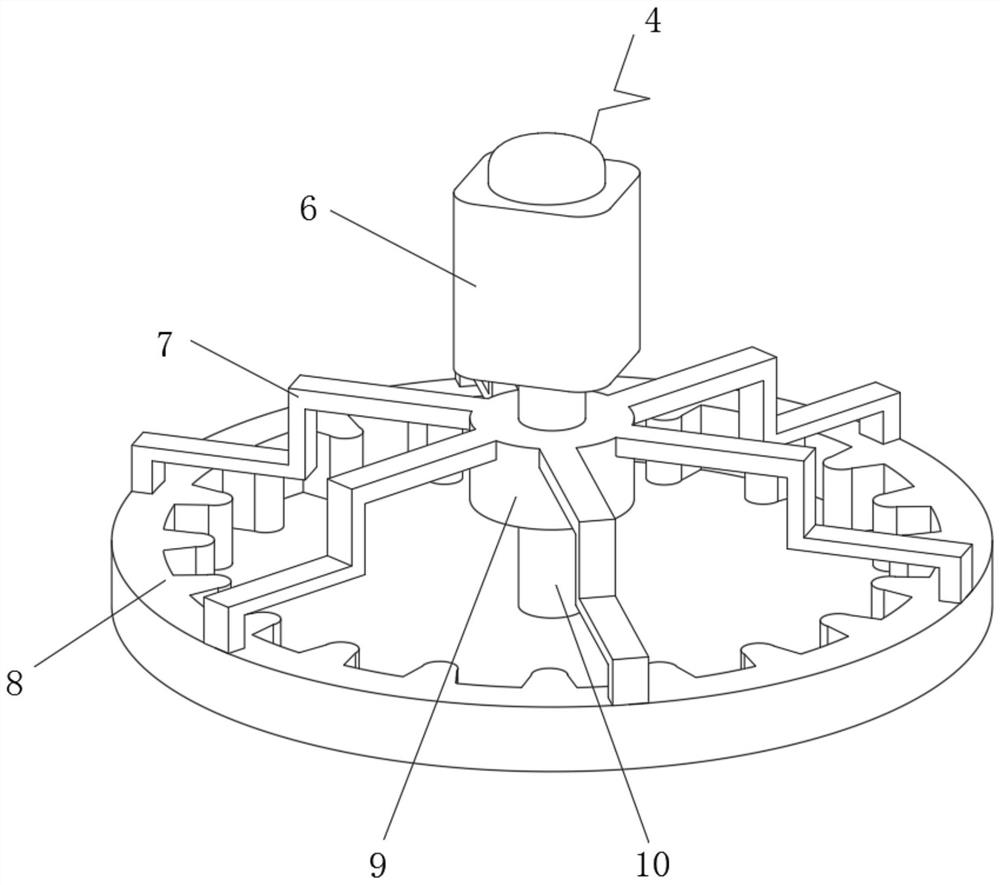

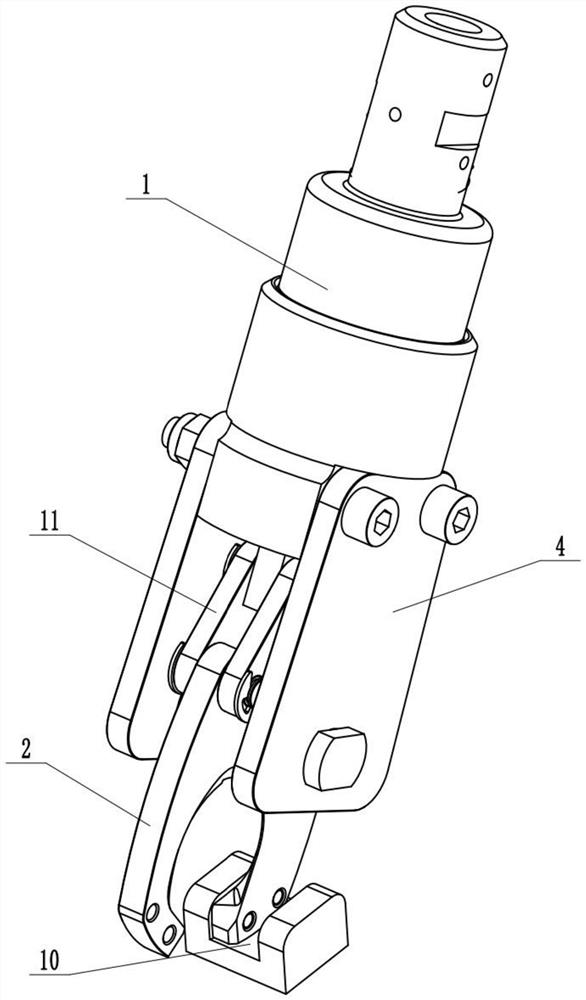

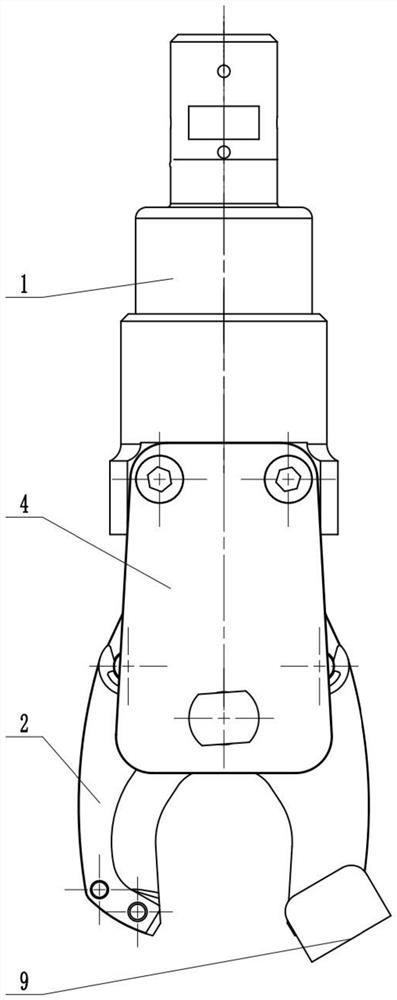

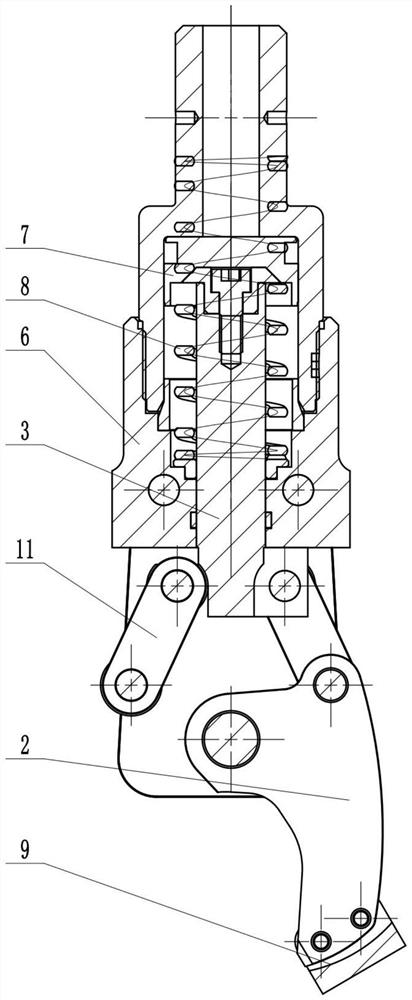

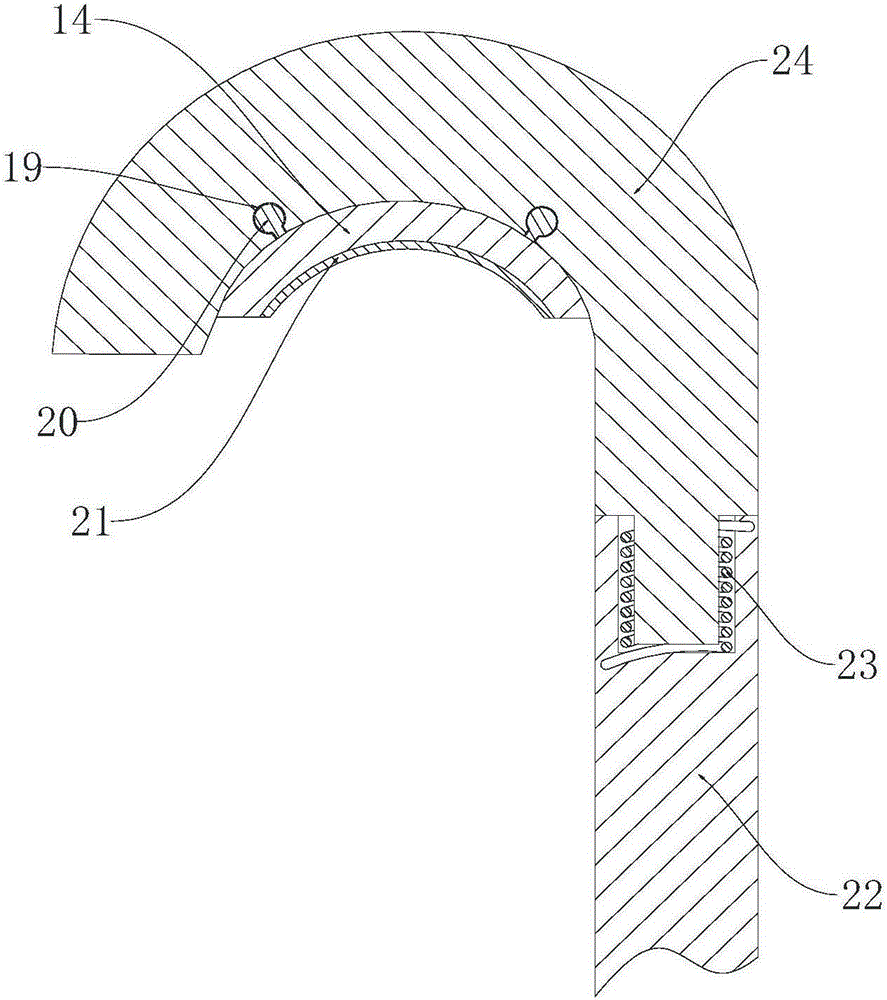

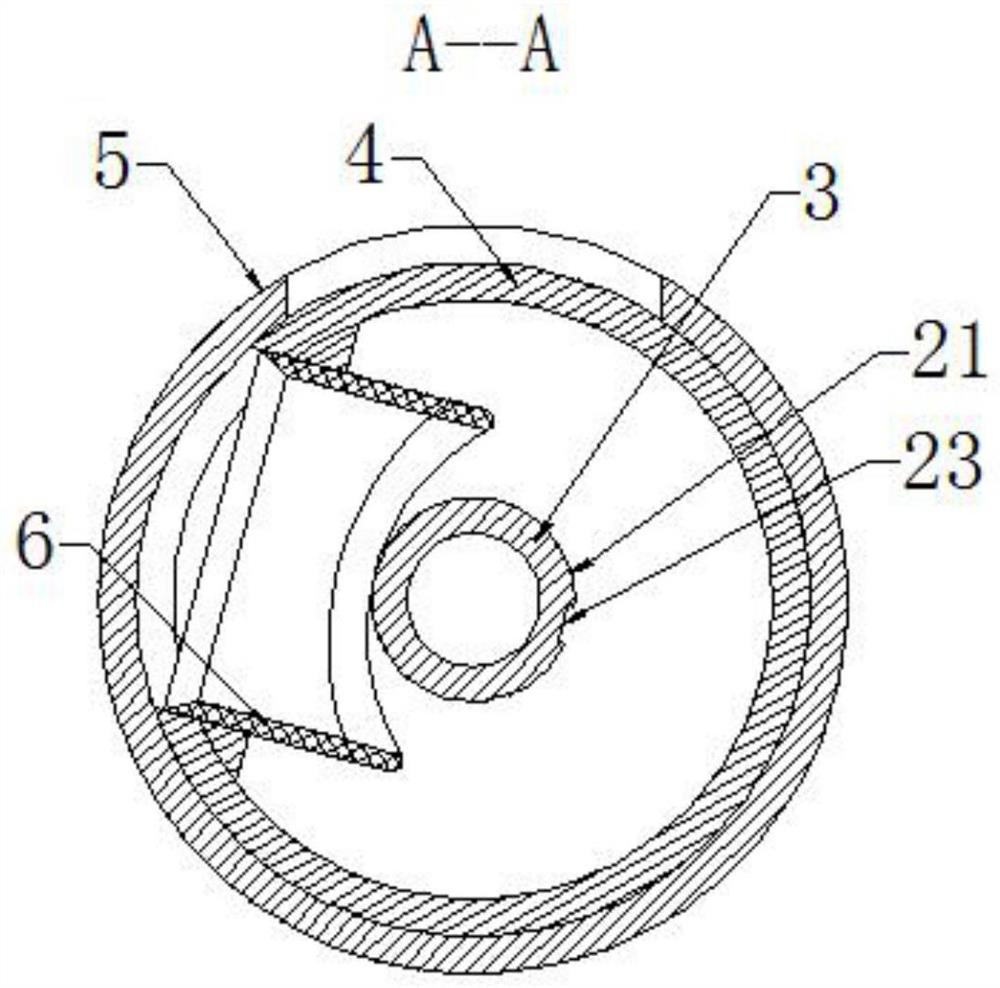

A drilling and milling head

InactiveCN103692270BFast cutting speedSimple structureFeeding apparatusLarge fixed membersHydraulic motorMotor shaft

The invention discloses a drilling and milling head. The drilling and milling head is arranged on the front end face of a moving disk of a tube cutter through a bottom plate; two parallel linear guide rails are fixedly arranged on the bottom plate; a box is fixedly arranged on the linear guide rails; a screw is arranged on the bottom plate through a supporting seat, and forms a screw-nut pair with the box; the box can move along the linear guide rails under the drive of the screw; a hydraulic motor is fixedly arranged on the back end face of the box through a square flange; the motor shaft extends into a cylindrical hole at the back end of a main shaft, and is connected with the cylindrical hole through a key; the main shaft is in a single-pivot bidirectional fixation formation; a cutter is connected with a collet into a whole; a wedge cushion block is arranged on the moving disk of the tube cutter; a drilling and milling head power device assembly is fixedly arranged on the wedge cushion block, so that the angle of inclination of the drilling and milling head power device assembly is changed, the cutter is inclined in the milling process, a welding groove is directly formed on the end face of a pipeline in the process of cutting the pipeline, and tube cutting and groove formation are integrated. The drilling and milling head is simple in structure and easy to implement.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

A corner cutting device for noodle processing

ActiveCN112293451BRealize cutting workAchieve driving purposeDough shaping and cutting apparatusBaked article cutting/slicingStructural engineeringElectric motor

