Cutting device

A technology of cutting device and cutting table, applied in metal processing and other directions, can solve the problems of low processing efficiency, lack of good limit protection, cumbersome operation process, etc., and achieve the effect of simple and reasonable installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

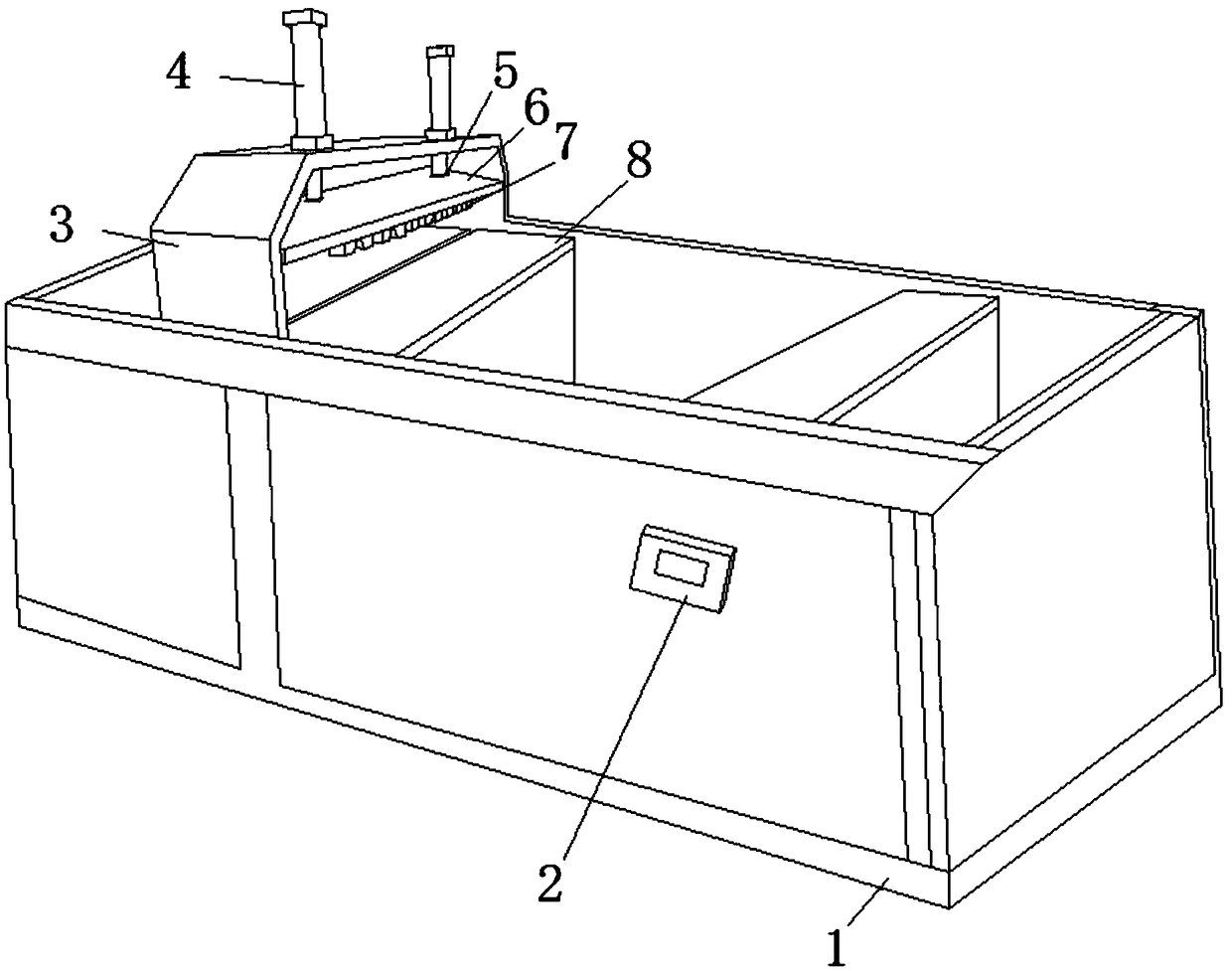

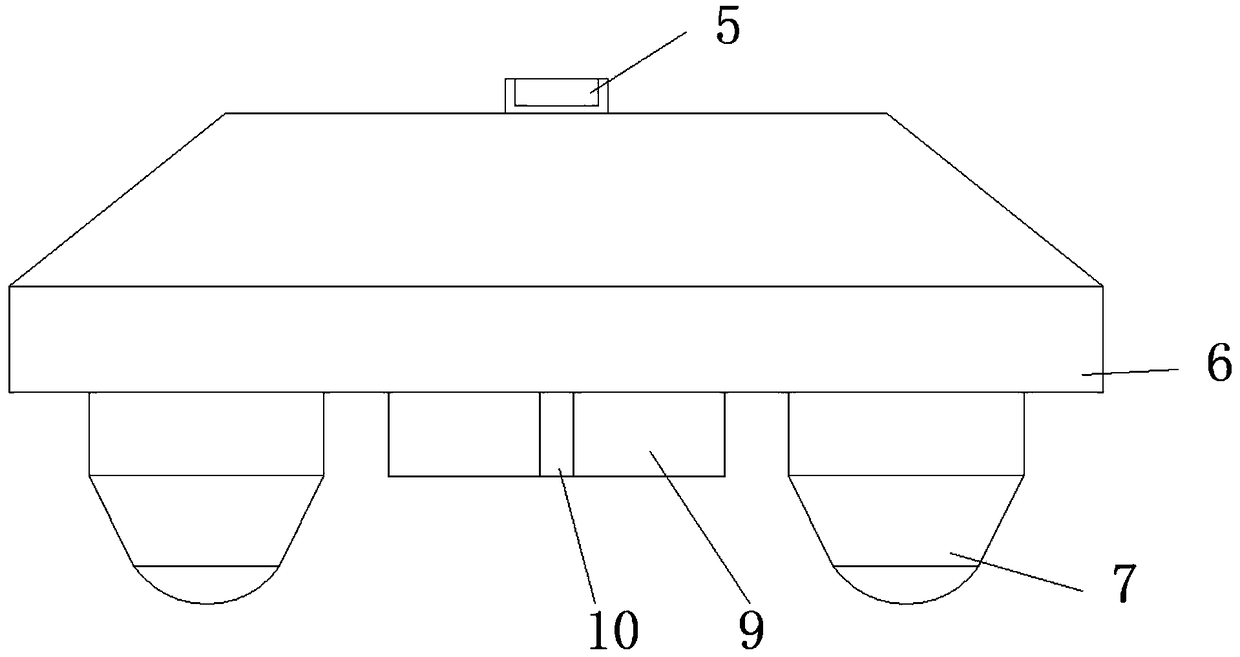

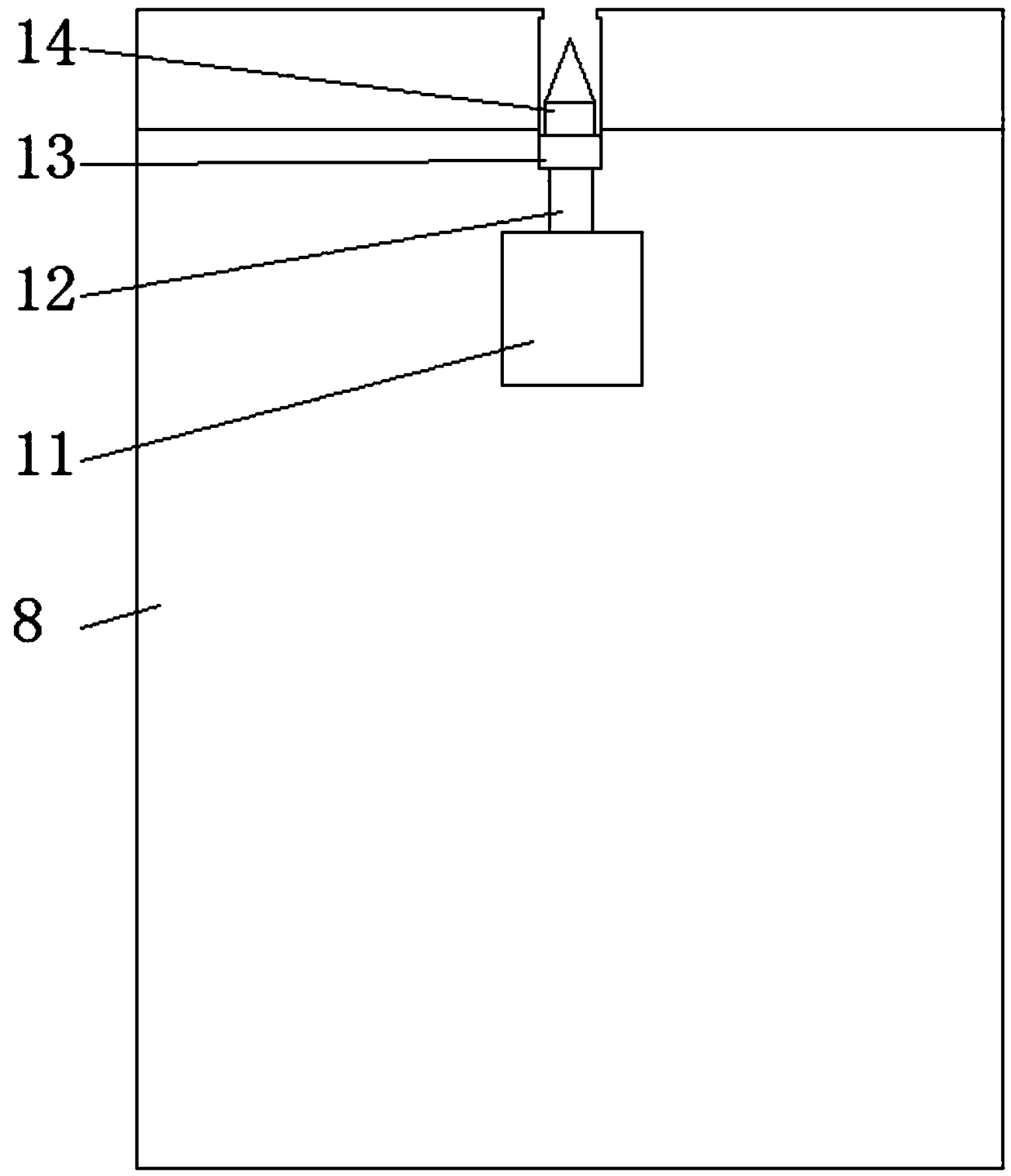

[0019] see Figure 1-3 , the present embodiment provides a cutting device, including a device main body 1, a control button 2 is embedded in one side of the device main body 1, and the control button 2 is connected with a hydraulic cylinder 4 and an electric control air cut-off oil cylinder 11 through a wire, and the device main body 1 A mounting frame 3 is provided on one side of the top of the hydraulic cylinder 4, and one end of the hydraulic cylinder 4 passing through the mounting frame 3 is connected with a locking member 5. The bottom of the locking member 5 is fixedly installed with a positioning platform 6, and the bottom of the positioning platform 6 is provided with a limit block 7. The center of the bottom of the positioning table 6 is embedded with a base 9, the middle part of the base 9 is provided with a knife groove 10, the lower part of the knife groove 10 is provided with a cutting table 8, and the inner center of the cutting table 8 is embedded with an electro...

Embodiment 2

[0022] see Figure 1-3 , on the basis of Embodiment 1, a further improvement has been made: the side of the cutting table 8 close to the telescopic column 12 is provided with a knife edge, which is convenient for the rapid expansion and contraction of the knife 14. There are material guide grooves on both sides, and the material is placed on the top of the material guide table, and at the same time, the side is placed in the material guide groove for smooth movement and limit support.

[0023] Among them, there are four telescopic columns 12, which are convenient to be evenly arranged horizontally on the bottom of the tool mounting seat 13, so as to ensure uniform force and precise cutting. Matching, two-way limit support, positioning cutting, one side of the control button 2 is provided with a protective cover, external protection, to prevent accidental touch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com