Patents

Literature

37results about How to "Quick cut job" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

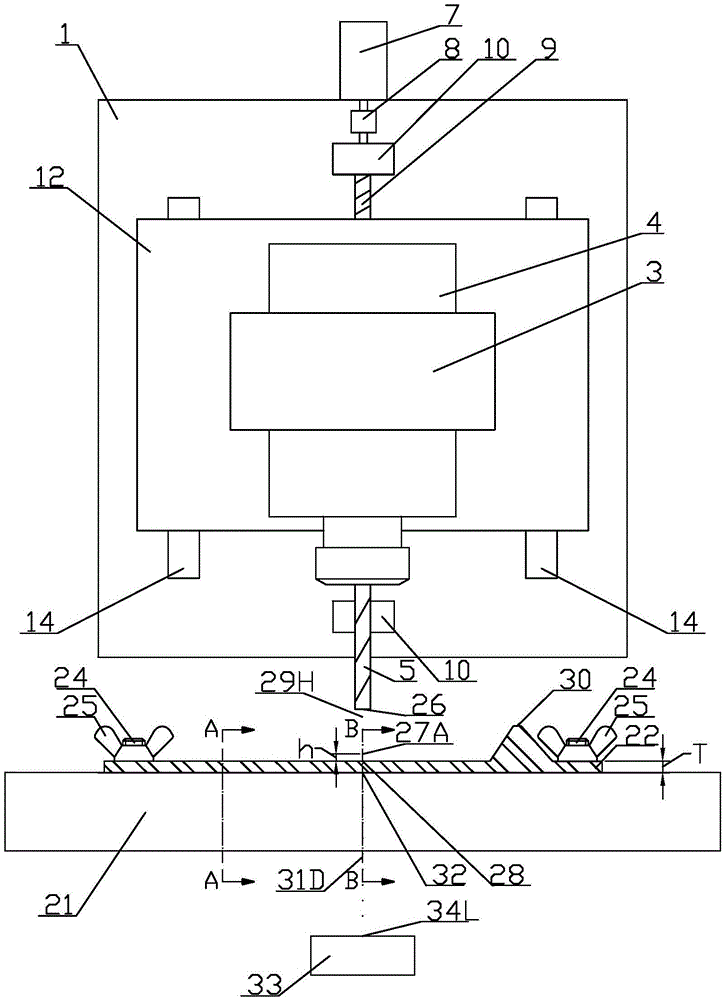

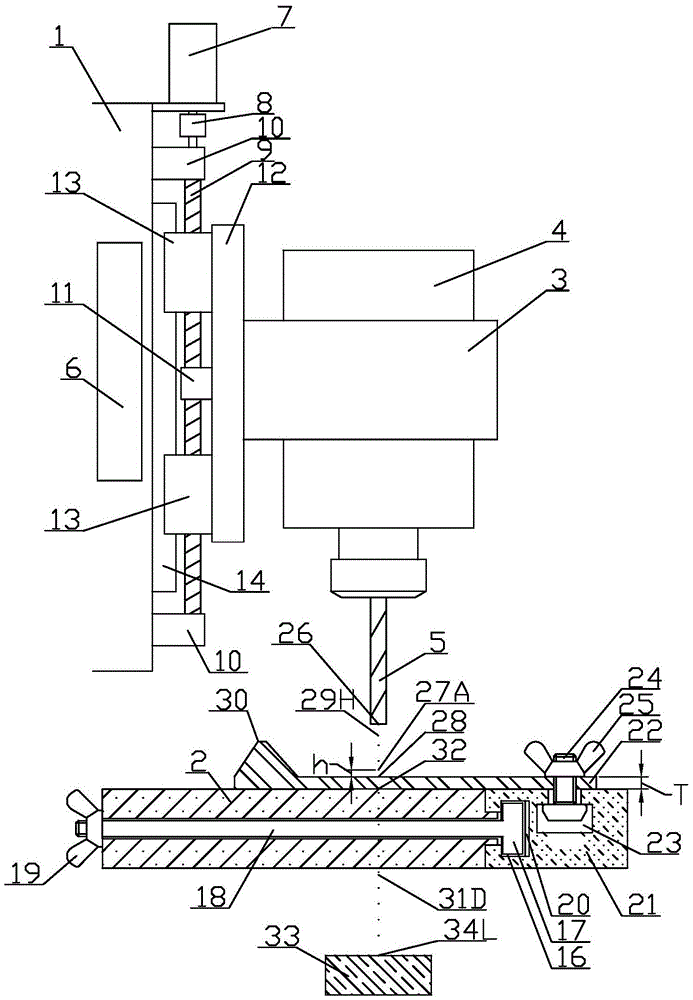

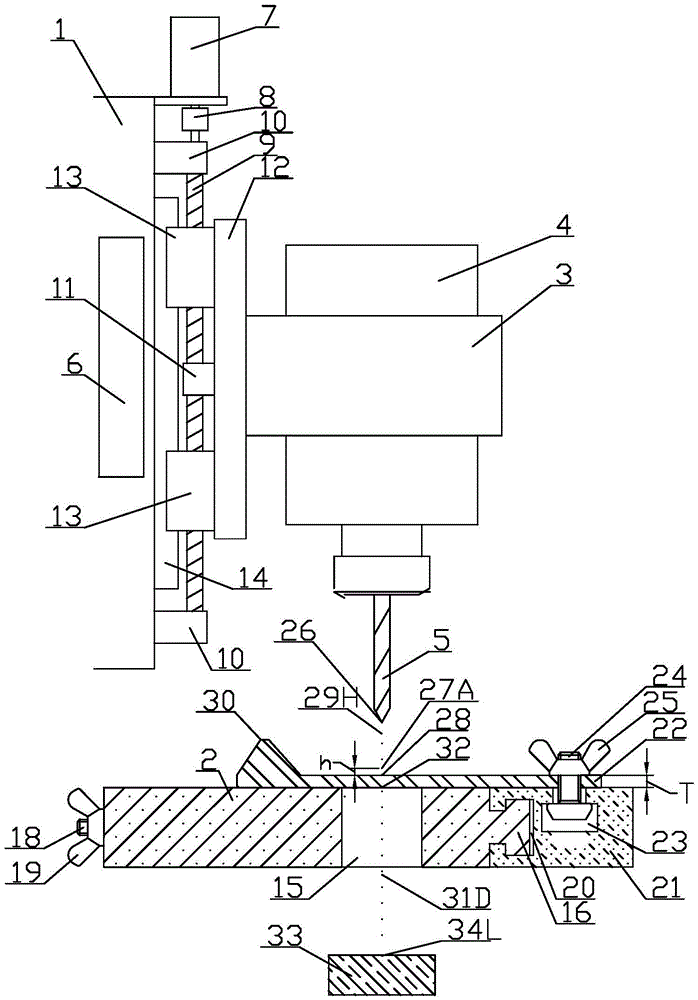

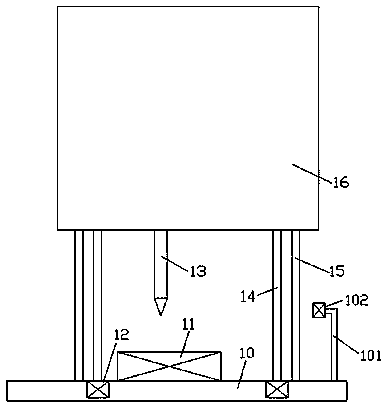

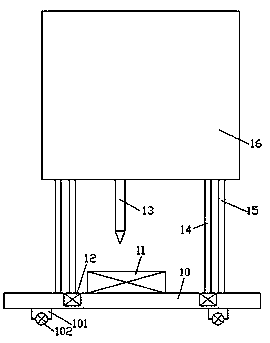

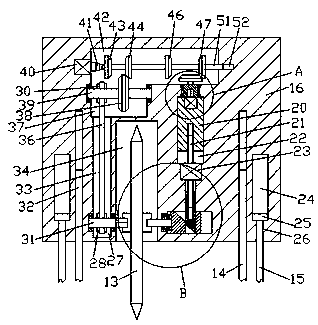

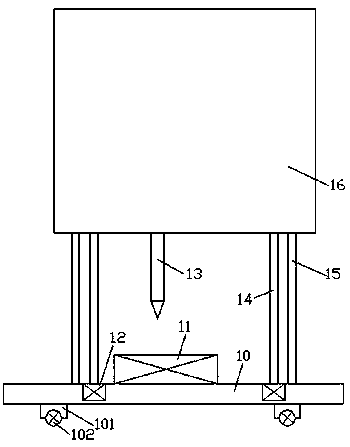

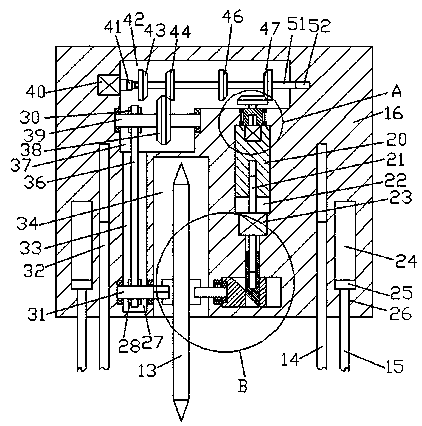

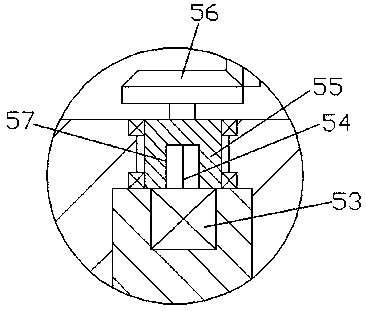

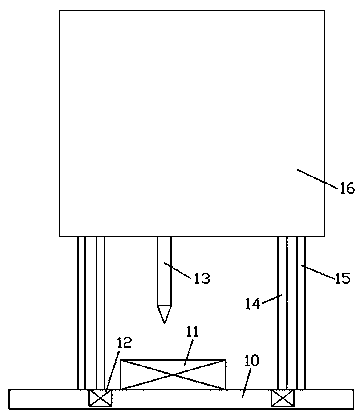

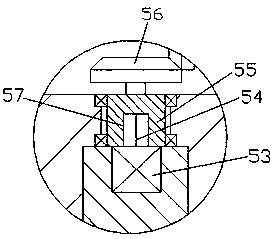

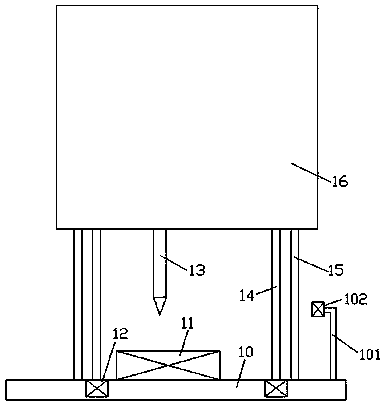

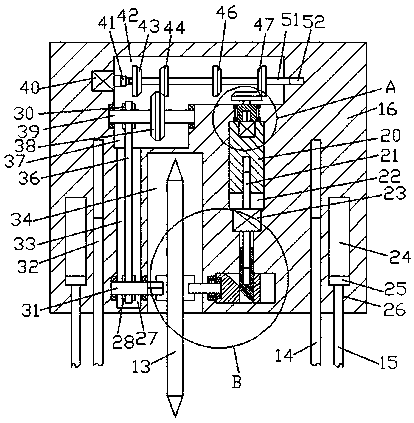

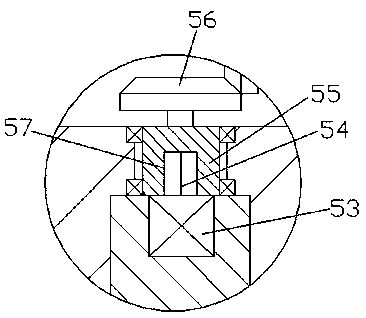

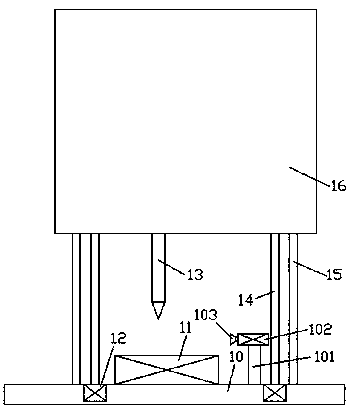

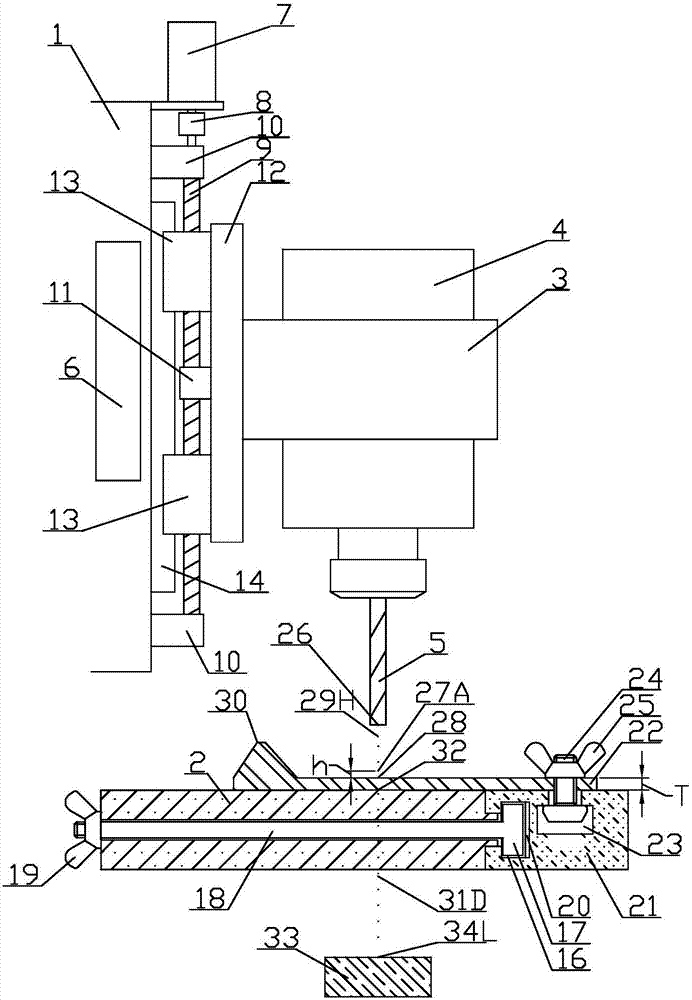

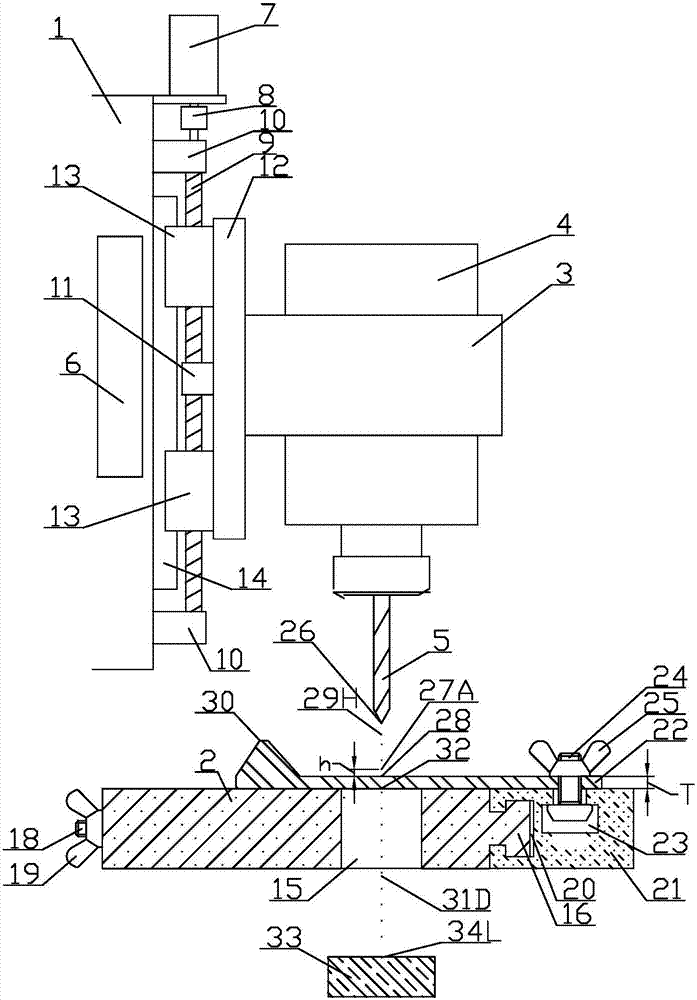

