Automatic cutting-off device for bottle mouth residual materials

An automatic and residual material technology, applied in the field of plastic molding, can solve problems such as the removal of residual material from the bottle mouth, and achieve the effects of strong adaptability, stable transmission and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

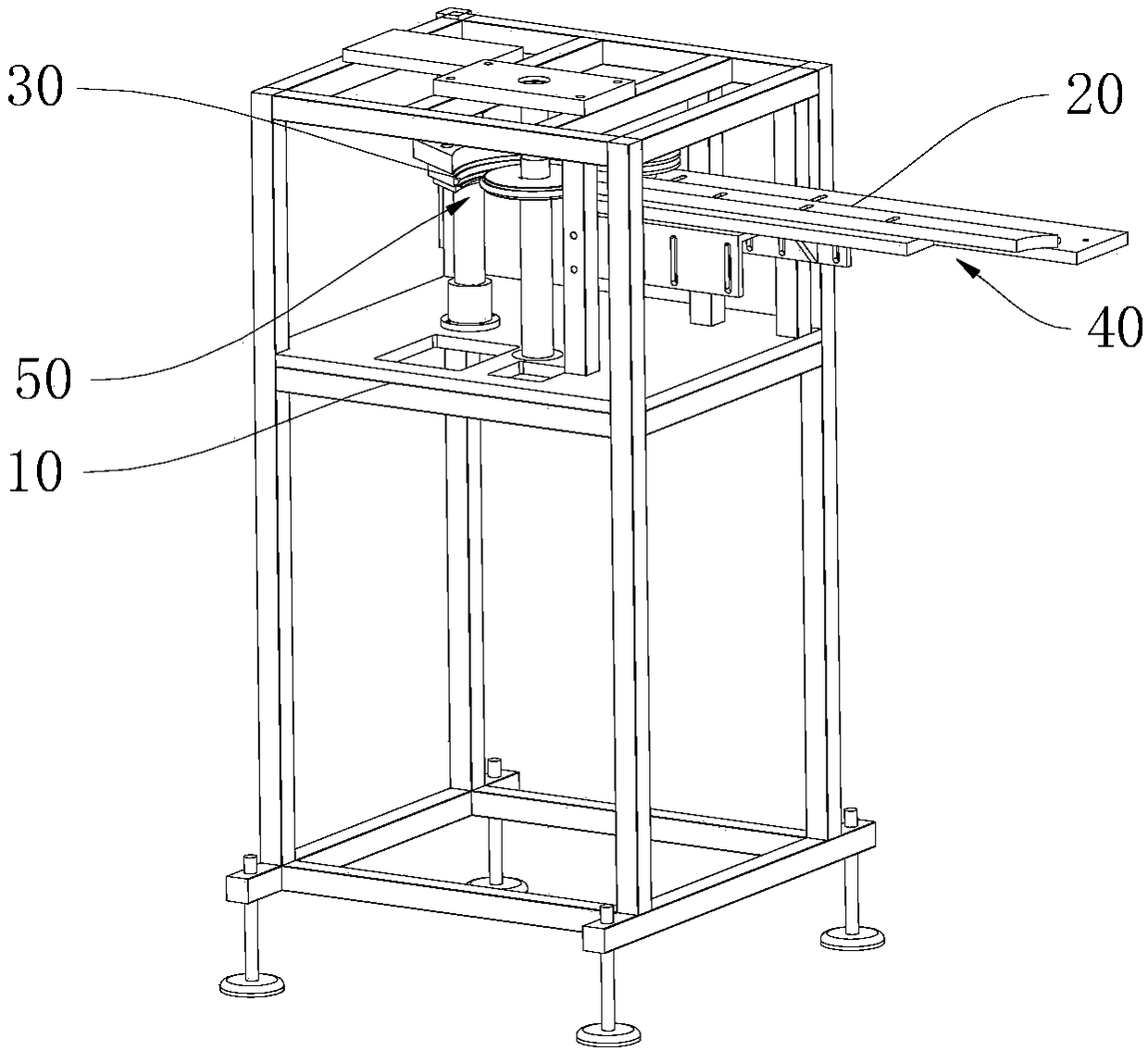

[0025] refer to figure 1 , the figure shows a bottle mouth residue automatic removal device provided by this embodiment, which provides a device that can quickly remove a large number of bottle mouth residues for plastic bottles that need to be removed after blow molding .

