End mill for wooden furniture production and processing

A technology for wooden furniture and end mills, which is applied to wood processing appliances, manufacturing tools, wood drilling tools, etc. It can solve the problems of inconvenient use and achieve stable clamping and fast cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

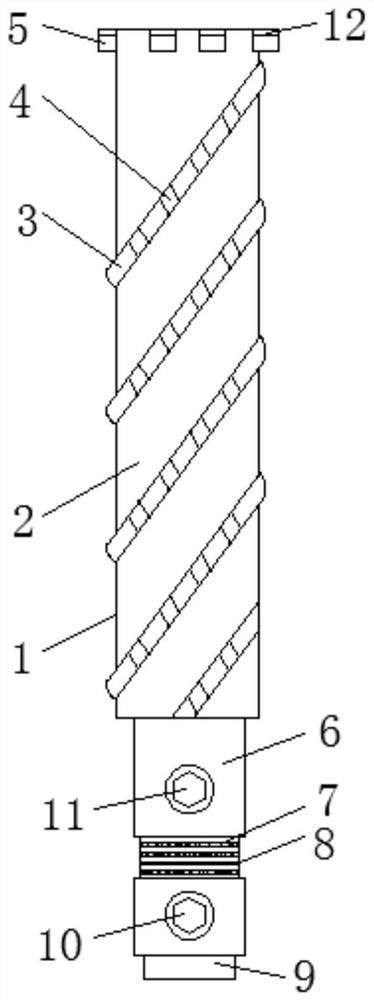

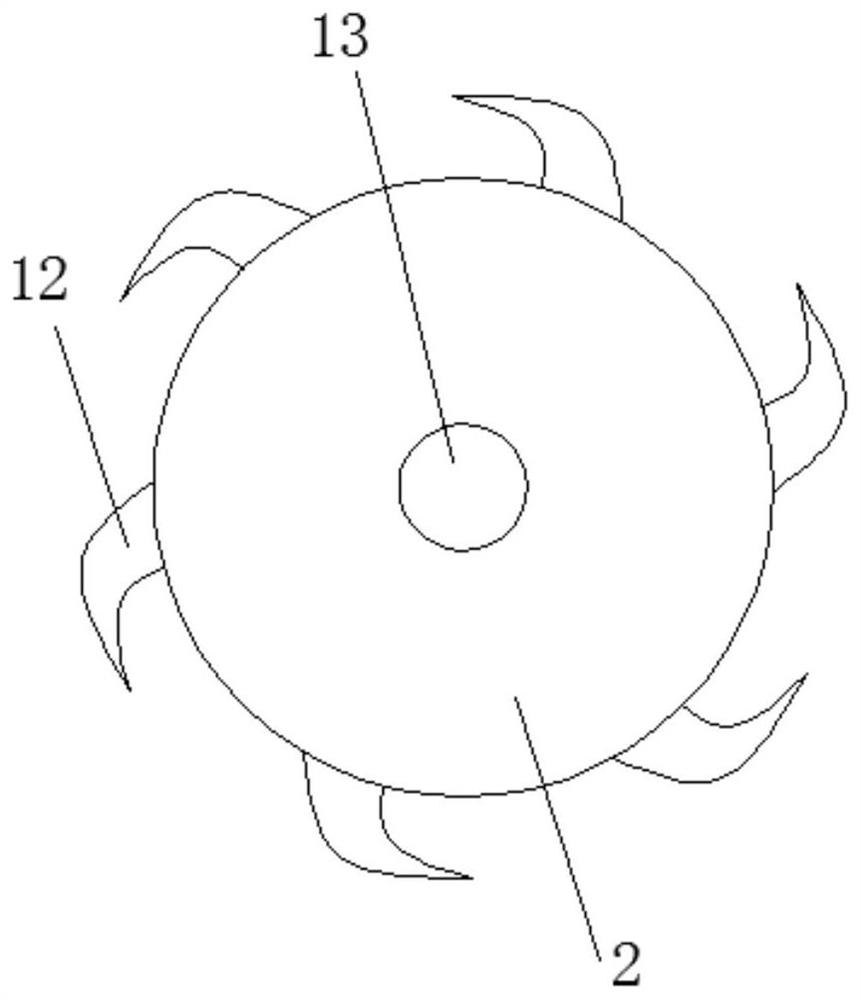

[0026] refer to Figure 1-3 , an end mill for wooden furniture production and processing, comprising a cutter body 1, the cutter body 1 includes a cutting edge 2 and a handle 6, the handle is fixed on the bottom outer wall of the cutting edge 2 by bolts, and the peripheral outer wall of the cutting edge 2 A spiral cutting edge 3 is welded on the top, and a plurality of card slots 4 are opened on the outer wall of the spiral cutting edge 3. A plurality of pads 5 are welded near the top of the outer wall of the cutting edge 2, and a plurality of pads 5 are welded near the top of the outer wall