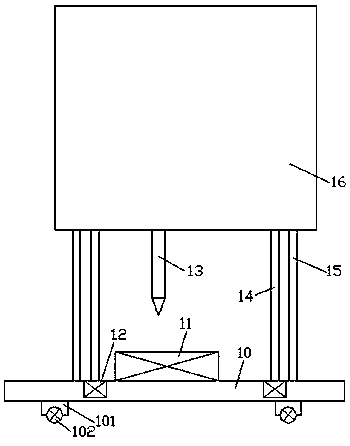

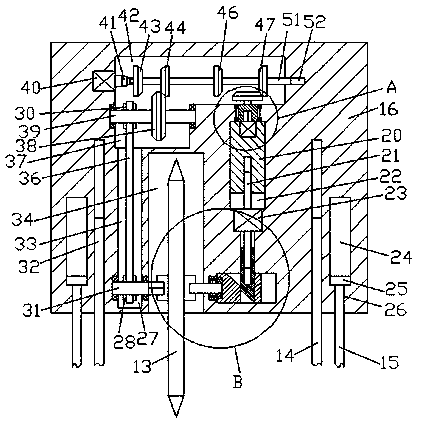

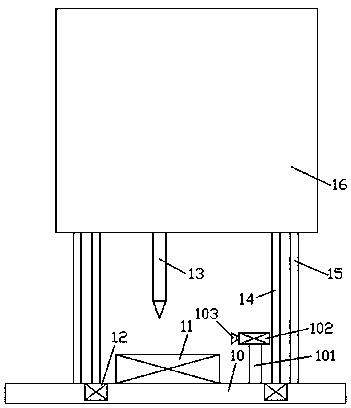

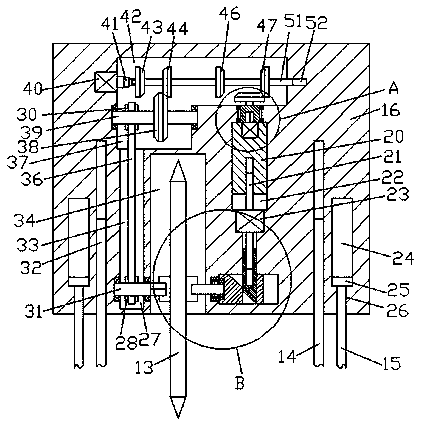

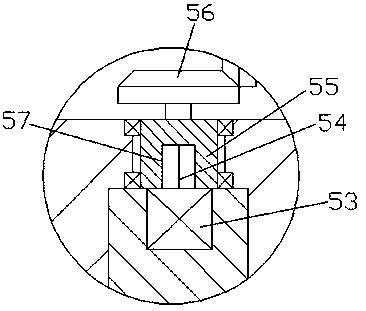

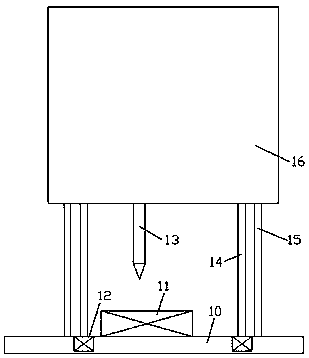

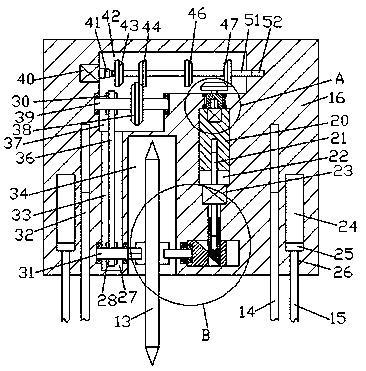

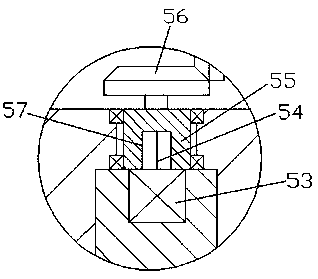

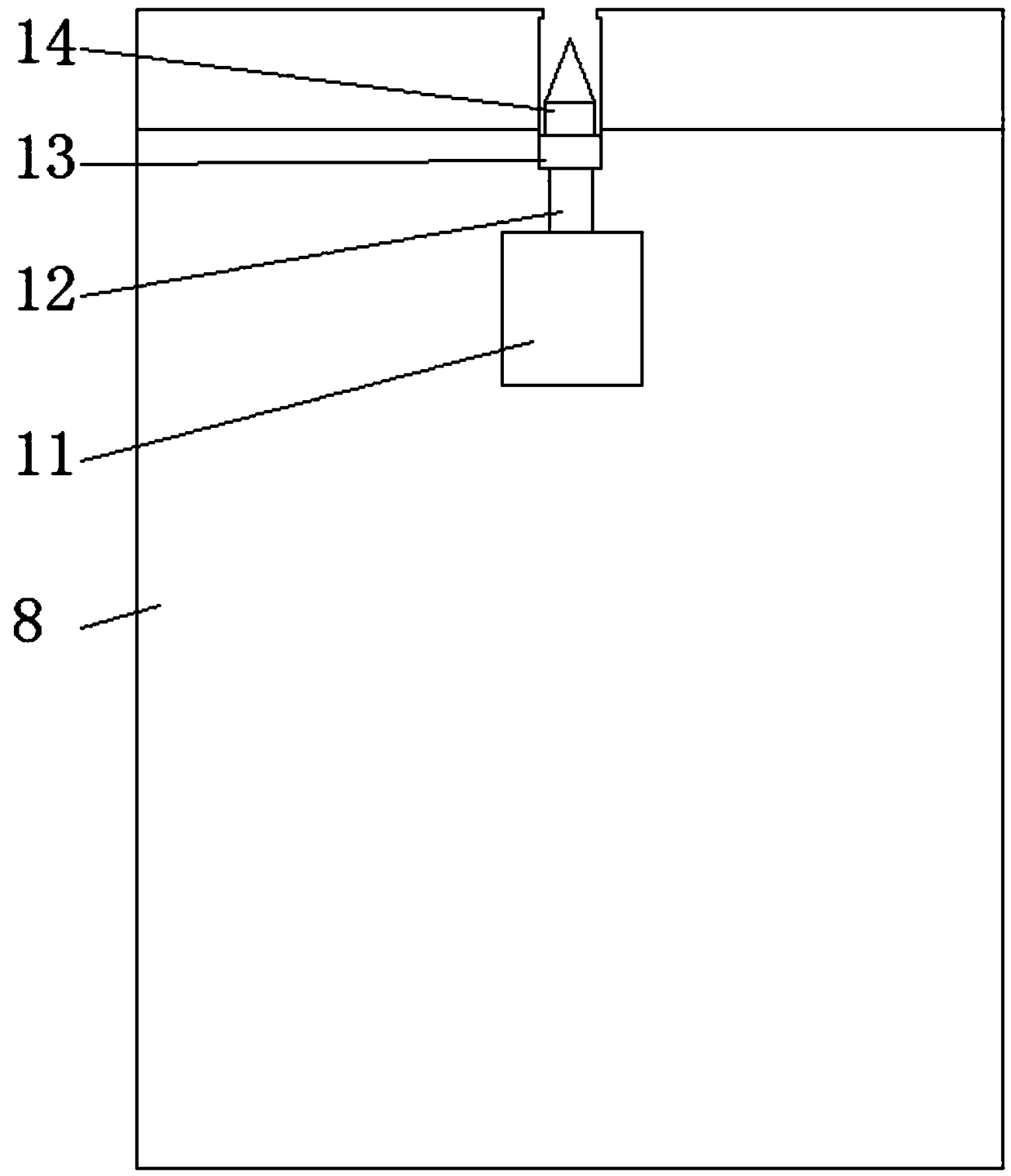

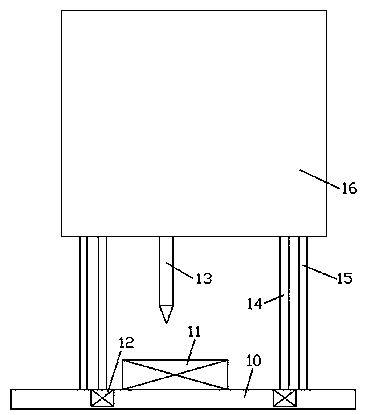

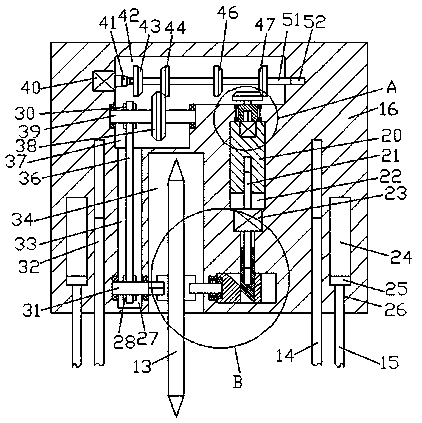

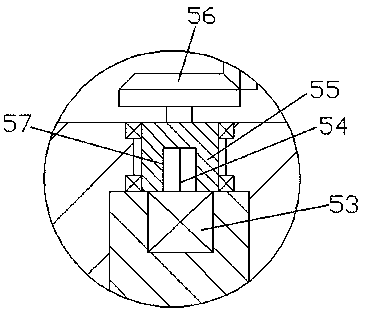

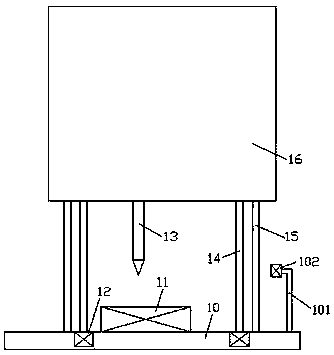

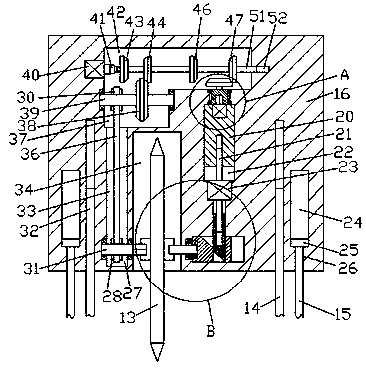

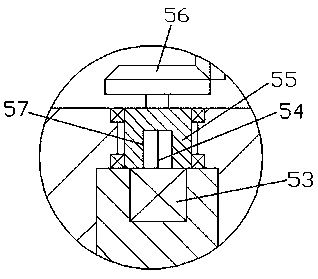

Numerical control punching and cutting integrated machine and alignment method thereof

ActiveCN105522185ASimplify the punching processImprove drilling accuracyAutomatic control devicesFeeding apparatusEngineeringPunching

