Air-added brick vertical swinging wire cutter

A wire cutting machine and vertical pendulum technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of green body vibration, hidden damage to the green body, and no solution to the one-way force on the green body, so as to solve the problem of one-way stress. force, reduce hidden damage, and improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

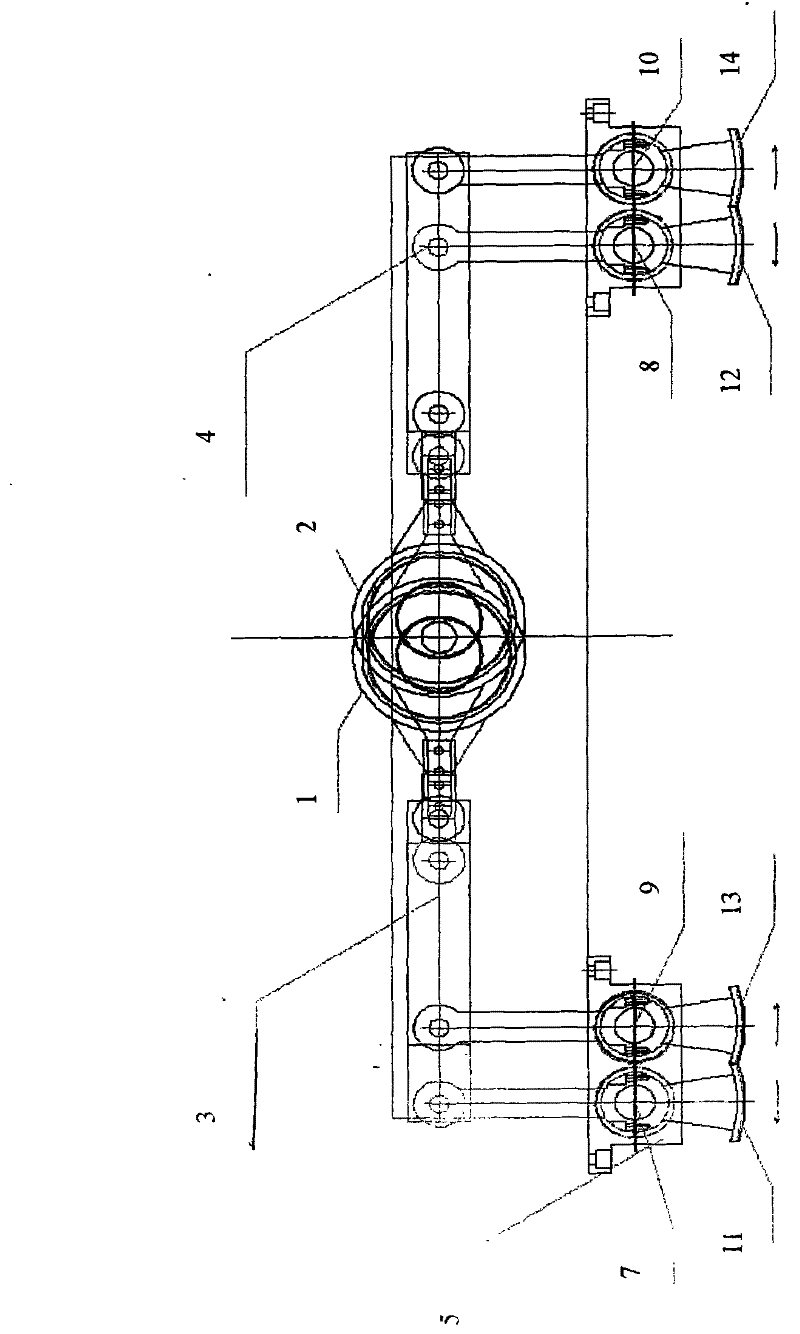

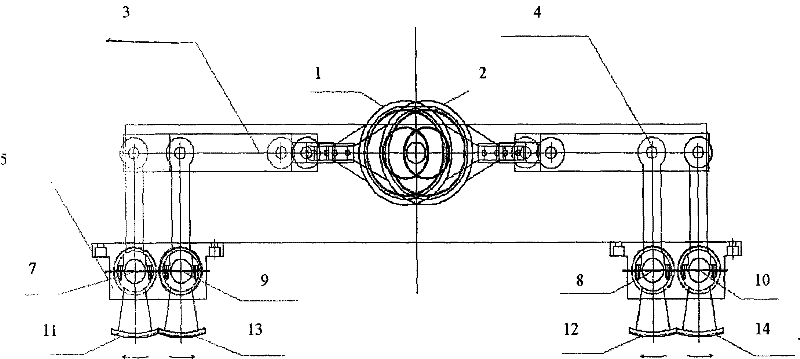

[0010] Such as figure 1 As shown, the aerated brick vertical swing wire cutting machine includes two sets of the same mechanism that can swing left and right, that is, including eccentric wheel a (1), eccentric wheel b (2), crank arm connecting rod a (3), crank Arm connecting rod b(4), bearing housing a(5), bearing housing b(6), transmission rod a(7), transmission rod a1(8), transmission rod b(9), transmission rod b1(10), Thread hanging plate a (11), thread hanging plate a1 (12), thread hanging plate b (13), thread hanging plate b1 (14), eccentric wheel a is connected with crank arm connecting rod a, and one end of crank arm connecting rod a The other end of the transmission rod a is connected to the hanging wire plate a, the other end of the crank arm connecting rod a is connected to the transmission rod a1 through the bearing seat b, and the other end of the transmission rod a1 is connected to the hanging wire The plate a1 is connected; the eccentric wheel b is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com