Power unit assembly of drill milling head

A power device, drilling and milling head technology, applied in the direction of the driving device, positioning device, feeding device, etc., can solve the problems of large clamping force at the incision, multiple tool changes, easy tool clamping, etc., to increase the cutting force, Speed up the cutting speed, the effect of adjustable rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

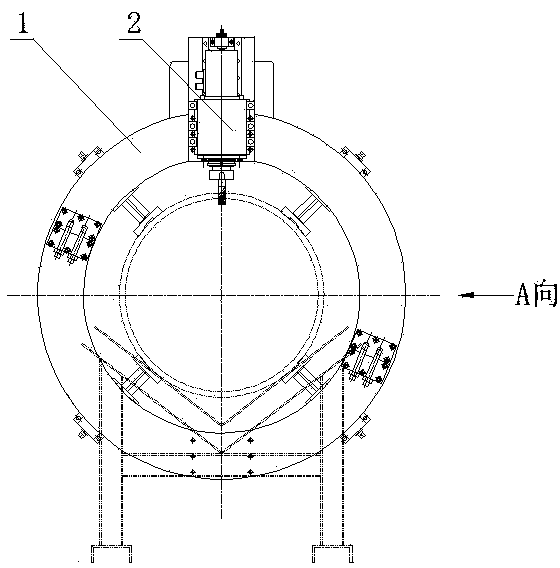

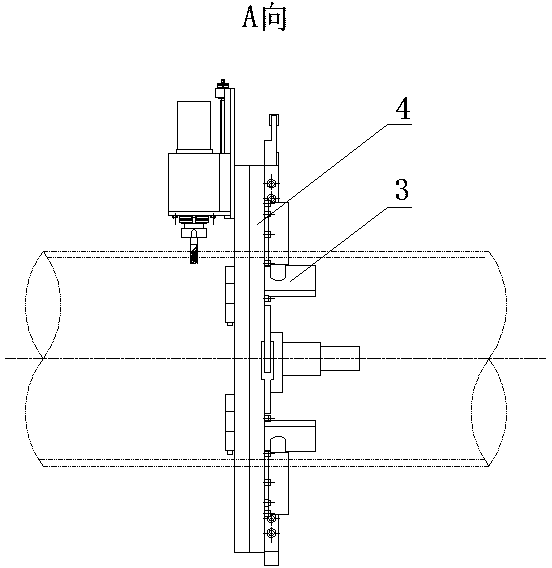

[0027] Such as figure 1 , 2 As shown, the drilling and milling head power assembly 2 of the present invention is fixedly installed on the front end face of the movable disk 1 of the pipe cutting machine. The fixed seat 3 of the pipe cutting machine is installed on the pipe through the clamping legs 4, and forms a concentric circle structure with the pipe. Drilling and milling head power unit assembly 2 just can realize the circular rotation around pipe along with pipe cutting machine movable plate 1 and do cutting processing feeding motion. The drilling and milling head power assembly 2 clamps the milling cutter and drives the milling cutter to rotate to perform the main movement of cutting. The drilling and milling head power assembly 2 can also realize the manual rotation of the lead screw to realize the radial feed movement along the radial direction of the pipeline.

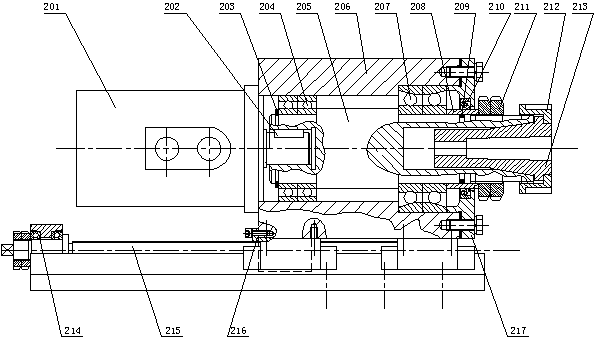

[0028] Such as image 3 , Figure 4 As shown, the drilling and milling head power assembly 2 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com