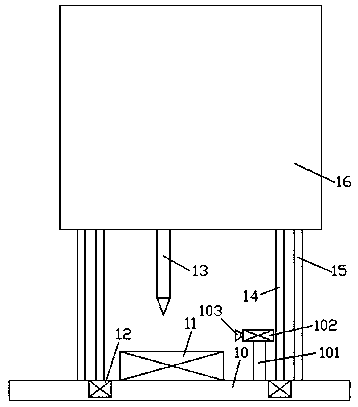

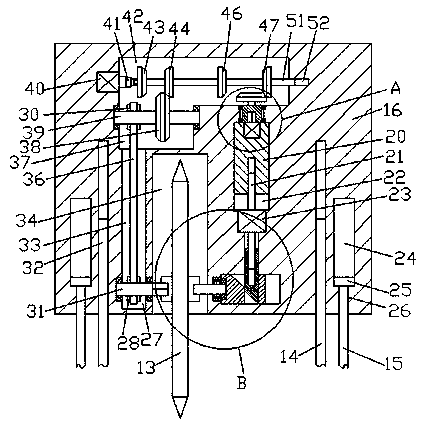

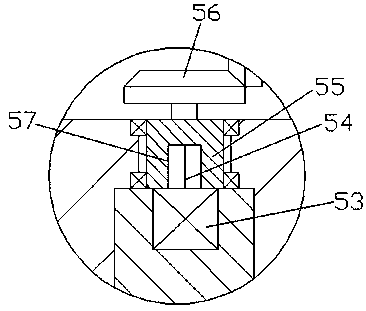

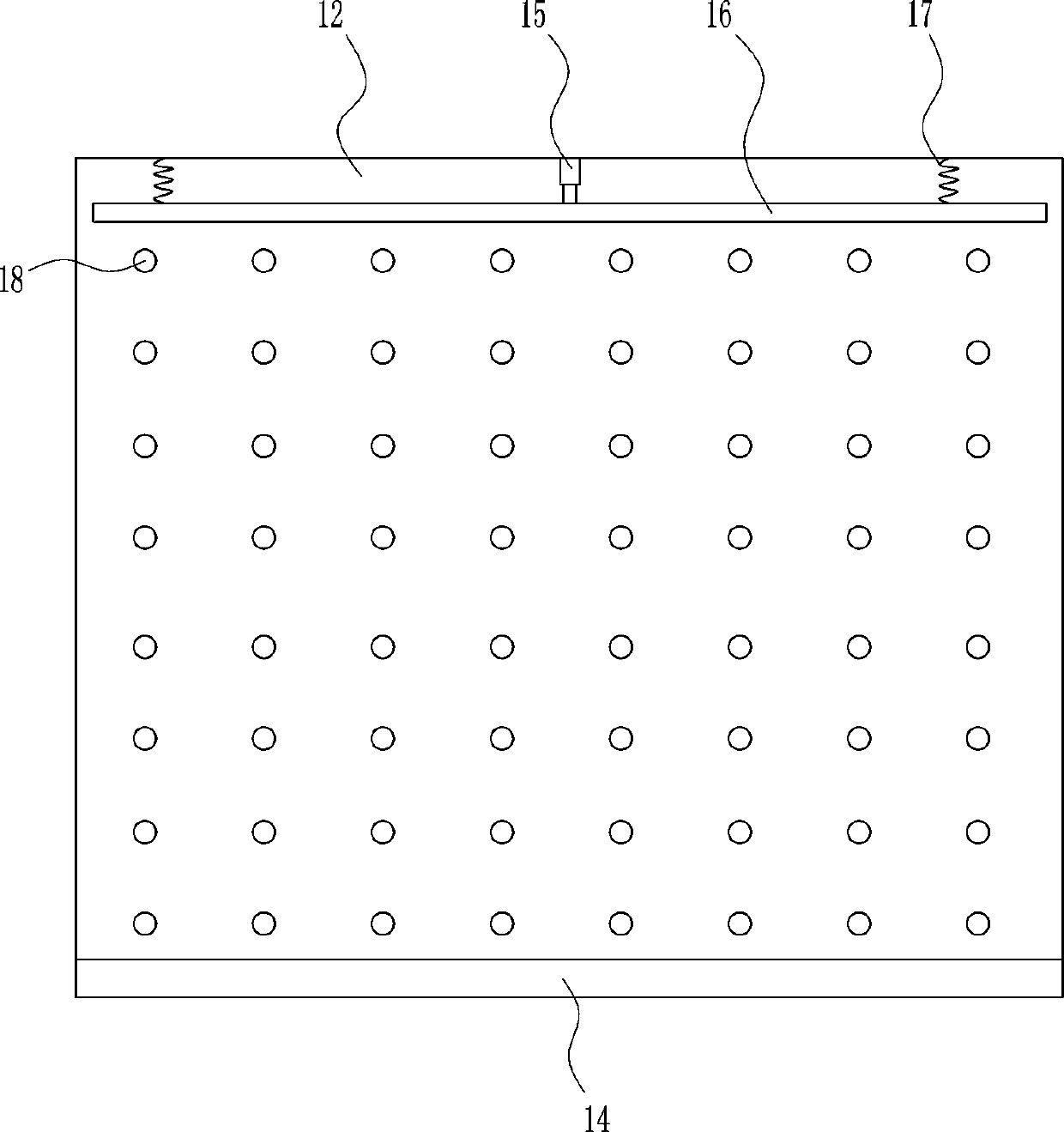

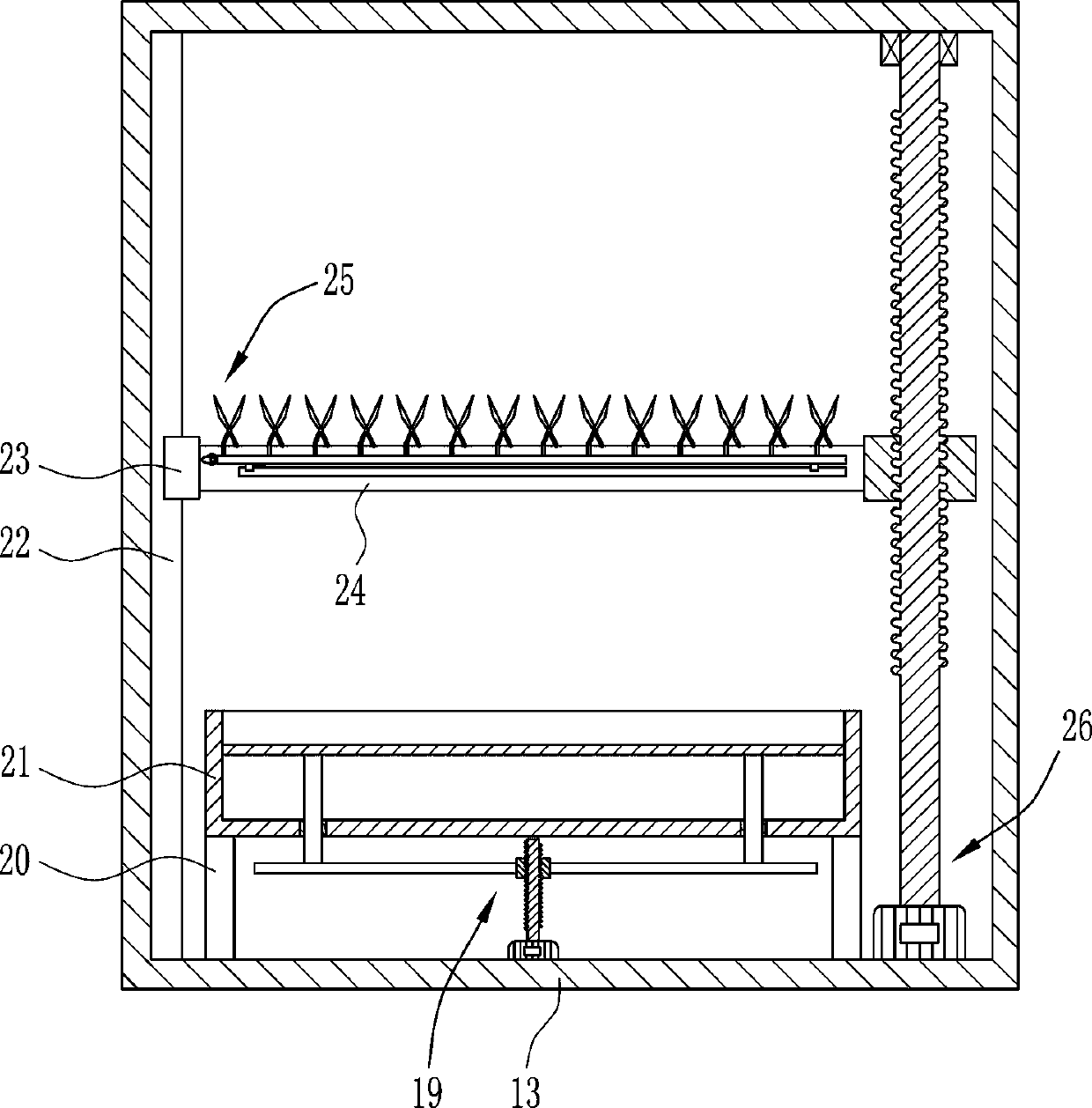

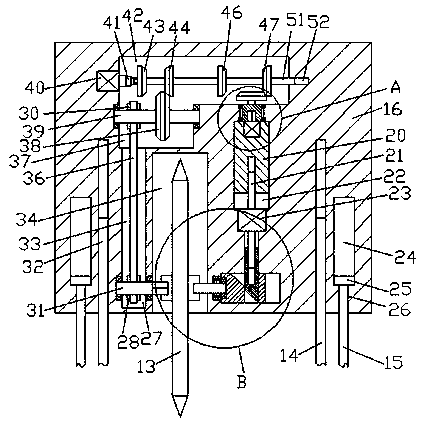

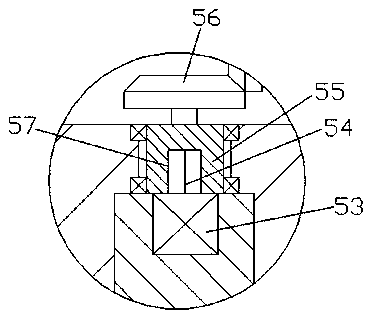

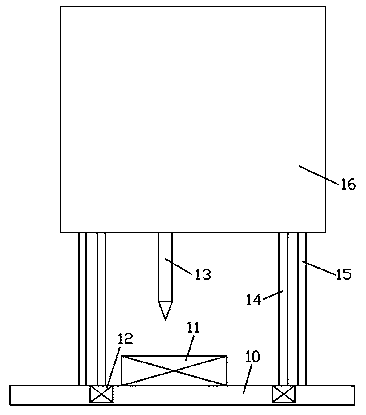

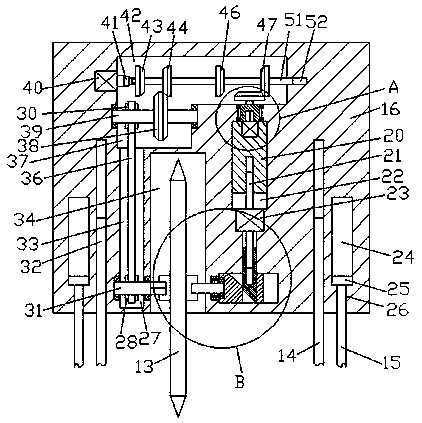

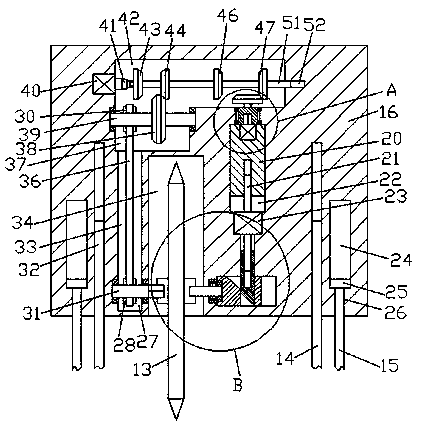

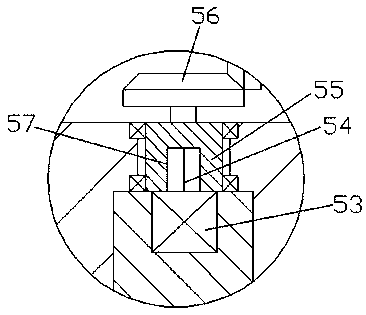

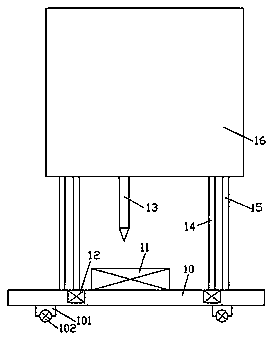

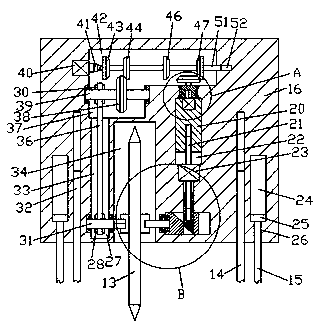

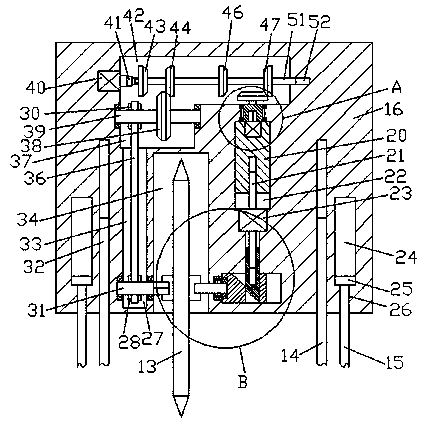

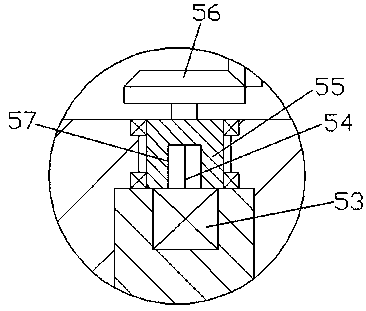

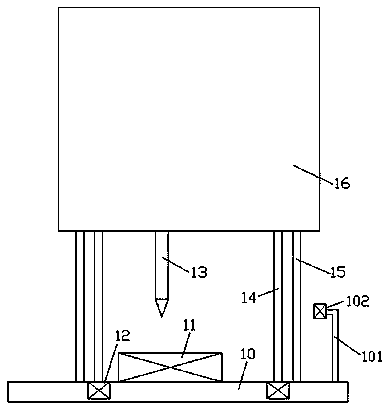

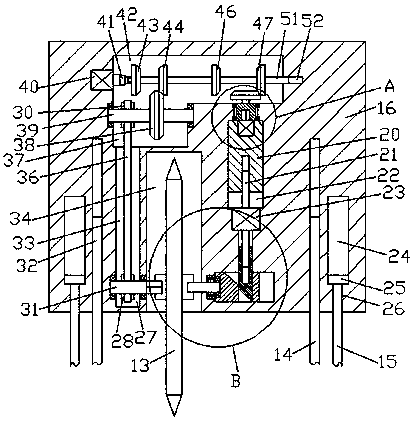

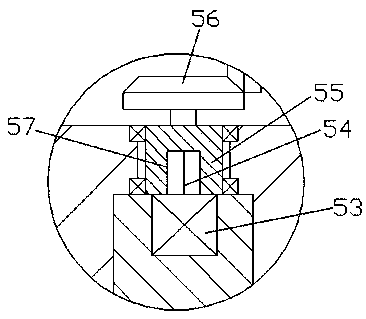

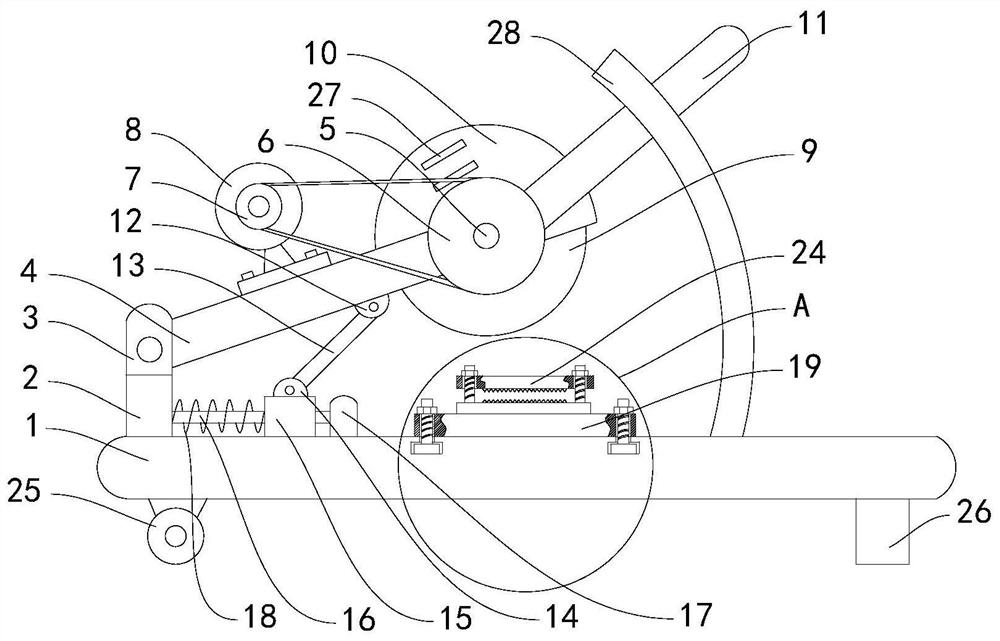

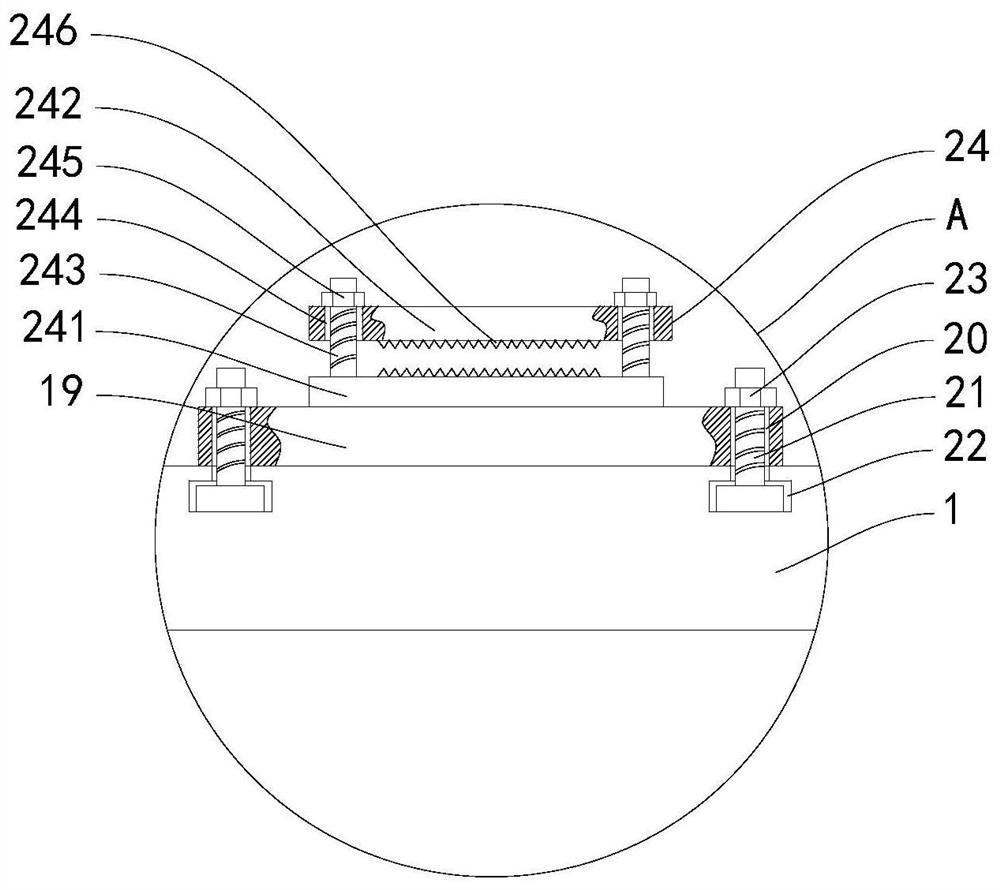

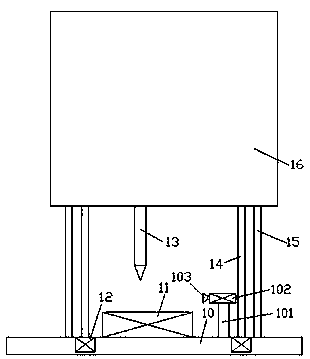

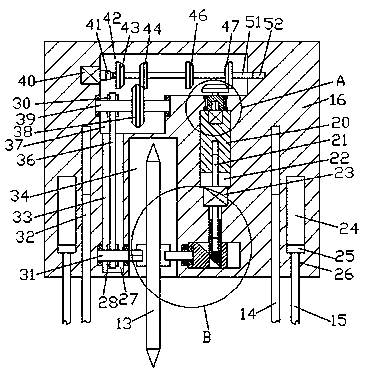

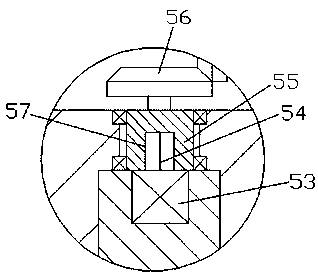

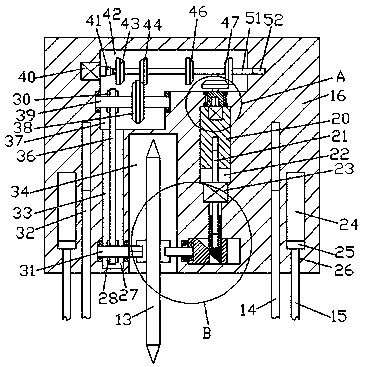

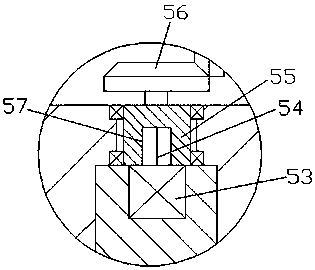

The invention discloses a numerical control punching and cutting integrated machine and an alignment method thereof, and relates to the numerical control punching and cutting integrated machine and the alignment method thereof. A slide table rail (16) is mounted on a worktable (2); a slide table locking block (17) is additionally mounted on the worktable (2); a locking connecting rod (18) is screwed into the slide table locking block (17), penetrates through the worktable (2), and is connected with a nut (19); a chute (20) slides in the slide table rail (16), is formed in a horizontal slide table (21), and is matched with the slide table locking block (17) for use; the horizontal slide table (21) and the worktable (2) commonly place workpieces (22); and the horizontal slide table is detachable. The numerical control punching and cutting integrated machine is applied to numerical control punching and cutting.