Owner:厦门市鼓浪屿食品厂有限公司

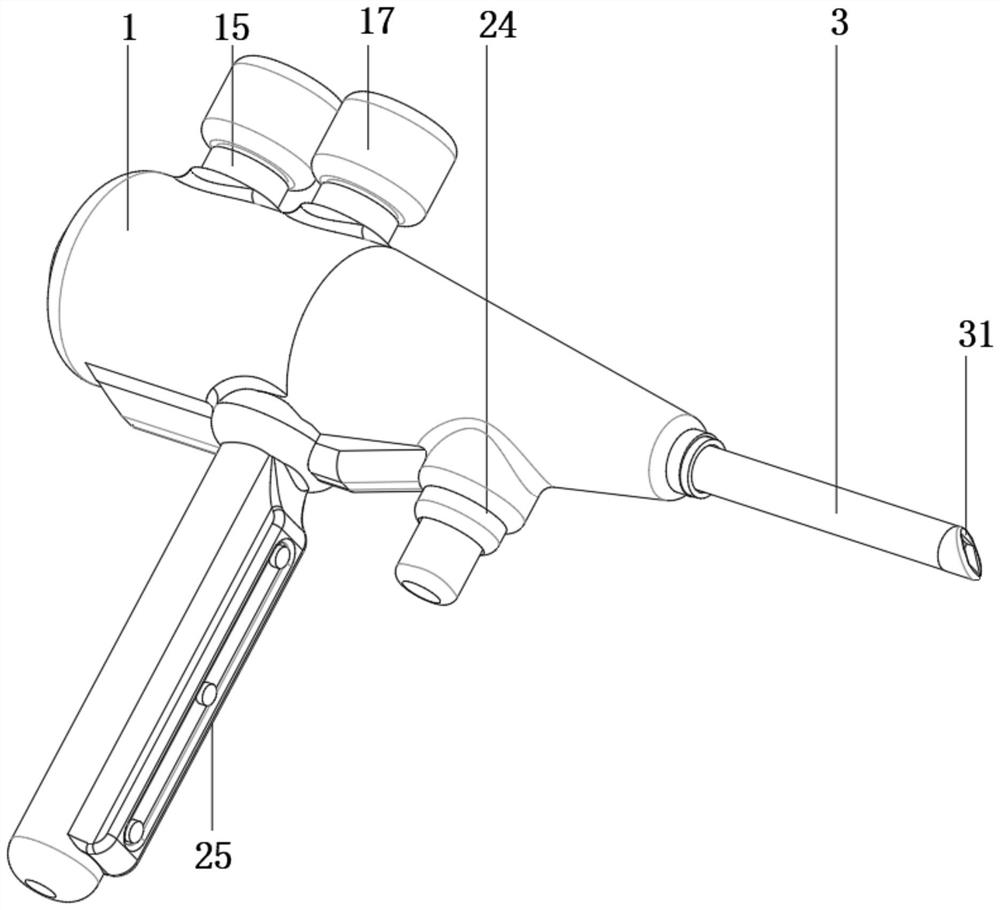

Scissors for cutting off high-altitude cable

PendingCN113500634ARealize cutting workGuaranteed shear force balanceApparatus for cutting/splicing cablesMetal working apparatusEngineeringReciprocating motion

The invention provides a pair of scissors for cutting off a high-altitude cable. The pair of scissors comprises a scissor holder, wherein a push rod of which the two ends extend out of the scissor holder is inserted into the scissor holder in a penetrating manner; the push rod does reciprocating linear motion along the scissor holder; two supporting plates which are arranged in parallel at an interval are fixed at the lower end of the scissor holder; the lower ends of the two supporting plates are connected through a connecting shaft; two blades which are positioned between the two supporting plates and are oppositely arranged are hinged to the connecting shaft; the lower end of the push rod is connected with each blade through a connecting rod; the connecting rods are hinged to the push rod and the blades; and the two blades are opened and closed under the action of reciprocating motion of the push rod. According to the pair of scissors, the cutting efficiency of the high-altitude cable can be improved, and the blades are prevented from being damaged.

Owner:STATE GRID ZHEJIANG YONGKANG POWER SUPPLY +1

Cutting device for high tree branches

InactiveCN106550780APrevent fallingAvoid accidental damageCuttersCutting implementsMechanical engineeringEngineering

The invention discloses a cutting device for high tree branches. The cutting device comprises a screw rod, a cutting base, a cutting assembly and a hanging arm assembly; the cutting assembly comprises two supporting block and a rotating shaft; and the hanging arm assembly comprises a short hanging arm rod, a long hanging arm rod, a first hanging arm head, a second hanging arm head and an arc-shaped anti-slipping block, and the widths of the first hanging arm head and the second hanging arm head in the axis directions of bending portions of the first hanging arm head and the second hanging arm head are both smaller than the width of the anti-slipping block in the corresponding axial directions. By installing a spring and a first torsional spring, branch cutting work of the cutting assembly can be better achieved due to the fact that the elastic deformation of the spring and the torsional spring gives way to gear saw blades, and particularly, when the positions of a residual part and a cutting part are slightly mismatched, cutting requirements can be met by the way that external force is applied to the long hanging arm rod, and thus the long hanging arm rod rotates on a small scale relative to the second hanging arm head under the effect of the elastic deformation of the first torsional spring.

