Telescopic hydraulic shear

A hydraulic shearing and telescopic technology, which is applied in the direction of hand-held metal shearing equipment, shearing machine equipment, shearing devices, etc., can solve the problems of increasing shearing time, increasing rescue difficulty, time-consuming and labor-intensive, etc., and achieves cutting quality High, simple structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

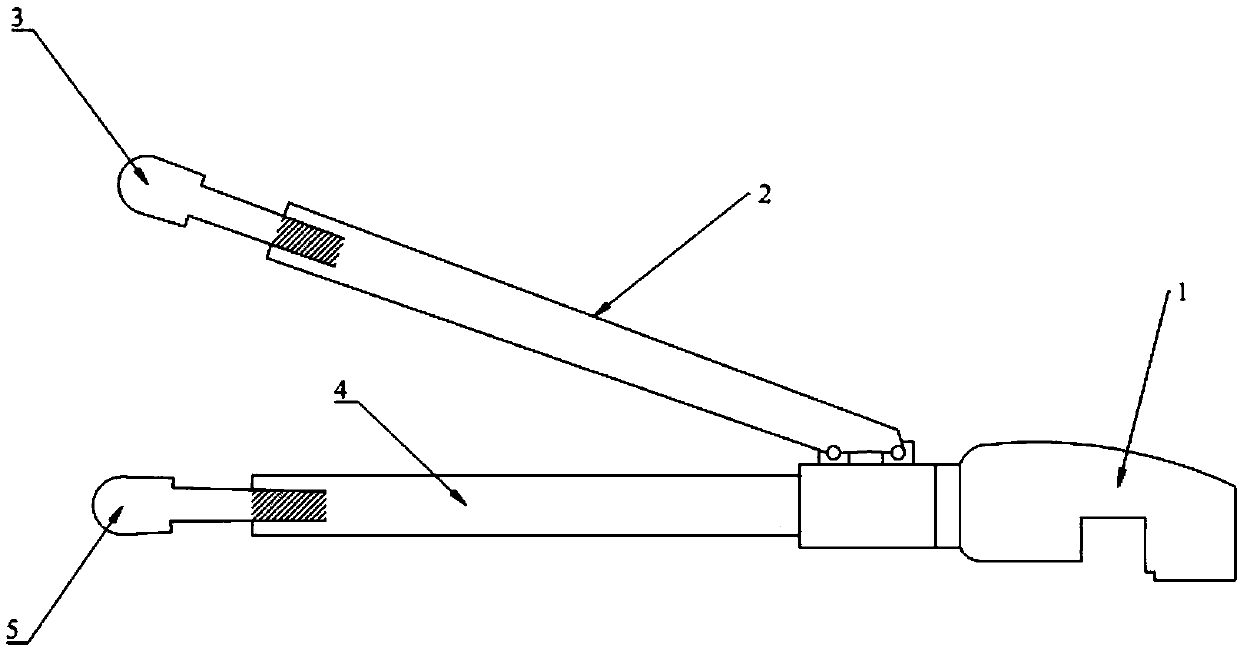

[0014] Such as figure 1 Shown: a retractable hydraulic shear, its structure includes: a cutting head, a first handle, a first telescopic rod, a second handle, and a second telescopic rod; the cutting head is forged by two blades, connected below the cutting head There are a first handle and a second handle. The first handle and the second handle are connected to the shear head through a piston and a piston push rod. The top of the first handle is threaded with a first telescopic rod, and the top of the second handle is threaded. A second telescopic rod is installed; the blade is forged from hot-rolled steel; the piston in the first handle and the second handle and the piston push rod are cast from hot-rolled alloy steel; the first handle and the second handle Distributed symmetrically from top to bottom; the first telescopic rod is nested inside the first handle, the second telescopic rod is nested inside the second handle, and the top parts of the first and second telescopic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com