Owner:日照鸿本机械制造有限公司 +1

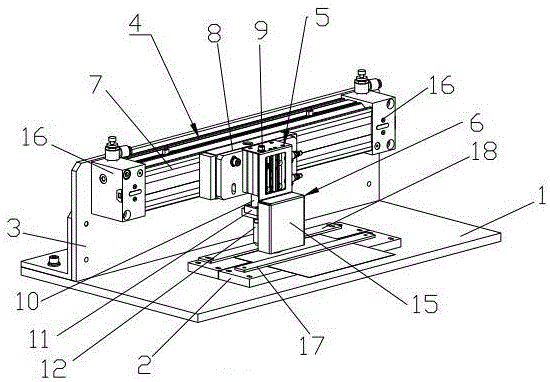

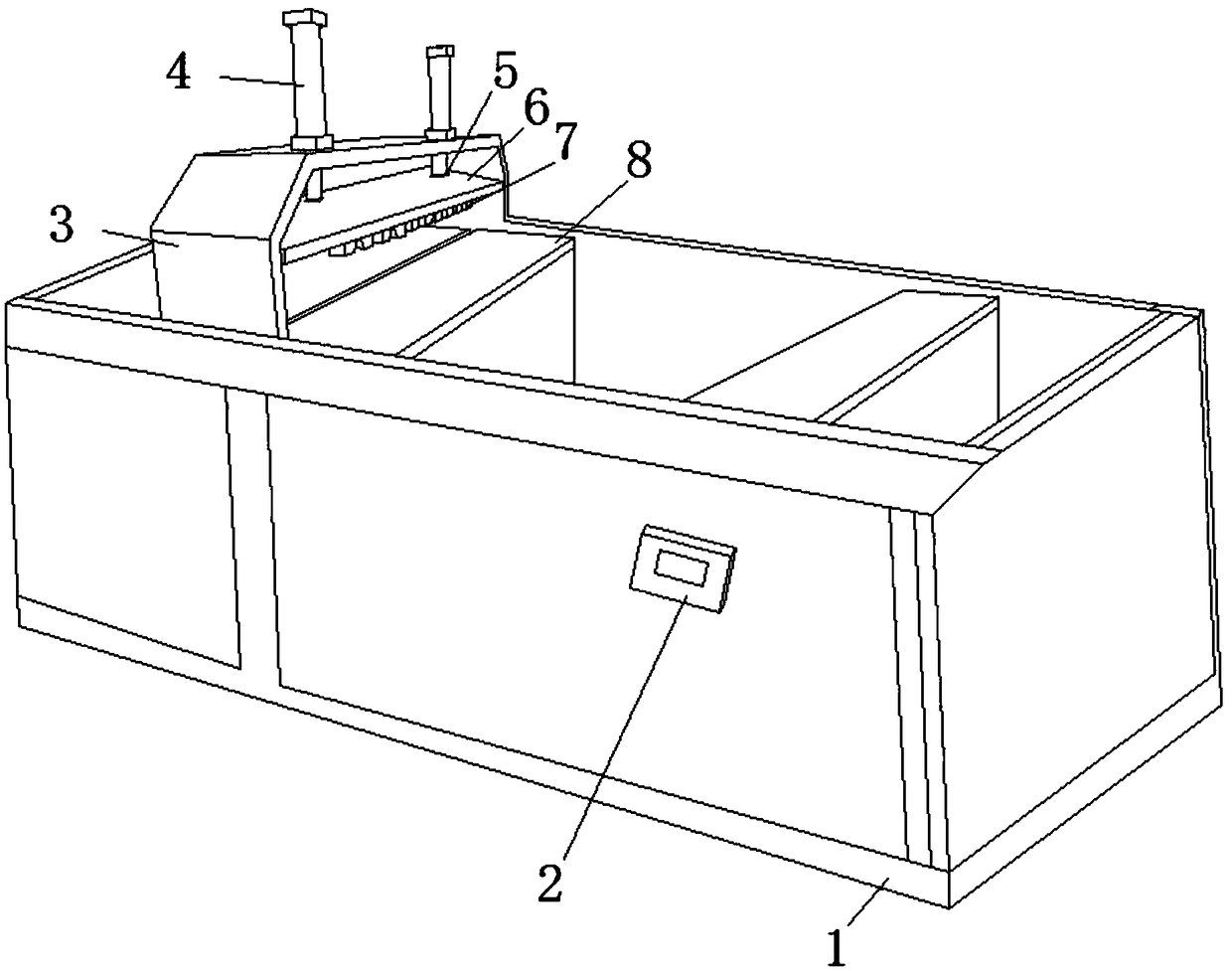

Sheet cutting machine

InactiveCN106738096AImprove cutting accuracyHigh precisionProfiling/shaping machinesEngineeringAutomation

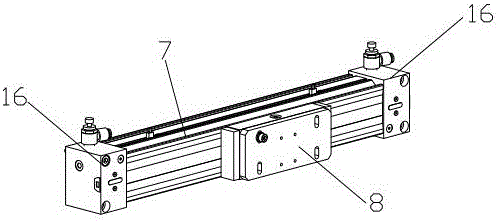

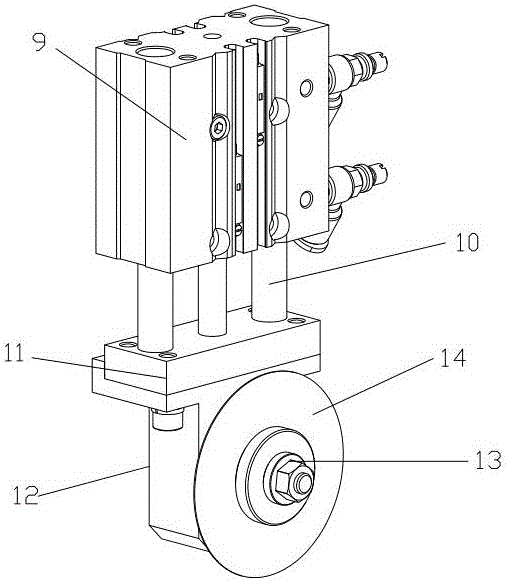

The invention discloses a sheet cutting machine. The sheet cutting machine comprises a bottom plate, a cutting table and a support plate, wherein a cutting device is arranged on the support plate, the cutting device comprises a horizontal moving mechanism, a vertical lifting mechanism and a cutting assembly, the horizontal moving mechanism comprises a connecting rod restoring cylinder and a sliding block, the connecting rod restoring cylinder is arranged on the support plate and is connected to the inner side of the sliding block, the vertical lifting mechanism is connected to the outer side of the sliding block, the vertical lifting mechanism comprises a guide rod cylinder, a piston rod and a lifting seat, the guide rod cylinder is installed on the sliding block and is connected with the piston rod, the piston rod is connected with the lifting seat, the lifting seat is connected with the cutting assembly, the cutting assembly comprises a cutting motor, a cutting shaft and a cutting knife, the cutting motor is installed on the lifting seat and is connected with the cutting shaft, and the cutting shaft is connected with the cutting knife. The machine has the advantages of simple structure, scientificity, convenience, high pertinence, high degree of automation and high cutting precision, and the sheet cutting problem is preferably solved.

Owner:林红英

Automatic cutting-off device for bottle mouth residual materials

The invention relates to the field of plastic molding, in particular to an automatic cutting-off device for bottle mouth residual materials. The automatic cutting-off device comprises a worktable, a conveying mechanism and a cutting mechanism; the conveying mechanism and the cutting mechanism are arranged on the worktable; the conveying mechanism comprises a first driving disk, a first baffle anda second baffle, the first baffle and the second baffle are arranged in the horizontal direction; a feeding channel is formed between the first baffle and the second baffle; the first driving disk isarranged at one end of the feeding channel and is spaced apart from the cutting mechanism; a cutting channel is defined by the cutting mechanism and the first driving disk; the cutting mechanism includes a blade extending into the cutting channel; the feeding channel is in communication with the cutting channel; and the first driving disk is configured to drive plastic bottles to move along the cutting channel. The automatic cutting-off device for the bottle mouth residual materials has the high degree of automation, can quickly realize the cutting work of the bottle mouth residual materials of a large number of plastic bottles, is stable in transmission and good in cutting-off effect, and has strong adaptability.

Owner:四川新升包装科技有限责任公司

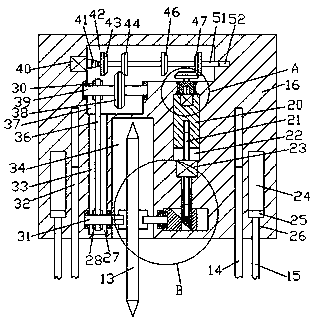

Aluminum alloy template system and manufacturing method thereof

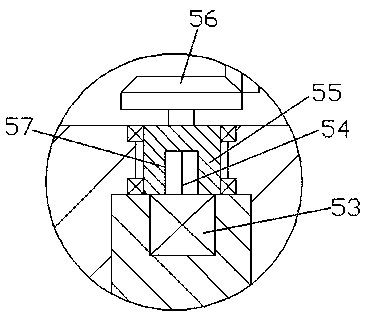

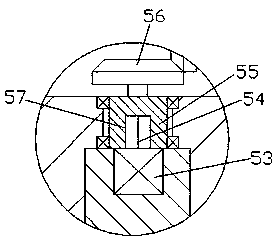

InactiveCN109079213AQuick cut jobImprove work efficiencyShearing machinesShearing toolsEngineeringCentral symmetry

The invention discloses an aluminum alloy template system and a manufacturing method thereof. Novel aluminum template equipment is used and comprises a main seat body and a lifting device arranged onthe lower side of the main seat body. A mounting groove is formed in the end face of the bottom of the main seat body; a blade is arranged in the mounting groove; convex heads are fixedly arranged symmetrically at the centers of the end faces of the left and right sides of the blade; a first spline cavity is formed in the end face of the left side of the convex head on the left side, and an inserting groove is formed in the end face of the right side of the convex head on the right side; a first transmitting cavity is formed in the position, on the left side of the mounting groove, of the mainseat body in an up-down extending mode; a first steering shaft is mounted on the lower side of the first transmitting cavity in a rotating fit mode; a first transmitting wheel is fixedly arranged onthe outer surface of the first steering shaft; the tail end of the right side of the first steering shaft extends into the mounting groove and is fixedly provided with a first spline shaft; and the first spline shaft is connected with the first spline cavity in a spline fit mode, and a second transmitting cavity is formed in the top wall of the first transmitting cavity in a communicating mode.

Owner:广州元莱信息科技有限公司

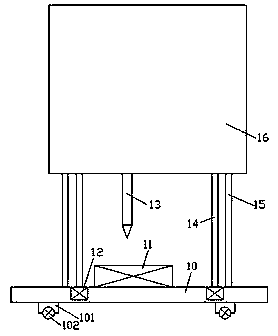

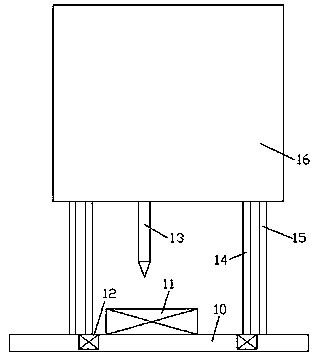

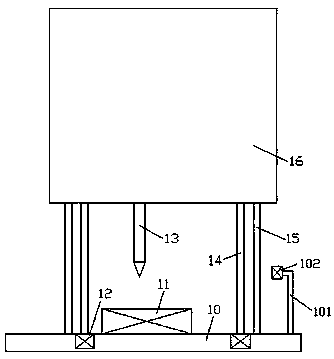

Vegetable root cutting device for soilless culture

InactiveCN111357479AQuick root cuttingQuick cut jobHarvestersAgricultural engineeringMechanical engineering

