Waste cable recovery device for resource regeneration

A recycling device, a technology for resource regeneration, applied in electronic waste recycling, recycling technology, equipment for dismantling/armoring cables, etc., can solve problems such as failure to achieve better automation and random shaking of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

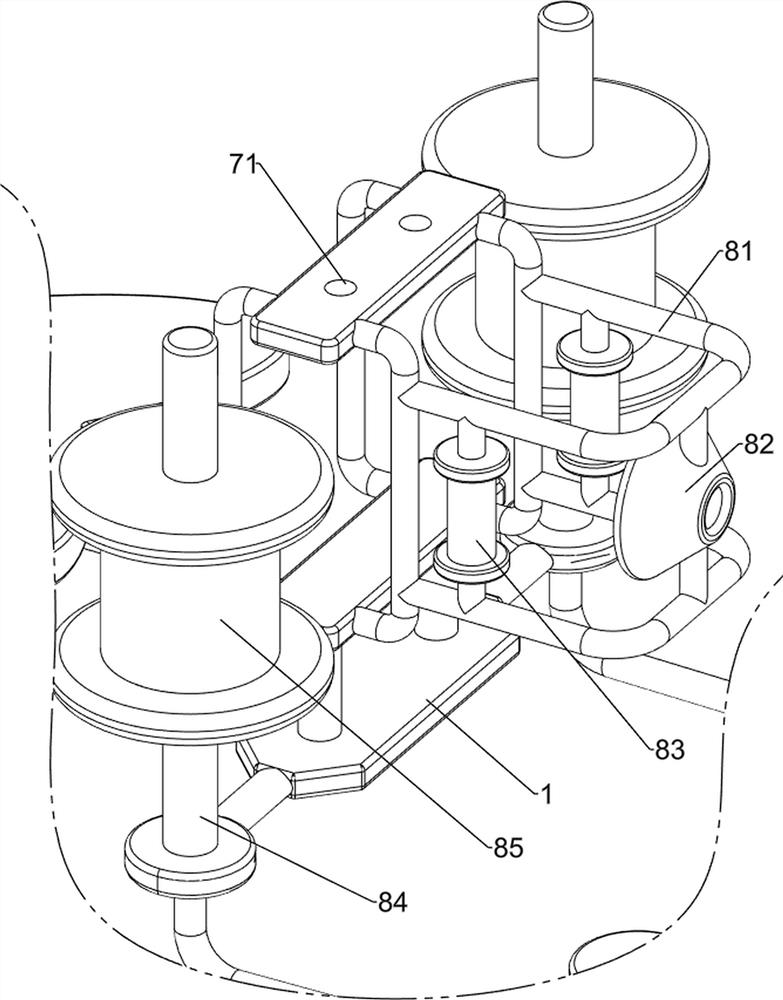

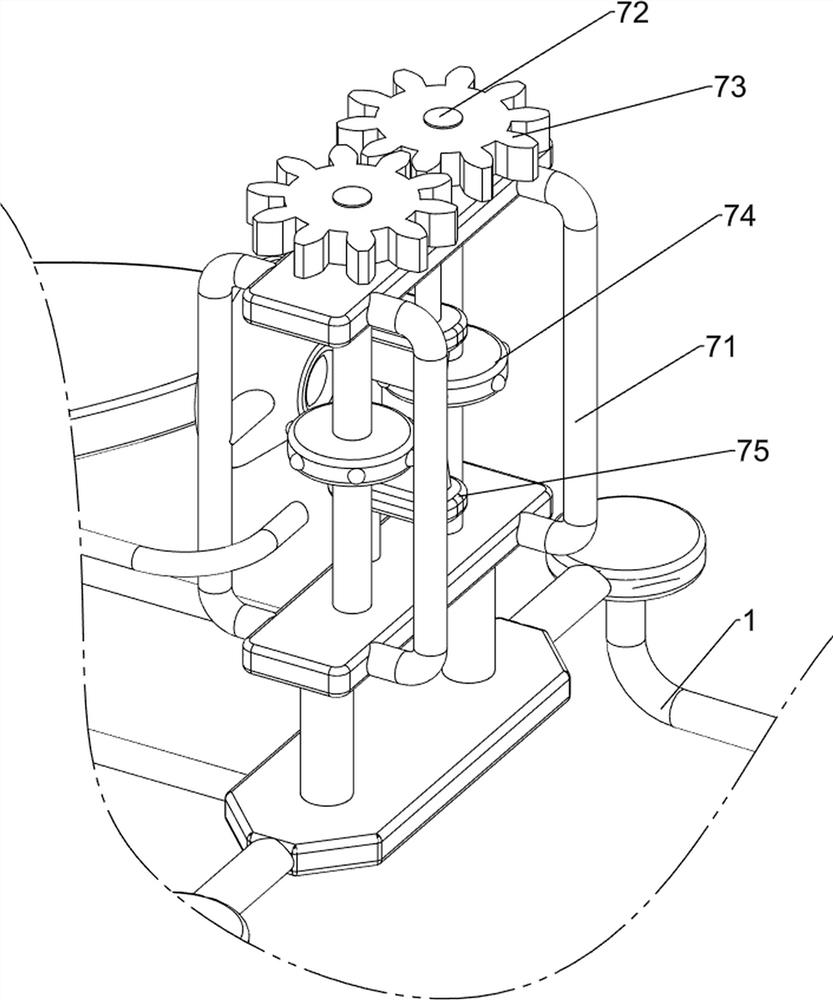

[0078] A waste cable recovery device for resource regeneration, such as figure 1 As shown, it includes a first support frame 1, a second support frame 2, a motor 3, a reciprocating mechanism 4 and a cutting mechanism 5, and a second support frame 2 is connected between the front sides of the first support frame 1, and the second support frame 2 The top end is fixedly connected with a motor 3 by bolts, and the left and right sides of the front side of the first support frame 1 are rotatably provided with a reciprocating mechanism 4 , and a cutting mechanism 5 is installed on the first support frame 1 and the second support frame 2 .

