A Split Drilling Milling Pipe Cutting Machine

A split-type, pipe cutting machine technology, applied in milling machine equipment, details of milling machine equipment, metal processing machinery parts, etc., can solve problems such as inapplicability to oil and gas pipeline maintenance and repair sites, achieve simple structure, easy implementation, and ensure stable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

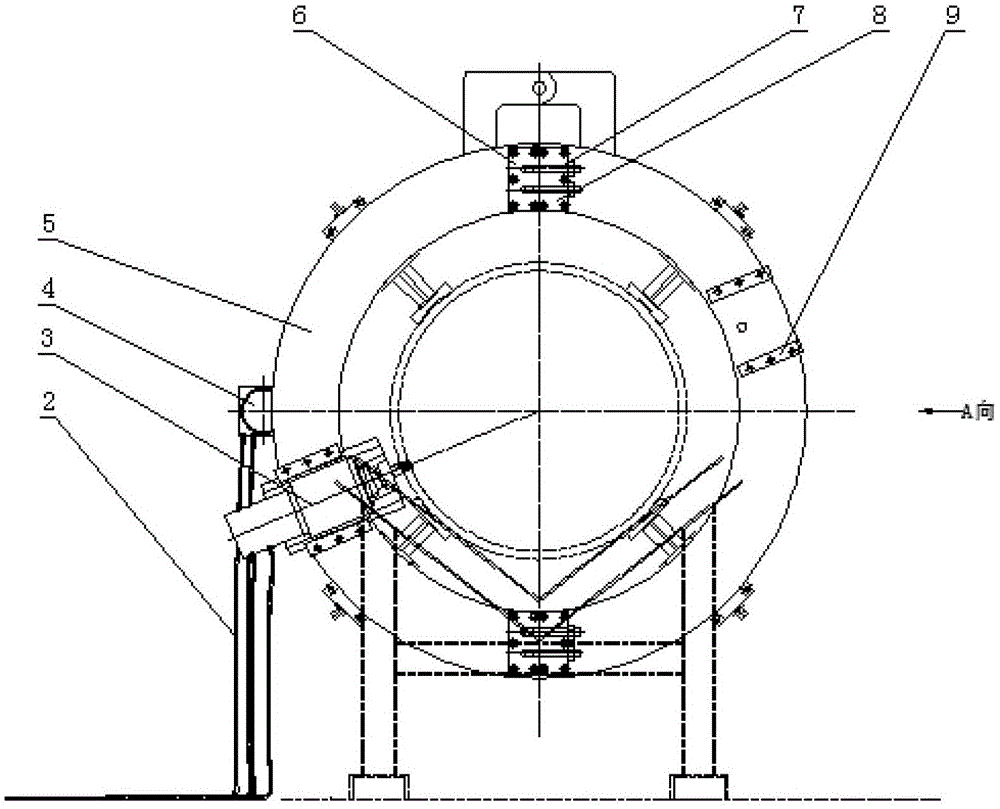

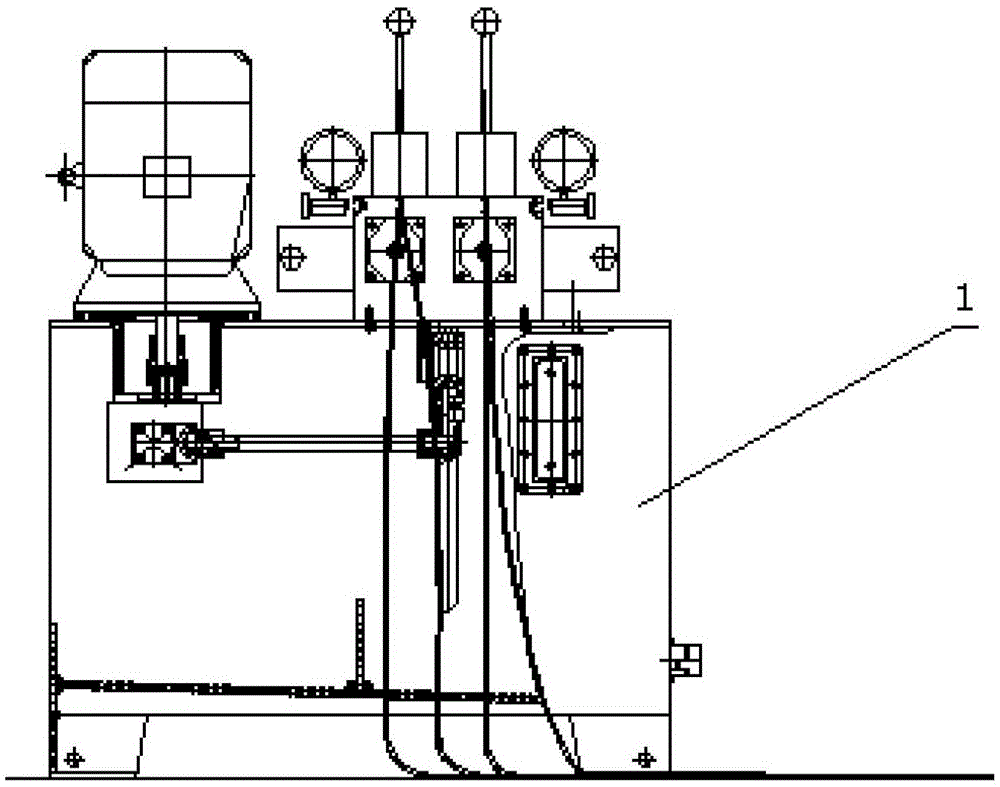

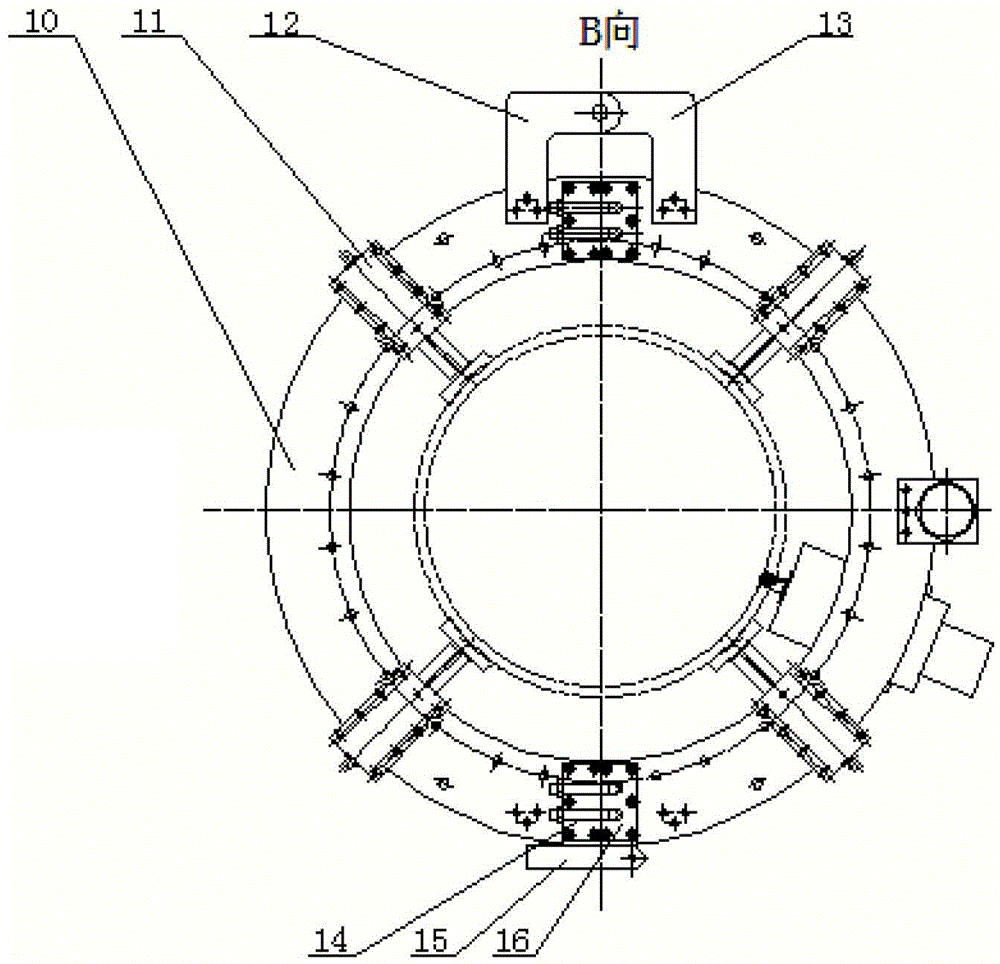

[0038] Such as figure 1 , 2 As shown, the present invention relates to a split drilling and milling pipe cutting machine, which has a fixed seat 10, an adjusting leg 11, a movable seat 5, a circular feed drive part 4, a drilling and milling head part 3 and a power source, wherein: The fixed seat 10 is a split structure, supports and connects the various parts of the pipe cutting machine, and positions the relative positions of each part; the adjusting leg 11 is installed on the rear end surface of the fixed seat 10, and the fixed seat 10 is fixed by the adjusting leg 11 to the outer wall of the pipe to be cut; the movable seat 5 is a split structure, and is connected to the front end of the fixed seat 10 through a rolling device; the circular feed drive part 4 is installed on the outer edge of the fixed seat 10, and the 5 transmission connection; the drilling and milling head part 3 is installed on the front end of the movable seat 5, the drilling and milling head part 3 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com