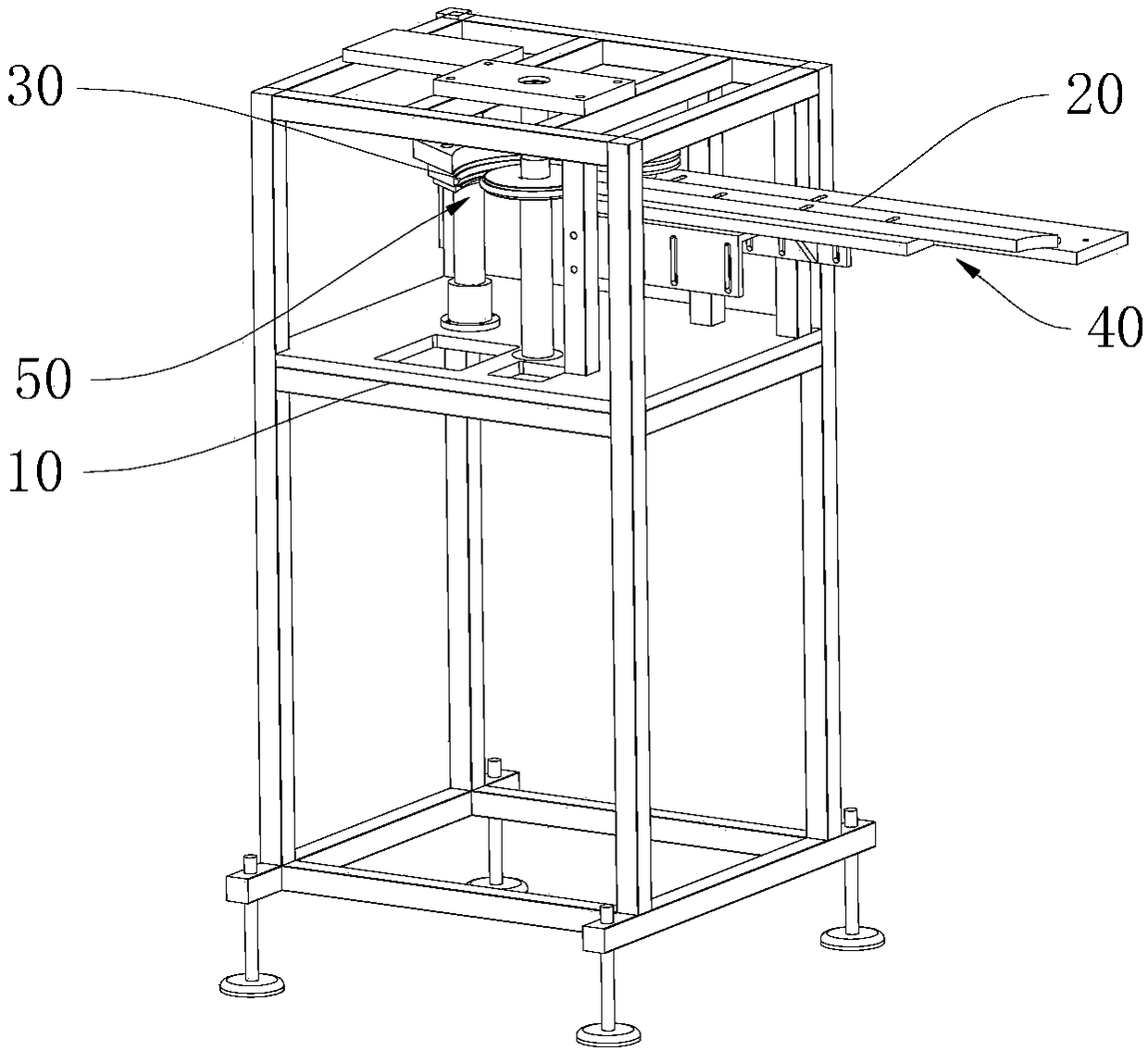

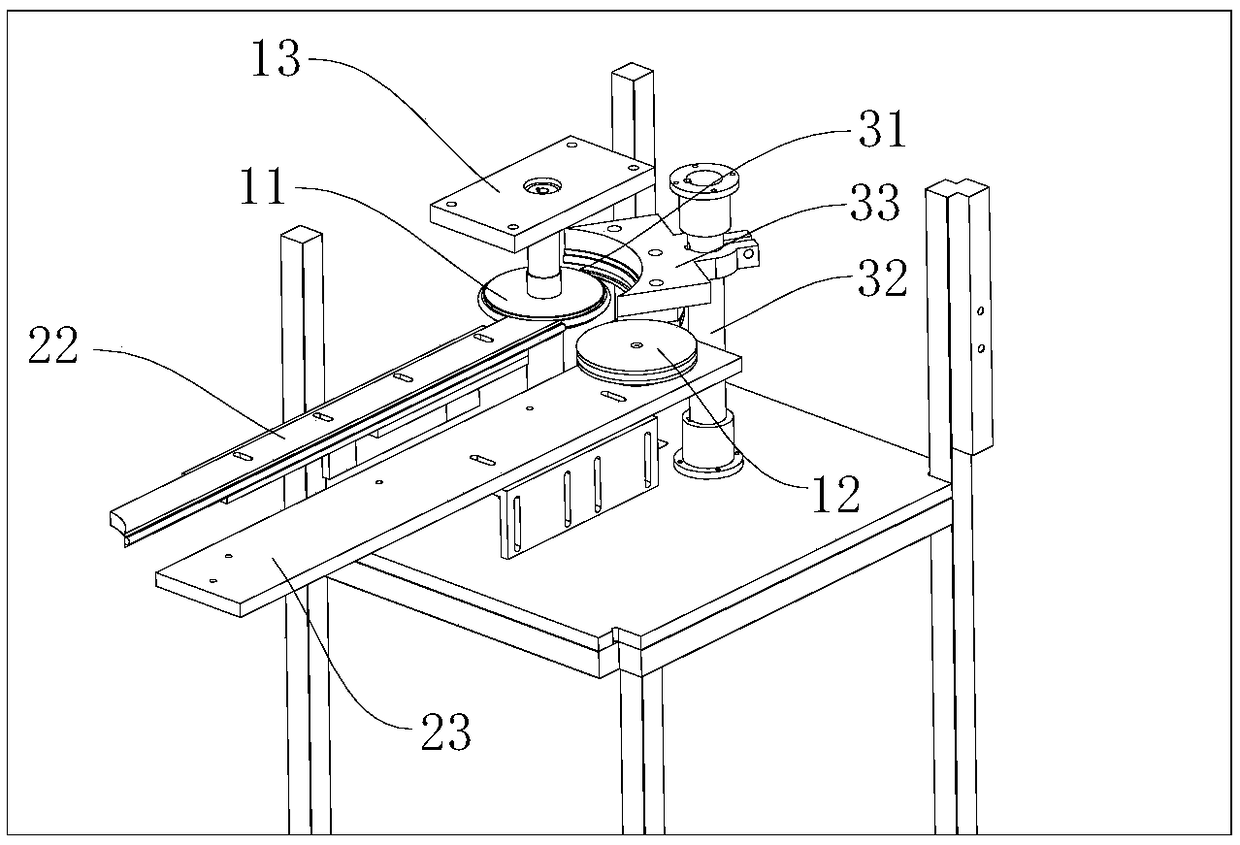

The invention relates to a root cutting device, in particular to a vegetable root cutting device for soilless culture. The technical problem to be solved by the invention is to provide a vegetable root cutting device for soilless culture, the root cutting efficiency of soilless culture vegetables can be improved, excessive manpower and material resources do not need to be consumed, and the labor burden of workers is relieved. In order to solve the technical problem, the vegetable root cutting device for soilless culture provided by the invention comprises a first supporting seat, a second supporting seat, a first mounting plate, a third supporting seat, a fourth supporting seat, a connecting plate, a mounting base, a first air cylinder, a root cutting mechanism, a first moving mechanism and the like; the first supporting seat is fixedly connected to one side of the first mounting plate, and the third supporting seat is fixedly connected to the other side of the first mounting plate. The vegetable root cutting device for soilless culture achieves the effects of rapidly cutting roots of soilless culture vegetables, improving the root cutting efficiency, and reducing the workload of workers without manual root cutting.

Owner:广州比佳智能设备股份有限公司

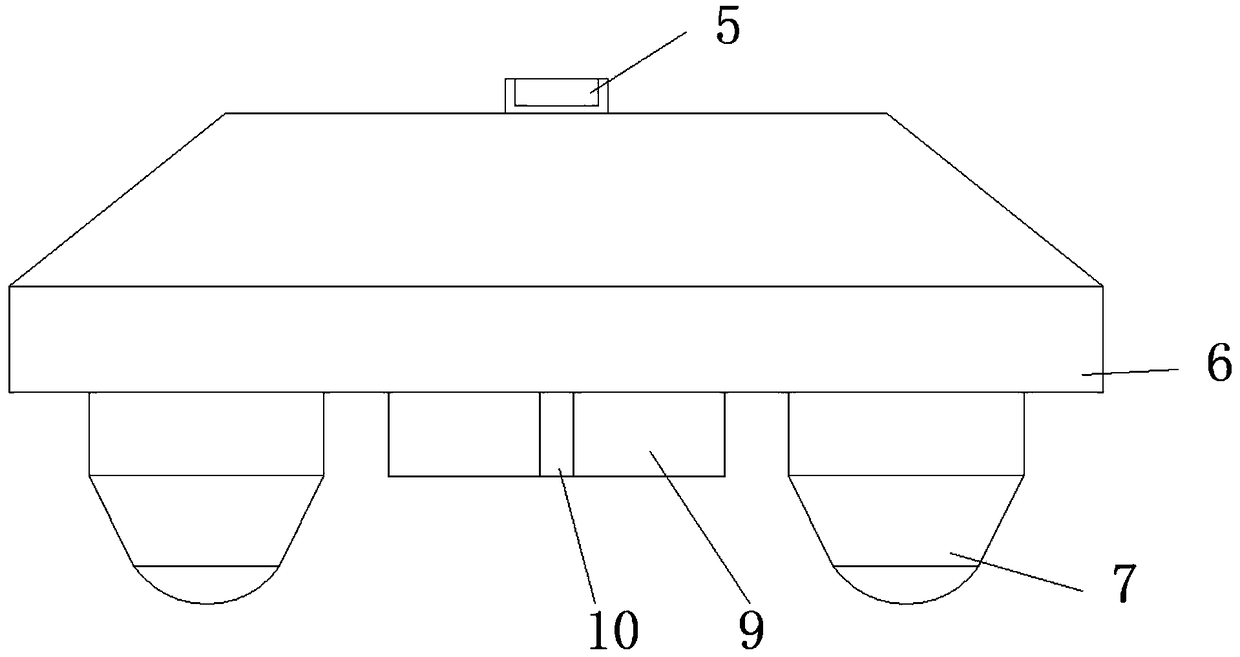

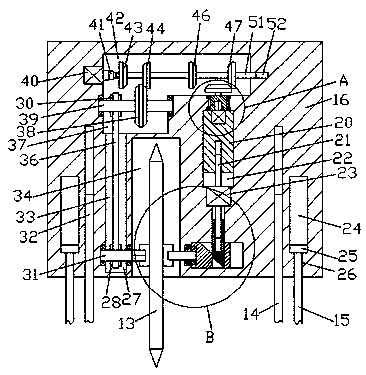

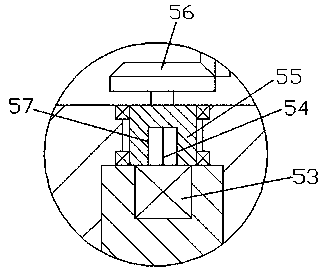

Cutting device for insulation boards

InactiveCN107116584AImprove cutting efficiencyReduce auxiliary operationsMetal working apparatusDrive motorEngineering

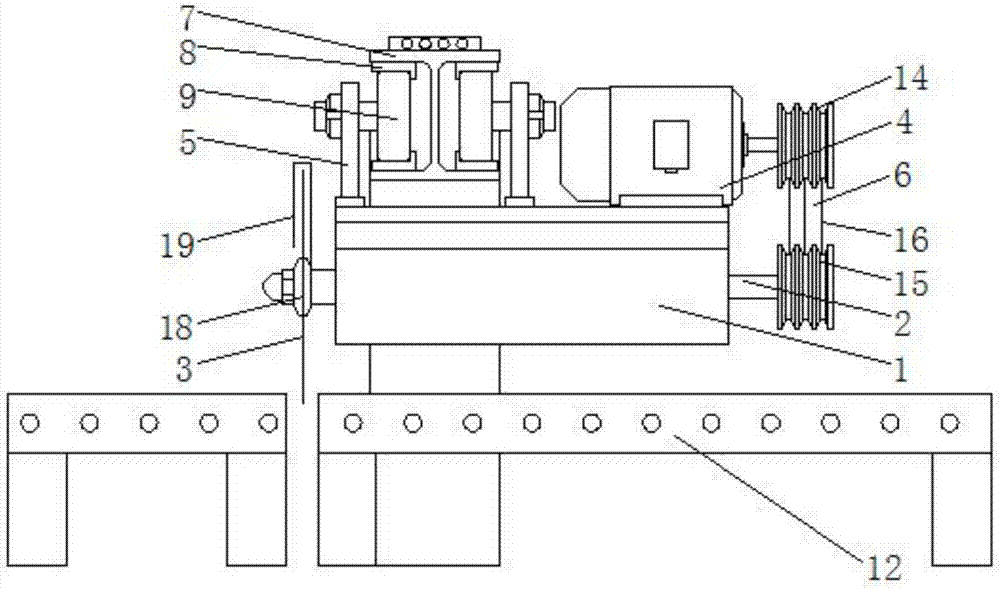

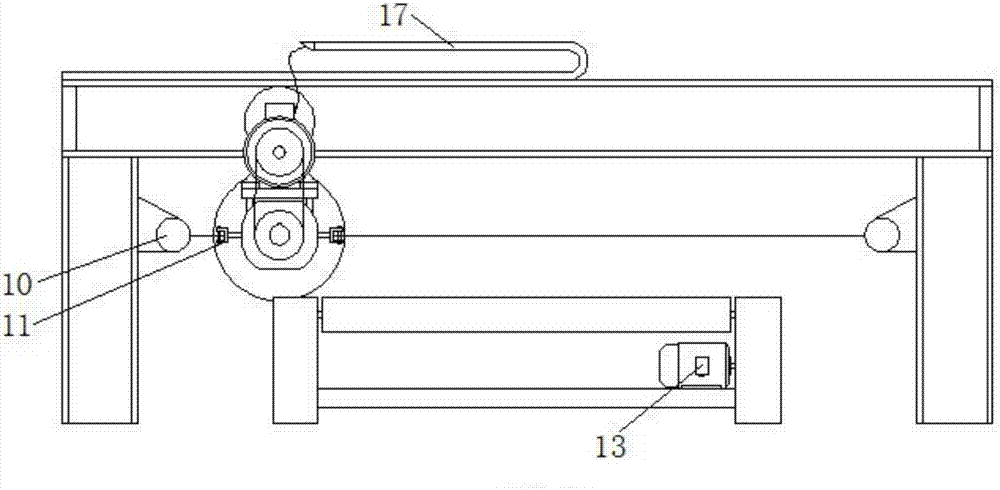

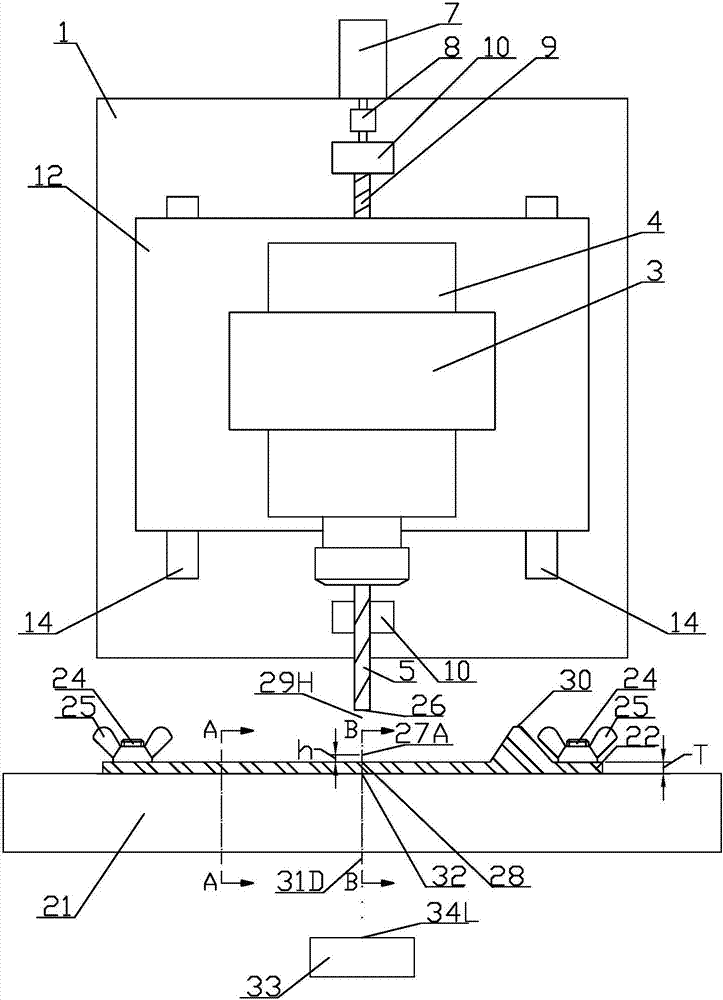

The invention discloses a cutting device for insulation boards. The cutting device comprises a cutting frame (1), a rotary shaft (2) is arranged in the cutting frame (1), a cutting blade (3) is arranged on one end of the rotary shaft (2), a driving motor (4) and a guide holder (5) are arranged on the cutting frame (1), and the driving motor (4) is connected with the rotary shaft (2) through a driving device (6); a rack (7) is arranged on the outer side of the cutting frame (1), guide rails (8) are arranged at the upper end of the rack (7), guide pulleys (9) are arranged on the guide rails (8), and the guide pulleys (9) are connected with the guide holders (5); and electric hoists (10) are arranged at the inner side of the rack (7), the electric hoists (10) are connected with the cutting frame (1) through mounting rods (11), a roller conveying machine (12) is arranged at the bottom of the rack (7), and a time relay (1) is arranged on the roller conveying machine (12). The cutting device for the insulation boards controls cutting work on the insulation boards through the driving motor and the electric hoists, and has the characteristics that the cutting efficiency is high, and the safety is good.

