Cutting device for high tree branches

A technology of cutters and branches, which is applied in the field of cutters for high-altitude branches, can solve the problems that the personal safety of workers cannot be guaranteed, the high cost of aerial work vehicles, and the high limitations of the applicable environment, so as to avoid accidental damage and maintain stability. The effect of doing work and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

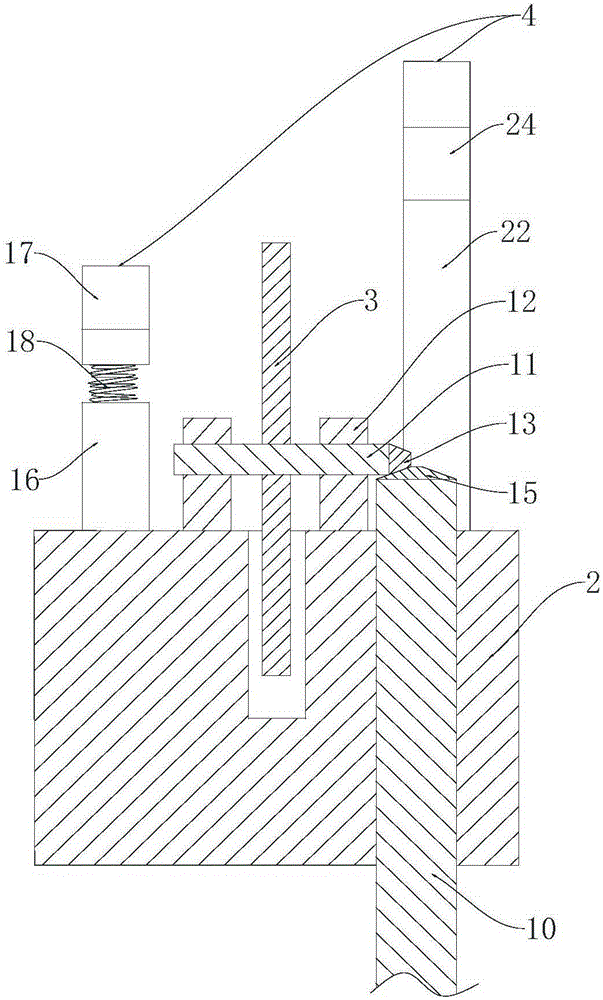

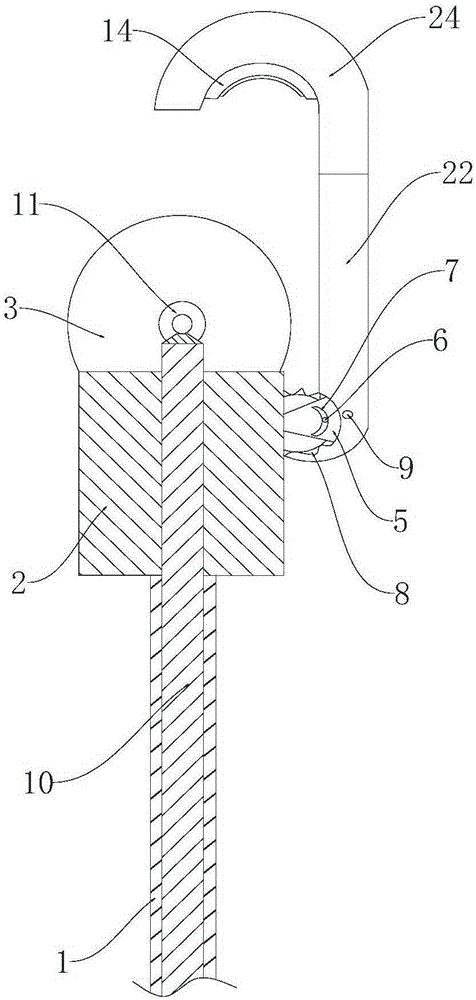

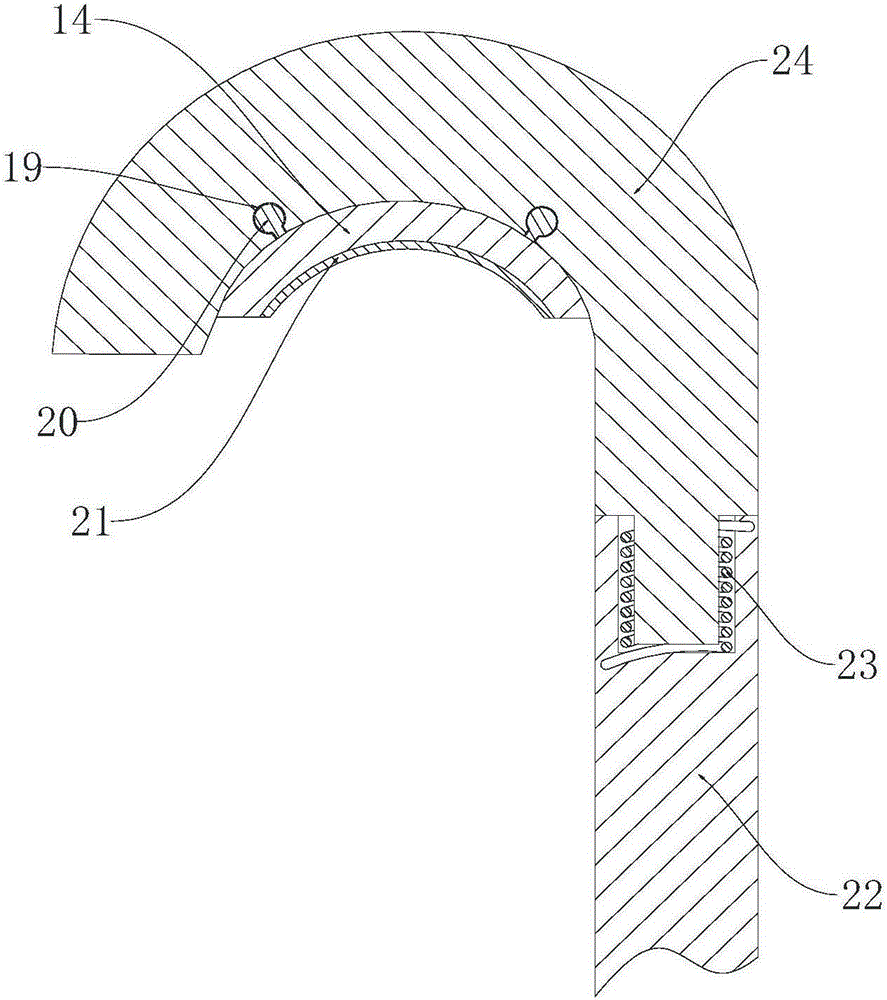

[0026] Such as Figure 1 to Figure 5Shown, a kind of cutter that is used for high-altitude tree branch comprises screw rod 10, cutting base 2 and cutting assembly, and cutting assembly comprises two support blocks 12 that are arranged oppositely and are fixedly connected on the upper end surface of cutting base 2 and are arranged on by bearing rotation. The rotating shaft 11 on the two supporting blocks 12, the rotating shaft 11 is covered with a gear saw blade 3, the lower end of the screw rod 10 is covered with a sleeve 1, the upper end of the screw rod 10 runs through the cutting base 2, and a cutting blade located at the end is installed on the end. The bevel gear 13 above the base 2, the bevel gear 15 matched with the bevel gear 13 is installed on the end of the rotating shaft 11; it also includes the hanging arm assembly 4, and the hanging arm assembly 4 includes a short hanging arm rod 16, which is longer than the short hanging arm The long arm bar 22 of the bar 16, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com