Aerated concrete green body cutting and swinging mechanism

A technology of aerated concrete and swing mechanism, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as hidden damage of green body, and achieve the effect of small hidden damage in cutting, solving one-way force, and fast cutting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

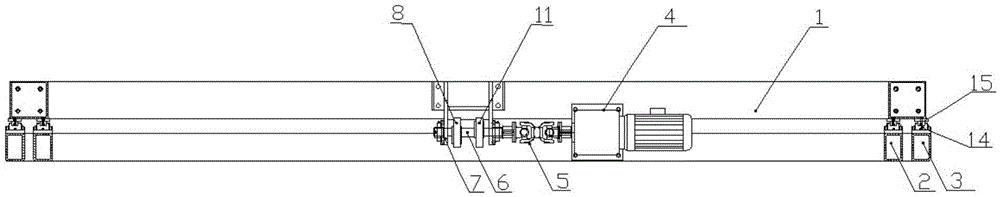

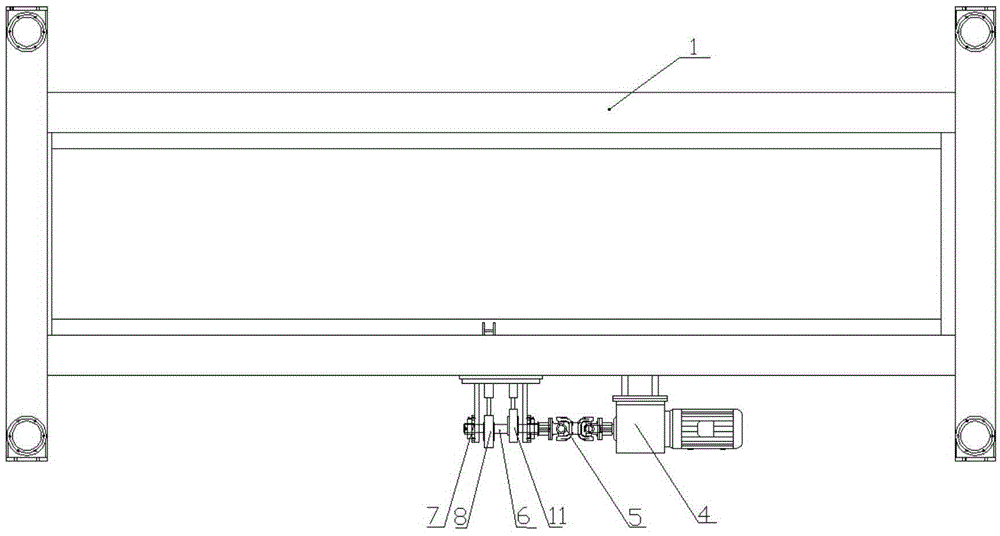

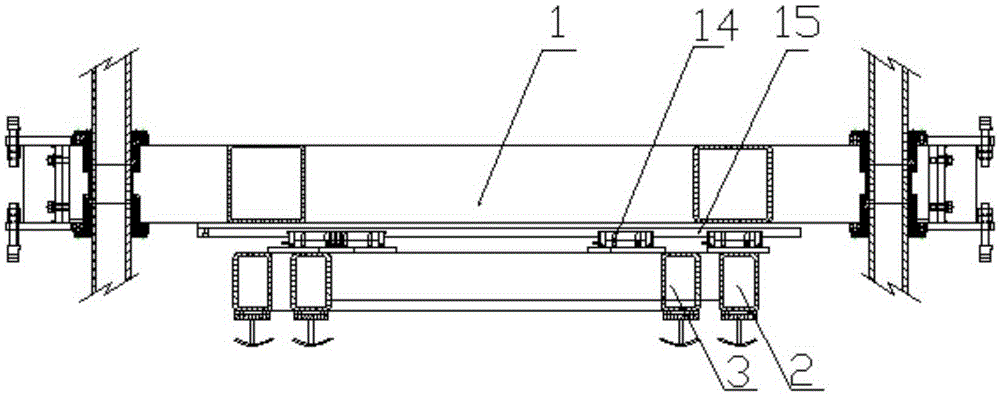

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0013] see figure 1 , figure 2 , image 3 with Figure 4 , a cutting and swinging mechanism for aerated concrete blanks, comprising an upper frame beam 1, an inner swinging frame 2, an outer swinging frame 3, and a drive mechanism for driving the inner and outer swinging frames to swing reciprocatingly in dislocation relative to the rack upper beam, the inner and outer The swing frame is misplaced, and the inner swing frame 2 is ahead of the outer swing frame 3 .

[0014] The drive mechanism includes a reduction motor 4, a universal coupling 5, a rotating shaft 6, a bearing seat 7, a first eccentric wheel 8, a first rocker arm 9, a first swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com