Novel cross grid cluster equipment

A horizontal grid, a new type of technology, applied in the direction of metal processing, etc., can solve the problems of cumbersome operation, large cutting size error, single function, etc., and achieve the effect of simple and efficient replacement operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

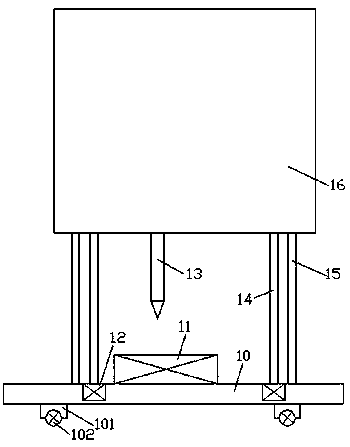

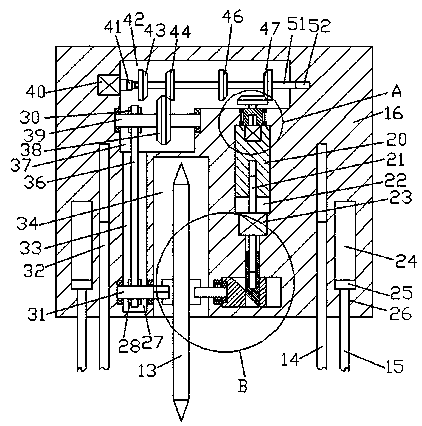

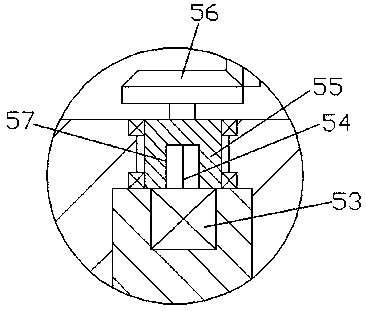

[0016] Combine below Figure 1-4 The present invention will be described in detail.

[0017] refer to Figure 1-4 , according to an embodiment of the present invention, a new type of horizontal grid cluster equipment includes a main frame body 16 and a lifting adjustment mechanism arranged on the lower side of the main frame body 16, and an installation cavity is provided in the bottom end surface of the main frame body 16 34. The installation cavity 34 is provided with a cutting piece 13, and the left and right sides of the cutting piece 13 are fixed with convex blocks 71 symmetrically in the center, and the left side of the left side of the convex block 71 is provided with a first flower. The key cavity 75, the right side of the right side of the protrusion 71 is provided with an insertion cavity 76, the first transmission cavity 33 is extended up and down in the main frame body 16 on the left side of the installation cavity 34, and the first transmission cavity 33 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com