Owner:CHONGQING LANXIN BEIER AGRI TECH CO LTD

Throat tumor sampling device

InactiveCN114711839AEfficient sampling workEfficiently complete sampling workSurgical needlesVaccination/ovulation diagnosticsThroatEngineering

The invention discloses a throat tumor sampling device. The bottom of the machine body is fixedly provided with a grip, the grip is internally and fixedly provided with a negative pressure module, the machine body is internally and slidably connected with an outer needle cylinder, the back surface of the outer needle cylinder is fixedly provided with a driving frame, the outer needle cylinder is internally and fixedly provided with a square flow cavity, and the inner wall of the square flow cavity is fixedly provided with a bracket; a transmission inner cylinder is slidably connected to the inner wall of the support, a conveying core pipe is slidably connected to the inner wall of the transmission inner cylinder, and a transmission mechanism matched with the transmission inner cylinder and the conveying core pipe is fixedly arranged on the back face of the driving frame. Through the design of the structures of the outer needle cylinder, the sampling sealing knives and the like, the device can efficiently complete the sampling work of the throat tumor in a minimally invasive puncture mode, and during the sampling work of the device, through the design of the double sampling sealing knives, the tumor tissue can be effectively cut off when the tumor tissue is sampled.

Owner:ZHENGZHOU CENT HOSPITAL

Sampling device for mineral product inspection and use method thereof

PendingCN114858515APrevent insertionRealize cutting workWithdrawing sample devicesEngineeringElectrical and Electronics engineering

The invention discloses a sampling device for mineral product inspection and a using method thereof. The sampling device comprises a sampling barrel, a sample storage bin is arranged in the sampling barrel, one end of the sample storage bin penetrates out of the sampling barrel, the sample storage bin is sleeved with an inner ring, a positioning groove is formed in the sample storage bin, the inner ring is connected with a positioning key, and the positioning key is arranged in the positioning groove in a sliding mode; the inner ring is rotatably connected with the sampling barrel, a top frame with two open ends is slidably connected in the inner ring, and the sampling barrel is provided with a feed port for the top frame to pass through; the top frame is arranged on one side of the sample storage bin, the sample storage bin comprises a horizontal plane and a lifting surface, a feeding port is formed in the lifting surface, and the caliber of the feeding port is smaller than the width of the top frame; the sample storage bin is detachably connected with a seal, the sampling barrel is detachably connected with a tip internally provided with a cavity, and the seal is arranged in the cavity of the tip in a sliding manner. The sampling device is convenient to operate, cutting work of mineral products can be achieved during sampling, meanwhile, the cut mineral products can be pulled into the sample storage bin, and therefore sampling work of the mineral products is achieved.

Owner:中华人民共和国日照海关

A cable stripping and cutting processing device

ActiveCN111049070BEasy to moveRealize cutting workApparatus for cutting/splicing cablesApparatus for removing/armouring cablesWire cuttingEngineering

The invention discloses a cable stripping and cutting processing device. It includes a mounting bracket, a wire stripping mechanism and a wire cutting mechanism. Both the wire stripping mechanism and the wire cutting mechanism are installed on the mounting bracket. Roller, the present invention can solve the problems existing in the existing cable stripping, such as the insecure fixation of the cable, the inability to automatically strip or cut the cable, and the inability to automatically wind the cable; by stripping The setting of the wire mechanism, the wire stripping mechanism can automatically strip the cable, the structure is set reasonably and fixed firmly, after the wire is stripped, the cable can enter the wire cutting mechanism, and then through the reciprocating work of the cutter, the cable can be cut The cutting work of the cable greatly improves the processing efficiency of the cable, avoids the cumbersome manual operation, and has strong practicability, so that it can be popularized and used.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com