Device capable of rapidly cutting rock wool insulation board

A technology for fast cutting and insulation boards, which is applied in the direction of working accessories, manufacturing tools, stone processing tools, etc., can solve the problems of low cutting efficiency, complicated operation, complex structure, etc., and achieve the effect of fast cutting and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

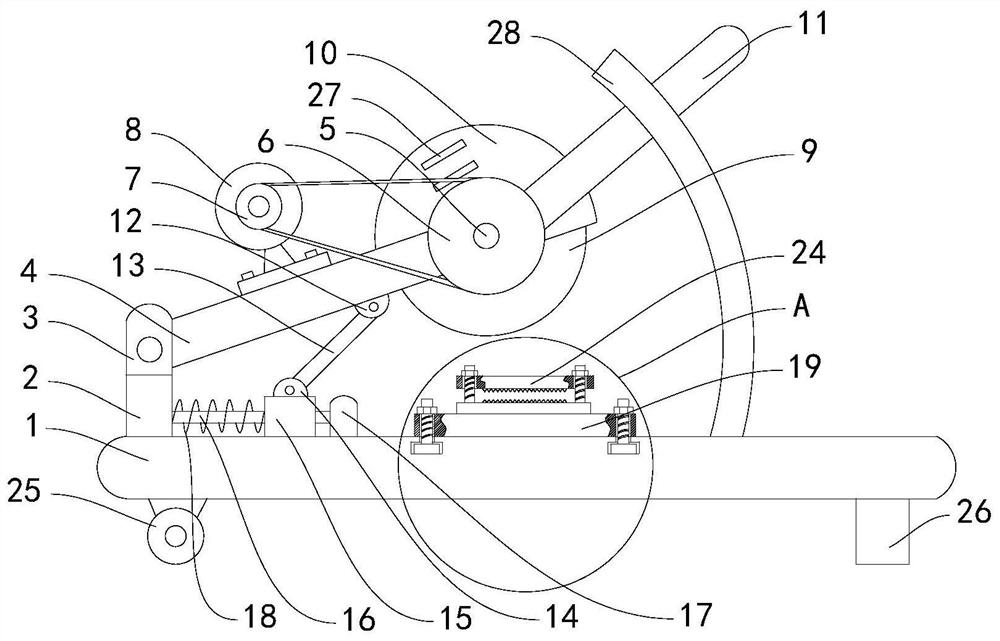

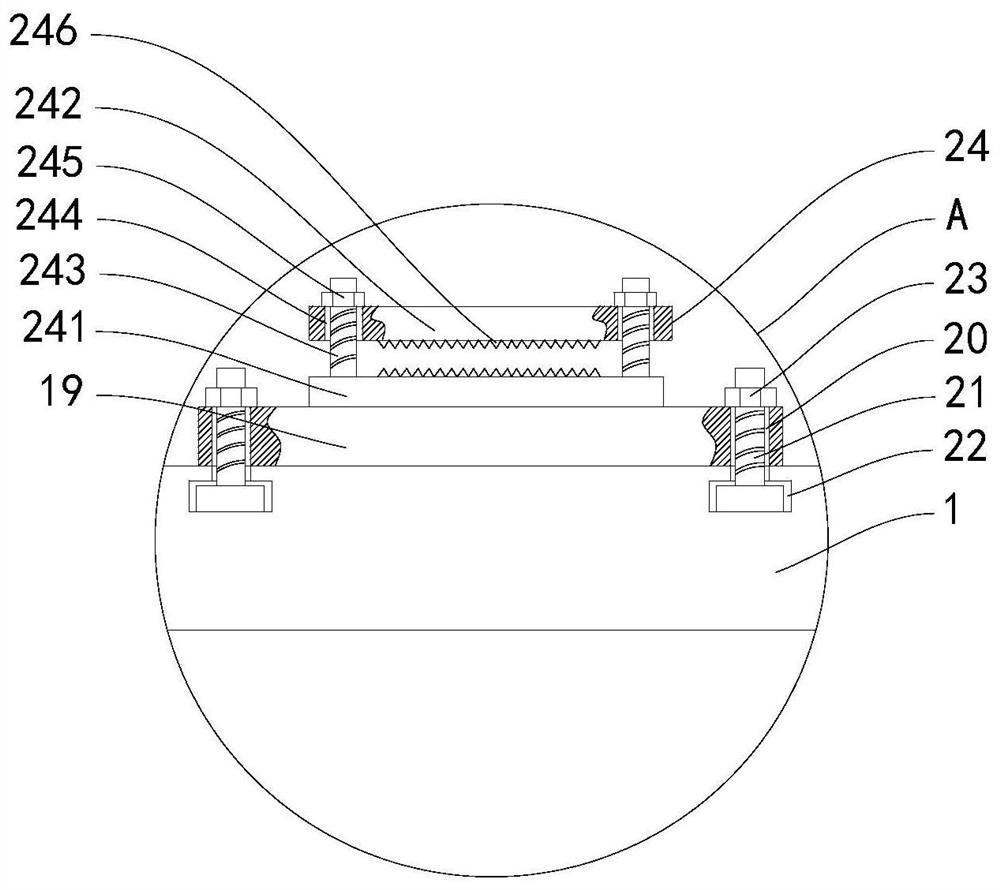

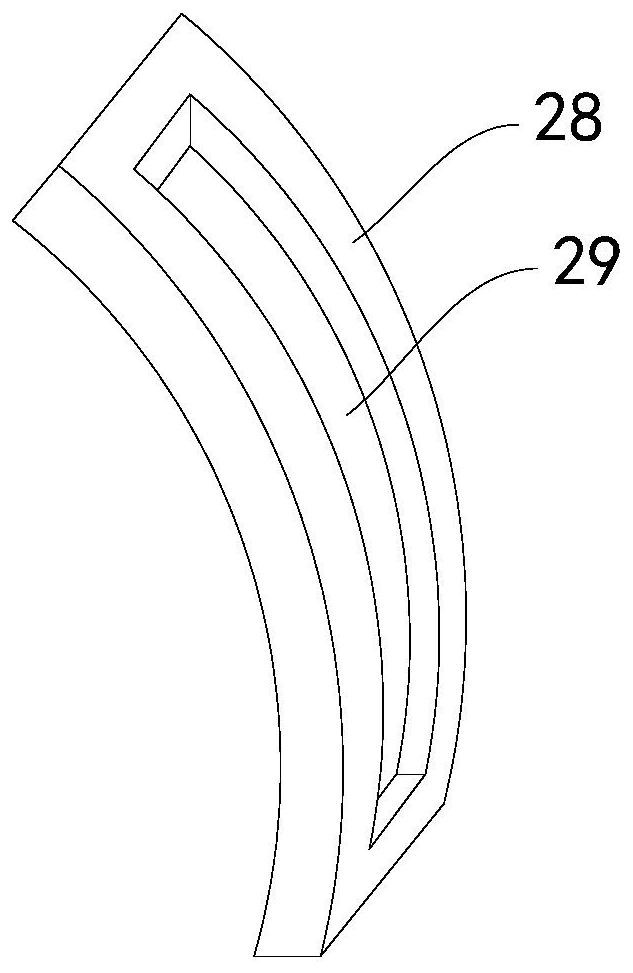

[0023] Such as Figure 1-3 As shown, a device that can quickly cut rock wool insulation boards includes a base 1, a support column 2 is installed on the top of the base 1, and a first ear seat 3 is installed on the top of the support column 2, and the first ear seat 3 is hinged to one end of the swing rod 4 , the other end of the swing lever 4 is installed with a rotating shaft 5 through a bearing, and one end of the rotating shaft 5 is provided with a driven wheel 6, the driven wheel 6 is connected with the driving wheel 7 through a belt, the driving wheel 7 is installed on the output shaft of the driving motor 8, and the driving motor 8 is installed On the top of the swing bar 4, the other end of the rotating shaft 5 is equipped with a cutting knife 9, the top of the cutting knife 9 is provided with a shield 10, the other end of the swing bar 4 is also provided with a handle 11, and the bottom of the swing bar 4 is equipped with a second ear seat 12, The second ear seat 12 i...

Embodiment 2