Owner:浙江中泰绝热材料有限公司

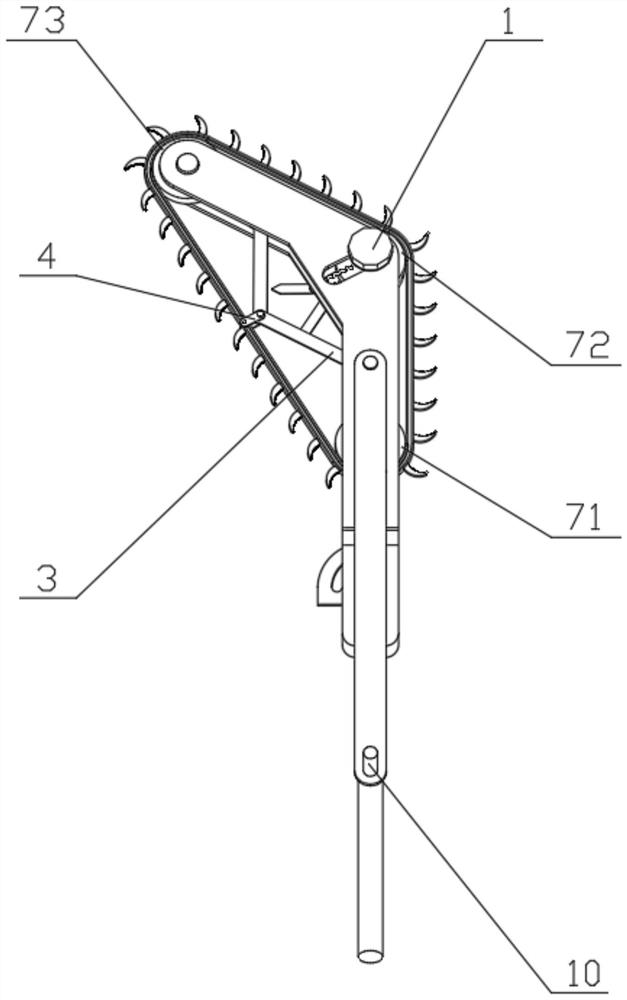

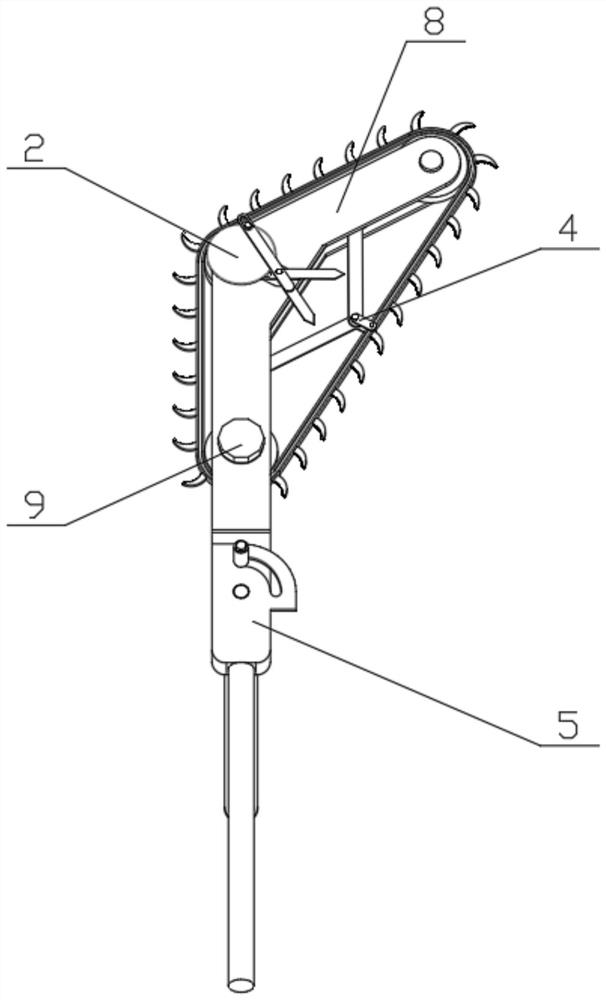

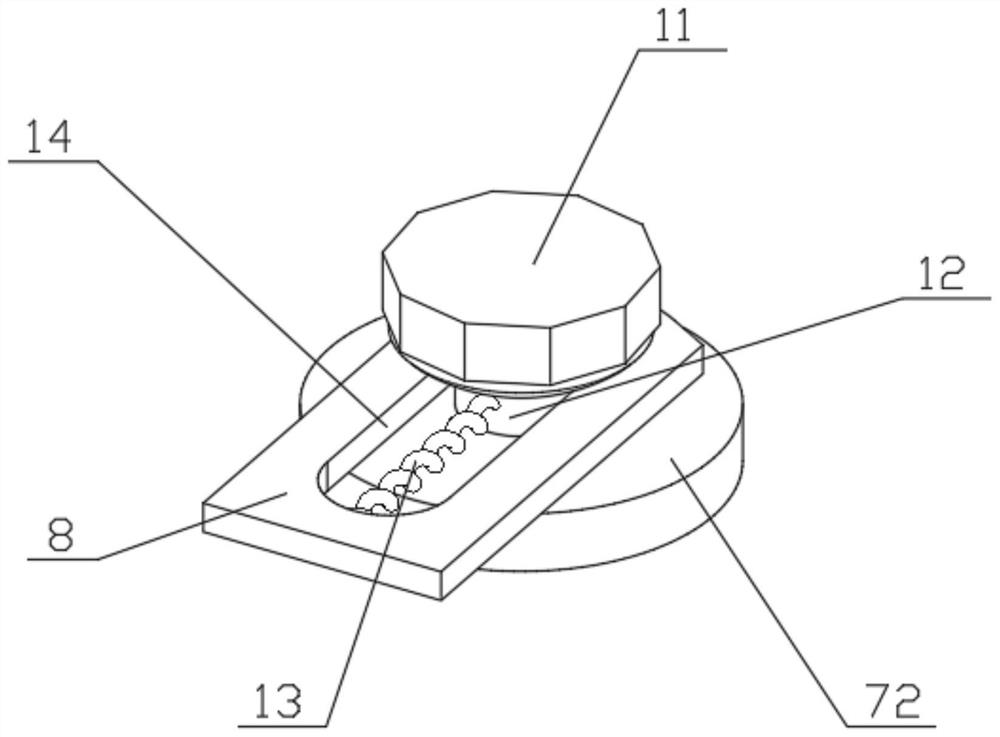

Walnut tree pruning device and method

ActiveCN113475258AImprove stabilityImprove functionalityCuttersCutting implementsAlgorithmStructural engineering

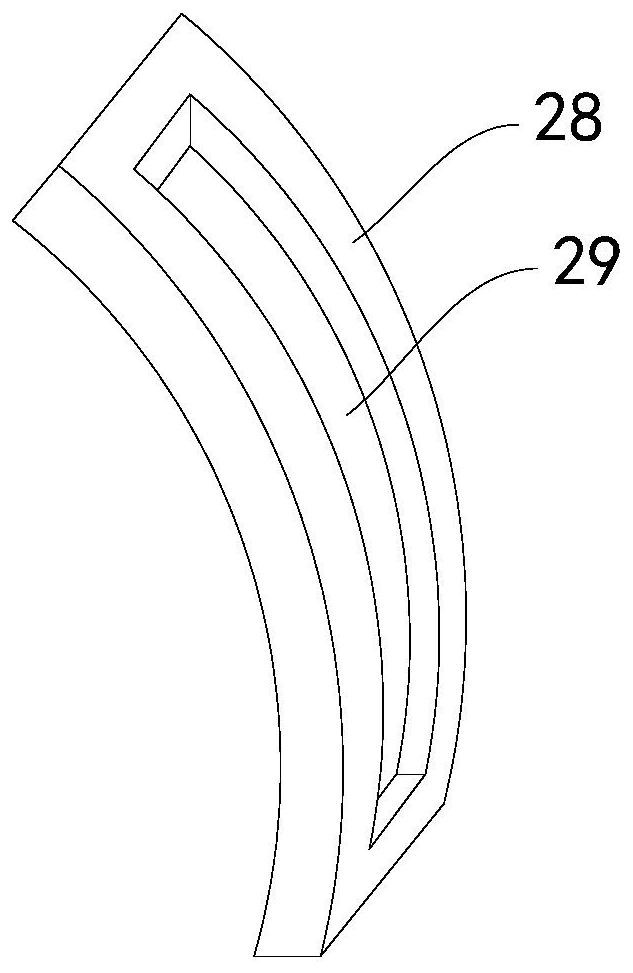

The invention discloses a walnut tree pruning device and method. The walnut tree pruning device comprises a shell and a tightening wheel mechanism, wherein the upper end and the lower end of the shell are of hollow structures, the tightening wheel mechanism is installed on the shell in a sliding mode, the lower end of the shell is connected with a steering structure used for adjusting the use angle of the shell, and rolling wheel assemblies are installed at the end corners of the shell. The tightening wheel mechanism can be arranged to push a connecting rod mechanism after making contact with a supporting rod or a rotating hook claw mechanism pulls the supporting rod, so that a shear mechanism can achieve feed shearing conveniently, different pruning devices and pruning methods can be used according to different branches, the stability of the walnut tree in the pruning process is improved, the functionality of the pruning tool is improved, the walnut tree pruning device is suitable for shearing operation of branches with different hardness, the angle of the device shell can be adjusted according to the height of the branches and the branch and trunk angles, the cutting position of the shear mechanism can be matched with the specific positions of the branches and trunks, accordingly, shearing operation can be rapidly carried out, the shearing efficiency can be improved, and meanwhile, various shearing requirements can be met.

Owner:濮阳市林业科学院

Improved environment-friendly PVC solid wall pipe for underground communication pipelines

InactiveCN109291108AQuick cut jobImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention discloses an improved environment-friendly PVC solid wall pipe for underground communication pipelines. The pipe comprises a preparation rack and a lifting assembly arranged on the lowerside of the preparation rack, wherein a loading cavity is formed in the end surface of the bottom of the preparation rack, a cutting knife is arranged in the loading cavity, protruding blocks are symmetrically arranged right centres of the left side and the right side of the cutting knife, a first spline cavity is formed in the left side end surface of the protruding block on the left side, and ainserting and connecting cavity is formed in the right side end surface of the protruding block on the right side; a first transmission and cooperation cavity is vertically extended in the preparation rack on the left side of the loading cavity, a first rotating arm is rotationally installed with the lower side of the first transmission and cooperation cavity in a matched mode, and a first synchronous wheel is fixedly arranged on the outer surface of the first rotating arm; and the tail end of the right side of the first rotating arm extends into the loading cavity, a first spline shaft is fixedly arranged at the tail end of the first rotating arm, the first spline shaft is connected with a spline of the first spline cavity in a matched mode, and the top wall of the first transmission andcooperation cavity is arranged with a second transmission and cooperation cavity in a communicating mode.

Owner:广州凯燃环保工程技术有限公司

Compact type transverse grid cluster equipment

The invention discloses compact type transverse grid cluster equipment which comprises a main frame body and a lifting adjusting mechanism arranged on the lower side of the main frame body. An installation cavity is formed in the end face of the bottom of the main frame body, a cutting blade is arranged in the installation cavity, convex blocks are symmetrically and fixedly arranged in the centersof the end faces of the left side and the right side of the cutting blade, a first spline cavity is formed in the end face of the left side of the convex block on the left side, an inserting cavity is formed in the end face of the right side of the convex block on the right side, a first transmission cavity is formed in the portion, on the left side of the installation cavity, in the main frame body in an up-down extension mode, a first rotating shaft is installed on the lower side of the first transmission cavity through normal running fit, a first belt wheel is fixedly arranged on the outersurface of the first rotating shaft, the tail end of the right side of the first rotating shaft stretches into the installation cavity and is fixedly provided with a first spline shaft, the first spline shaft is in spline matching connection with the first spline cavity, and a second transmission cavity is arranged on the top wall of the first transmission cavity in a communicating mode.

Owner:广州建德农业科技有限公司

Novel environment-friendly PVC solid wall pipe material for underground communication pipe

InactiveCN109262690AQuick cut jobImprove work efficiencyMetal working apparatusSolid wallEngineering

The invention discloses a novel environment-friendly PVC solid wall pipe material for an underground communication pipe. The pipe material comprises a making rack and a lifting combination part arranged at the lower side of the making rack, a placement cavity is formed in the end face of the bottom of the making rack, and a cutter is arranged in the placement cavity; protruded blocks are symmetrically and fixedly arranged in the centers of the end faces of the left and right sides of the cutter, a first spline cavity is formed in the end face of the left side of the protruded block of the leftside, and an insertion connection cavity is formed in the end face of the right side of the protruded block of the right side; a first transfer matching cavity which extends up and down is formed inthe portion, in the making rack, of the left side of the placement cavity, a first rotation arm is rotatably and cooperatively installed at the lower side of the first transfer matching cavity, and afirst synchronous wheel is fixedly arranged on the outer surface of the first rotation arm; the tail end of the right side of the first rotation arm extends in the placement cavity, a first spline shaft is fixedly arranged at the tail end of the right side of the first rotation arm and cooperatively connected with a spline of the first spline cavity, and a second transfer matching cavity is communicated with the top wall of the first transfer matching cavity.

Owner:广州凯燃环保工程技术有限公司

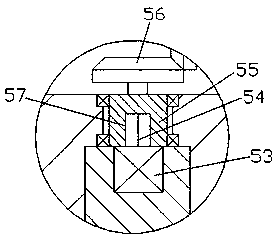

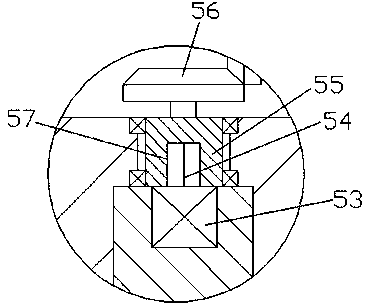

Novel cross grid cluster equipment

InactiveCN109262700AFor quick replacementEasy replacementMetal working apparatusEngineeringMechanical engineering

The invention discloses novel cross grid cluster equipment. The novel cross grid cluster equipment comprises a main frame body and a lifting adjusting mechanism arranged on the lower side of the mainframe body. A mounting cavity is formed in the bottom end face of the main frame body, a cutting piece is arranged in the mounting cavity, convex blocks are symmetrically fixedly arranged in the centers of the left end face and the right end face of the cutting piece, a first spline cavity is formed in the left end face of the convex block on the left side, an inserting cavity is formed in the right end face of the convex block on the right side, a first transmission cavity vertically stretches to the portion, on the left side of the mounting cavity, in the main frame body, a first rotary shaft is mounted on the lower side of the first transmission cavity in rotary fit, a first belt wheel is fixedly arranged on the outer surface of the first rotary shaft, the tail end of the right side ofthe first rotary shaft stretches into the mounting cavity, a first spline shaft is fixedly arranged at the tail end of the right side of the first rotary shaft, the first spline shaft and the first spline cavity are in spline fit connection, and the top wall of the first transmission cavity is communicated with a second transmission cavity.

Owner:广州建德农业科技有限公司

Environment-friendly PVC solid-wall pipe for underground communication pipeline

InactiveCN108908448AFor quick replacementEasy replacementMetal working apparatusMechanical engineering

The invention discloses an environment-friendly PVC solid-wall pipe for an underground communication pipeline. The environment-friendly PVC solid-wall pipe comprises a preparation frame and a liftingcomposite member arranged on the lower side of the preparation frame. A loading cavity is formed in the bottom end face of the preparation frame, a cutter is arranged in the loading cavity, convex blocks are fixedly arranged in the centers of the end faces of the left side and the right side of the cutter symmetrically, a first spline cavity is formed in the end face of the left side of the convexblock on the left side, an insertion-connecting cavity is formed in the end face of the right side of the convex block on the right side, a first transmission fit cavity is formed in the portion, onthe left side of the loading cavity, in the preparation frame in an up-and-down stretching manner, a first rotary arm is mounted at the position of the lower side of the first transmission fit cavityin a rotary fit manner, a first synchronous wheel is fixedly arranged on the outer surface of the first rotary arm, the tail end of the right side of the first rotary arm stretches into the loading cavity, a first spline shaft is fixedly arranged at the tail end, the first spline shaft is cooperatively connected with a spline of the first spline cavity, and a second transmission fit cavity is formed in the top wall of the first transmission fit cavity in a communicating manner.