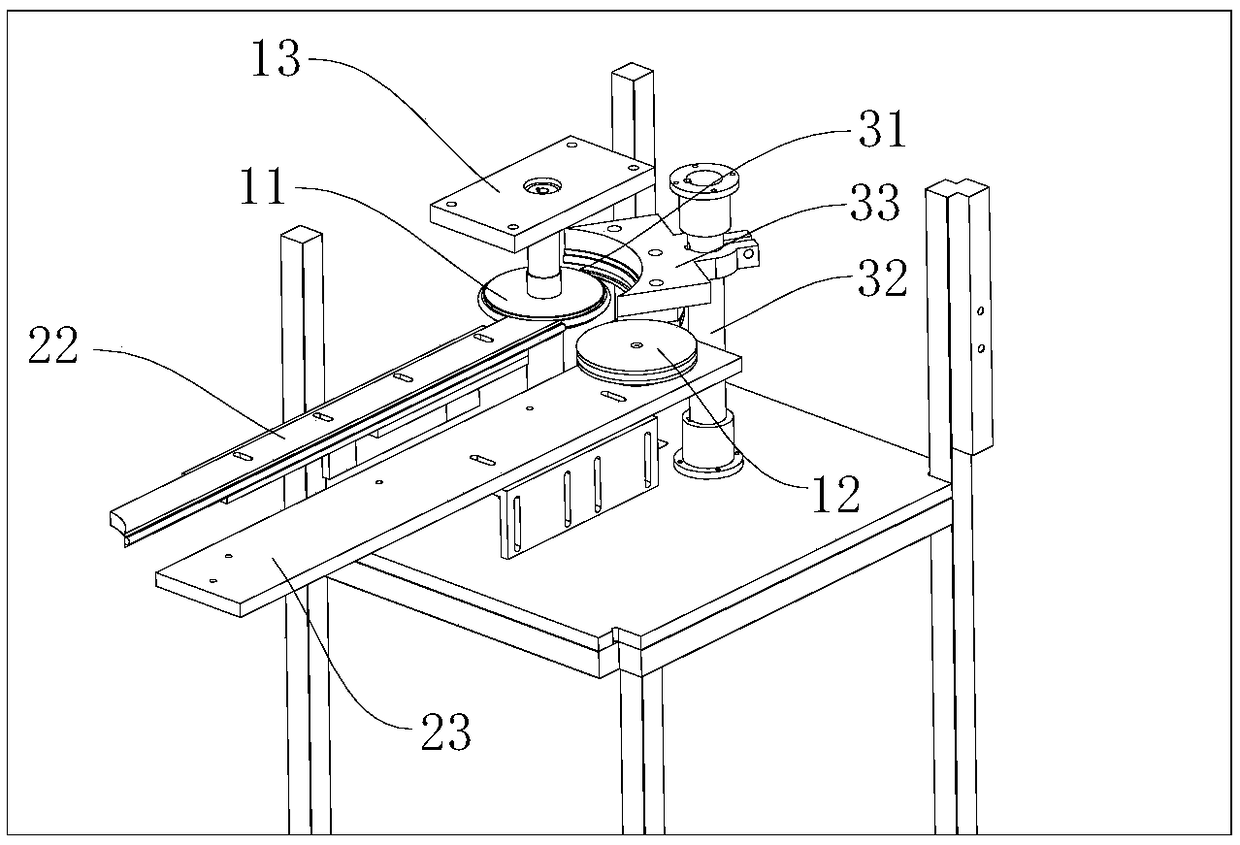

[0026] Specifically, refer to figure 2 , the bottle mouth residual material automatic cutting device comprises a workbench 10, a conveying mechanism 20 and a cutting mechanism 30; the conveying mechanism 20 and the cutting mechanism 30 are arranged on the workbench 10; The first baffle plate 22 and the second baffle plate 23 ; a feed channel 40 is formed between the first baffle plate 22 and the second baffle plate 23 . After blow molding, the plastic bottles that have not been cut off are arranged in the feeding channel 40 in sequence according to the direction. The first driving disc 11 is located at one end of the feeding channel 40 and is spaced apart from the cutting mechanism 30; a cutting channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com