[0079] When the cable insulation protection layer peels off, the worker first needs to put the cable on the cutting mechanism 5. When the cable is on the cutting mechanism 5, the worker needs to control the rotation of the motor 3, and the rotation of the output shaft of the motor 3 will drive the reciprocating mechanism 4 to rotate. The rotation ...

Embodiment 2

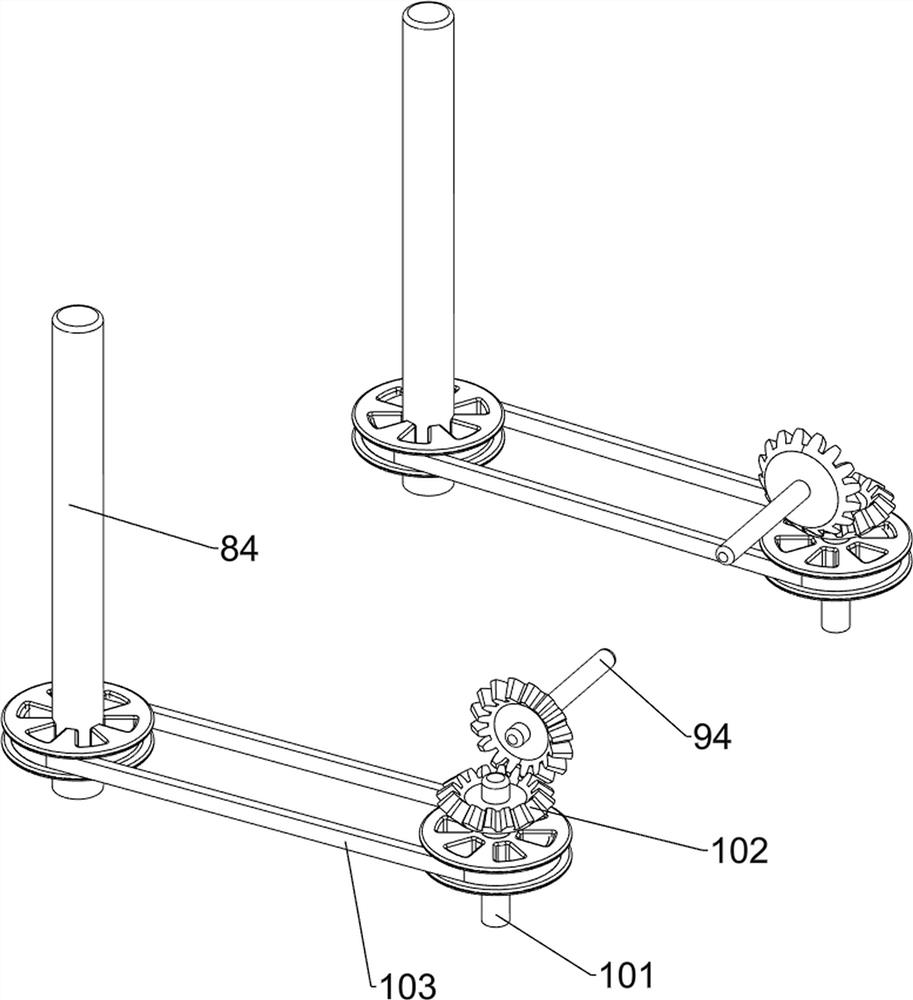

[0081] In a preferred embodiment of the present invention, as figure 2 As shown, the reciprocating mechanism 4 includes a first bevel gear assembly 41, a third support frame 42, a first rotating shaft 43, and a space cam 44. 42. The two third support frames 42 are equipped with first rotating shafts 43 in a rotating manner, and a first bevel gear assembly 41 is connected between the outer sides of the two output shafts of the motor 3 and the tops of the corresponding first rotating shafts 43 , and the two first rotating shafts 43 are connected. A space cam 44 is fixedly connected to a rotating shaft 43 .

[0082] When the cable is on the cutting mechanism 5, the worker needs to start the motor 3, the output shaft of the motor 3 will drive the first bevel gear assembly 41 to rotate, and the rotation of the first bevel gear assembly 41 will drive the first rotating shaft 43 in the third support frame 42 Rotate, the rotation of the first rotating shaft 43 can drive the space ca...

Embodiment 3

[0084] In a preferred embodiment of the present invention, as figure 1 and Figure 3-Figure 9 As shown, the cutting mechanism 5 includes a loading platform 51, a first slide rail 52, a cutting knife 53 and a driving lever 54, and the loading platform 51 is fixedly connected between the front sides of the first support frame 1, and the upper part of the second support frame 2 The front side is symmetrically fixed with a first slide rail 52, and a cutting knife 53 is slidingly provided between the two first slide rails 52. The cutting knife 53 is in contact with the stage 51, and the left and right sides of the cutting knife 53 are symmetrically provided with dials. Rod 54, driving lever 54 and space cam 44 slide type cooperation.

[0085] Workers first need to place the cable on the stage 51. When the cable is on the stage 51, the space cam 44 will drive the driving lever 54 to slide downward, and the downward sliding of the driving lever 54 will drive the cutting knife 53 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com