Owner:安溪杰创新能源科技有限公司

Novel metal plate transverse cutting production line

InactiveCN109047884AFor quick replacementEasy replacementShearing machinesProduction lineEngineering

The invention discloses a novel metal plate transverse cutting production line. The novel metal plate transverse cutting production line comprises a production frame body and a lifting unit arranged on the lower side of the production frame body, an installing opening is formed in the end face of the bottom of the production frame body, a rotating knife is arranged in the installing opening, flanges are symmetrically arranged at the dead centers of the end faces of the two sides of the rotating knife, a first spline cavity is formed in the left side end face of the left flange, an inserting opening is formed in the right side end surface of the right flange, a first transmission cavity is vertically formed in the production frame body on the left side of the installing opening, the lower side of the first transmission connection cavity is provided with a first transfer shaft in a rotating fit mode, the outer surface of the first adapter shaft is fixedly provided with a first strap wheel, the tail end of the right side of the first adapter shaft extends into the installing opening, a first spline shaft is fixedly arranged at the tail end of the first adapter shaft, the first splineshaft is connected with the spline of the first spline cavity in a matched mode, and the top wall of a first sensing cavity communicates with a second sensing cavity.

Owner:佛山腾谱工业设计有限公司

Improved metal plate transverse cutting production line

The invention discloses an improved metal plate transverse cutting production line. The improved metal plate transverse cutting production line comprises a production frame body and a lifting unit which is arranged on the lower side of the production frame body; a mounting port is formed in the bottom end surface of the production frame body; a rotating knife is arranged in the mounting port; flanges are fixedly arranged on the left and right side end surfaces of the rotating knife in a very centrosymmetric manner; a first spline cavity is formed in the end surface of the left side of the flange on the left right; an inserting port is formed in the end surface of the right side of the flange on the right side; a first passing and receiving cavity is formed in the production frame body on the left side of the mounting port to extend up and down; a first coupling shaft is mounted on the lower side of the first passing and receiving cavity in a running fit manner; a first belt wheel is fixedly arranged on the external surface of the first coupling shaft; the tail end of the right side of the first coupling shaft extends into the mounting port; a first spline shaft is fixedly arrangedat the tail end of the right side of the first coupling shaft; the first spline shaft is connected with the first spline cavity through a spline in a matched manner; and a second passing and receivingcavity is formed in the top wall of the first passing and receiving cavity in a communication manner.

Owner:佛山腾谱工业设计有限公司

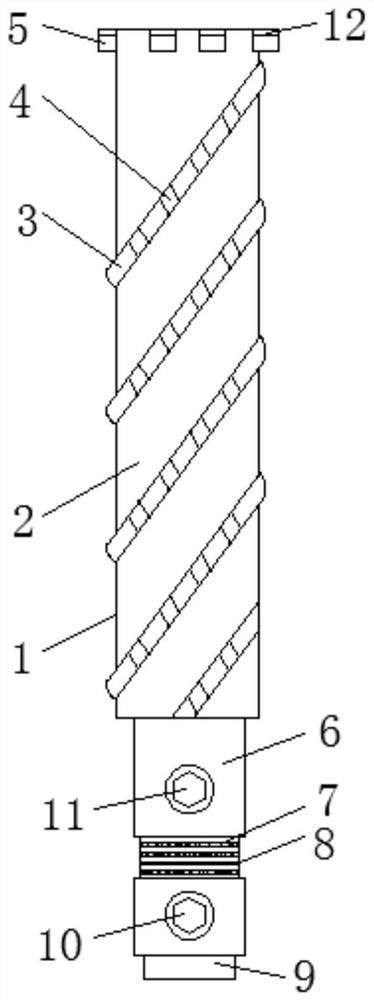

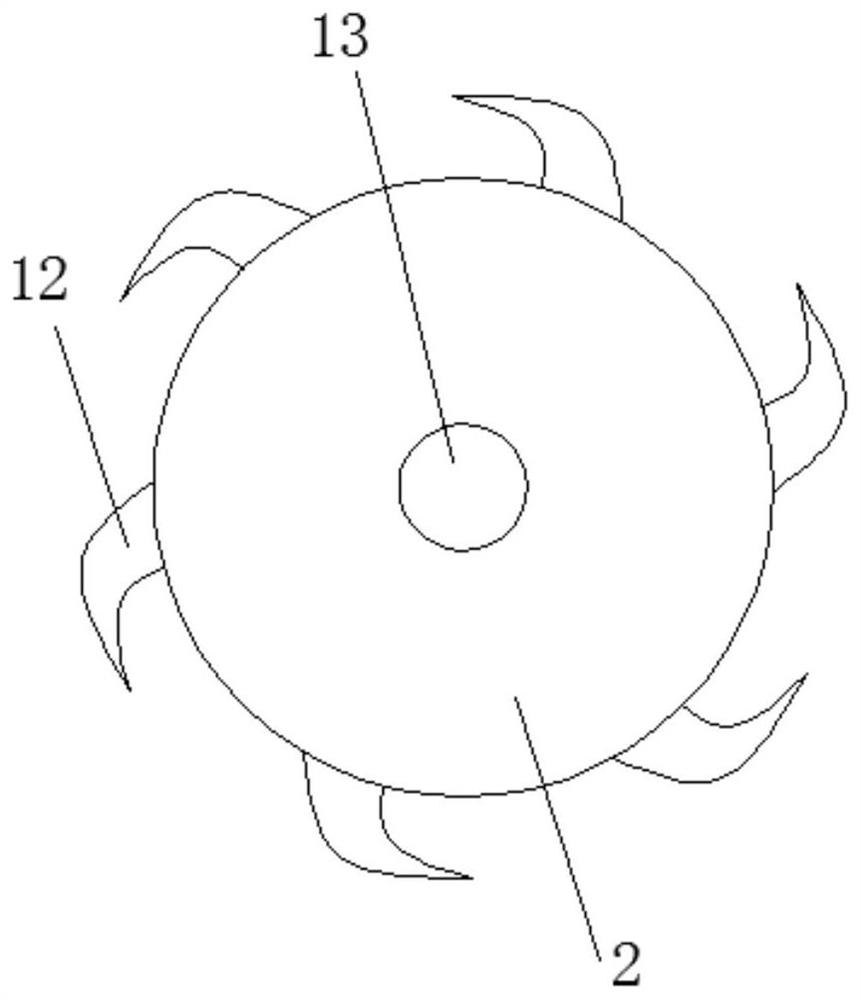

End mill for wooden furniture production and processing

InactiveCN111687972AEasy to cutEasy to holdWood turning toolsWood boring toolsEnd millIndustrial engineering

The invention discloses an end mill for wooden furniture production and processing, and aims at a problem of only carrying out cutting in a single direction. According to the scheme, the end mill comprises a body, wherein the body comprises a cutting edge and a handle; the handle is fixed to the outer wall of the bottom of the cutting edge through a bolt; a spiral cutting edge is welded to the outer wall of the circumference of the cutting edge; a plurality of clamping grooves are arranged in the outer wall of the spiral cutting edge; a plurality of cushion blocks are welded to a position, close to the top, of the outer wall of the circumference of the cutting edge; a cutting blade is welded to the position, close to the top, of the outer wall of the circumference of the cutting edge; andthe outer wall of the top of the cutting blade is flush with the top of the cutting edge. According to the end mill, the cylindrical surface and the end face of the cutting edge can be both used for cutting, the cutting can be carried out simultaneously or separately, the wood can be conveniently cut, the handle can be conveniently held, and the handle can be conveniently fixed into a mechanical fixture, so that the clamping becomes more stable, and the rapid cutting work is facilitated.

Owner:MAANSHAN GUQING DOOR IND

Acrylic/PC plate equipment

The invention discloses acrylic / PC plate equipment. The acrylic / PC plate equipment comprises a main machine body and a lifting assembly arranged on the lower side of the main machine body; an installing hole is formed in the end face of the bottom of the main machine body, a cutting knife is arranged in the installing hole, convex lugs symmetrically and fixedly arranged at the centers of the end faces of the left side and the right side of the cutting knife, a first spline cavity is formed in the end face of the left side of the left-side convex lug, and an inserting hole is formed in the endface of the right side of the right-side convex lug; a first transmission cavity is formed in the portion, on the left side of the installing hole, of the main machine body in a vertical extending mode, a first rotating pin shaft is installed on the lower side of the first transmission cavity in a rotating fit mode, and a first transmission wheel is fixedly arranged on the outer surface of the first rotating pin shaft; and the tail end of the right side of the first rotating pin shaft stretches into the installing hole and is fixedly provided with a first spline shaft, the first spline shaft is connected with the first spline cavity in a spline fit mode, and a second transmission cavity is formed in the top wall of the first transmission cavity in a communicating mode.

Owner:深圳绿淋环保科技有限公司

Intelligent light guide plate assembling device

InactiveCN109128338AQuick cut jobImprove work efficiencyShearing machinesShearing machine accessoriesLight guideEngineering

The invention discloses an intelligent light guide plate assembling device. The device comprises a main machine body and a lifting assembly arranged at the lower side of the main machine body, a mounting hole is formed in the bottom end face of the main machine body, a cutter is arranged in the mounting hole, lugs are symmetrically and fixedly arranged in the center of the left end face and in thecenter the right end face of the cutter, and a first spline cavity is formed in the left end face of the left lug. An inserting hole is formed in the right end face of the right lug, a first transmission cavity vertically extends in the portion, on the left side of the mounting hole, of the main machine body, and a first rotating pin shaft is rotationally matched with the lower side of the firsttransmission cavity. A first transmission wheel is fixedly arranged on the outer surface of the first rotating pin shaft, the tail end of the right side of the first rotating pin shaft extends into the mounting, and a first spline shaft is fixedly arranged at the tail end of the first rotating pin shaft. The first spline shaft is cooperatively connected with a spline of the first spline cavity, and the top wall of the first transmission cavity communicates with a second transmission cavity.

Owner:深圳绿淋环保科技有限公司

Device capable of rapidly cutting rock wool insulation board

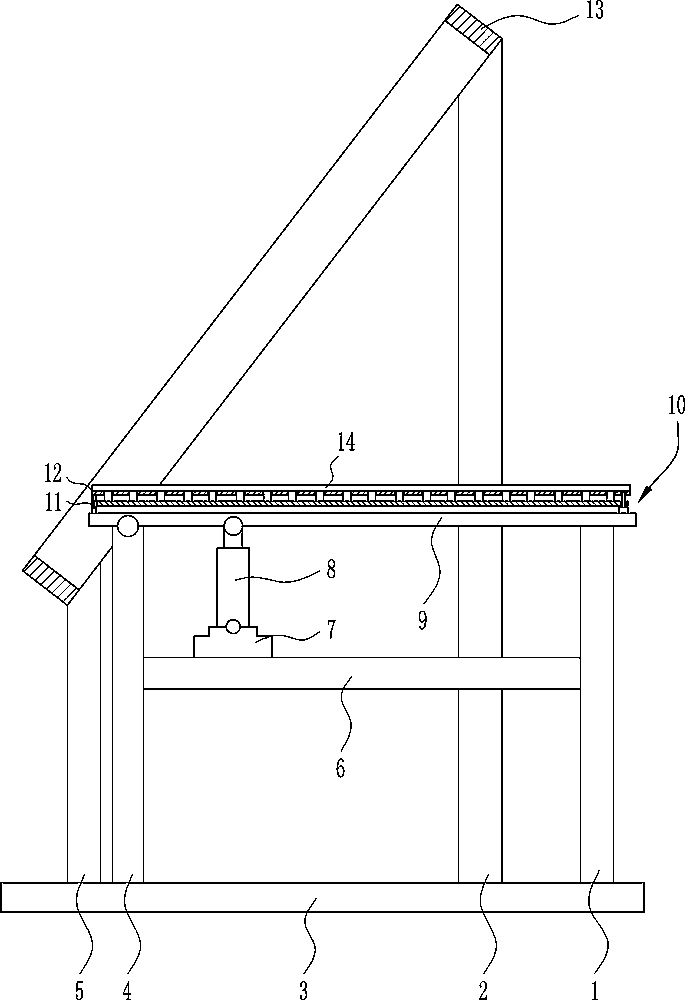

PendingCN114393720AQuick cut jobEasy to operateWorking accessoriesStone-like material working toolsDrive motorKnife blades

The invention relates to a device capable of rapidly cutting a rock wool insulation board. The device comprises a base, a supporting column is installed at the top of the base, a first lug is installed at the top of the supporting column and hinged to one end of a swing rod, a rotating shaft is installed at the other end of the swing rod through a bearing, and a driven wheel is arranged at one end of the rotating shaft and connected with a driving wheel through a belt. And the driving wheel is mounted on an output shaft of the driving motor. The device capable of rapidly cutting the rock wool insulation board has the beneficial effects that when the device capable of rapidly cutting the rock wool insulation board is used, one side of the rock wool insulation board is fixed to the fixing clamp, then a first nut is loosened, a movable plate is moved to enable the cutting position of the rock wool insulation board to be located below a cutting knife, and after adjustment is completed, the movable plate is fixed to the base through the first nut; then the driving motor is started and drives the cutting knife to rotate, and finally the cutting blade descends to cut the rock wool insulation board by pressing the handle with hands, so that the operation is convenient, and the cutting work of the rock wool insulation board can be quickly completed.

Owner:武汉市德华测试工程有限公司

Substrate equipment and producing method thereof

InactiveCN109249078AQuick cut jobImprove work efficiencyShearing machinesShearing toolsEngineeringCopper

The invention discloses substrate equipment and a producing method thereof. Ultra-thin non-adhesive-coating copper plate equipment is used, the ultra-thin non-adhesive-coating copper plate equipment comprises a processing seat and a lifting and lower member arranged on the lower side of the processing seat, an assembling groove is formed in the end face of the bottom of the processing seat, a rotary cutter body is arranged in the assembly groove, protruded handles are symmetrically and fixedly arranged on the two side end faces of the rotary cutter body taking the center of end faces as the axial center, a first spline cavity is formed in the left side end face of protruded handle on the left side, an inserting cavity is formed in the right side end face of the protruded handle on the right side, a first conveying cavity extending up and down is formed in the left side of the assembly groove, a first rotary rod is rotatably and cooperatively installed on the part on the lower side of the first conveying cavity, a first conveying wheel is fixedly arranged on the outer surface of the first rotary rod, the rear end of the right side of the first rotary rod extends to the interior of the assembly groove to be fixedly provided with a first spline shaft, the first spline shaft is in spline cooperative connection with the first spline cavity, and a second conveying cavity is communicated with the top wall of the first delivery cavity.

Owner:众顶(广州)科技有限公司

CNC punching and cutting machine and its alignment method

ActiveCN105522185BSimple punching processImprove drilling accuracyAutomatic control devicesFeeding apparatusNumerical controlPunching

The invention discloses a numerical control punching and cutting integrated machine and an alignment method thereof, and relates to the numerical control punching and cutting integrated machine and the alignment method thereof. A slide table rail (16) is mounted on a worktable (2); a slide table locking block (17) is additionally mounted on the worktable (2); a locking connecting rod (18) is screwed into the slide table locking block (17), penetrates through the worktable (2), and is connected with a nut (19); a chute (20) slides in the slide table rail (16), is formed in a horizontal slide table (21), and is matched with the slide table locking block (17) for use; the horizontal slide table (21) and the worktable (2) commonly place workpieces (22); and the horizontal slide table is detachable. The numerical control punching and cutting integrated machine is applied to numerical control punching and cutting.

Owner:日照鸿本机械制造有限公司 +1

Novel light guide plate assembly device

InactiveCN109203003AQuick cut jobImprove work efficiencyMetal working apparatusLight guideMechanical engineering

The invention discloses a novel light guide plate assembly device comprising a main machine body and a lifting assembly arranged on the lower side of the main machine body. A mounting hole is formed in the bottom end surface of the main machine body, a cutter is arranged in the mounting hole, protruding lugs are symmetrically and fixedly arranged in the centers of the end faces of the left and right sides of the cutter, the end face of the left side of the protruding lug on the left side is internally provided with a first spline cavity, and the end face of the right side of the protruding lugon the right side is provided with an inserting hole; and a first transmission cavity extending up and down is arranged in the position, on the left side of the mounting hole, in the main machine body, a first revolving pin shaft is mounted at the lower side of the first transmission cavity in a rotary fit manner, a first transferring wheel is fixed on the outer surface of the first revolving pinshaft, the tail end of the right side of the first revolving pin shaft extends into the mounting hole, the tail end is fixedly provided with a first spline shaft, the first spline shaft is connectedwith a first spline cavity in a spline fit manner, and the top wall of the first transmission cavity is provided with a second transmission cavity in a communicating manner.