of the cutting edge 2. There is a cutting piece 12 , the top outer wall of the cutting piece 12 is flush with the top of the cutting edge 2 , and the bottom outer wall of the cutting piece 12 is in contact with the spacer 5 .

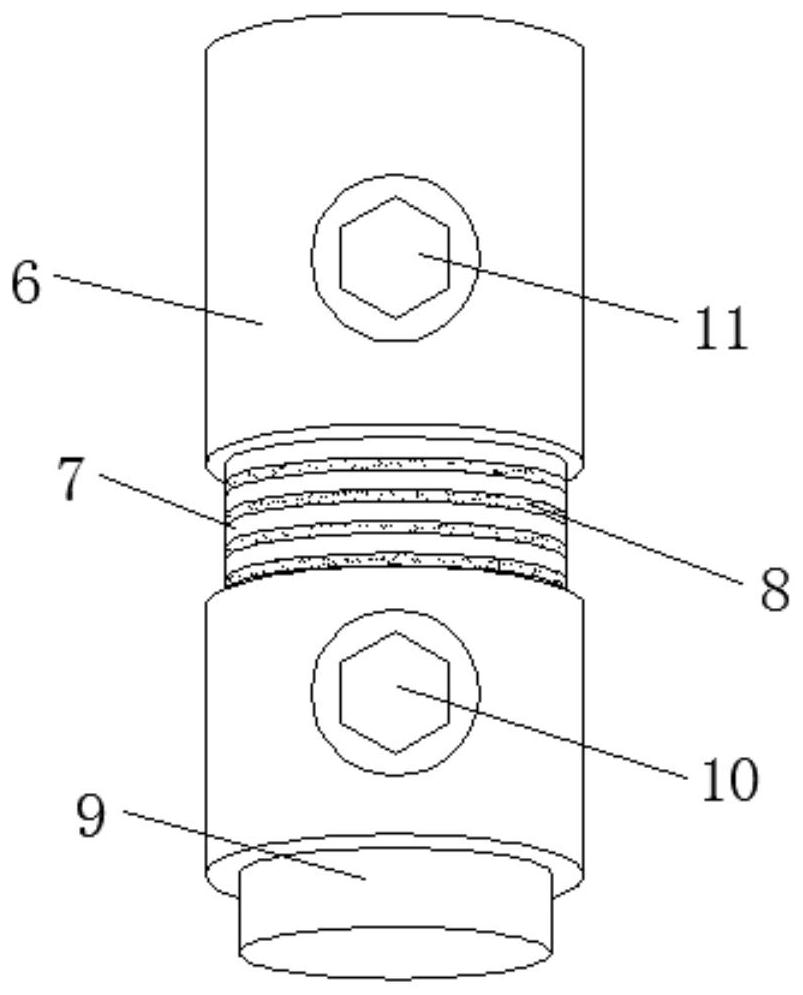

[0027] In the present invention, an annular groove 7 is formed on the peripheral outer wall of the handle 6, and a plurality of thread anti-skid grooves 8 are forme...

Embodiment 2

[0030] refer to Figure 4 , a wooden furniture production and processing end mill, compared with embodiment 1 in this embodiment, the top outer wall of the cutting edge 2 is clamped with a tapered drilling part 14, and the peripheral outer wall of the tapered drilling part 14 is Have spiral chip feeding flute 15.

[0031] During use, the tapered drilling part 14 makes the drilling of the device stronger, and the spiral chip feeding groove 15 on its outside facilitates the discharge of chips, making drilling more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com