Connecting-rod-type pipe bending and cutting integrated device

A connecting rod type and pipe material technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as unfavorable efficiency and increased processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

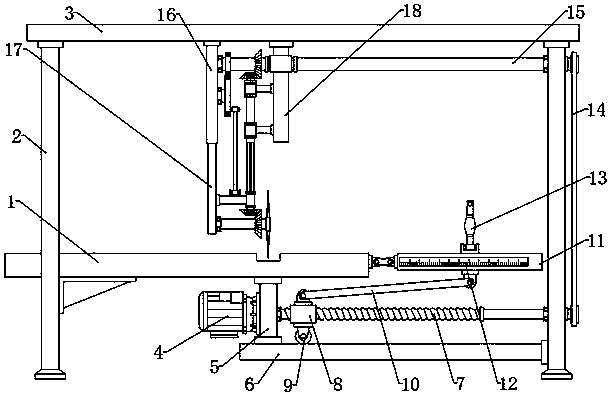

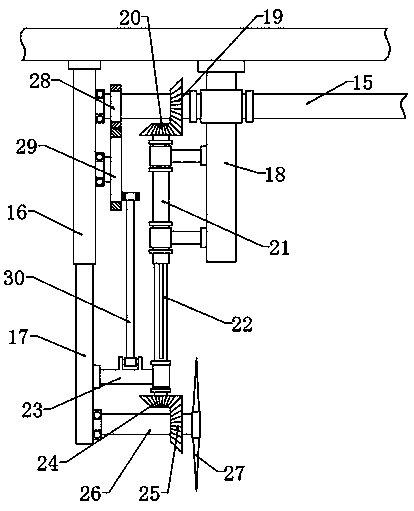

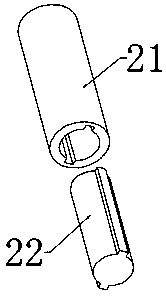

[0025] see Figure 1~4 , in an embodiment of the present invention, a connecting rod type pipe bending and cutting integrated device, including a workbench 1, a top plate 3, a screw rod 7, a movable plate 11, a sleeve 21 and a cutting knife 27; the two sides below the top plate 3 Support rods 2 are respectively fixed, wherein the lower part of one side of the support rod 2 is fixed to the workbench 1 by reinforcing ribs, the upper end of one side of the bottom plate 6 is fixed by the connection plate 5 under the workbench 1, and the other side of the bottom plate 6 is fixed on the other side of the support rod 2 The lower part, and the flange on the connecting plate 5 is equipped with a drive motor 4. Further, the drive motor 4 is connected to the power supply and the switch, and the drive motor 4 is controlled by the switch to work when the power is turned on. The connection strength of 1 improves the overall stability; the output end of the drive motor 4 is connected with a ...

Embodiment 2

[0029] In order to further explain the above-mentioned connecting rod type pipe bending and cutting integrated device, this application provides another embodiment. The connecting rod type pipe bending and cutting integrated device in this embodiment has the following technical features: the movable plate 11 A scale 12 is fixed for measuring the length of the bending part of the pipe. The middle part above the movable plate 11 is hinged at the end of the insert 13. The other end of the insert 13 is connected to the movable plate 11 by bolts. The middle part of the insert is curved in a circular arc shape. The arc-shaped insert 13 facilitates clamping and fixing of pipes with different diameters, the rotating movable plate 11 drives the bending of the steel pipe, and the scale 12 can be used to control the length of the bending part according to actual production needs.

[0030] According to the specific description of the above-mentioned embodiment, it is easy to know that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com