Owner:深圳绿淋环保科技有限公司

Aluminum formwork and manufacturing method

InactiveCN109128337AQuick cut jobImprove work efficiencyShearing machinesShearing toolsRight convexEngineering

The invention discloses an aluminum formwork and a manufacturing method. A novel aluminum formwork device is used and comprises a main base body and a lifting device arranged on the lower side of themain base body, a mounting groove is formed in the bottom end face of the main base body, a blade is arranged in the mounting groove, and convex heads are symmetrically and fixed arranged in the center of the left side and in the center of the right side of the blade. A first spline cavity is formed in the left end face of the left convex head, an inserting groove is formed in the right end face of the right convex head, and a first transmission cavity vertically extends in the portion, on the left side of the mounting groove, of the main base body. A first steering shaft is rotationally matched with the lower side of the first transmission cavity, a first transmission wheel is fixedly arranged on the outer surface of the first steering shaft, the tail end of the right side of the first steering shaft extends into the mounting groove, and a first spline shaft is fixedly arranged at the tail end of the first steering shaft. The first spline shaft is cooperatively connected with a splineof the first spline cavity, and the top wall of the first transmission cavity communicates with a second transmission cavity.

Owner:广州元莱信息科技有限公司

Silkworm breeding equipment

InactiveCN109262699AFor quick replacementEasy replacementDirt cleaningMetal working apparatusEngineeringPulley

The invention discloses silkworm breeding equipment. The equipment comprises a main frame body and a lifting adjustment mechanism disposed on the lower side of the main frame body, the bottom end surface of the main frame body is provided with a mounting cavity, the mounting cavity is provided with cutting pieces, the centers of the left and right end faces of the cutting pieces are symmetricallyfixedly provided with convex blocks, the left side end face of the convex block on the left side is provided with a first spline cavity, the right side end face of the convex block on the right side is provided with an inserting cavity, a first transmission cavity which extends upward and downward is disposed on the main frame body of the left side of the mounting cavity, a first rotating shaft isrotatably cooperatively mounted on the lower side of the first transmission cavity, the outer surface of the first rotating shaft is fixed to a first pulley, the end of the right side of the first rotating shaft extends into the mounting cavity, a first spline shaft is fixed at the end, the first spline shaft and the first spline cavity are in spline cooperation connection, and the top wall of the first transmission cavity is communicated with a second transmission cavity.

Owner:广州建德农业科技有限公司

Light guide plate assembling device

InactiveCN109203015AQuick cut jobImprove work efficiencyMetal working apparatusLight guideEngineering

The invention discloses a light guide plate assembling device. The device comprises a main machine body, and a lifting assembly which is arranged at the lower side of the main machine body, wherein amounting hole in which a cutting tool is formed in the end surface of the bottom part of the main machine body; lugs are symmetrically fixedly arranged in the centers of the end surfaces of the left side and the right side of the cutting tool; a first spline chamber is formed in the end surface of the left side of the lug at the left side; an inserting hole is formed in the end surface of the right side of the lug at the right side; a first transmission chamber up and down extends in the main machine body at the left side of the mounting hole; a first rotating hinge pin is mounted at the lowerside of the first transmission chamber in a rotating fitting manner; a first transmission wheel is fixedly arranged on the outer surface of the first rotating hinge pin; the tail end of the right side of the first rotating hinge pin extends into the mounting hole and is fixedly equipped with a first spline shaft; the first spline shaft is connected to the first spline chamber in a spline fittingmanner; and a second transmission chamber communicates with the top wall of the first transmission chamber.

Owner:泉州睿骋企业管理咨询有限公司

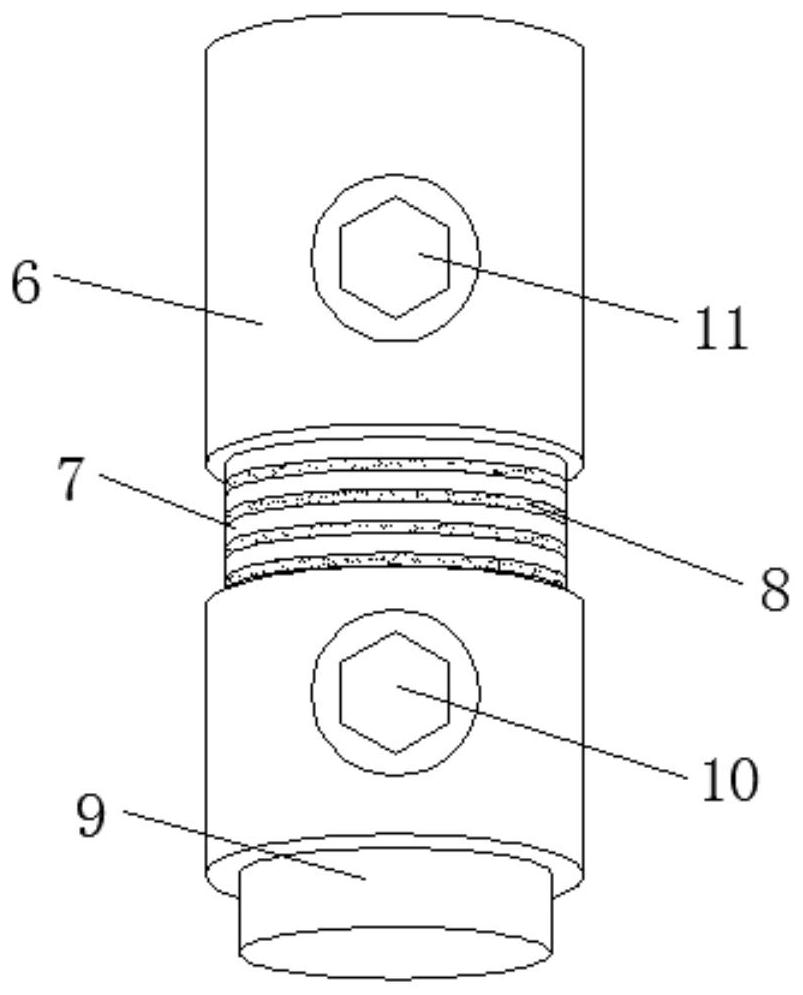

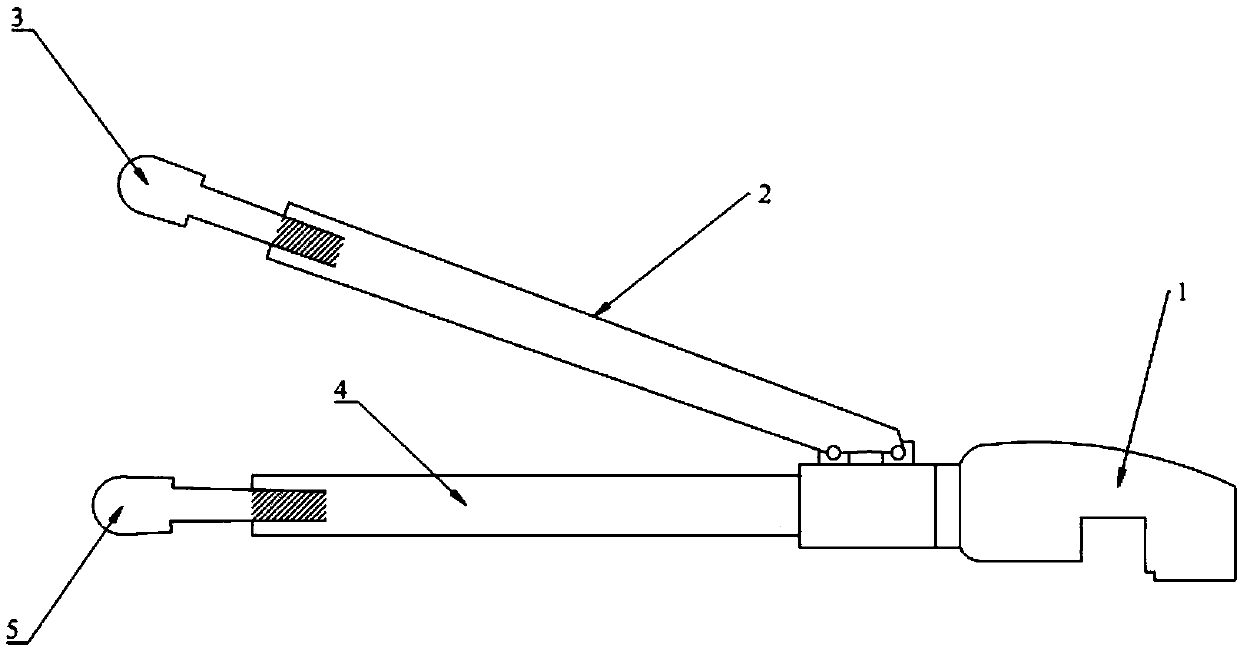

Telescopic hydraulic shear

InactiveCN107775088AEliminate gapsEasy resectionPortable handheld shearing machinesEmergency rescueEngineering

The invention discloses a retractable hydraulic shear, which belongs to the field of mechanical equipment and mainly solves the problem that most of the current hydraulic shears have fixed handles, and the steel bars at high places cannot be directly cut by hydraulic shears, and can only be used when they are close to the sheared object by means of external force. , this operation is not only time-consuming and labor-intensive, but also increases the cutting time and increases the difficulty of rescue in case of emergency. The cutting head is forged from two blades. , The second handle is connected with the shearing head through the piston and the piston push rod, the first telescopic rod is mounted on the thread at the top of the first handle, and the second telescopic rod is mounted on the thread at the top of the second handle. The gap between the blades of the present invention is adjusted by the handle, which is fast, accurate and convenient. The precision sliding guide rail is used to eliminate the gap between the guide rails, and the cutting quality is high. Complete cutting work, easy to use.

Owner:刘艳萍

Ultra-thin non-rubber-coating copper plate and production method thereof

The invention discloses an ultra-thin non-rubber-coating copper plate and a production method thereof. Ultra-thin non-rubber-coating copper plate equipment is used, the ultra-thin non-rubber-coating copper plate equipment comprises a processing seat and a lifting and lowering member which is arranged on the lower side of the processing seat, an assembly groove is formed in the bottom end face of the processing seat, a rotary cutter body is arranged in the assembly groove, protruded handles are symmetrically and fixedly arranged on the centers of the both left and right side end faces of the rotary cutter body, a first spline cavity is formed in the left side end face of the protruded handle on the left side, an inserting cavity is formed in the right side end face of the protruded handle on the right side, a first delivery cavity extending up and down is formed in the processing seat located on the left side of the assembly groove, a first rotary rod is rotatably and cooperatively installed on the lower side of a first delivery cavity, a first delivery wheel is fixedly arranged on the outer surface of the first rotary rod, the rear end of the right side of the first rotary rod extends to the assembly groove to be fixedly provided with a first spline shaft, the first spline shaft is in spline cooperative connection with the first spline cavity, and a second delivery cavity is communicated with the top wall of the first delivery cavity.

Owner:福建泉州远方致远自动化科技有限公司

Cutting device

PendingCN109262678AStable installation environmentSimple installation structureMetal working apparatusHydraulic cylinderEngineering

The invention discloses a cutting device which comprises a device body. A control button is mounted on a side of the device body in an embedded manner and is connected with hydraulic cylinders and anelectric control gas shutoff oil cylinder by wires, a mounting frame is arranged on a side of the top of the device body, a locking component is connected with the end, which penetrates the mounting frame, of each hydraulic cylinder, a positioning table is fixedly mounted at the bottoms of the locking components, limit blocks are arranged at the bottom of the positioning table, a base is mounted in the center of the bottom of the positioning table in an embedded manner, and a cutter groove is formed in the middle of the base. The cutting device has the advantages that the problem of deviationof supplied materials in case of excessively high cutting force in cutting procedures due to the fact that the supplied materials are generally directly cut by existing cutting devices without good limit protection functions can be solved by the aid of the cutting device, and the problems of relatively low machining efficiency due to relatively complicated structures of the existing cutting devices, tedious operation procedures and excessively high skill requirements on staffs can be solved by the aid of the cutting device.

Owner:YINGSHANG BOHAO PLASTIC IND TECH CO LTD

Improved cross-grid cocooning equipment

InactiveCN109352706AFor quick replacementEasy replacementMetal working apparatusMechanical engineering

The invention discloses the improved cross-grid cocooning equipment. The equipment comprises a main frame body and a lifting adjusting mechanism arranged on the lower side of the main frame body, a mounting cavity is formed in the end surface of the bottom of the main frame body, a cutting piece is arranged in the mounting cavity, convex blocks are symmetrically and fixedly arranged at the centersof the left side end face and the right side end face of the cutting piece, a first spline cavity is formed in the left side end face of the convex block on the left side, an inserting cavity is formed in the right side end face of the convex block on the right side, a first transmission cavity is formed in the portion, on the left side of the mounting cavity, of the main frame body in an up-downextending mode, a first rotating shaft is arranged on the lower side of the first transmission cavity in a rotating fit mode, a first belt wheel is fixedly arranged on the outer surface of the firstrotating shaft, the tail end of the right side of the first rotating shaft extends into the mounting cavity, moreover, a first spline shaft is fixedly arranged at the tail end of the first rotating shaft, the first spline shaft is connected with the first spline cavity spline in a cooperative mode, and the top wall of the first transmission cavity communicates with a second transmission cavity.

Owner:广州建德农业科技有限公司

Novel aluminum template and manufacturing method

InactiveCN109352076AFor quick replacementEasy replacementMetal sawing devicesMating connectionAgricultural engineering

The invention discloses a novel aluminum template and a manufacturing method. Novel aluminum template equipment is used in the manufacturing method, the novel aluminum template equipment comprises a main seat body and a lifting device arranged on the lower side of the main seat body, a mounting groove is formed in the end surface of the bottom of the main seat body, a blade is arranged in the mounting groove, convex heads are symmetrically and fixedly arranged in the centers of the left side end face and the right side end face of the blade, a first spline cavity is formed in the left side endface of the convex head on the left side, an inserting groove is formed in the right side end face of the convex head on the right side, a first transmission cavity is formed in the portion, on the left side of the mounting groove, of the main seat body in an up-down extending mode, a first steering shaft is arranged on the lower side of the first transmission cavity in a rotating fit mode, a first transmission wheel is fixedly arranged on the outer surface of the first steering shaft, the tail end of the right side of the first steering shaft extends into the mounting groove and is fixedly provided with a first spline shaft, the first spline shaft is cooperatively connected with the first spline cavity through splines, and a second transmission cavity is formed in the top wall of the first transmission cavity in a communicating mode.

Owner:广州元莱信息科技有限公司

Improved aluminum template and manufacturing method thereof

InactiveCN109079553AFor quick replacementEasy replacementFeeding apparatusPositioning apparatusEngineeringMechanical engineering

The invention discloses an improved aluminum template and a manufacturing method thereof. Novel aluminum template equipment is used and comprises a main seat body and a lifting device arranged on thelower side of the main seat body. A mounting groove is formed in the end face of the bottom of the main seat body; a blade is arranged in the mounting groove; convex heads are fixedly arranged symmetrically at the centers of the end faces of the left and right sides of the blade; a first spline cavity is formed in the end face of the left side of the convex head on the left side, and an insertinggroove is formed in the end face of the right side of the convex head on the right side; a first transmitting cavity is formed in the position, on the left side of the mounting groove, of the main seat body in an up-down extending mode; a first steering shaft is mounted on the lower side of the first transmitting cavity in a rotating fit mode; a first transmitting wheel is fixedly arranged on theouter surface of the first steering shaft; the tail end of the right side of the first steering shaft extends into the mounting groove and is fixedly provided with a first spline shaft; and the firstspline shaft is connected with the first spline cavity in a spline fit mode, and a second transmitting cavity is formed in the top wall of the first transmitting cavity in a communicating mode.

Owner:广州元莱信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com