Coleoptile cutting system and method based on PLC control system

A technology of control system and cutting system, applied in the field of coleoptile cutting, can solve the problems of low mechanization and automation of cutting, manual cutting process of coleoptile, manual recognition process of coleoptile, etc., so as to realize automatic identification and cutting work, Realize real-time monitoring and control, and solve the effect of time-consuming, labor-intensive and low-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

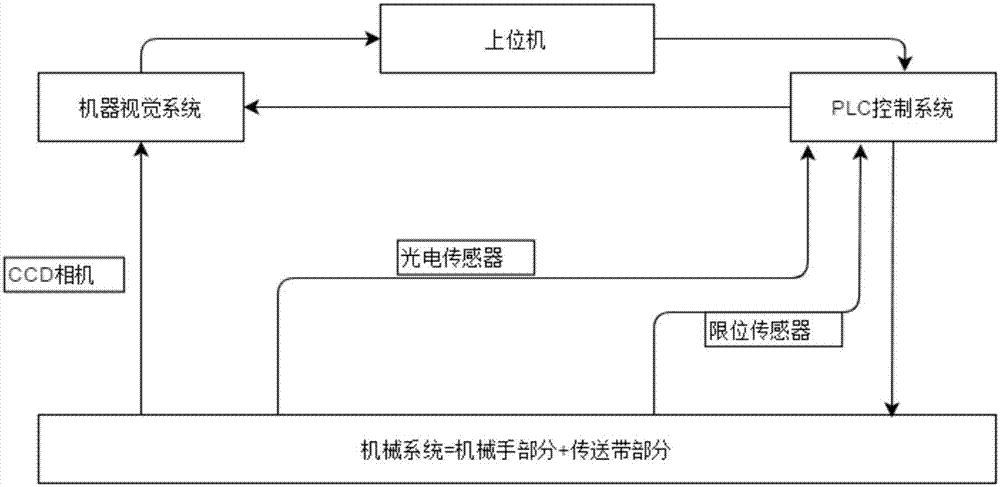

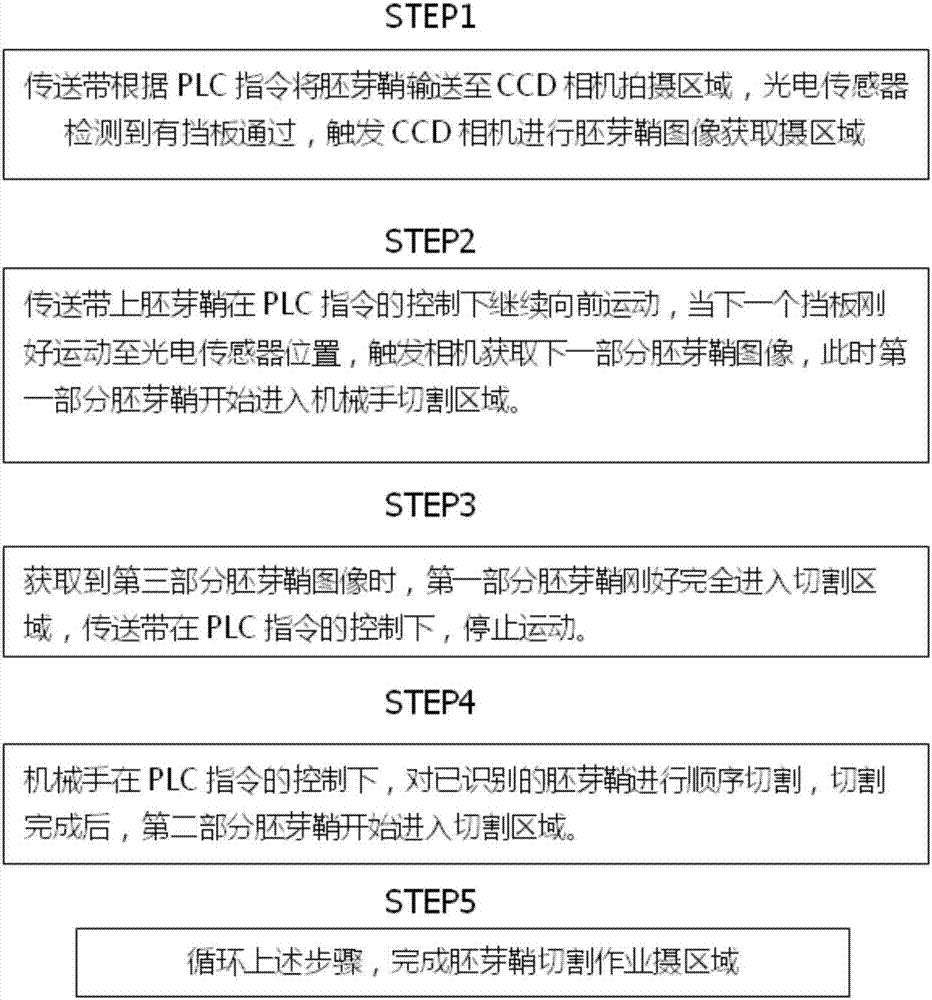

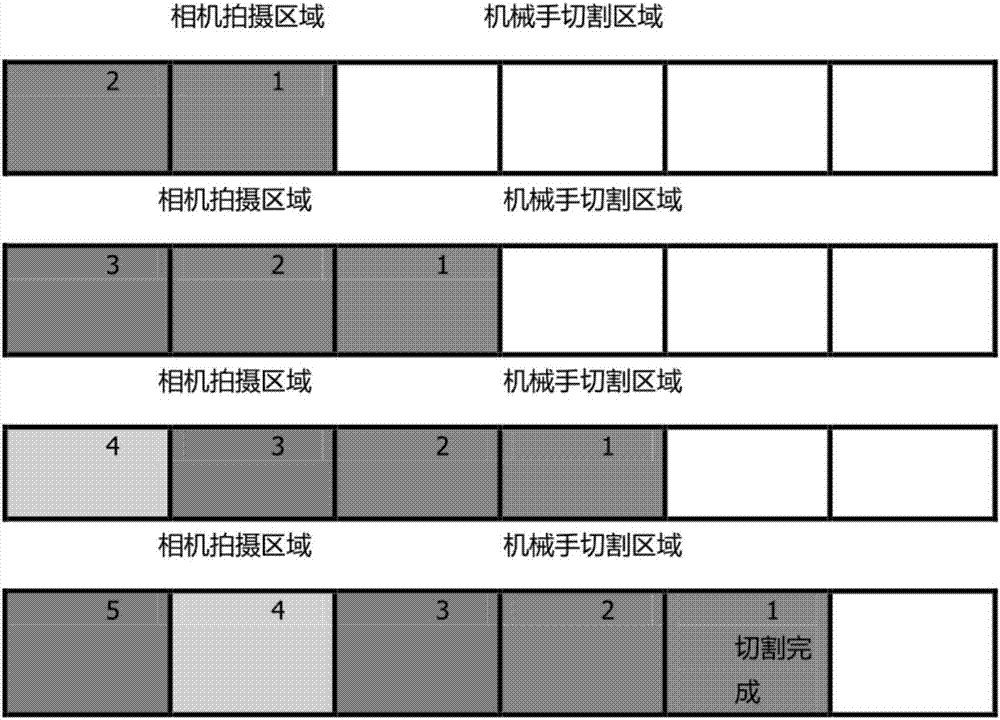

[0025] A coleoptile cutting system based on a PLC control system. It includes a mechanical system, a PLC control system and a machine vision system. The mechanical system includes a manipulator 1 and a conveyor belt 3. The manipulator 1 is installed on the conveyor belt 3, and the hardware part of the machine vision system 2 is installed On the conveyor belt 3; the photoelectric sensor 4 and the limit sensor installed on the conveyor belt 3 are respectively connected with the PLC control system wires; the PLC system is connected with the upper computer; the machine vision system 2 is respectively connected with the PLC control system and the upper position.

[0026] The conveyor belt 3 includes a conveyor belt with baffles and an aluminum profile truss structure; the conveyor belt 3 includes transmission shafts at both ends of the conveyor belt, one of which is connected to the synchronous belt wheel 5, and the synchronous belt wheel 5 is connected to the servo motor shaft through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com