[0027] Such as Figure 1-3 As shown, a device that can quickly cut rock wool insulation boards includes a base 1, a support column 2 is installed on the top of the base 1, and a first ear seat 3 is installed on the top of the support column 2, and the first ear seat 3 is hinged to one end of the swing rod 4 , the other end of the swing lever 4 is installed with a rotating shaft 5 through a bearing, and one end of the rotating shaft 5 is provided with a driven wheel 6, the driven wheel 6 is connected with the driving wheel 7 through a belt, the driving wheel 7 is installed on the output shaft of the driving motor 8, and the driving motor 8 is installed On the top of the swing bar 4, the other end of the rotating shaft 5 is equipped with a cutting knife 9, the top of the cutting knife 9 is provided with a shield 10, the other end of the swing bar 4 is also provided with a handle 11, and the bottom of the swing bar 4 is equipped with a second ear seat 12, The second ear seat 12 i...

Embodiment 3

[0031] Such as Figure 1-3 As shown, a device that can quickly cut rock wool insulation boards includes a base 1, a support column 2 is installed on the top of the base 1, and a first ear seat 3 is installed on the top of the support column 2, and the first ear seat 3 is hinged to one end of the swing rod 4 , the other end of the swing lever 4 is installed with a rotating shaft 5 through a bearing, and one end of the rotating shaft 5 is provided with a driven wheel 6, the driven wheel 6 is connected with the driving wheel 7 through a belt, the driving wheel 7 is installed on the output shaft of the driving motor 8, and the driving motor 8 is installed On the top of the swing bar 4, the other end of the rotating shaft 5 is equipped with a cutting knife 9, the top of the cutting knife 9 is provided with a shield 10, the other end of the swing bar 4 is also provided with a handle 11, and the bottom of the swing bar 4 is equipped with a second ear seat 12, The second ear seat 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com